LM7 engine diagnostic tools for professional analysis

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Diagnostics Overview and Objectives

The LM7 engine, a member of the GM Gen III small-block V8 family, has been a popular choice for automotive enthusiasts and professionals since its introduction in 1999. As vehicle technology has advanced, so too have the diagnostic tools and techniques used to analyze and troubleshoot these engines. This overview aims to explore the current landscape of LM7 engine diagnostic tools for professional analysis and outline the objectives for their continued development and implementation.

Professional LM7 engine diagnostic tools have evolved significantly over the past two decades, incorporating advanced electronic systems and software interfaces to provide more accurate and comprehensive analysis. These tools are designed to interface with the engine's onboard diagnostic (OBD-II) system, allowing technicians to access a wealth of real-time data and stored fault codes. The primary goal of these diagnostic tools is to streamline the troubleshooting process, reduce downtime, and improve the overall efficiency of engine maintenance and repair.

Current LM7 engine diagnostic tools offer a range of features, including live data streaming, freeze frame analysis, and advanced graphing capabilities. These features enable technicians to monitor multiple engine parameters simultaneously, identify intermittent issues, and perform in-depth analysis of engine performance under various operating conditions. Additionally, many modern diagnostic tools incorporate wireless connectivity, allowing for remote diagnostics and real-time collaboration between technicians and experts.

The objectives for LM7 engine diagnostic tools are multifaceted, focusing on enhancing accuracy, expanding functionality, and improving user experience. One key objective is to develop more sophisticated algorithms for predictive diagnostics, enabling technicians to identify potential issues before they lead to engine failure. This proactive approach aims to reduce maintenance costs and extend the lifespan of LM7 engines.

Another important objective is to integrate artificial intelligence and machine learning capabilities into diagnostic tools. These technologies have the potential to analyze vast amounts of data from multiple LM7 engines, identifying patterns and trends that may not be apparent to human technicians. By leveraging AI, diagnostic tools can provide more accurate fault diagnoses and suggest optimal repair strategies based on historical data and successful outcomes.

Improving the user interface and overall usability of diagnostic tools is also a critical objective. As the complexity of engine systems increases, it becomes essential to present diagnostic information in a clear, intuitive manner. This includes developing more user-friendly software interfaces, implementing augmented reality features for guided diagnostics, and creating comprehensive training programs to ensure technicians can fully utilize the advanced capabilities of these tools.

In conclusion, the development of LM7 engine diagnostic tools for professional analysis continues to be driven by the need for more accurate, efficient, and user-friendly solutions. By focusing on these objectives, the automotive industry aims to enhance the overall reliability and performance of LM7 engines while reducing maintenance costs and vehicle downtime.

Professional LM7 engine diagnostic tools have evolved significantly over the past two decades, incorporating advanced electronic systems and software interfaces to provide more accurate and comprehensive analysis. These tools are designed to interface with the engine's onboard diagnostic (OBD-II) system, allowing technicians to access a wealth of real-time data and stored fault codes. The primary goal of these diagnostic tools is to streamline the troubleshooting process, reduce downtime, and improve the overall efficiency of engine maintenance and repair.

Current LM7 engine diagnostic tools offer a range of features, including live data streaming, freeze frame analysis, and advanced graphing capabilities. These features enable technicians to monitor multiple engine parameters simultaneously, identify intermittent issues, and perform in-depth analysis of engine performance under various operating conditions. Additionally, many modern diagnostic tools incorporate wireless connectivity, allowing for remote diagnostics and real-time collaboration between technicians and experts.

The objectives for LM7 engine diagnostic tools are multifaceted, focusing on enhancing accuracy, expanding functionality, and improving user experience. One key objective is to develop more sophisticated algorithms for predictive diagnostics, enabling technicians to identify potential issues before they lead to engine failure. This proactive approach aims to reduce maintenance costs and extend the lifespan of LM7 engines.

