The science behind LM7 engine fuel atomization process

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Fuel Atomization Background and Objectives

The LM7 engine, a member of the General Motors LS engine family, has been a cornerstone in the automotive industry since its introduction in the early 2000s. This V8 engine's fuel atomization process plays a crucial role in its performance, efficiency, and emissions control. The science behind this process involves a complex interplay of fluid dynamics, thermodynamics, and combustion chemistry.

Fuel atomization in the LM7 engine refers to the breaking down of liquid fuel into fine droplets, creating a mist-like spray that can be efficiently mixed with air for combustion. This process is fundamental to achieving optimal engine performance and meeting increasingly stringent environmental regulations. The primary objectives of fuel atomization in the LM7 engine are to enhance fuel economy, reduce emissions, and improve overall engine efficiency.

The evolution of fuel atomization technology in the LM7 engine reflects broader trends in automotive engineering. Initially, carburetors were used for fuel delivery, but they were replaced by more precise fuel injection systems. The LM7 engine utilizes a sequential fuel injection system, which allows for more accurate control over fuel delivery timing and quantity.

One of the key technological advancements in the LM7's fuel atomization process is the use of high-pressure fuel injectors. These injectors operate at pressures significantly higher than those in earlier fuel injection systems, allowing for finer atomization of the fuel. The increased pressure results in smaller fuel droplets, which vaporize more quickly and mix more thoroughly with the incoming air.

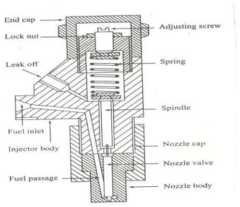

The design of the fuel injector nozzles is another critical aspect of the LM7's atomization process. These nozzles are engineered to create specific spray patterns that optimize fuel distribution within the combustion chamber. Factors such as the number of nozzle holes, their size, and orientation are carefully calibrated to achieve the desired atomization characteristics.

The LM7 engine's fuel atomization process also benefits from advanced electronic control systems. These systems use data from various sensors to adjust fuel injection parameters in real-time, ensuring optimal atomization under varying operating conditions. This adaptive approach allows the engine to maintain efficiency and performance across a wide range of speeds, loads, and environmental conditions.

Understanding and improving the science behind the LM7 engine's fuel atomization process continues to be a focus of research and development. Engineers and scientists are exploring ways to further refine this process, with the goals of increasing fuel efficiency, reducing emissions, and enhancing engine performance. This ongoing research is crucial for meeting future automotive standards and consumer expectations in an increasingly environmentally conscious market.

Fuel atomization in the LM7 engine refers to the breaking down of liquid fuel into fine droplets, creating a mist-like spray that can be efficiently mixed with air for combustion. This process is fundamental to achieving optimal engine performance and meeting increasingly stringent environmental regulations. The primary objectives of fuel atomization in the LM7 engine are to enhance fuel economy, reduce emissions, and improve overall engine efficiency.

The evolution of fuel atomization technology in the LM7 engine reflects broader trends in automotive engineering. Initially, carburetors were used for fuel delivery, but they were replaced by more precise fuel injection systems. The LM7 engine utilizes a sequential fuel injection system, which allows for more accurate control over fuel delivery timing and quantity.

One of the key technological advancements in the LM7's fuel atomization process is the use of high-pressure fuel injectors. These injectors operate at pressures significantly higher than those in earlier fuel injection systems, allowing for finer atomization of the fuel. The increased pressure results in smaller fuel droplets, which vaporize more quickly and mix more thoroughly with the incoming air.

The design of the fuel injector nozzles is another critical aspect of the LM7's atomization process. These nozzles are engineered to create specific spray patterns that optimize fuel distribution within the combustion chamber. Factors such as the number of nozzle holes, their size, and orientation are carefully calibrated to achieve the desired atomization characteristics.

The LM7 engine's fuel atomization process also benefits from advanced electronic control systems. These systems use data from various sensors to adjust fuel injection parameters in real-time, ensuring optimal atomization under varying operating conditions. This adaptive approach allows the engine to maintain efficiency and performance across a wide range of speeds, loads, and environmental conditions.

