How LM7 engine design enhances combustion dynamics

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Background and Objectives

The LM7 engine, also known as the Vortec 5300, is a V8 engine developed by General Motors as part of their Gen III small-block engine family. Introduced in 1999, the LM7 was designed to enhance combustion dynamics and overall engine performance while meeting increasingly stringent emissions standards and fuel efficiency requirements.

The primary objective of the LM7 engine design was to improve upon its predecessor, the Gen II small-block, by incorporating advanced technologies and engineering solutions. This included the implementation of a deep-skirt engine block for increased rigidity, coil-near-plug ignition for more precise spark timing, and a revised combustion chamber design for better fuel mixture and flame propagation.

One of the key innovations in the LM7 engine was the introduction of a high-flow cylinder head design. This feature significantly improved the engine's breathing capabilities, allowing for more efficient air and fuel intake and exhaust flow. The redesigned intake and exhaust ports, coupled with larger valves, contributed to enhanced combustion dynamics by promoting better mixture formation and more complete fuel burning.

The LM7 engine also incorporated advanced electronic engine control systems, which played a crucial role in optimizing combustion dynamics. These systems allowed for precise control of fuel injection timing and duration, as well as ignition timing, adapting to various operating conditions to maximize efficiency and power output while minimizing emissions.

Another significant aspect of the LM7 design was the use of a higher compression ratio compared to its predecessors. This increase in compression ratio, typically around 9.5:1, contributed to improved thermal efficiency and combustion dynamics. The higher compression ratio allowed for more complete fuel burning and increased power output without sacrificing fuel economy.

The engine's combustion dynamics were further enhanced by the implementation of a redesigned piston and ring package. The new pistons featured a revised crown design that promoted better fuel mixture swirl within the combustion chamber, leading to more efficient and complete combustion. The improved ring design helped to maintain better cylinder sealing, reducing blow-by and improving overall engine efficiency.

In terms of materials and manufacturing, the LM7 engine utilized advanced casting techniques and materials, such as cast aluminum for the cylinder heads and engine block. These lightweight materials contributed to overall weight reduction while maintaining structural integrity, allowing for improved power-to-weight ratios and better vehicle dynamics.

The development of the LM7 engine represented a significant step forward in GM's engine technology, setting new standards for performance, efficiency, and emissions control in the automotive industry. Its design innovations and focus on enhancing combustion dynamics laid the groundwork for future engine developments and continue to influence modern engine design principles.

The primary objective of the LM7 engine design was to improve upon its predecessor, the Gen II small-block, by incorporating advanced technologies and engineering solutions. This included the implementation of a deep-skirt engine block for increased rigidity, coil-near-plug ignition for more precise spark timing, and a revised combustion chamber design for better fuel mixture and flame propagation.

One of the key innovations in the LM7 engine was the introduction of a high-flow cylinder head design. This feature significantly improved the engine's breathing capabilities, allowing for more efficient air and fuel intake and exhaust flow. The redesigned intake and exhaust ports, coupled with larger valves, contributed to enhanced combustion dynamics by promoting better mixture formation and more complete fuel burning.

The LM7 engine also incorporated advanced electronic engine control systems, which played a crucial role in optimizing combustion dynamics. These systems allowed for precise control of fuel injection timing and duration, as well as ignition timing, adapting to various operating conditions to maximize efficiency and power output while minimizing emissions.

Another significant aspect of the LM7 design was the use of a higher compression ratio compared to its predecessors. This increase in compression ratio, typically around 9.5:1, contributed to improved thermal efficiency and combustion dynamics. The higher compression ratio allowed for more complete fuel burning and increased power output without sacrificing fuel economy.

The engine's combustion dynamics were further enhanced by the implementation of a redesigned piston and ring package. The new pistons featured a revised crown design that promoted better fuel mixture swirl within the combustion chamber, leading to more efficient and complete combustion. The improved ring design helped to maintain better cylinder sealing, reducing blow-by and improving overall engine efficiency.

In terms of materials and manufacturing, the LM7 engine utilized advanced casting techniques and materials, such as cast aluminum for the cylinder heads and engine block. These lightweight materials contributed to overall weight reduction while maintaining structural integrity, allowing for improved power-to-weight ratios and better vehicle dynamics.

The development of the LM7 engine represented a significant step forward in GM's engine technology, setting new standards for performance, efficiency, and emissions control in the automotive industry. Its design innovations and focus on enhancing combustion dynamics laid the groundwork for future engine developments and continue to influence modern engine design principles.

