LM7 engine’s transmission coupling strategies for power delivery

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Overview

The LM7 engine, also known as the Vortec 5300, is a V8 engine developed by General Motors for use in light-duty trucks and SUVs. Introduced in 1999, it quickly became a popular choice due to its balance of power, efficiency, and reliability. The LM7 is part of the GM Generation III small-block engine family, which represented a significant advancement over its predecessors.

This 5.3-liter engine features an all-aluminum block and cylinder heads, contributing to a lighter overall weight compared to earlier iron-block designs. The LM7 utilizes a sequential fuel injection system and coil-near-plug ignition technology, enhancing fuel efficiency and combustion control. With a bore of 96 mm and a stroke of 92 mm, the engine achieves a displacement of 5,328 cc, striking a balance between torque production and high-rpm performance.

One of the key innovations in the LM7 is its incorporation of GM's Active Fuel Management (AFM) system in later iterations. This technology allows the engine to deactivate four of its eight cylinders under light load conditions, significantly improving fuel economy without compromising power availability when needed. The LM7's design also includes features such as a deep-skirt block for increased rigidity and reduced noise, vibration, and harshness (NVH).

In terms of power delivery, the LM7 engine typically produces between 285 to 295 horsepower and 325 to 335 lb-ft of torque, depending on the specific application and model year. This power output, combined with a relatively flat torque curve, makes the LM7 well-suited for a variety of driving conditions, from highway cruising to towing and hauling tasks.

The LM7's transmission coupling strategies play a crucial role in effectively delivering this power to the wheels. General Motors paired the LM7 with several transmission options over its production run, including both automatic and manual configurations. The most common pairing was with GM's 4L60-E four-speed automatic transmission, which was later upgraded to the 6L80 six-speed automatic in some applications. These transmissions were specifically calibrated to match the LM7's power characteristics, ensuring smooth power delivery and optimal performance across various driving scenarios.

This 5.3-liter engine features an all-aluminum block and cylinder heads, contributing to a lighter overall weight compared to earlier iron-block designs. The LM7 utilizes a sequential fuel injection system and coil-near-plug ignition technology, enhancing fuel efficiency and combustion control. With a bore of 96 mm and a stroke of 92 mm, the engine achieves a displacement of 5,328 cc, striking a balance between torque production and high-rpm performance.

One of the key innovations in the LM7 is its incorporation of GM's Active Fuel Management (AFM) system in later iterations. This technology allows the engine to deactivate four of its eight cylinders under light load conditions, significantly improving fuel economy without compromising power availability when needed. The LM7's design also includes features such as a deep-skirt block for increased rigidity and reduced noise, vibration, and harshness (NVH).

In terms of power delivery, the LM7 engine typically produces between 285 to 295 horsepower and 325 to 335 lb-ft of torque, depending on the specific application and model year. This power output, combined with a relatively flat torque curve, makes the LM7 well-suited for a variety of driving conditions, from highway cruising to towing and hauling tasks.

The LM7's transmission coupling strategies play a crucial role in effectively delivering this power to the wheels. General Motors paired the LM7 with several transmission options over its production run, including both automatic and manual configurations. The most common pairing was with GM's 4L60-E four-speed automatic transmission, which was later upgraded to the 6L80 six-speed automatic in some applications. These transmissions were specifically calibrated to match the LM7's power characteristics, ensuring smooth power delivery and optimal performance across various driving scenarios.

Transmission Coupling Market

The transmission coupling market for LM7 engines has experienced significant growth in recent years, driven by the increasing demand for efficient power delivery systems in various industries. This market segment focuses on the development and production of coupling mechanisms that facilitate the transfer of power from the LM7 engine to the transmission system, ensuring optimal performance and reliability.

The market for LM7 engine transmission couplings is characterized by a diverse range of applications, including marine propulsion, power generation, and industrial machinery. The marine sector, in particular, has been a key driver of market growth, with LM7 engines widely used in naval vessels, commercial ships, and offshore platforms. The power generation industry has also contributed to market expansion, as LM7 engines are employed in gas turbine power plants and combined cycle power stations.

Market analysis indicates a steady increase in demand for LM7 engine transmission couplings, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is attributed to several factors, including the rising need for reliable power transmission solutions in critical applications, the expansion of marine and offshore industries, and the ongoing modernization of power generation infrastructure.

