LM7 engine modularity as a solution for customization

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Modularity Background and Objectives

The LM7 engine, a revolutionary modular design concept in automotive engineering, has emerged as a potential solution for customization challenges in the industry. This innovative approach to engine architecture represents a significant shift from traditional monolithic designs, offering unprecedented flexibility and adaptability.

The development of modular engine designs can be traced back to the early 2000s when automotive manufacturers began exploring ways to reduce production costs and increase efficiency. However, it was not until recent years that the concept of modularity gained traction as a means to address the growing demand for customization in the automotive sector.

The primary objective of the LM7 engine modularity is to create a versatile platform that can be easily adapted to meet diverse performance requirements and regulatory standards across different markets. This approach aims to streamline the manufacturing process, reduce time-to-market for new engine variants, and ultimately enhance the overall competitiveness of automotive companies in a rapidly evolving industry landscape.

One of the key drivers behind the development of modular engine designs is the increasing complexity of global emissions regulations. As different regions implement varying standards, manufacturers are faced with the challenge of producing engines that can comply with multiple regulatory frameworks. The LM7's modular architecture allows for the integration of different components and technologies to meet specific emissions targets without necessitating a complete engine redesign.

Furthermore, the LM7 engine modularity seeks to address the growing consumer demand for personalization in vehicle performance. By offering a range of interchangeable modules, manufacturers can provide customers with a wider array of engine options, from fuel-efficient variants for urban driving to high-performance configurations for enthusiasts, all based on a single core platform.

The technological evolution leading to the LM7 engine modularity has been marked by advancements in materials science, manufacturing processes, and digital simulation tools. These developments have enabled engineers to design and validate complex modular systems with greater precision and efficiency than ever before.

As the automotive industry continues to navigate the challenges of electrification and autonomous driving, the LM7 engine modularity represents a strategic approach to future-proofing internal combustion engine technology. By providing a flexible foundation for integrating hybrid and alternative fuel technologies, this modular design concept aims to extend the relevance and competitiveness of combustion engines in an increasingly diverse powertrain landscape.

The development of modular engine designs can be traced back to the early 2000s when automotive manufacturers began exploring ways to reduce production costs and increase efficiency. However, it was not until recent years that the concept of modularity gained traction as a means to address the growing demand for customization in the automotive sector.

The primary objective of the LM7 engine modularity is to create a versatile platform that can be easily adapted to meet diverse performance requirements and regulatory standards across different markets. This approach aims to streamline the manufacturing process, reduce time-to-market for new engine variants, and ultimately enhance the overall competitiveness of automotive companies in a rapidly evolving industry landscape.

One of the key drivers behind the development of modular engine designs is the increasing complexity of global emissions regulations. As different regions implement varying standards, manufacturers are faced with the challenge of producing engines that can comply with multiple regulatory frameworks. The LM7's modular architecture allows for the integration of different components and technologies to meet specific emissions targets without necessitating a complete engine redesign.

Furthermore, the LM7 engine modularity seeks to address the growing consumer demand for personalization in vehicle performance. By offering a range of interchangeable modules, manufacturers can provide customers with a wider array of engine options, from fuel-efficient variants for urban driving to high-performance configurations for enthusiasts, all based on a single core platform.

The technological evolution leading to the LM7 engine modularity has been marked by advancements in materials science, manufacturing processes, and digital simulation tools. These developments have enabled engineers to design and validate complex modular systems with greater precision and efficiency than ever before.

As the automotive industry continues to navigate the challenges of electrification and autonomous driving, the LM7 engine modularity represents a strategic approach to future-proofing internal combustion engine technology. By providing a flexible foundation for integrating hybrid and alternative fuel technologies, this modular design concept aims to extend the relevance and competitiveness of combustion engines in an increasingly diverse powertrain landscape.

Market Demand for Customizable Engines

The market demand for customizable engines, particularly in the context of LM7 engine modularity, has been steadily growing in recent years. This trend is driven by several factors, including the increasing diversity of vehicle applications, stricter emissions regulations, and the need for manufacturers to differentiate their products in a competitive market.

Automotive manufacturers are facing pressure to produce a wide range of vehicles with varying performance characteristics while minimizing development and production costs. This has led to a growing interest in modular engine designs that can be easily customized to meet specific requirements. The LM7 engine, known for its versatility and potential for customization, has become a focal point in this market trend.