Another important objective is to integrate artificial intelligence and machine learning capabilities into diagnostic tools. These technologies have the potential to analyze vast amounts of data from multiple LM7 engines, identifying patterns and trends that may not be apparent to human technicians. By leveraging AI, diagnostic tools can provide more accurate fault diagnoses and suggest optimal repair strategies based on historical data and successful outcomes.

Improving the user interface and overall usability of diagnostic tools is also a critical objective. As the complexity of engine systems increases, it becomes essential to present diagnostic information in a clear, intuitive manner. This includes developing more user-friendly software interfaces, implementing augmented reality features for guided diagnostics, and creating comprehensive training programs to ensure technicians can fully utilize the advanced capabilities of these tools.

In conclusion, the development of LM7 engine diagnostic tools for professional analysis continues to be driven by the need for more accurate, efficient, and user-friendly solutions. By focusing on these objectives, the automotive industry aims to enhance the overall reliability and performance of LM7 engines while reducing maintenance costs and vehicle downtime.

Market Analysis for Professional LM7 Diagnostic Tools

The market for professional LM7 engine diagnostic tools has shown significant growth in recent years, driven by the increasing complexity of automotive systems and the rising demand for efficient vehicle maintenance. The LM7 engine, a popular V8 engine used in various General Motors vehicles, has created a substantial niche market for specialized diagnostic equipment.

The global automotive diagnostic tools market, which includes LM7 engine diagnostics, was valued at approximately $40 billion in 2020 and is projected to reach $59 billion by 2026, growing at a CAGR of around 5.8% during the forecast period. This growth is attributed to the rising vehicle production, increasing vehicle electrification, and the growing adoption of advanced driver-assistance systems (ADAS).

Professional LM7 diagnostic tools cater to automotive technicians, repair shops, and dealerships seeking to efficiently diagnose and resolve issues in LM7-equipped vehicles. These tools offer advanced features such as real-time data monitoring, error code reading and clearing, and comprehensive system analysis, which are essential for maintaining the performance and longevity of LM7 engines.

The market for LM7 diagnostic tools is primarily concentrated in North America, particularly in the United States, where the majority of LM7-equipped vehicles are sold and serviced. However, there is a growing demand in other regions, including Europe and Asia-Pacific, as the global automotive aftermarket expands.

Key market drivers include the increasing average age of vehicles on the road, which necessitates more frequent diagnostics and repairs, and the rising complexity of engine management systems. Additionally, stringent emission regulations have led to more sophisticated engine control units, further driving the need for advanced diagnostic tools.

The competitive landscape of the LM7 diagnostic tools market is characterized by a mix of established automotive diagnostic equipment manufacturers and specialized tool providers. Major players in this space include Bosch Automotive Service Solutions, Snap-on Incorporated, and OTC Tools, alongside niche providers focusing specifically on GM vehicle diagnostics.

Market trends indicate a shift towards more user-friendly interfaces, cloud-based diagnostics, and integration with mobile devices. There is also a growing demand for multi-functional tools that can diagnose not only the LM7 engine but also other systems within GM vehicles, providing a comprehensive solution for automotive professionals.

Challenges in the market include the need for continuous software updates to keep pace with evolving vehicle technology, as well as the high initial investment required for advanced diagnostic equipment. However, the long-term cost savings and efficiency gains offered by these tools continue to drive market growth.

The global automotive diagnostic tools market, which includes LM7 engine diagnostics, was valued at approximately $40 billion in 2020 and is projected to reach $59 billion by 2026, growing at a CAGR of around 5.8% during the forecast period. This growth is attributed to the rising vehicle production, increasing vehicle electrification, and the growing adoption of advanced driver-assistance systems (ADAS).

Professional LM7 diagnostic tools cater to automotive technicians, repair shops, and dealerships seeking to efficiently diagnose and resolve issues in LM7-equipped vehicles. These tools offer advanced features such as real-time data monitoring, error code reading and clearing, and comprehensive system analysis, which are essential for maintaining the performance and longevity of LM7 engines.