Market Demand for Advanced Engine Technologies

The market demand for advanced engine technologies has been steadily increasing in recent years, driven by several key factors. Stringent environmental regulations, particularly in developed countries, have pushed automotive manufacturers to seek more efficient and cleaner engine designs. The LM7 engine, with its enhanced combustion dynamics, addresses these regulatory pressures while also meeting consumer expectations for improved performance and fuel economy.

Consumer preferences have shifted towards vehicles that offer better fuel efficiency without compromising on power and performance. This trend has created a significant market opportunity for advanced engine technologies like the LM7. The automotive industry has responded by investing heavily in research and development of innovative engine designs that can deliver on these seemingly contradictory demands.

The global market for advanced engine technologies is projected to grow substantially over the next decade. This growth is fueled by the increasing adoption of hybrid and electric vehicles, which often incorporate advanced combustion engines as part of their powertrain systems. The LM7 engine's improved combustion dynamics make it particularly well-suited for integration into hybrid powertrains, potentially expanding its market reach.

In the commercial vehicle sector, there is a growing demand for engines that can deliver improved fuel efficiency and reduced emissions while maintaining the power and durability required for heavy-duty applications. The LM7 engine's enhanced combustion dynamics could potentially address these needs, opening up new market opportunities in the trucking and transportation industries.

Emerging markets, particularly in Asia and South America, represent a significant growth potential for advanced engine technologies. As these regions continue to develop and implement stricter emissions standards, the demand for engines with improved combustion dynamics is expected to rise. The LM7 engine's design could position it favorably in these expanding markets.

The aftermarket and retrofit sectors also present opportunities for advanced engine technologies. As vehicle owners seek ways to improve the performance and efficiency of their existing vehicles, there may be a market for LM7-inspired upgrades or retrofit solutions that can enhance combustion dynamics in older engine designs.

Consumer preferences have shifted towards vehicles that offer better fuel efficiency without compromising on power and performance. This trend has created a significant market opportunity for advanced engine technologies like the LM7. The automotive industry has responded by investing heavily in research and development of innovative engine designs that can deliver on these seemingly contradictory demands.

The global market for advanced engine technologies is projected to grow substantially over the next decade. This growth is fueled by the increasing adoption of hybrid and electric vehicles, which often incorporate advanced combustion engines as part of their powertrain systems. The LM7 engine's improved combustion dynamics make it particularly well-suited for integration into hybrid powertrains, potentially expanding its market reach.

In the commercial vehicle sector, there is a growing demand for engines that can deliver improved fuel efficiency and reduced emissions while maintaining the power and durability required for heavy-duty applications. The LM7 engine's enhanced combustion dynamics could potentially address these needs, opening up new market opportunities in the trucking and transportation industries.

Emerging markets, particularly in Asia and South America, represent a significant growth potential for advanced engine technologies. As these regions continue to develop and implement stricter emissions standards, the demand for engines with improved combustion dynamics is expected to rise. The LM7 engine's design could position it favorably in these expanding markets.

The aftermarket and retrofit sectors also present opportunities for advanced engine technologies. As vehicle owners seek ways to improve the performance and efficiency of their existing vehicles, there may be a market for LM7-inspired upgrades or retrofit solutions that can enhance combustion dynamics in older engine designs.

Current State and Challenges in Combustion Dynamics

The current state of combustion dynamics in LM7 engine design reflects significant advancements, yet faces several challenges. Recent developments have focused on optimizing fuel-air mixture, improving ignition timing, and enhancing overall combustion efficiency. The LM7 engine, known for its robust performance in various applications, has benefited from these improvements, resulting in better fuel economy and reduced emissions.

One of the key advancements in LM7 engine combustion dynamics is the implementation of advanced fuel injection systems. Direct injection technology has been widely adopted, allowing for precise control over fuel delivery and atomization. This has led to more complete combustion and reduced fuel waste. Additionally, variable valve timing systems have been integrated to optimize air intake and exhaust flow, further enhancing combustion efficiency across different engine speeds and loads.

However, challenges persist in achieving optimal combustion dynamics. One major hurdle is the management of combustion instabilities, particularly at high engine speeds or under heavy loads. These instabilities can lead to increased noise, vibration, and potential engine damage. Engineers are working to develop more sophisticated control algorithms and sensor systems to detect and mitigate these instabilities in real-time.