One of the primary drivers of demand for customizable engines is the expanding range of vehicle types and use cases. From compact city cars to heavy-duty trucks, and from high-performance sports cars to fuel-efficient hybrids, each vehicle category requires specific engine characteristics. Modular engine designs like the LM7 allow manufacturers to adapt a single base engine platform to suit multiple applications, reducing development time and costs.

Environmental regulations are also playing a significant role in shaping the demand for customizable engines. As emission standards become more stringent globally, manufacturers need the flexibility to quickly adapt their engines to meet varying regional requirements. The modularity of the LM7 engine allows for easier integration of new technologies and components that can improve fuel efficiency and reduce emissions, making it an attractive option for manufacturers looking to comply with evolving regulations.

The aftermarket and performance tuning sectors have also contributed to the growing demand for customizable engines. Enthusiasts and specialized tuning companies seek engines that can be easily modified to achieve higher performance or specific characteristics. The LM7's modular design facilitates easier upgrades and modifications, making it popular among this segment of the market.

Furthermore, the commercial vehicle sector has shown increased interest in customizable engines. Fleet operators often require engines tailored to their specific operational needs, whether it's for long-haul trucking, urban delivery, or specialized industrial applications. The ability to customize the LM7 engine to meet these diverse requirements has expanded its potential market beyond personal vehicles.

As the automotive industry moves towards electrification, there is also a growing demand for customizable hybrid powertrains. The modularity of engines like the LM7 allows for easier integration with electric motors and battery systems, enabling manufacturers to create a range of hybrid vehicles with varying levels of electrification to suit different market segments and regulatory requirements.

Automotive manufacturers are facing pressure to produce a wide range of vehicles with varying performance characteristics while minimizing development and production costs. This has led to a growing interest in modular engine designs that can be easily customized to meet specific requirements. The LM7 engine, known for its versatility and potential for customization, has become a focal point in this market trend.

One of the primary drivers of demand for customizable engines is the expanding range of vehicle types and use cases. From compact city cars to heavy-duty trucks, and from high-performance sports cars to fuel-efficient hybrids, each vehicle category requires specific engine characteristics. Modular engine designs like the LM7 allow manufacturers to adapt a single base engine platform to suit multiple applications, reducing development time and costs.

Environmental regulations are also playing a significant role in shaping the demand for customizable engines. As emission standards become more stringent globally, manufacturers need the flexibility to quickly adapt their engines to meet varying regional requirements. The modularity of the LM7 engine allows for easier integration of new technologies and components that can improve fuel efficiency and reduce emissions, making it an attractive option for manufacturers looking to comply with evolving regulations.

The aftermarket and performance tuning sectors have also contributed to the growing demand for customizable engines. Enthusiasts and specialized tuning companies seek engines that can be easily modified to achieve higher performance or specific characteristics. The LM7's modular design facilitates easier upgrades and modifications, making it popular among this segment of the market.

Furthermore, the commercial vehicle sector has shown increased interest in customizable engines. Fleet operators often require engines tailored to their specific operational needs, whether it's for long-haul trucking, urban delivery, or specialized industrial applications. The ability to customize the LM7 engine to meet these diverse requirements has expanded its potential market beyond personal vehicles.

As the automotive industry moves towards electrification, there is also a growing demand for customizable hybrid powertrains. The modularity of engines like the LM7 allows for easier integration with electric motors and battery systems, enabling manufacturers to create a range of hybrid vehicles with varying levels of electrification to suit different market segments and regulatory requirements.

Current State and Challenges of Engine Modularity

Engine modularity has become a key focus in the automotive industry, with the LM7 engine serving as a prime example of this approach. Currently, the state of engine modularity is characterized by a shift towards more flexible and customizable powertrain solutions. Manufacturers are increasingly adopting modular designs to meet diverse market demands while optimizing production efficiency.

The LM7 engine, part of General Motors' LS engine family, exemplifies the current state of engine modularity. Its design allows for easy customization and adaptation across various vehicle platforms, from trucks to performance cars. This modularity enables manufacturers to tailor engine specifications to meet specific power, efficiency, and emissions requirements without completely redesigning the engine architecture.