Understanding and improving the science behind the LM7 engine's fuel atomization process continues to be a focus of research and development. Engineers and scientists are exploring ways to further refine this process, with the goals of increasing fuel efficiency, reducing emissions, and enhancing engine performance. This ongoing research is crucial for meeting future automotive standards and consumer expectations in an increasingly environmentally conscious market.

Market Demand for Efficient Fuel Atomization

The market demand for efficient fuel atomization in LM7 engines has been steadily increasing due to the growing emphasis on fuel efficiency and environmental regulations. As automotive manufacturers strive to meet stringent emission standards and improve overall engine performance, the importance of advanced fuel atomization technologies has become paramount.

In recent years, there has been a significant shift towards more efficient and cleaner combustion processes in internal combustion engines. This trend has been driven by both consumer demand for fuel-efficient vehicles and government regulations aimed at reducing greenhouse gas emissions. The LM7 engine, being a popular choice for many General Motors vehicles, has become a focal point for improvements in fuel atomization technology.

The automotive industry has witnessed a surge in research and development activities focused on enhancing fuel atomization processes. This has led to increased investment in technologies that can achieve finer fuel droplets, more uniform fuel distribution, and improved air-fuel mixing. These advancements not only contribute to better fuel economy but also help in reducing harmful emissions.

Market analysts have observed a growing demand for aftermarket fuel atomization solutions for LM7 engines. This indicates a strong consumer interest in upgrading existing engines to achieve better performance and fuel efficiency. The aftermarket sector has responded by offering a range of products, including high-performance fuel injectors and advanced fuel management systems designed specifically for LM7 engines.

Furthermore, the commercial vehicle sector has shown particular interest in efficient fuel atomization technologies for LM7 engines. Fleet operators are increasingly looking for ways to reduce fuel consumption and operational costs, making improved fuel atomization a key selling point for engine manufacturers and retrofit solution providers.

The market for efficient fuel atomization in LM7 engines is not limited to the automotive sector alone. There is a growing interest from the marine and industrial sectors, where LM7 engines are sometimes used in various applications. These sectors are also under pressure to improve efficiency and reduce emissions, creating additional demand for advanced fuel atomization technologies.

As the global focus on sustainability intensifies, the market for efficient fuel atomization in LM7 engines is expected to continue its growth trajectory. Engine manufacturers, automotive companies, and aftermarket parts suppliers are likely to invest more in research and development to meet this increasing demand. This trend is expected to drive innovation in fuel injection systems, combustion chamber designs, and engine control units specifically tailored for optimizing fuel atomization in LM7 engines.

In recent years, there has been a significant shift towards more efficient and cleaner combustion processes in internal combustion engines. This trend has been driven by both consumer demand for fuel-efficient vehicles and government regulations aimed at reducing greenhouse gas emissions. The LM7 engine, being a popular choice for many General Motors vehicles, has become a focal point for improvements in fuel atomization technology.

The automotive industry has witnessed a surge in research and development activities focused on enhancing fuel atomization processes. This has led to increased investment in technologies that can achieve finer fuel droplets, more uniform fuel distribution, and improved air-fuel mixing. These advancements not only contribute to better fuel economy but also help in reducing harmful emissions.

Market analysts have observed a growing demand for aftermarket fuel atomization solutions for LM7 engines. This indicates a strong consumer interest in upgrading existing engines to achieve better performance and fuel efficiency. The aftermarket sector has responded by offering a range of products, including high-performance fuel injectors and advanced fuel management systems designed specifically for LM7 engines.

Furthermore, the commercial vehicle sector has shown particular interest in efficient fuel atomization technologies for LM7 engines. Fleet operators are increasingly looking for ways to reduce fuel consumption and operational costs, making improved fuel atomization a key selling point for engine manufacturers and retrofit solution providers.