Another significant challenge is the reduction of emissions while maintaining or improving engine performance. Stricter environmental regulations have pushed for cleaner combustion processes, necessitating innovative solutions. The development of low-temperature combustion strategies and the integration of exhaust gas recirculation (EGR) systems are ongoing areas of research to address this challenge.

The pursuit of higher thermal efficiency remains a constant challenge in LM7 engine design. While advancements have been made, there is still room for improvement in converting fuel energy into mechanical work. This involves optimizing combustion chamber geometry, reducing heat losses, and exploring new materials that can withstand higher combustion temperatures and pressures.

Knock prevention continues to be a critical aspect of combustion dynamics research. As engineers strive for higher compression ratios to improve efficiency, the risk of engine knock increases. Developing more effective knock detection systems and implementing adaptive control strategies to prevent knock occurrence are ongoing challenges in LM7 engine design.

Lastly, the integration of advanced combustion modeling and simulation tools presents both opportunities and challenges. While these tools allow for more accurate prediction of combustion behavior, their complexity and computational requirements pose challenges in real-time engine control applications. Striking a balance between model accuracy and computational efficiency remains an area of active research and development in the field of combustion dynamics for LM7 engines.

One of the key advancements in LM7 engine combustion dynamics is the implementation of advanced fuel injection systems. Direct injection technology has been widely adopted, allowing for precise control over fuel delivery and atomization. This has led to more complete combustion and reduced fuel waste. Additionally, variable valve timing systems have been integrated to optimize air intake and exhaust flow, further enhancing combustion efficiency across different engine speeds and loads.

However, challenges persist in achieving optimal combustion dynamics. One major hurdle is the management of combustion instabilities, particularly at high engine speeds or under heavy loads. These instabilities can lead to increased noise, vibration, and potential engine damage. Engineers are working to develop more sophisticated control algorithms and sensor systems to detect and mitigate these instabilities in real-time.

Another significant challenge is the reduction of emissions while maintaining or improving engine performance. Stricter environmental regulations have pushed for cleaner combustion processes, necessitating innovative solutions. The development of low-temperature combustion strategies and the integration of exhaust gas recirculation (EGR) systems are ongoing areas of research to address this challenge.

The pursuit of higher thermal efficiency remains a constant challenge in LM7 engine design. While advancements have been made, there is still room for improvement in converting fuel energy into mechanical work. This involves optimizing combustion chamber geometry, reducing heat losses, and exploring new materials that can withstand higher combustion temperatures and pressures.

Knock prevention continues to be a critical aspect of combustion dynamics research. As engineers strive for higher compression ratios to improve efficiency, the risk of engine knock increases. Developing more effective knock detection systems and implementing adaptive control strategies to prevent knock occurrence are ongoing challenges in LM7 engine design.

Lastly, the integration of advanced combustion modeling and simulation tools presents both opportunities and challenges. While these tools allow for more accurate prediction of combustion behavior, their complexity and computational requirements pose challenges in real-time engine control applications. Striking a balance between model accuracy and computational efficiency remains an area of active research and development in the field of combustion dynamics for LM7 engines.

Existing Solutions for Enhancing Combustion Dynamics

01 Combustion dynamics monitoring and control

Advanced systems for monitoring and controlling combustion dynamics in LM7 engines. These systems utilize sensors and algorithms to analyze combustion parameters in real-time, allowing for optimized engine performance and reduced emissions. The technology enables precise adjustments to fuel injection timing, air-fuel ratio, and other factors to maintain stable combustion across various operating conditions.- Combustion dynamics monitoring and control: Advanced systems for monitoring and controlling combustion dynamics in LM7 engines. These systems utilize sensors and algorithms to analyze combustion parameters in real-time, allowing for optimized engine performance and reduced emissions. The technology enables precise adjustments to fuel injection timing, air-fuel ratio, and other factors to maintain stable combustion across various operating conditions.

- Fuel injection optimization: Innovative fuel injection strategies to improve combustion dynamics in LM7 engines. These methods focus on optimizing fuel spray patterns, injection timing, and pressure to enhance fuel atomization and mixing with air. The result is more efficient combustion, reduced fuel consumption, and lower emissions. Advanced injector designs and electronic control systems play a crucial role in implementing these strategies.

- Combustion chamber design improvements: Enhancements to the LM7 engine's combustion chamber geometry and materials to optimize combustion dynamics. These improvements focus on factors such as piston crown shape, cylinder head design, and valve positioning to promote better air-fuel mixing and flame propagation. The use of advanced materials and coatings can also contribute to improved thermal management and reduced friction within the combustion chamber.