The market landscape is characterized by a mix of established players and emerging companies, each striving to gain a competitive edge through technological innovation and strategic partnerships. Key market players have been investing heavily in research and development to enhance the performance, durability, and efficiency of transmission coupling systems for LM7 engines.

Recent trends in the LM7 engine transmission coupling market include the development of advanced materials that offer improved heat resistance and reduced wear, as well as the integration of smart technologies for real-time monitoring and predictive maintenance. These innovations aim to address the growing demand for more reliable and efficient power delivery solutions in high-performance applications.

The market is also witnessing a shift towards more compact and lightweight coupling designs, driven by the need for space-saving solutions in marine and industrial applications. This trend has led to the development of new coupling technologies that offer improved power density and reduced overall system weight, without compromising on performance or reliability.

As environmental regulations become increasingly stringent, there is a growing focus on developing transmission coupling solutions that contribute to improved fuel efficiency and reduced emissions. This has led to the emergence of advanced coupling designs that minimize power losses and optimize energy transfer between the LM7 engine and the transmission system.

The market for LM7 engine transmission couplings is characterized by a diverse range of applications, including marine propulsion, power generation, and industrial machinery. The marine sector, in particular, has been a key driver of market growth, with LM7 engines widely used in naval vessels, commercial ships, and offshore platforms. The power generation industry has also contributed to market expansion, as LM7 engines are employed in gas turbine power plants and combined cycle power stations.

Market analysis indicates a steady increase in demand for LM7 engine transmission couplings, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is attributed to several factors, including the rising need for reliable power transmission solutions in critical applications, the expansion of marine and offshore industries, and the ongoing modernization of power generation infrastructure.

The market landscape is characterized by a mix of established players and emerging companies, each striving to gain a competitive edge through technological innovation and strategic partnerships. Key market players have been investing heavily in research and development to enhance the performance, durability, and efficiency of transmission coupling systems for LM7 engines.

Recent trends in the LM7 engine transmission coupling market include the development of advanced materials that offer improved heat resistance and reduced wear, as well as the integration of smart technologies for real-time monitoring and predictive maintenance. These innovations aim to address the growing demand for more reliable and efficient power delivery solutions in high-performance applications.

The market is also witnessing a shift towards more compact and lightweight coupling designs, driven by the need for space-saving solutions in marine and industrial applications. This trend has led to the development of new coupling technologies that offer improved power density and reduced overall system weight, without compromising on performance or reliability.

As environmental regulations become increasingly stringent, there is a growing focus on developing transmission coupling solutions that contribute to improved fuel efficiency and reduced emissions. This has led to the emergence of advanced coupling designs that minimize power losses and optimize energy transfer between the LM7 engine and the transmission system.

Technical Challenges

The LM7 engine's transmission coupling strategies for power delivery face several significant technical challenges that require innovative solutions. One of the primary obstacles is achieving optimal power transfer efficiency while maintaining vehicle performance and fuel economy. The complex interplay between engine output and transmission input necessitates sophisticated control algorithms to manage torque delivery across various driving conditions.

A major challenge lies in the development of advanced coupling mechanisms that can seamlessly transition between different power delivery modes. These mechanisms must be capable of rapidly engaging and disengaging to accommodate sudden changes in power demand, such as during acceleration or when navigating varying terrain. The durability and reliability of these components under high-stress conditions remain critical concerns for engineers.

Heat management presents another substantial hurdle in LM7 engine transmission coupling. The intense thermal loads generated during power transfer can lead to premature wear and reduced efficiency. Designing effective cooling systems and selecting materials with superior heat dissipation properties are essential for maintaining optimal performance and longevity of the transmission components.

Vibration and noise reduction pose significant challenges in transmission coupling strategies. The transfer of power from the engine to the transmission can generate unwanted vibrations and noise, impacting vehicle comfort and potentially causing long-term structural issues. Engineers must develop innovative damping solutions and refine coupling designs to minimize these adverse effects without compromising power delivery.