The market for efficient fuel atomization in LM7 engines is not limited to the automotive sector alone. There is a growing interest from the marine and industrial sectors, where LM7 engines are sometimes used in various applications. These sectors are also under pressure to improve efficiency and reduce emissions, creating additional demand for advanced fuel atomization technologies.

As the global focus on sustainability intensifies, the market for efficient fuel atomization in LM7 engines is expected to continue its growth trajectory. Engine manufacturers, automotive companies, and aftermarket parts suppliers are likely to invest more in research and development to meet this increasing demand. This trend is expected to drive innovation in fuel injection systems, combustion chamber designs, and engine control units specifically tailored for optimizing fuel atomization in LM7 engines.

Current State and Challenges in LM7 Fuel Atomization

The LM7 engine, a member of the GM Gen III small-block V8 family, has been widely used in various General Motors vehicles since its introduction in 1999. The fuel atomization process in the LM7 engine plays a crucial role in its performance, efficiency, and emissions. Currently, the LM7 utilizes a sequential fuel injection system with multi-port fuel injectors, which represents a significant advancement over earlier carbureted systems.

The current state of fuel atomization in the LM7 engine involves high-pressure fuel injectors that spray finely atomized fuel directly into the intake ports. These injectors are electronically controlled by the engine control module (ECM), which precisely times the fuel delivery based on various engine parameters such as load, speed, and temperature. The atomization process breaks down the liquid fuel into tiny droplets, increasing the surface area for better mixing with air and more efficient combustion.

Despite its advancements, the LM7 fuel atomization system faces several challenges. One of the primary issues is carbon buildup on intake valves, particularly in direct injection variants. This occurs because the fuel no longer washes over the valves, leading to deposits that can affect engine performance and efficiency over time. Additionally, as emission standards become increasingly stringent, there is a constant need to improve the atomization process for better fuel economy and reduced emissions.

Another challenge lies in the balance between atomization quality and injector durability. Finer atomization generally requires higher injection pressures, which can lead to increased wear on injector components. This necessitates a careful design approach to ensure longevity while maintaining optimal spray patterns.

The LM7 engine also faces challenges in cold-start conditions, where fuel atomization is less efficient due to lower temperatures. This can result in increased emissions and reduced performance during the warm-up period. Engineers are continually working on strategies to improve cold-start atomization, such as optimizing injector spray patterns and exploring heating technologies for the fuel system.

Furthermore, as the automotive industry shifts towards alternative fuels and electrification, the LM7's fuel atomization system must adapt to accommodate these changes. This includes developing injectors capable of handling different fuel compositions and exploring ways to integrate the atomization process with hybrid powertrains.

In conclusion, while the LM7 engine's fuel atomization technology has made significant strides, it continues to face challenges in areas such as deposit formation, emissions reduction, and adaptability to future fuel technologies. Ongoing research and development efforts are focused on addressing these issues to further enhance the engine's performance, efficiency, and environmental impact.

The current state of fuel atomization in the LM7 engine involves high-pressure fuel injectors that spray finely atomized fuel directly into the intake ports. These injectors are electronically controlled by the engine control module (ECM), which precisely times the fuel delivery based on various engine parameters such as load, speed, and temperature. The atomization process breaks down the liquid fuel into tiny droplets, increasing the surface area for better mixing with air and more efficient combustion.

Despite its advancements, the LM7 fuel atomization system faces several challenges. One of the primary issues is carbon buildup on intake valves, particularly in direct injection variants. This occurs because the fuel no longer washes over the valves, leading to deposits that can affect engine performance and efficiency over time. Additionally, as emission standards become increasingly stringent, there is a constant need to improve the atomization process for better fuel economy and reduced emissions.

Another challenge lies in the balance between atomization quality and injector durability. Finer atomization generally requires higher injection pressures, which can lead to increased wear on injector components. This necessitates a careful design approach to ensure longevity while maintaining optimal spray patterns.