- Exhaust gas recirculation (EGR) integration: Implementation of EGR systems in LM7 engines to influence combustion dynamics and reduce emissions. By recirculating a portion of the exhaust gases back into the combustion chamber, these systems can lower peak combustion temperatures and reduce NOx formation. Advanced EGR control strategies are employed to optimize the amount of recirculated exhaust gas based on engine operating conditions.

- Combustion analysis and diagnostics: Development of sophisticated combustion analysis and diagnostic tools for LM7 engines. These tools utilize advanced sensors, data acquisition systems, and signal processing techniques to provide detailed insights into combustion dynamics. The technology enables engineers to identify and address issues such as knock, misfire, and incomplete combustion, leading to improved engine performance, efficiency, and durability.

02 Fuel injection optimization

Innovative fuel injection strategies to enhance combustion dynamics in LM7 engines. These methods focus on improving fuel atomization, distribution, and timing to achieve more efficient combustion. Advanced injector designs and control systems are employed to optimize fuel delivery based on engine load, speed, and environmental conditions, resulting in improved power output and reduced fuel consumption.Expand Specific Solutions03 Combustion chamber design improvements

Enhancements to the LM7 engine's combustion chamber geometry and materials to optimize combustion dynamics. These improvements focus on factors such as piston crown shape, cylinder head design, and valve positioning to promote better air-fuel mixing, flame propagation, and heat distribution. The result is more complete combustion, increased thermal efficiency, and reduced emissions.Expand Specific Solutions04 Exhaust gas recirculation (EGR) management

Advanced EGR systems and control strategies for LM7 engines to improve combustion dynamics and reduce emissions. These systems precisely regulate the amount of exhaust gas recirculated into the combustion chamber based on engine operating conditions. By optimizing EGR rates, the technology helps control combustion temperatures, reduce NOx emissions, and improve overall engine efficiency.Expand Specific Solutions05 Combustion analysis and diagnostics

Sophisticated tools and methods for analyzing and diagnosing combustion dynamics in LM7 engines. These technologies employ advanced sensors, data acquisition systems, and analysis algorithms to provide detailed insights into the combustion process. By monitoring parameters such as in-cylinder pressure, heat release rate, and combustion stability, engineers can optimize engine performance, identify potential issues, and develop improved combustion strategies.Expand Specific Solutions

Key Players in Engine Design Industry

The LM7 engine design's impact on combustion dynamics represents a competitive landscape in a mature automotive industry with significant market size. The technology's maturity varies among key players, with established manufacturers like Toyota, Ford, GM, and Caterpillar leading in research and development. Emerging companies such as Weichai Power and Hyundai are also making strides in engine innovation. The competition is intensifying as automakers strive to enhance fuel efficiency and reduce emissions, driving continuous improvements in combustion technology. This technological race is further propelled by stringent environmental regulations and the industry's shift towards more sustainable powertrain solutions.

Toyota Motor Corp.

Technical Solution: Toyota's LM7 engine design enhances combustion dynamics through several innovative features. The engine utilizes a high compression ratio of 13:1 and direct fuel injection technology, which improves fuel atomization and mixture formation[1]. This results in more efficient combustion and reduced emissions. The LM7 also incorporates variable valve timing (VVT) on both intake and exhaust camshafts, allowing for optimized air-fuel mixture across different engine speeds and loads[2]. Additionally, Toyota has implemented an advanced exhaust gas recirculation (EGR) system that helps lower combustion temperatures, reducing NOx emissions while maintaining performance[3].

Strengths: Improved fuel efficiency, reduced emissions, and enhanced performance across a wide range of operating conditions. Weaknesses: Potentially higher manufacturing costs and increased complexity compared to conventional engine designs.

Ford Global Technologies LLC

Technical Solution: Ford's approach to enhancing combustion dynamics in their LM7 engine design focuses on advanced turbocharging and direct injection technologies. The engine features a twin-scroll turbocharger that improves low-end torque and reduces turbo lag[1]. Ford's direct injection system operates at high pressures (up to 2,150 bar), ensuring precise fuel delivery and atomization[2]. The LM7 also incorporates a dual cooling system, with separate circuits for the cylinder head and engine block, allowing for optimized thermal management and improved combustion efficiency[3]. Furthermore, Ford has implemented cylinder deactivation technology, which can shut down cylinders under light load conditions to improve fuel economy[4].