However, the implementation of engine modularity faces several challenges. One significant hurdle is balancing standardization with customization. While modularity aims to streamline production and reduce costs through standardized components, it must also allow for sufficient customization to meet diverse market needs. This balance is crucial for maintaining competitiveness in a rapidly evolving automotive landscape.

Another challenge lies in managing the complexity of modular systems. As engines become more modular, the number of potential configurations increases exponentially. This complexity can lead to difficulties in inventory management, quality control, and maintenance. Manufacturers must develop robust systems and processes to handle this increased complexity without compromising reliability or efficiency.

The integration of advanced technologies, such as electrification and digital systems, into modular engine designs presents another significant challenge. As the industry moves towards hybrid and electric powertrains, modular engine designs must evolve to accommodate these new technologies seamlessly. This integration requires substantial investment in research and development, as well as retooling of production facilities.

Furthermore, regulatory pressures, particularly regarding emissions and fuel efficiency, pose ongoing challenges to engine modularity. Manufacturers must ensure that their modular engine designs can adapt to increasingly stringent environmental standards across different markets. This often requires the development of flexible emission control systems that can be easily modified or upgraded to meet varying regional requirements.

Lastly, the global supply chain disruptions have highlighted vulnerabilities in the modular approach. The interdependence of components in modular systems means that shortages or delays in one area can have cascading effects on production. Manufacturers are now grappling with the need to build more resilient supply chains while maintaining the benefits of modularity.

The LM7 engine, part of General Motors' LS engine family, exemplifies the current state of engine modularity. Its design allows for easy customization and adaptation across various vehicle platforms, from trucks to performance cars. This modularity enables manufacturers to tailor engine specifications to meet specific power, efficiency, and emissions requirements without completely redesigning the engine architecture.

However, the implementation of engine modularity faces several challenges. One significant hurdle is balancing standardization with customization. While modularity aims to streamline production and reduce costs through standardized components, it must also allow for sufficient customization to meet diverse market needs. This balance is crucial for maintaining competitiveness in a rapidly evolving automotive landscape.

Another challenge lies in managing the complexity of modular systems. As engines become more modular, the number of potential configurations increases exponentially. This complexity can lead to difficulties in inventory management, quality control, and maintenance. Manufacturers must develop robust systems and processes to handle this increased complexity without compromising reliability or efficiency.

The integration of advanced technologies, such as electrification and digital systems, into modular engine designs presents another significant challenge. As the industry moves towards hybrid and electric powertrains, modular engine designs must evolve to accommodate these new technologies seamlessly. This integration requires substantial investment in research and development, as well as retooling of production facilities.

Furthermore, regulatory pressures, particularly regarding emissions and fuel efficiency, pose ongoing challenges to engine modularity. Manufacturers must ensure that their modular engine designs can adapt to increasingly stringent environmental standards across different markets. This often requires the development of flexible emission control systems that can be easily modified or upgraded to meet varying regional requirements.

Lastly, the global supply chain disruptions have highlighted vulnerabilities in the modular approach. The interdependence of components in modular systems means that shortages or delays in one area can have cascading effects on production. Manufacturers are now grappling with the need to build more resilient supply chains while maintaining the benefits of modularity.

Existing Modular Solutions for LM7 Engines

01 Modular software architecture for engine control

The LM7 engine employs a modular software architecture for its control system. This approach allows for easier updates, maintenance, and customization of engine management software. The modular design enables separate development and testing of different engine control functions, improving overall system reliability and flexibility.- Modular software architecture for engine control: The LM7 engine employs a modular software architecture for its control system. This approach allows for easier updates, maintenance, and customization of engine management software. The modular design enables separate development and testing of individual components, improving overall system reliability and flexibility.

- Interchangeable hardware components: The LM7 engine features a design that incorporates interchangeable hardware components. This modularity allows for easy replacement, upgrading, or customization of various engine parts without requiring extensive modifications to the entire system. It enhances serviceability and adaptability to different vehicle applications.

- Modular fuel injection system: A key aspect of the LM7 engine's modularity is its fuel injection system. The system is designed with separate, replaceable modules for fuel injectors, fuel rails, and pressure regulators. This modular approach simplifies maintenance, allows for easy upgrades, and enables fine-tuning of the fuel delivery system for different performance requirements.