The market for LM7 diagnostic tools is primarily concentrated in North America, particularly in the United States, where the majority of LM7-equipped vehicles are sold and serviced. However, there is a growing demand in other regions, including Europe and Asia-Pacific, as the global automotive aftermarket expands.

Key market drivers include the increasing average age of vehicles on the road, which necessitates more frequent diagnostics and repairs, and the rising complexity of engine management systems. Additionally, stringent emission regulations have led to more sophisticated engine control units, further driving the need for advanced diagnostic tools.

The competitive landscape of the LM7 diagnostic tools market is characterized by a mix of established automotive diagnostic equipment manufacturers and specialized tool providers. Major players in this space include Bosch Automotive Service Solutions, Snap-on Incorporated, and OTC Tools, alongside niche providers focusing specifically on GM vehicle diagnostics.

Market trends indicate a shift towards more user-friendly interfaces, cloud-based diagnostics, and integration with mobile devices. There is also a growing demand for multi-functional tools that can diagnose not only the LM7 engine but also other systems within GM vehicles, providing a comprehensive solution for automotive professionals.

Challenges in the market include the need for continuous software updates to keep pace with evolving vehicle technology, as well as the high initial investment required for advanced diagnostic equipment. However, the long-term cost savings and efficiency gains offered by these tools continue to drive market growth.

Current Challenges in LM7 Engine Diagnostics

The LM7 engine, a popular V8 engine produced by General Motors, has been widely used in various vehicles since its introduction in 1999. As these engines age and accumulate mileage, the need for accurate and efficient diagnostic tools becomes increasingly critical. However, the current landscape of LM7 engine diagnostics presents several challenges that hinder professional analysis and maintenance.

One of the primary challenges is the complexity of modern engine management systems. The LM7 engine incorporates sophisticated electronic control units (ECUs) and multiple sensors, making it difficult for technicians to pinpoint issues without specialized diagnostic equipment. Traditional OBD-II scanners often provide limited information, failing to capture the nuanced data required for comprehensive analysis of LM7-specific problems.

Another significant hurdle is the lack of standardization in diagnostic protocols across different vehicle models and years equipped with the LM7 engine. This variability necessitates multiple diagnostic tools or frequent software updates, increasing costs and complexity for repair shops and professional mechanics. The absence of a unified diagnostic approach hampers efficiency and can lead to misdiagnosis or incomplete problem resolution.

The rapid evolution of engine technology also poses a challenge for diagnostic tool manufacturers. As new features and control strategies are implemented in LM7 engines, diagnostic equipment must be continuously updated to remain relevant. This constant need for updates creates a lag between the latest engine modifications and the availability of corresponding diagnostic capabilities, potentially leaving technicians ill-equipped to handle emerging issues.

Furthermore, the interpretation of diagnostic data remains a significant challenge. While advanced tools can retrieve vast amounts of information from the engine's systems, translating this data into actionable insights requires considerable expertise. Many technicians struggle to correlate multiple data points and symptoms to arrive at accurate diagnoses, highlighting the need for more intuitive and intelligent diagnostic interfaces.

Access to proprietary information and diagnostic procedures from General Motors presents another obstacle. Without comprehensive access to manufacturer-specific data and troubleshooting guides, third-party diagnostic tool developers and independent mechanics face limitations in creating and using fully-featured diagnostic solutions for the LM7 engine.

Lastly, the integration of diagnostic tools with other workshop systems and databases remains underdeveloped. The inability to seamlessly connect diagnostic results with repair histories, parts inventories, and technical bulletins hinders the efficiency of professional analysis and repair processes. This lack of integration forces technicians to juggle multiple systems, potentially overlooking critical information that could expedite problem resolution.

One of the primary challenges is the complexity of modern engine management systems. The LM7 engine incorporates sophisticated electronic control units (ECUs) and multiple sensors, making it difficult for technicians to pinpoint issues without specialized diagnostic equipment. Traditional OBD-II scanners often provide limited information, failing to capture the nuanced data required for comprehensive analysis of LM7-specific problems.