Strengths: Enhanced low-end performance, improved fuel efficiency, and flexible power delivery. Weaknesses: Increased system complexity and potential reliability concerns due to advanced technologies.

Core Innovations in LM7 Engine Design

Combustion engine design

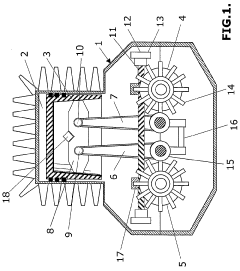

PatentWO2003093667A1

Innovation

- The engine design incorporates an intermediate part with two support points connected to separate crankshafts, providing stable piston support and allowing for adjustable compression ratio and stroke volume through synchronized motion of the connecting rods and crankshafts.

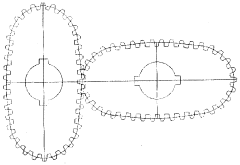

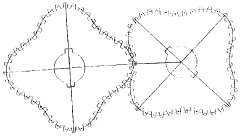

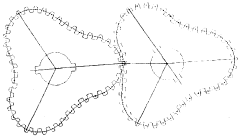

Method of combustion engine performance improvement

PatentInactiveCA2500917A1

Innovation

- Incorporating two special gears, one on the output shaft and another on a separate shaft connected via a coupling, with additional regular gears to maintain engine direction and axis position, allowing for variable gear ratios to enhance torque delivery and engine efficiency.

Environmental Impact and Regulations

The LM7 engine design's impact on combustion dynamics has significant environmental implications and is subject to various regulations. As automotive manufacturers strive to meet increasingly stringent emission standards, the LM7's enhanced combustion efficiency plays a crucial role in reducing harmful exhaust emissions. The improved fuel atomization and mixture formation in the combustion chamber lead to more complete combustion, resulting in lower levels of carbon monoxide (CO) and unburned hydrocarbons (HC) in the exhaust gases.

Furthermore, the LM7's advanced combustion dynamics contribute to better fuel economy, which directly translates to reduced carbon dioxide (CO2) emissions per mile driven. This aligns with global efforts to combat climate change and meets the requirements of corporate average fuel economy (CAFE) standards in many countries. The engine's ability to maintain optimal combustion across a wide range of operating conditions also helps in reducing nitrogen oxide (NOx) emissions, a major contributor to smog and acid rain.

Regulatory bodies worldwide have implemented strict emission standards, such as Euro 6 in Europe and Tier 3 in the United States. The LM7 engine's design innovations assist manufacturers in complying with these regulations by minimizing pollutant formation at the source. Additionally, the engine's compatibility with advanced aftertreatment systems, such as catalytic converters and particulate filters, further enhances its environmental performance.

The LM7's improved combustion dynamics also contribute to reduced engine wear and extended service life, indirectly benefiting the environment by decreasing the frequency of engine replacements and associated manufacturing emissions. Moreover, the engine's efficiency improvements align with the growing trend of vehicle electrification, as it can be effectively integrated into hybrid powertrains to maximize overall system efficiency and further reduce emissions.

As environmental regulations continue to evolve, the LM7 engine design provides a solid foundation for future adaptations. Its flexibility in accommodating alternative fuels, such as biofuels or synthetic fuels, positions it well for potential future regulatory shifts towards renewable energy sources in the transportation sector. This adaptability ensures that vehicles equipped with LM7 engines can remain compliant with environmental regulations for years to come, reducing the need for premature vehicle replacements and associated environmental impacts.

Furthermore, the LM7's advanced combustion dynamics contribute to better fuel economy, which directly translates to reduced carbon dioxide (CO2) emissions per mile driven. This aligns with global efforts to combat climate change and meets the requirements of corporate average fuel economy (CAFE) standards in many countries. The engine's ability to maintain optimal combustion across a wide range of operating conditions also helps in reducing nitrogen oxide (NOx) emissions, a major contributor to smog and acid rain.

Regulatory bodies worldwide have implemented strict emission standards, such as Euro 6 in Europe and Tier 3 in the United States. The LM7 engine's design innovations assist manufacturers in complying with these regulations by minimizing pollutant formation at the source. Additionally, the engine's compatibility with advanced aftertreatment systems, such as catalytic converters and particulate filters, further enhances its environmental performance.