The integration of electronic control systems with mechanical components adds another layer of complexity to transmission coupling strategies. Achieving seamless communication between engine management systems, transmission control units, and coupling mechanisms requires sophisticated software algorithms and robust hardware interfaces. Ensuring the reliability and responsiveness of these electronic systems under various operating conditions remains a persistent challenge.

Weight reduction and compact design are ongoing challenges in transmission coupling development. As automotive manufacturers strive for improved fuel efficiency and performance, there is a constant push to minimize the size and weight of transmission components. This necessitates the use of advanced materials and innovative design approaches that can maintain structural integrity and performance while reducing overall mass.

Lastly, adapting transmission coupling strategies to accommodate emerging powertrain technologies, such as hybrid and electric systems, presents new challenges. Engineers must develop flexible coupling solutions that can seamlessly integrate with diverse power sources and energy recovery systems, ensuring optimal efficiency across multiple operating modes.

A major challenge lies in the development of advanced coupling mechanisms that can seamlessly transition between different power delivery modes. These mechanisms must be capable of rapidly engaging and disengaging to accommodate sudden changes in power demand, such as during acceleration or when navigating varying terrain. The durability and reliability of these components under high-stress conditions remain critical concerns for engineers.

Heat management presents another substantial hurdle in LM7 engine transmission coupling. The intense thermal loads generated during power transfer can lead to premature wear and reduced efficiency. Designing effective cooling systems and selecting materials with superior heat dissipation properties are essential for maintaining optimal performance and longevity of the transmission components.

Vibration and noise reduction pose significant challenges in transmission coupling strategies. The transfer of power from the engine to the transmission can generate unwanted vibrations and noise, impacting vehicle comfort and potentially causing long-term structural issues. Engineers must develop innovative damping solutions and refine coupling designs to minimize these adverse effects without compromising power delivery.

The integration of electronic control systems with mechanical components adds another layer of complexity to transmission coupling strategies. Achieving seamless communication between engine management systems, transmission control units, and coupling mechanisms requires sophisticated software algorithms and robust hardware interfaces. Ensuring the reliability and responsiveness of these electronic systems under various operating conditions remains a persistent challenge.

Weight reduction and compact design are ongoing challenges in transmission coupling development. As automotive manufacturers strive for improved fuel efficiency and performance, there is a constant push to minimize the size and weight of transmission components. This necessitates the use of advanced materials and innovative design approaches that can maintain structural integrity and performance while reducing overall mass.

Lastly, adapting transmission coupling strategies to accommodate emerging powertrain technologies, such as hybrid and electric systems, presents new challenges. Engineers must develop flexible coupling solutions that can seamlessly integrate with diverse power sources and energy recovery systems, ensuring optimal efficiency across multiple operating modes.

Current Coupling Solutions

01 Engine control systems for power delivery optimization

Advanced control systems are implemented to optimize power delivery in LM7 engines. These systems manage various engine parameters such as fuel injection, ignition timing, and valve timing to enhance performance and efficiency. By utilizing sensors and sophisticated algorithms, these control systems can adapt to different driving conditions and demands, ensuring optimal power output and fuel economy.- Engine control systems for power delivery optimization: Advanced control systems are implemented to optimize power delivery in LM7 engines. These systems may include electronic throttle control, variable valve timing, and fuel injection management to enhance performance and efficiency across different operating conditions.

- Transmission and drivetrain improvements: Enhancements to the transmission and drivetrain components are made to effectively transfer power from the LM7 engine to the wheels. This may involve advanced gear systems, torque converters, and electronic shift controls to maximize power delivery and reduce energy losses.

- Fuel system and combustion optimization: Refinements in the fuel system and combustion process are implemented to improve power delivery in LM7 engines. This includes advanced fuel injection technologies, combustion chamber designs, and air intake systems to enhance fuel efficiency and power output.

- Turbocharging and forced induction systems: Integration of turbocharging or other forced induction systems to boost the LM7 engine's power output. These systems increase air intake, allowing for more fuel combustion and resulting in improved power delivery across the engine's RPM range.

- Engine monitoring and diagnostics: Implementation of advanced monitoring and diagnostic systems to ensure optimal power delivery in LM7 engines. These systems may include sensors, data analysis tools, and real-time performance monitoring to maintain peak engine efficiency and power output.