Another significant hurdle is the lack of standardization in diagnostic protocols across different vehicle models and years equipped with the LM7 engine. This variability necessitates multiple diagnostic tools or frequent software updates, increasing costs and complexity for repair shops and professional mechanics. The absence of a unified diagnostic approach hampers efficiency and can lead to misdiagnosis or incomplete problem resolution.

The rapid evolution of engine technology also poses a challenge for diagnostic tool manufacturers. As new features and control strategies are implemented in LM7 engines, diagnostic equipment must be continuously updated to remain relevant. This constant need for updates creates a lag between the latest engine modifications and the availability of corresponding diagnostic capabilities, potentially leaving technicians ill-equipped to handle emerging issues.

Furthermore, the interpretation of diagnostic data remains a significant challenge. While advanced tools can retrieve vast amounts of information from the engine's systems, translating this data into actionable insights requires considerable expertise. Many technicians struggle to correlate multiple data points and symptoms to arrive at accurate diagnoses, highlighting the need for more intuitive and intelligent diagnostic interfaces.

Access to proprietary information and diagnostic procedures from General Motors presents another obstacle. Without comprehensive access to manufacturer-specific data and troubleshooting guides, third-party diagnostic tool developers and independent mechanics face limitations in creating and using fully-featured diagnostic solutions for the LM7 engine.

Lastly, the integration of diagnostic tools with other workshop systems and databases remains underdeveloped. The inability to seamlessly connect diagnostic results with repair histories, parts inventories, and technical bulletins hinders the efficiency of professional analysis and repair processes. This lack of integration forces technicians to juggle multiple systems, potentially overlooking critical information that could expedite problem resolution.

Existing LM7 Diagnostic Solutions

01 On-board diagnostic systems for LM7 engines

Advanced on-board diagnostic systems are developed for LM7 engines to monitor various engine parameters in real-time. These systems use sensors and electronic control units to detect and report issues, enabling quick identification of potential problems and facilitating timely maintenance.- On-board diagnostic systems for LM7 engines: Advanced on-board diagnostic systems are developed for LM7 engines to monitor various engine parameters in real-time. These systems use sensors and electronic control units to detect and report issues, enabling quick identification of problems and facilitating timely maintenance.

- Handheld diagnostic tools for LM7 engines: Portable diagnostic tools are designed specifically for LM7 engines, allowing technicians to perform comprehensive diagnostics outside the vehicle. These tools can connect to the engine's electronic control module, retrieve error codes, and provide detailed analysis of engine performance.

- Software-based diagnostic solutions for LM7 engines: Specialized software applications are developed for diagnosing LM7 engines. These software tools can interface with the engine's computer systems, analyze data, and provide detailed reports on engine health, performance metrics, and potential issues.

- Remote diagnostic capabilities for LM7 engines: Remote diagnostic systems are implemented for LM7 engines, allowing technicians to monitor and diagnose engine issues from a distance. These systems use telematics and wireless communication technologies to transmit engine data in real-time, enabling proactive maintenance and reducing downtime.

- Advanced sensor technologies for LM7 engine diagnostics: Cutting-edge sensor technologies are developed to enhance the diagnostic capabilities of LM7 engines. These sensors can detect subtle changes in engine performance, emissions, and component wear, providing early warning of potential issues and improving overall engine reliability.

02 Handheld diagnostic tools for LM7 engines

Portable diagnostic tools are designed specifically for LM7 engines, allowing technicians to perform comprehensive diagnostics outside the vehicle. These tools can connect to the engine's electronic control module, retrieve error codes, and provide detailed analysis of engine performance.Expand Specific Solutions03 Software-based diagnostic solutions for LM7 engines

Specialized software applications are developed for diagnosing LM7 engines. These software tools can interface with the engine's computer systems, analyze data, and provide detailed reports on engine health, performance metrics, and potential issues, assisting in accurate diagnosis and repair.Expand Specific Solutions04 Remote diagnostic capabilities for LM7 engines