- Configurable engine control modules: The LM7 engine utilizes configurable engine control modules (ECMs) that can be programmed and adjusted to suit various applications. These modules allow for easy modification of engine parameters, tuning for different fuel types, and adaptation to diverse operating conditions without requiring hardware changes.

- Modular exhaust system design: The exhaust system of the LM7 engine features a modular design, allowing for easy customization and optimization. This includes interchangeable components such as catalytic converters, mufflers, and exhaust manifolds. The modular approach facilitates compliance with different emissions standards and enables performance tuning for various applications.

02 Interchangeable hardware components

The LM7 engine features a design that incorporates interchangeable hardware components. This modularity allows for easy replacement and upgrading of individual parts without affecting the entire engine system. It also facilitates customization and adaptation of the engine for different applications or performance requirements.Expand Specific Solutions03 Modular fuel injection system

The fuel injection system of the LM7 engine is designed with a modular approach. This allows for easy maintenance, replacement, and optimization of individual injectors or fuel system components. The modular design also enables the engine to be adapted for different fuel types or injection strategies without major modifications.Expand Specific Solutions04 Scalable engine architecture

The LM7 engine employs a scalable architecture that allows for easy modification of engine displacement or configuration. This modularity enables the engine platform to be adapted for various vehicle types or power requirements while maintaining commonality in core components and manufacturing processes.Expand Specific Solutions05 Modular sensor and actuator integration

The LM7 engine features a modular approach to sensor and actuator integration. This design allows for easy addition, removal, or upgrade of various sensors and actuators without significant modifications to the engine structure. It enhances the engine's adaptability to different emission standards or performance requirements.Expand Specific Solutions

Key Players in Modular Engine Manufacturing

The LM7 engine modularity market is in a growth phase, driven by increasing demand for customizable automotive solutions. The market size is expanding as major players like Robert Bosch GmbH, Continental Automotive GmbH, and ZF Friedrichshafen AG invest in modular engine technologies. The technology's maturity is advancing rapidly, with companies like AVL List GmbH and Scania CV AB leading in research and development. Chinese manufacturers such as Chery Automobile and Geely are also making significant strides, indicating a global push towards modular engine solutions. This competitive landscape suggests a dynamic market with potential for further innovation and market expansion in the coming years.

Robert Bosch GmbH

Technical Solution: Bosch's approach to engine modularity for the LM7 platform emphasizes advanced fuel injection systems and engine management technologies. Their solution incorporates a modular common rail system that can be easily adapted to various engine configurations, allowing for precise fuel delivery and improved efficiency across different power outputs[4]. Bosch has also developed a flexible engine control unit (ECU) architecture that supports rapid reconfiguration for different engine variants, enabling quick customization of performance characteristics[5]. The company's modular approach extends to exhaust gas treatment systems, with scalable solutions for meeting diverse emission standards globally[6].

Strengths: High-precision fuel management, adaptable ECU systems, and comprehensive emissions control solutions. Weaknesses: Potential higher component costs and reliance on sophisticated electronic systems.

AVL List GmbH

Technical Solution: AVL's LM7 engine modularity solution focuses on advanced simulation and testing technologies to support rapid customization. Their approach includes a comprehensive digital twin framework that allows for virtual prototyping and optimization of modular engine configurations[7]. AVL has developed specialized software tools for modular engine design, enabling quick assessment of performance, emissions, and durability across various configurations. The company's solution also incorporates modular test bed systems that can be rapidly reconfigured to accommodate different engine variants, streamlining the development and validation process[8].

Strengths: Advanced simulation capabilities, rapid virtual prototyping, and flexible testing infrastructure. Weaknesses: High initial investment in simulation and testing technologies.

Core Innovations in LM7 Engine Modularity

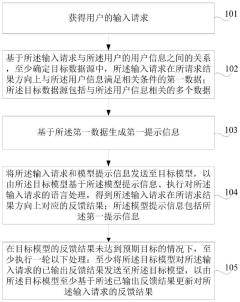

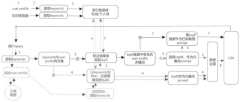

Question and answer method and device and electronic equipment

PatentPendingCN118227758A

Innovation

- The local model is used to work together with the large cloud model. The local model is used to perform preliminary reasoning on the problem, obtain the middle layer feature vector, and transmit it to the cloud model for further reasoning. The output of the cloud model is combined with the local model for analysis to determine the answer. Avoid private data leakage.