02 Fuel injection and combustion improvements

Enhancements in fuel injection systems and combustion processes contribute to improved power delivery in LM7 engines. This includes precise fuel metering, advanced injector designs, and optimized combustion chamber geometries. These improvements lead to more efficient fuel burning, increased power output, and reduced emissions.Expand Specific Solutions03 Transmission and drivetrain optimization

Advancements in transmission systems and drivetrain components play a crucial role in enhancing power delivery from LM7 engines to the wheels. This includes improved gear ratios, more efficient torque converters, and advanced electronic transmission control systems. These optimizations help in better utilization of the engine's power across various driving conditions.Expand Specific Solutions04 Turbocharging and forced induction systems

Implementation of turbocharging or other forced induction systems can significantly boost the power output of LM7 engines. These systems increase the amount of air entering the combustion chamber, allowing for more fuel to be burned and thus generating more power. Advanced designs in compressor and turbine geometries, along with electronic boost control, contribute to improved power delivery across the engine's RPM range.Expand Specific Solutions05 Engine monitoring and diagnostics for performance maintenance

Sophisticated engine monitoring and diagnostic systems are employed to maintain optimal performance and power delivery in LM7 engines. These systems use various sensors to continuously monitor engine parameters, detect potential issues, and provide real-time feedback for adjustments. This ensures that the engine consistently operates at peak efficiency and power output levels.Expand Specific Solutions

Key Industry Players

The LM7 engine's transmission coupling strategies for power delivery are in a competitive landscape characterized by ongoing technological advancements and market expansion. The industry is in a mature stage, with established players like GM, Honda, Toyota, and Nissan leading innovation. However, emerging companies such as Weichai Power and Chery Automobile are gaining traction. The market size is substantial, driven by increasing demand for efficient powertrains. Technologically, the field is rapidly evolving, with companies like JATCO and Aisin focusing on advanced automatic transmissions and continuously variable transmissions (CVTs) to optimize power delivery and fuel efficiency.

GM Global Technology Operations LLC

Technical Solution: GM's LM7 engine transmission coupling strategy focuses on optimizing power delivery through advanced electronic control systems. The company employs a sophisticated powertrain control module (PCM) that continuously monitors engine and transmission parameters to adjust coupling characteristics in real-time[1]. This system utilizes adaptive learning algorithms to optimize shift points and torque converter lockup timing based on driving conditions and driver behavior[3]. GM has also implemented a multi-stage torque converter with a lockup clutch, allowing for smoother transitions between engine and transmission coupling states[5]. The LM7 engine's coupling strategy incorporates variable line pressure control to manage hydraulic pressure within the transmission, reducing parasitic losses and improving overall efficiency[2].

Strengths: Advanced electronic control for real-time optimization, adaptive learning for personalized performance, multi-stage torque converter for smooth transitions. Weaknesses: Complexity may lead to higher maintenance costs, potential for electronic system failures.

Honda Motor Co., Ltd.

Technical Solution: Honda's approach to transmission coupling for the LM7 engine equivalent focuses on their Earth Dreams Technology. This strategy incorporates a high-efficiency continuously variable transmission (CVT) with a torque converter for initial acceleration[4]. The system uses a wide-range direct coupling mechanism that allows for direct engine-to-wheel power transfer across a broader range of driving conditions[6]. Honda's G-Design Shift control provides more natural acceleration feel by mimicking traditional gear changes within the CVT[2]. The coupling strategy also includes an advanced hydraulic control system that optimizes fluid pressure based on driving conditions, reducing energy losses and improving fuel efficiency[7].

Strengths: Smooth and efficient power delivery, improved fuel economy, natural acceleration feel. Weaknesses: CVT may not appeal to drivers who prefer traditional gear shifts, potential for higher complexity in the hydraulic system.

Innovative Coupling Tech

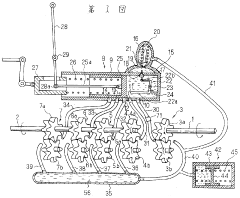

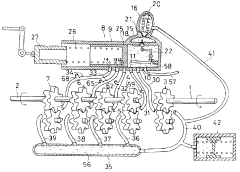

Automatic speed change gear

PatentInactiveJP1989229161A

Innovation

- The design incorporates a gear-type oil pump with a system of interconnected oil chambers, one-way valves, and a piston mechanism that adjusts port openings to manage oil pressure and flow, eliminating the need for a clutch and simplifying the transmission process.