Remote diagnostic systems are implemented for LM7 engines, allowing technicians to monitor and diagnose engine issues from a distance. These systems use telematics and wireless communication technologies to transmit real-time engine data to service centers, enabling proactive maintenance and reducing downtime.Expand Specific Solutions05 Artificial intelligence-enhanced diagnostics for LM7 engines

AI-powered diagnostic tools are developed to enhance the accuracy and efficiency of LM7 engine diagnostics. These advanced systems use machine learning algorithms to analyze engine data, predict potential failures, and provide intelligent recommendations for maintenance and repairs.Expand Specific Solutions

Key Players in LM7 Diagnostic Tool Industry

The LM7 engine diagnostic tools market for professional analysis is in a mature stage, with established players dominating the landscape. The market size is substantial, driven by the increasing complexity of automotive systems and the growing demand for advanced diagnostic solutions. Technologically, the field is well-developed, with major companies like Robert Bosch GmbH, Snap-On, Inc., and Siemens AG offering sophisticated diagnostic tools. These industry leaders continually innovate to maintain their competitive edge, incorporating features such as real-time data analysis and cloud connectivity. Emerging players like Astemo Ltd. and Ford Global Technologies LLC are also making strides in this space, focusing on specialized solutions for specific engine types or vehicle brands.

Robert Bosch GmbH

Technical Solution: Bosch's LM7 engine diagnostic tools for professional analysis incorporate advanced OBD-II technology and proprietary algorithms. Their KTS series scanners feature high-speed processors and large color touchscreens for efficient diagnostics[1]. The tools support multi-protocol interfaces, including CAN FD, DoIP, and PassThru J2534, ensuring compatibility with a wide range of vehicles[2]. Bosch's ESI[tronic] 2.0 software provides comprehensive vehicle coverage, guided troubleshooting, and real-time data analysis. The system integrates with Bosch's Connected Repair platform, allowing seamless data sharing across workshop equipment[3].

Strengths: Extensive vehicle coverage, advanced software integration, and robust hardware. Weaknesses: Higher cost compared to some competitors, may require frequent software updates.

Snap-On, Inc.

Technical Solution: Snap-On's LM7 engine diagnostic tools utilize their VERUS Edge platform, which combines a rugged tablet design with powerful diagnostic software. The system features a fast boot-up time and intuitive user interface for efficient diagnostics[4]. Snap-On's software includes SureTrack, a comprehensive database of real-world fixes and expert knowledge[5]. Their diagnostic tools support advanced functions such as bi-directional controls, adaptive relearns, and module coding. The ZEUS platform incorporates Intelligent Diagnostics, which guides technicians through the entire repair process, from code to fix[6].

Strengths: User-friendly interface, extensive knowledge database, and guided diagnostics. Weaknesses: Premium pricing, may require ongoing subscription for full feature access.

Core Innovations in LM7 Engine Analysis

Using On-Board Monitoring (Mode 6) Misfire Tests in Data Stream and Physical Addressing

PatentActiveCN108255153A

Innovation

- Provides a diagnostic tool that utilizes CAN protocol and physical addressing of the engine controller to continuously retrieve and display Mode 6 cylinder misfire data, generate selectable icons to represent misfire conditions for each cylinder, and activate web browsing via a remote device to start the repair process.

Engine diagnostic apparatus and method

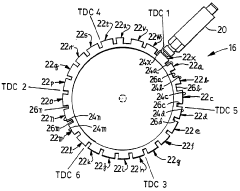

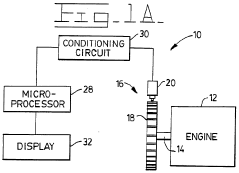

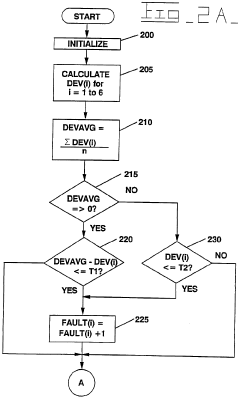

PatentWO1991019260A1

Innovation

- An apparatus that includes a sensor to measure time intervals between successive angular positions of a rotating member, producing period signals, which are processed by a microprocessor to calculate deviations and averages, generating fault signals for individual cylinders based on thresholds, enabling continuous monitoring and identification of malfunctioning cylinders.