The LM7's improved combustion dynamics also contribute to reduced engine wear and extended service life, indirectly benefiting the environment by decreasing the frequency of engine replacements and associated manufacturing emissions. Moreover, the engine's efficiency improvements align with the growing trend of vehicle electrification, as it can be effectively integrated into hybrid powertrains to maximize overall system efficiency and further reduce emissions.

As environmental regulations continue to evolve, the LM7 engine design provides a solid foundation for future adaptations. Its flexibility in accommodating alternative fuels, such as biofuels or synthetic fuels, positions it well for potential future regulatory shifts towards renewable energy sources in the transportation sector. This adaptability ensures that vehicles equipped with LM7 engines can remain compliant with environmental regulations for years to come, reducing the need for premature vehicle replacements and associated environmental impacts.

Performance Metrics and Testing Methodologies

The performance evaluation of the LM7 engine design's impact on combustion dynamics requires a comprehensive set of metrics and rigorous testing methodologies. Key performance indicators include fuel efficiency, power output, emissions levels, and combustion stability. Fuel efficiency is typically measured in miles per gallon (MPG) or liters per 100 kilometers (L/100km), while power output is assessed through dynamometer testing to determine horsepower and torque curves across the engine's operating range.

Emissions testing is crucial, focusing on carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM) levels. These are measured using standardized procedures such as the Federal Test Procedure (FTP) in the United States or the New European Driving Cycle (NEDC) in Europe. Combustion stability is evaluated through in-cylinder pressure analysis, examining cycle-to-cycle variations and combustion phasing.

Advanced testing methodologies employ high-speed cameras and laser-induced fluorescence to visualize fuel spray patterns and flame propagation within the combustion chamber. This allows engineers to optimize fuel injection timing and spray characteristics for enhanced combustion dynamics. Computational Fluid Dynamics (CFD) simulations complement physical testing, providing detailed insights into air-fuel mixing and combustion processes.

Thermal efficiency is another critical metric, assessed through careful measurement of heat release rates and exhaust gas temperatures. The LM7's improved combustion dynamics are expected to result in higher thermal efficiency, translating to better overall engine performance and reduced fuel consumption.

Durability testing is essential to ensure that the enhanced combustion dynamics do not compromise engine longevity. This involves extended running periods under various load conditions, followed by detailed component analysis to assess wear patterns and material degradation.

Noise, Vibration, and Harshness (NVH) testing is conducted to evaluate the acoustic and vibrational characteristics of the engine. This is particularly relevant for the LM7 design, as changes in combustion dynamics can significantly impact NVH profiles. Specialized equipment, including accelerometers and microphones, is used to capture and analyze these parameters across different operating conditions.

Finally, real-world performance testing is carried out through extensive road trials, encompassing a wide range of driving conditions and environments. This provides valuable data on how the LM7's enhanced combustion dynamics translate to practical benefits in everyday use, including improved drivability, responsiveness, and overall user satisfaction.

Emissions testing is crucial, focusing on carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM) levels. These are measured using standardized procedures such as the Federal Test Procedure (FTP) in the United States or the New European Driving Cycle (NEDC) in Europe. Combustion stability is evaluated through in-cylinder pressure analysis, examining cycle-to-cycle variations and combustion phasing.

Advanced testing methodologies employ high-speed cameras and laser-induced fluorescence to visualize fuel spray patterns and flame propagation within the combustion chamber. This allows engineers to optimize fuel injection timing and spray characteristics for enhanced combustion dynamics. Computational Fluid Dynamics (CFD) simulations complement physical testing, providing detailed insights into air-fuel mixing and combustion processes.

Thermal efficiency is another critical metric, assessed through careful measurement of heat release rates and exhaust gas temperatures. The LM7's improved combustion dynamics are expected to result in higher thermal efficiency, translating to better overall engine performance and reduced fuel consumption.

Durability testing is essential to ensure that the enhanced combustion dynamics do not compromise engine longevity. This involves extended running periods under various load conditions, followed by detailed component analysis to assess wear patterns and material degradation.

Noise, Vibration, and Harshness (NVH) testing is conducted to evaluate the acoustic and vibrational characteristics of the engine. This is particularly relevant for the LM7 design, as changes in combustion dynamics can significantly impact NVH profiles. Specialized equipment, including accelerometers and microphones, is used to capture and analyze these parameters across different operating conditions.

Finally, real-world performance testing is carried out through extensive road trials, encompassing a wide range of driving conditions and environments. This provides valuable data on how the LM7's enhanced combustion dynamics translate to practical benefits in everyday use, including improved drivability, responsiveness, and overall user satisfaction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!