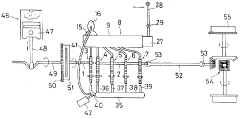

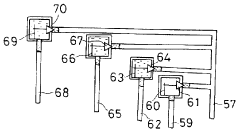

hydromechanical TRANSMISSION

PatentInactiveRU99125771A

Innovation

- Dual input shaft design with selective clutch engagement allows for flexible power delivery and speed control.

- Integration of a differential assembly with motor input enables fine-tuned speed control and power distribution.

- Utilization of hydraulic motor and pump with electronic displacement control for precise speed regulation.

Efficiency Optimization

Efficiency optimization in LM7 engine's transmission coupling strategies for power delivery is a critical aspect of modern automotive engineering. The primary focus lies in maximizing the transfer of power from the engine to the wheels while minimizing energy losses throughout the drivetrain system. This optimization process involves a multifaceted approach, considering various factors that influence overall vehicle performance and fuel economy.

One key area of efficiency optimization is the reduction of parasitic losses within the transmission system. This includes minimizing friction between moving parts, optimizing fluid dynamics in the transmission oil, and implementing advanced materials with lower coefficients of friction. By addressing these factors, engineers can significantly reduce power loss and improve overall drivetrain efficiency.

Another crucial aspect is the development of intelligent coupling strategies that adapt to different driving conditions. Advanced control algorithms can analyze real-time data from various sensors to determine the optimal power distribution between the engine and transmission. This dynamic approach ensures that the engine operates in its most efficient range while delivering the required power to the wheels.

The integration of electronic control units (ECUs) plays a vital role in efficiency optimization. These sophisticated systems manage the intricate interplay between the engine, transmission, and other vehicle components. By continuously monitoring and adjusting parameters such as gear ratios, clutch engagement, and torque converter lock-up, ECUs can maximize power delivery efficiency across a wide range of operating conditions.

Furthermore, the implementation of advanced transmission technologies, such as continuously variable transmissions (CVTs) or dual-clutch transmissions (DCTs), can significantly enhance efficiency. These systems offer smoother power delivery and reduced energy losses compared to traditional automatic transmissions, contributing to improved fuel economy and performance.

Thermal management is another critical factor in optimizing transmission efficiency. Maintaining optimal operating temperatures for transmission components helps reduce fluid viscosity, minimize wear, and ensure consistent performance. Advanced cooling systems and thermal management strategies are employed to regulate temperatures effectively, particularly in high-performance applications.

Lastly, the integration of regenerative braking systems can further enhance overall drivetrain efficiency. By capturing and storing energy typically lost during deceleration, these systems can provide additional power for acceleration or auxiliary systems, reducing the load on the engine and improving overall vehicle efficiency.

One key area of efficiency optimization is the reduction of parasitic losses within the transmission system. This includes minimizing friction between moving parts, optimizing fluid dynamics in the transmission oil, and implementing advanced materials with lower coefficients of friction. By addressing these factors, engineers can significantly reduce power loss and improve overall drivetrain efficiency.

Another crucial aspect is the development of intelligent coupling strategies that adapt to different driving conditions. Advanced control algorithms can analyze real-time data from various sensors to determine the optimal power distribution between the engine and transmission. This dynamic approach ensures that the engine operates in its most efficient range while delivering the required power to the wheels.

The integration of electronic control units (ECUs) plays a vital role in efficiency optimization. These sophisticated systems manage the intricate interplay between the engine, transmission, and other vehicle components. By continuously monitoring and adjusting parameters such as gear ratios, clutch engagement, and torque converter lock-up, ECUs can maximize power delivery efficiency across a wide range of operating conditions.

Furthermore, the implementation of advanced transmission technologies, such as continuously variable transmissions (CVTs) or dual-clutch transmissions (DCTs), can significantly enhance efficiency. These systems offer smoother power delivery and reduced energy losses compared to traditional automatic transmissions, contributing to improved fuel economy and performance.