The LM7 engine also faces challenges in cold-start conditions, where fuel atomization is less efficient due to lower temperatures. This can result in increased emissions and reduced performance during the warm-up period. Engineers are continually working on strategies to improve cold-start atomization, such as optimizing injector spray patterns and exploring heating technologies for the fuel system.

Furthermore, as the automotive industry shifts towards alternative fuels and electrification, the LM7's fuel atomization system must adapt to accommodate these changes. This includes developing injectors capable of handling different fuel compositions and exploring ways to integrate the atomization process with hybrid powertrains.

In conclusion, while the LM7 engine's fuel atomization technology has made significant strides, it continues to face challenges in areas such as deposit formation, emissions reduction, and adaptability to future fuel technologies. Ongoing research and development efforts are focused on addressing these issues to further enhance the engine's performance, efficiency, and environmental impact.

Existing LM7 Fuel Atomization Solutions

01 Fuel injection system optimization

Improving the fuel injection system in LM7 engines to enhance fuel atomization. This includes optimizing injector design, spray patterns, and injection timing to achieve finer fuel droplets and more efficient combustion.- Fuel injection system optimization: Improving the fuel injection system in LM7 engines to enhance fuel atomization. This includes optimizing injector design, spray patterns, and injection timing to achieve finer droplet size and more uniform fuel distribution in the combustion chamber.

- Advanced combustion chamber design: Modifying the combustion chamber geometry in LM7 engines to promote better fuel atomization and mixing. This may involve redesigning piston crown shapes, cylinder head contours, and intake port configurations to create optimal turbulence and swirl for improved fuel-air mixture formation.

- High-pressure fuel delivery systems: Implementing high-pressure fuel delivery systems in LM7 engines to enhance fuel atomization. This includes using advanced fuel pumps, pressure regulators, and fuel rails to maintain consistent high pressure throughout the fuel system, resulting in improved spray characteristics and finer droplet formation.

- Electronic control unit (ECU) enhancements: Upgrading the engine control unit software and hardware to optimize fuel atomization in LM7 engines. This involves implementing advanced algorithms for precise fuel metering, adaptive injection timing, and real-time monitoring of engine parameters to ensure optimal fuel atomization under various operating conditions.

- Alternative fuel compatibility: Adapting LM7 engines to utilize alternative fuels while maintaining or improving fuel atomization. This includes modifying fuel system components, adjusting injection parameters, and implementing specialized injectors to accommodate fuels with different properties, such as ethanol blends or compressed natural gas.

02 Advanced fuel atomization technologies

Implementing advanced technologies such as ultrasonic atomization or high-pressure fuel systems to achieve better fuel atomization in LM7 engines. These methods can produce smaller fuel droplets, leading to improved combustion efficiency and reduced emissions.Expand Specific Solutions03 Combustion chamber design modifications

Modifying the combustion chamber design of LM7 engines to enhance fuel atomization and mixing. This may include changes to piston crown geometry, cylinder head design, or the introduction of swirl-inducing features to promote better fuel-air mixing and atomization.Expand Specific Solutions04 Electronic control system enhancements

Improving the electronic control systems in LM7 engines to optimize fuel atomization. This involves refining engine management software, implementing advanced sensors, and utilizing adaptive control strategies to adjust fuel delivery based on real-time operating conditions.Expand Specific Solutions05 Alternative fuel compatibility

Adapting LM7 engines to be compatible with alternative fuels that offer improved atomization characteristics. This may include modifications to fuel systems and engine components to accommodate fuels with different properties, such as ethanol blends or gaseous fuels.Expand Specific Solutions

Key Players in Engine Fuel Atomization Industry

The LM7 engine fuel atomization process is in a mature stage of development, with major automotive manufacturers like Toyota, Honda, and Ford leading the way. The market for this technology is substantial, driven by the global automotive industry's demand for efficient and environmentally friendly engines. The technology's maturity is evident in its widespread adoption across various vehicle models. Companies such as GM Global Technology Operations, Caterpillar, and Cummins have made significant advancements in fuel atomization, particularly for larger engines. Research institutions like Shenyang Aerospace University and the Commonwealth Scientific & Industrial Research Organisation continue to contribute to refinements in the process, indicating ongoing innovation in this well-established field.