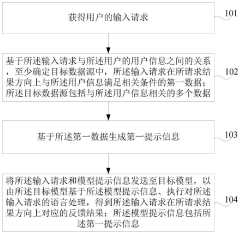

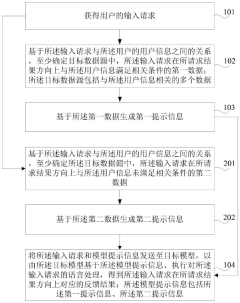

Information processing method and device

PatentPendingCN117390076A

Innovation

- By obtaining user input requests and user information, the target data source is determined, prompt information is generated, and sent to the target model for language processing to improve the degree of customization of the output. The method includes determining relevant data sources based on the relationship between input requests and user information, generating first and second prompt information, and updating model feedback results when the feedback results do not meet expectations.

Environmental Impact of Modular Engines

The modularity of the LM7 engine, designed for customization, presents significant implications for environmental sustainability in the automotive industry. This approach to engine design allows for more efficient resource utilization and potentially reduced environmental impact throughout the engine's lifecycle.

Modular engines offer the advantage of component interchangeability, which can lead to extended engine life and reduced waste. When individual modules wear out or become obsolete, they can be replaced without necessitating the replacement of the entire engine. This modularity contributes to a more circular economy model, where parts are more easily reused, refurbished, or recycled.

The customization aspect of modular engines also allows for optimized performance based on specific vehicle requirements. This tailored approach can result in improved fuel efficiency and reduced emissions across a range of applications. Manufacturers can fine-tune engine configurations to meet varying emission standards in different markets without redesigning the entire powertrain.

From a manufacturing perspective, the modular design of the LM7 engine can lead to streamlined production processes. This efficiency in manufacturing can translate to reduced energy consumption and lower carbon emissions during the production phase. Additionally, the ability to produce standardized modules in larger quantities may lead to economies of scale, further enhancing resource efficiency.

The potential for easier upgrades in modular engines also contributes to their environmental benefits. As new technologies emerge, such as improved fuel injection systems or more efficient combustion methods, these can be integrated into existing engines through module replacements. This adaptability extends the useful life of the engine and delays the need for complete engine replacement, thereby reducing the overall environmental impact associated with new engine production.

However, it is important to consider the potential drawbacks of modular engine design from an environmental perspective. The increased complexity of modular systems may require more specialized maintenance, potentially leading to higher resource consumption in the servicing phase. There is also a risk that the ease of customization could lead to over-engineering or unnecessary modifications, which might negate some of the environmental benefits.

In conclusion, while the LM7 engine's modularity as a solution for customization offers significant potential for reducing environmental impact through improved efficiency, longevity, and adaptability, careful consideration must be given to the entire lifecycle of the engine to ensure that these benefits are fully realized.

Modular engines offer the advantage of component interchangeability, which can lead to extended engine life and reduced waste. When individual modules wear out or become obsolete, they can be replaced without necessitating the replacement of the entire engine. This modularity contributes to a more circular economy model, where parts are more easily reused, refurbished, or recycled.

The customization aspect of modular engines also allows for optimized performance based on specific vehicle requirements. This tailored approach can result in improved fuel efficiency and reduced emissions across a range of applications. Manufacturers can fine-tune engine configurations to meet varying emission standards in different markets without redesigning the entire powertrain.

From a manufacturing perspective, the modular design of the LM7 engine can lead to streamlined production processes. This efficiency in manufacturing can translate to reduced energy consumption and lower carbon emissions during the production phase. Additionally, the ability to produce standardized modules in larger quantities may lead to economies of scale, further enhancing resource efficiency.

The potential for easier upgrades in modular engines also contributes to their environmental benefits. As new technologies emerge, such as improved fuel injection systems or more efficient combustion methods, these can be integrated into existing engines through module replacements. This adaptability extends the useful life of the engine and delays the need for complete engine replacement, thereby reducing the overall environmental impact associated with new engine production.