Environmental Impact of LM7 Diagnostics

The environmental impact of LM7 engine diagnostic tools for professional analysis is a crucial consideration in the automotive industry's efforts towards sustainability. These diagnostic tools play a significant role in optimizing engine performance and reducing emissions, thereby contributing to overall environmental protection.

One of the primary environmental benefits of LM7 diagnostic tools is their ability to accurately identify and address engine inefficiencies. By pinpointing specific issues within the engine, these tools enable technicians to make precise adjustments and repairs. This targeted approach leads to improved fuel efficiency, which directly translates to reduced carbon emissions. Studies have shown that properly maintained engines can achieve up to 15% better fuel economy compared to poorly maintained ones, resulting in a substantial decrease in greenhouse gas emissions over the vehicle's lifetime.

Furthermore, LM7 diagnostic tools contribute to the reduction of harmful pollutants such as nitrogen oxides (NOx) and particulate matter. These tools allow for fine-tuning of the engine's combustion process, ensuring optimal air-fuel ratios and minimizing the production of these pollutants. This is particularly important in urban areas where air quality is a major concern, as it helps mitigate the negative health impacts associated with vehicle emissions.

The use of advanced diagnostic tools also extends the lifespan of engine components. By detecting potential issues early, technicians can prevent more severe damage that might lead to premature part replacement. This reduction in component turnover not only saves resources but also minimizes the environmental impact associated with manufacturing and disposing of automotive parts.

However, it is important to consider the environmental footprint of the diagnostic tools themselves. The production, distribution, and eventual disposal of these electronic devices contribute to e-waste and resource consumption. Manufacturers are increasingly focusing on developing more sustainable diagnostic tools, incorporating recyclable materials and energy-efficient designs to mitigate these impacts.

In the broader context of vehicle lifecycle management, LM7 diagnostic tools play a crucial role in supporting the transition to more environmentally friendly transportation solutions. By enabling the continued optimization of internal combustion engines, these tools help bridge the gap between current vehicle fleets and future zero-emission technologies. This transitional role is vital in reducing overall environmental impact while the automotive industry gradually shifts towards fully electric and alternative fuel vehicles.

One of the primary environmental benefits of LM7 diagnostic tools is their ability to accurately identify and address engine inefficiencies. By pinpointing specific issues within the engine, these tools enable technicians to make precise adjustments and repairs. This targeted approach leads to improved fuel efficiency, which directly translates to reduced carbon emissions. Studies have shown that properly maintained engines can achieve up to 15% better fuel economy compared to poorly maintained ones, resulting in a substantial decrease in greenhouse gas emissions over the vehicle's lifetime.

Furthermore, LM7 diagnostic tools contribute to the reduction of harmful pollutants such as nitrogen oxides (NOx) and particulate matter. These tools allow for fine-tuning of the engine's combustion process, ensuring optimal air-fuel ratios and minimizing the production of these pollutants. This is particularly important in urban areas where air quality is a major concern, as it helps mitigate the negative health impacts associated with vehicle emissions.

The use of advanced diagnostic tools also extends the lifespan of engine components. By detecting potential issues early, technicians can prevent more severe damage that might lead to premature part replacement. This reduction in component turnover not only saves resources but also minimizes the environmental impact associated with manufacturing and disposing of automotive parts.

However, it is important to consider the environmental footprint of the diagnostic tools themselves. The production, distribution, and eventual disposal of these electronic devices contribute to e-waste and resource consumption. Manufacturers are increasingly focusing on developing more sustainable diagnostic tools, incorporating recyclable materials and energy-efficient designs to mitigate these impacts.

In the broader context of vehicle lifecycle management, LM7 diagnostic tools play a crucial role in supporting the transition to more environmentally friendly transportation solutions. By enabling the continued optimization of internal combustion engines, these tools help bridge the gap between current vehicle fleets and future zero-emission technologies. This transitional role is vital in reducing overall environmental impact while the automotive industry gradually shifts towards fully electric and alternative fuel vehicles.