GM Global Technology Operations LLC

Technical Solution: GM's LM7 engine, part of the Vortec 5300 series, employs advanced fuel atomization techniques to enhance combustion efficiency. The engine utilizes a high-pressure direct injection system, operating at pressures up to 2,000 bar, to create a fine mist of fuel particles[1]. This process is further optimized through the use of multiple injection events per combustion cycle, allowing for precise control over fuel delivery[2]. The injectors feature carefully designed nozzle geometries with multiple holes, typically ranging from 6 to 8 orifices, each less than 0.1 mm in diameter[3]. This configuration promotes rapid fuel vaporization and mixing with air, leading to more complete combustion and reduced emissions.

Strengths: Improved fuel efficiency, reduced emissions, and enhanced engine performance. Weaknesses: Increased system complexity and potential for injector fouling over time.

Ford Global Technologies LLC

Technical Solution: Ford's approach to fuel atomization in engines similar to the LM7 involves a combination of high-pressure direct injection and advanced injector design. Their EcoBoost technology, which can be applied to various engine sizes, utilizes injection pressures up to 2,150 bar[4]. The injectors are designed with multiple laser-drilled holes, typically 6-8 per injector, with diameters as small as 0.08 mm[5]. Ford also implements a stratified charge combustion strategy in some engines, where fuel is injected late in the compression stroke to create a fuel-rich zone near the spark plug, surrounded by a leaner mixture[6]. This approach allows for precise control of the combustion process, optimizing fuel efficiency and power output.

Strengths: Excellent fuel economy, reduced CO2 emissions, and improved low-end torque. Weaknesses: Higher production costs and increased sensitivity to fuel quality.

Core Innovations in LM7 Fuel Atomization

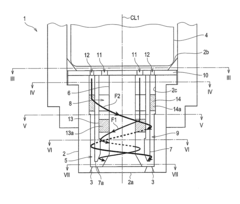

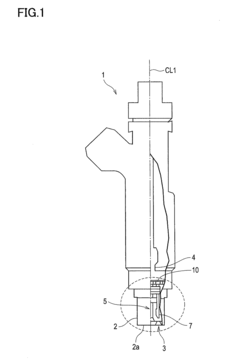

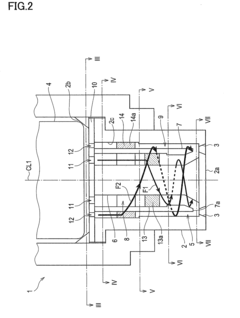

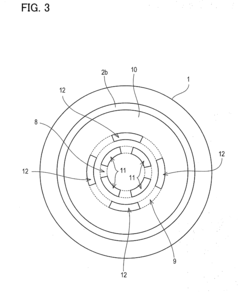

Fuel injection valve

PatentInactiveUS20120152202A1

Innovation

- A fuel injection valve design featuring a nozzle body with multiple nozzle holes, utilizing two opposing swirl flows generated by first and second fuel swirling devices, which swirl the fuel in opposite directions to create a strong centrifugal force, thinning the fuel and enhancing atomization.

An assembly for improving the fuel injection characteristics of internal combustion engines

PatentPendingIN202341017594A

Innovation

- Varying the intake manifold inclination in conjunction with increasing fuel injection pressure to optimize combustion efficiency, achieving better atomization and reduced emissions by adjusting the manifold inclination to specific angles such as 600 degrees, which maximizes brake thermal efficiency and minimizes pollutant emissions.

Environmental Impact of Fuel Atomization Technologies

The environmental impact of fuel atomization technologies in the LM7 engine is a critical consideration in the automotive industry's efforts to reduce emissions and improve fuel efficiency. The atomization process, which breaks fuel into fine droplets for more efficient combustion, plays a significant role in determining the engine's overall environmental performance.