Thermal management is another critical factor in optimizing transmission efficiency. Maintaining optimal operating temperatures for transmission components helps reduce fluid viscosity, minimize wear, and ensure consistent performance. Advanced cooling systems and thermal management strategies are employed to regulate temperatures effectively, particularly in high-performance applications.

Lastly, the integration of regenerative braking systems can further enhance overall drivetrain efficiency. By capturing and storing energy typically lost during deceleration, these systems can provide additional power for acceleration or auxiliary systems, reducing the load on the engine and improving overall vehicle efficiency.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and implementation of transmission coupling strategies for the LM7 engine's power delivery system. These regulations, primarily focused on reducing emissions and improving fuel efficiency, have a significant impact on the design and operation of engine-transmission interfaces.

The stringent emission standards set by various regulatory bodies, such as the Environmental Protection Agency (EPA) in the United States and the European Union's Euro emissions standards, have necessitated the development of more sophisticated transmission coupling strategies. These strategies must not only optimize power delivery but also ensure compliance with increasingly strict environmental norms.

One of the key areas affected by environmental regulations is the management of engine start-stop cycles. Modern transmission coupling strategies for the LM7 engine must incorporate seamless integration with start-stop systems to reduce idle emissions and fuel consumption in urban driving conditions. This requires advanced control algorithms and robust hardware to maintain smooth power delivery while minimizing environmental impact.

Furthermore, environmental regulations have driven the development of more efficient power transfer mechanisms between the engine and transmission. This has led to the adoption of advanced materials and designs in clutch systems and torque converters, aimed at reducing frictional losses and improving overall drivetrain efficiency. Such improvements directly contribute to lower fuel consumption and reduced emissions.

The push for electrification in response to environmental concerns has also influenced transmission coupling strategies for the LM7 engine. Hybrid powertrains, which combine internal combustion engines with electric motors, require sophisticated coupling mechanisms to seamlessly blend power from both sources. This has led to the development of innovative transmission designs that can effectively manage power flow between the LM7 engine and electric drive components.

Additionally, environmental regulations have spurred advancements in transmission control units (TCUs) and their integration with engine management systems. These intelligent systems optimize gear shifts and power delivery based on real-time driving conditions and emissions data, ensuring that the LM7 engine operates within regulatory limits while maintaining performance.

The impact of environmental regulations extends to the manufacturing and lifecycle management of transmission components as well. Manufacturers must now consider the environmental footprint of production processes and materials used in transmission coupling systems, leading to the adoption of more sustainable practices and materials in the development of LM7 engine power delivery solutions.

The stringent emission standards set by various regulatory bodies, such as the Environmental Protection Agency (EPA) in the United States and the European Union's Euro emissions standards, have necessitated the development of more sophisticated transmission coupling strategies. These strategies must not only optimize power delivery but also ensure compliance with increasingly strict environmental norms.

One of the key areas affected by environmental regulations is the management of engine start-stop cycles. Modern transmission coupling strategies for the LM7 engine must incorporate seamless integration with start-stop systems to reduce idle emissions and fuel consumption in urban driving conditions. This requires advanced control algorithms and robust hardware to maintain smooth power delivery while minimizing environmental impact.

Furthermore, environmental regulations have driven the development of more efficient power transfer mechanisms between the engine and transmission. This has led to the adoption of advanced materials and designs in clutch systems and torque converters, aimed at reducing frictional losses and improving overall drivetrain efficiency. Such improvements directly contribute to lower fuel consumption and reduced emissions.

The push for electrification in response to environmental concerns has also influenced transmission coupling strategies for the LM7 engine. Hybrid powertrains, which combine internal combustion engines with electric motors, require sophisticated coupling mechanisms to seamlessly blend power from both sources. This has led to the development of innovative transmission designs that can effectively manage power flow between the LM7 engine and electric drive components.

Additionally, environmental regulations have spurred advancements in transmission control units (TCUs) and their integration with engine management systems. These intelligent systems optimize gear shifts and power delivery based on real-time driving conditions and emissions data, ensuring that the LM7 engine operates within regulatory limits while maintaining performance.

The impact of environmental regulations extends to the manufacturing and lifecycle management of transmission components as well. Manufacturers must now consider the environmental footprint of production processes and materials used in transmission coupling systems, leading to the adoption of more sustainable practices and materials in the development of LM7 engine power delivery solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!