However, it is important to consider the potential drawbacks of modular engine design from an environmental perspective. The increased complexity of modular systems may require more specialized maintenance, potentially leading to higher resource consumption in the servicing phase. There is also a risk that the ease of customization could lead to over-engineering or unnecessary modifications, which might negate some of the environmental benefits.

In conclusion, while the LM7 engine's modularity as a solution for customization offers significant potential for reducing environmental impact through improved efficiency, longevity, and adaptability, careful consideration must be given to the entire lifecycle of the engine to ensure that these benefits are fully realized.

Cost-Benefit Analysis of LM7 Modularity

The cost-benefit analysis of LM7 engine modularity as a solution for customization reveals both significant advantages and potential challenges. On the benefit side, modularity offers enhanced flexibility in engine configuration, allowing manufacturers to tailor the LM7 to specific vehicle requirements without extensive redesign. This adaptability can lead to reduced development costs and shorter time-to-market for new vehicle models. Additionally, modular design facilitates easier maintenance and repairs, potentially lowering long-term ownership costs for consumers.

From a manufacturing perspective, modularity can streamline production processes by standardizing components across different engine variants. This standardization may result in economies of scale, reducing per-unit production costs. Furthermore, it allows for more efficient inventory management and simplified supply chain logistics, as fewer unique parts need to be stocked and managed.

However, the initial investment required to implement a modular design can be substantial. Redesigning the LM7 engine for modularity involves significant engineering hours, tooling changes, and potential retooling of production lines. These upfront costs must be carefully weighed against the projected long-term savings and market benefits.

Another consideration is the potential impact on engine performance. While modularity offers customization options, it may introduce design compromises that could affect overall engine efficiency or power output. Engineers must carefully balance the desire for flexibility with the need to maintain optimal performance characteristics across various configurations.

From a market perspective, the ability to quickly adapt the LM7 engine to changing consumer preferences or regulatory requirements could provide a competitive advantage. This agility may allow manufacturers to respond more rapidly to market trends or introduce niche products with minimal additional investment.

Maintenance costs could also be reduced through modularity, as standardized components may be more readily available and easier to replace. This could benefit both service centers and end-users, potentially enhancing customer satisfaction and brand loyalty.

However, the complexity of managing multiple engine configurations may increase administrative and logistical burdens. Proper tracking and documentation of various modular combinations will be crucial to ensure quality control and regulatory compliance.

In conclusion, while LM7 engine modularity offers promising benefits in terms of customization, production efficiency, and market responsiveness, it also presents challenges in terms of initial investment and potential performance trade-offs. A thorough analysis of market demands, production capabilities, and long-term strategic goals is essential to determine if the benefits of modularity outweigh the costs for a specific manufacturer or product line.

From a manufacturing perspective, modularity can streamline production processes by standardizing components across different engine variants. This standardization may result in economies of scale, reducing per-unit production costs. Furthermore, it allows for more efficient inventory management and simplified supply chain logistics, as fewer unique parts need to be stocked and managed.

However, the initial investment required to implement a modular design can be substantial. Redesigning the LM7 engine for modularity involves significant engineering hours, tooling changes, and potential retooling of production lines. These upfront costs must be carefully weighed against the projected long-term savings and market benefits.

Another consideration is the potential impact on engine performance. While modularity offers customization options, it may introduce design compromises that could affect overall engine efficiency or power output. Engineers must carefully balance the desire for flexibility with the need to maintain optimal performance characteristics across various configurations.

From a market perspective, the ability to quickly adapt the LM7 engine to changing consumer preferences or regulatory requirements could provide a competitive advantage. This agility may allow manufacturers to respond more rapidly to market trends or introduce niche products with minimal additional investment.

Maintenance costs could also be reduced through modularity, as standardized components may be more readily available and easier to replace. This could benefit both service centers and end-users, potentially enhancing customer satisfaction and brand loyalty.

However, the complexity of managing multiple engine configurations may increase administrative and logistical burdens. Proper tracking and documentation of various modular combinations will be crucial to ensure quality control and regulatory compliance.

In conclusion, while LM7 engine modularity offers promising benefits in terms of customization, production efficiency, and market responsiveness, it also presents challenges in terms of initial investment and potential performance trade-offs. A thorough analysis of market demands, production capabilities, and long-term strategic goals is essential to determine if the benefits of modularity outweigh the costs for a specific manufacturer or product line.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!