Improved fuel atomization leads to more complete combustion, resulting in reduced emissions of harmful pollutants such as carbon monoxide (CO), unburned hydrocarbons (HC), and particulate matter (PM). The LM7 engine's fuel atomization process, when optimized, can contribute to lower levels of these pollutants, helping vehicles meet increasingly stringent emission standards and reducing their environmental footprint.

Furthermore, enhanced fuel atomization can improve fuel economy, which indirectly reduces the overall carbon dioxide (CO2) emissions associated with vehicle operation. By ensuring that a higher percentage of the fuel is burned efficiently, the LM7 engine can extract more energy from each unit of fuel, potentially reducing the total amount of fuel consumed and, consequently, the CO2 emissions produced.

The atomization process also influences the formation of nitrogen oxides (NOx), which are major contributors to air pollution and smog formation. While higher combustion temperatures generally lead to increased NOx production, advanced atomization techniques can help mitigate this effect by promoting more uniform fuel distribution and combustion, potentially reducing peak combustion temperatures.

However, it is important to note that the environmental benefits of improved fuel atomization may be partially offset by the potential increase in ultrafine particle emissions. As fuel droplets become smaller, there is a risk of producing more nano-sized particles that can penetrate deeper into the respiratory system and pose health risks. This aspect requires careful consideration and further research to ensure that advancements in atomization technology do not inadvertently create new environmental challenges.

The materials and manufacturing processes used in producing fuel atomization components also have environmental implications. The production of high-precision injectors and other atomization-related parts may involve energy-intensive processes and the use of rare or environmentally sensitive materials. As such, a comprehensive environmental assessment of fuel atomization technologies must consider the entire lifecycle of these components, from production to disposal.

In conclusion, while fuel atomization technologies in the LM7 engine offer significant potential for reducing environmental impact through improved combustion efficiency and reduced emissions, a holistic approach is necessary to fully understand and optimize their environmental performance across all aspects of production, operation, and end-of-life management.

Improved fuel atomization leads to more complete combustion, resulting in reduced emissions of harmful pollutants such as carbon monoxide (CO), unburned hydrocarbons (HC), and particulate matter (PM). The LM7 engine's fuel atomization process, when optimized, can contribute to lower levels of these pollutants, helping vehicles meet increasingly stringent emission standards and reducing their environmental footprint.

Furthermore, enhanced fuel atomization can improve fuel economy, which indirectly reduces the overall carbon dioxide (CO2) emissions associated with vehicle operation. By ensuring that a higher percentage of the fuel is burned efficiently, the LM7 engine can extract more energy from each unit of fuel, potentially reducing the total amount of fuel consumed and, consequently, the CO2 emissions produced.

The atomization process also influences the formation of nitrogen oxides (NOx), which are major contributors to air pollution and smog formation. While higher combustion temperatures generally lead to increased NOx production, advanced atomization techniques can help mitigate this effect by promoting more uniform fuel distribution and combustion, potentially reducing peak combustion temperatures.

However, it is important to note that the environmental benefits of improved fuel atomization may be partially offset by the potential increase in ultrafine particle emissions. As fuel droplets become smaller, there is a risk of producing more nano-sized particles that can penetrate deeper into the respiratory system and pose health risks. This aspect requires careful consideration and further research to ensure that advancements in atomization technology do not inadvertently create new environmental challenges.

The materials and manufacturing processes used in producing fuel atomization components also have environmental implications. The production of high-precision injectors and other atomization-related parts may involve energy-intensive processes and the use of rare or environmentally sensitive materials. As such, a comprehensive environmental assessment of fuel atomization technologies must consider the entire lifecycle of these components, from production to disposal.

In conclusion, while fuel atomization technologies in the LM7 engine offer significant potential for reducing environmental impact through improved combustion efficiency and reduced emissions, a holistic approach is necessary to fully understand and optimize their environmental performance across all aspects of production, operation, and end-of-life management.