Data Security in LM7 Diagnostic Tools

Data security is a critical aspect of LM7 engine diagnostic tools for professional analysis. These tools handle sensitive vehicle and engine data, making them potential targets for cyber attacks and unauthorized access. To address these concerns, manufacturers and developers of LM7 diagnostic tools have implemented various security measures.

One of the primary security features is encryption of data both in transit and at rest. Advanced encryption algorithms are used to protect diagnostic data as it is transmitted between the tool and the vehicle's onboard computer. This ensures that intercepted data cannot be easily deciphered by malicious actors. Additionally, data stored on the diagnostic tool itself is encrypted to prevent unauthorized access in case of theft or loss of the device.

Authentication and access control mechanisms are another crucial component of data security in LM7 diagnostic tools. Multi-factor authentication is often employed to verify the identity of users before granting access to sensitive diagnostic functions. Role-based access control systems ensure that users only have access to the specific data and features necessary for their job functions, minimizing the risk of data breaches.

Secure software update processes are implemented to protect against potential vulnerabilities. Regular updates are provided to address newly discovered security issues and improve overall system integrity. These updates are typically digitally signed to prevent tampering and ensure they come from a trusted source.

Many LM7 diagnostic tools now incorporate secure boot processes and hardware-based security features. Secure boot ensures that only authorized firmware is loaded during the tool's startup, preventing malware from compromising the system at a fundamental level. Hardware security modules (HSMs) are often integrated to provide secure storage for cryptographic keys and to perform sensitive security operations.

To maintain data integrity, LM7 diagnostic tools employ checksums and digital signatures for diagnostic data. This allows technicians to verify that the data has not been altered or corrupted during transmission or storage. Audit logging is also a standard feature, recording all access attempts and data modifications to aid in forensic analysis in the event of a security incident.

As the automotive industry continues to evolve, with increasing connectivity and complexity in vehicle systems, the importance of data security in diagnostic tools grows. Manufacturers are investing in ongoing research and development to stay ahead of emerging threats and to ensure that LM7 diagnostic tools remain secure and reliable for professional analysis in an ever-changing technological landscape.

One of the primary security features is encryption of data both in transit and at rest. Advanced encryption algorithms are used to protect diagnostic data as it is transmitted between the tool and the vehicle's onboard computer. This ensures that intercepted data cannot be easily deciphered by malicious actors. Additionally, data stored on the diagnostic tool itself is encrypted to prevent unauthorized access in case of theft or loss of the device.

Authentication and access control mechanisms are another crucial component of data security in LM7 diagnostic tools. Multi-factor authentication is often employed to verify the identity of users before granting access to sensitive diagnostic functions. Role-based access control systems ensure that users only have access to the specific data and features necessary for their job functions, minimizing the risk of data breaches.

Secure software update processes are implemented to protect against potential vulnerabilities. Regular updates are provided to address newly discovered security issues and improve overall system integrity. These updates are typically digitally signed to prevent tampering and ensure they come from a trusted source.

Many LM7 diagnostic tools now incorporate secure boot processes and hardware-based security features. Secure boot ensures that only authorized firmware is loaded during the tool's startup, preventing malware from compromising the system at a fundamental level. Hardware security modules (HSMs) are often integrated to provide secure storage for cryptographic keys and to perform sensitive security operations.

To maintain data integrity, LM7 diagnostic tools employ checksums and digital signatures for diagnostic data. This allows technicians to verify that the data has not been altered or corrupted during transmission or storage. Audit logging is also a standard feature, recording all access attempts and data modifications to aid in forensic analysis in the event of a security incident.

As the automotive industry continues to evolve, with increasing connectivity and complexity in vehicle systems, the importance of data security in diagnostic tools grows. Manufacturers are investing in ongoing research and development to stay ahead of emerging threats and to ensure that LM7 diagnostic tools remain secure and reliable for professional analysis in an ever-changing technological landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!