Regulatory Framework for Engine Emissions

The regulatory framework for engine emissions plays a crucial role in shaping the development and implementation of fuel atomization technologies in engines like the LM7. These regulations are designed to mitigate the environmental impact of vehicle emissions and promote the adoption of cleaner, more efficient engine technologies.

In the United States, the Environmental Protection Agency (EPA) sets the standards for vehicle emissions under the Clean Air Act. These standards have become increasingly stringent over the years, pushing manufacturers to develop more advanced fuel atomization processes. The EPA's Tier 3 emission standards, implemented in 2017, require significant reductions in nitrogen oxides (NOx), particulate matter (PM), and non-methane organic gases (NMOG).

Similarly, the European Union has implemented Euro emission standards, with Euro 6 being the current standard for light-duty vehicles. These regulations have driven the development of more precise fuel atomization techniques to achieve lower emissions and improved fuel efficiency.

The California Air Resources Board (CARB) often sets even stricter standards than the federal EPA, influencing the entire U.S. automotive market due to California's large consumer base. CARB's Low Emission Vehicle (LEV) III standards have pushed for further reductions in criteria pollutants and greenhouse gas emissions.

These regulatory frameworks have directly impacted the science behind fuel atomization in engines like the LM7. Manufacturers have been compelled to invest in research and development of advanced fuel injection systems, such as direct injection and high-pressure common rail systems, to achieve finer atomization and more precise fuel delivery.

The regulations have also led to the integration of sophisticated engine control units (ECUs) that can dynamically adjust fuel atomization parameters based on real-time engine conditions. This adaptive approach helps maintain optimal combustion efficiency and minimize emissions across various operating conditions.

Furthermore, the regulatory landscape has encouraged the adoption of technologies such as variable valve timing and lift, which work in conjunction with advanced fuel atomization processes to enhance overall engine performance and emissions control. These systems allow for better control of the air-fuel mixture, leading to more complete combustion and reduced emissions.

As emissions standards continue to evolve, the science behind fuel atomization in engines like the LM7 will need to advance further. Future regulations are likely to focus on reducing greenhouse gas emissions and improving real-world driving emissions performance, which will necessitate even more sophisticated fuel atomization technologies and control strategies.

In the United States, the Environmental Protection Agency (EPA) sets the standards for vehicle emissions under the Clean Air Act. These standards have become increasingly stringent over the years, pushing manufacturers to develop more advanced fuel atomization processes. The EPA's Tier 3 emission standards, implemented in 2017, require significant reductions in nitrogen oxides (NOx), particulate matter (PM), and non-methane organic gases (NMOG).

Similarly, the European Union has implemented Euro emission standards, with Euro 6 being the current standard for light-duty vehicles. These regulations have driven the development of more precise fuel atomization techniques to achieve lower emissions and improved fuel efficiency.

The California Air Resources Board (CARB) often sets even stricter standards than the federal EPA, influencing the entire U.S. automotive market due to California's large consumer base. CARB's Low Emission Vehicle (LEV) III standards have pushed for further reductions in criteria pollutants and greenhouse gas emissions.

These regulatory frameworks have directly impacted the science behind fuel atomization in engines like the LM7. Manufacturers have been compelled to invest in research and development of advanced fuel injection systems, such as direct injection and high-pressure common rail systems, to achieve finer atomization and more precise fuel delivery.

The regulations have also led to the integration of sophisticated engine control units (ECUs) that can dynamically adjust fuel atomization parameters based on real-time engine conditions. This adaptive approach helps maintain optimal combustion efficiency and minimize emissions across various operating conditions.

Furthermore, the regulatory landscape has encouraged the adoption of technologies such as variable valve timing and lift, which work in conjunction with advanced fuel atomization processes to enhance overall engine performance and emissions control. These systems allow for better control of the air-fuel mixture, leading to more complete combustion and reduced emissions.

As emissions standards continue to evolve, the science behind fuel atomization in engines like the LM7 will need to advance further. Future regulations are likely to focus on reducing greenhouse gas emissions and improving real-world driving emissions performance, which will necessitate even more sophisticated fuel atomization technologies and control strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!