The influence of LM7 engine on vehicle overall aerodynamics

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Background and Objectives

The LM7 engine, a member of the GM Gen III small-block V8 family, has played a significant role in shaping vehicle aerodynamics since its introduction in 1999. This 5.3-liter powerplant was designed to balance performance and efficiency, making it a popular choice for various GM vehicles, including trucks and SUVs. The engine's compact design and lightweight aluminum construction have contributed to its widespread adoption and influence on vehicle aerodynamics.

The primary objective of integrating the LM7 engine into vehicle designs is to optimize overall aerodynamic performance while maintaining the engine's power output and efficiency. This goal aligns with the automotive industry's ongoing efforts to improve fuel economy and reduce emissions without compromising vehicle performance. The LM7's relatively compact dimensions allow for more flexibility in vehicle design, potentially enabling sleeker body shapes and improved airflow management.

As the automotive industry has evolved, the focus on aerodynamics has intensified due to stricter fuel efficiency standards and the growing emphasis on environmental sustainability. The LM7 engine's design has been instrumental in allowing engineers to explore innovative approaches to vehicle aerodynamics, particularly in larger vehicles where engine size and placement can significantly impact overall drag coefficients.

The development of the LM7 engine has been closely tied to advancements in computational fluid dynamics (CFD) and wind tunnel testing. These technologies have enabled engineers to better understand and optimize the interaction between the engine's heat dissipation requirements and the vehicle's external airflow. This synergy has led to more refined cooling systems and engine bay designs that contribute to improved overall aerodynamic performance.

Looking at the technological evolution, the LM7 engine has undergone several iterations since its inception. Each version has brought incremental improvements in power delivery, fuel efficiency, and thermal management. These enhancements have directly influenced vehicle designers' ability to create more aerodynamic profiles, as the engine's efficiency gains have allowed for smaller cooling openings and more streamlined front-end designs.

The influence of the LM7 engine on vehicle aerodynamics extends beyond its physical dimensions and thermal characteristics. Its widespread use across multiple vehicle platforms has driven the development of standardized aerodynamic solutions that can be applied across different models. This approach has accelerated the implementation of aerodynamic improvements and contributed to a more cohesive design language within GM's vehicle lineup.

The primary objective of integrating the LM7 engine into vehicle designs is to optimize overall aerodynamic performance while maintaining the engine's power output and efficiency. This goal aligns with the automotive industry's ongoing efforts to improve fuel economy and reduce emissions without compromising vehicle performance. The LM7's relatively compact dimensions allow for more flexibility in vehicle design, potentially enabling sleeker body shapes and improved airflow management.

As the automotive industry has evolved, the focus on aerodynamics has intensified due to stricter fuel efficiency standards and the growing emphasis on environmental sustainability. The LM7 engine's design has been instrumental in allowing engineers to explore innovative approaches to vehicle aerodynamics, particularly in larger vehicles where engine size and placement can significantly impact overall drag coefficients.

The development of the LM7 engine has been closely tied to advancements in computational fluid dynamics (CFD) and wind tunnel testing. These technologies have enabled engineers to better understand and optimize the interaction between the engine's heat dissipation requirements and the vehicle's external airflow. This synergy has led to more refined cooling systems and engine bay designs that contribute to improved overall aerodynamic performance.

Looking at the technological evolution, the LM7 engine has undergone several iterations since its inception. Each version has brought incremental improvements in power delivery, fuel efficiency, and thermal management. These enhancements have directly influenced vehicle designers' ability to create more aerodynamic profiles, as the engine's efficiency gains have allowed for smaller cooling openings and more streamlined front-end designs.

The influence of the LM7 engine on vehicle aerodynamics extends beyond its physical dimensions and thermal characteristics. Its widespread use across multiple vehicle platforms has driven the development of standardized aerodynamic solutions that can be applied across different models. This approach has accelerated the implementation of aerodynamic improvements and contributed to a more cohesive design language within GM's vehicle lineup.

Market Analysis for LM7-Equipped Vehicles

The market for LM7-equipped vehicles has shown significant growth and potential in recent years, driven by the engine's impact on overall vehicle aerodynamics. The LM7 engine, known for its compact design and efficient performance, has become increasingly popular among automakers seeking to improve their vehicles' fuel efficiency and performance without compromising on aerodynamics.

In the passenger vehicle segment, LM7-equipped models have seen a steady increase in market share. This growth can be attributed to the engine's ability to provide a balance between power output and aerodynamic efficiency. Consumers are increasingly prioritizing fuel economy and environmental considerations, making LM7-equipped vehicles an attractive option in the mid-range and premium markets.

The commercial vehicle sector has also witnessed a rising demand for LM7-equipped vehicles. Fleet operators and logistics companies are recognizing the long-term cost benefits of improved fuel efficiency and reduced aerodynamic drag. This has led to a notable uptick in the adoption of LM7 engines in light and medium-duty trucks, as well as in some specialized heavy-duty applications.

Geographically, North America and Europe have emerged as the primary markets for LM7-equipped vehicles. These regions' stringent emissions regulations and consumer preferences for fuel-efficient vehicles have created a favorable environment for the adoption of aerodynamically optimized powertrains. In Asia-Pacific, particularly in China and Japan, there is a growing interest in LM7 technology, driven by urbanization and increasing environmental awareness.

Market forecasts suggest a compound annual growth rate (CAGR) for LM7-equipped vehicles that outpaces the overall automotive market growth. This trend is expected to continue as automakers invest in research and development to further enhance the integration of LM7 engines with advanced aerodynamic designs.

The competitive landscape for LM7-equipped vehicles is characterized by a mix of established automotive manufacturers and emerging players specializing in aerodynamic technologies. Major automakers are forming strategic partnerships with aerodynamics experts to leverage the full potential of LM7 engines in their vehicle designs.

Looking ahead, the market for LM7-equipped vehicles is poised for further expansion. Advancements in materials science and computational fluid dynamics are expected to unlock new possibilities for integrating LM7 engines into even more aerodynamically efficient vehicle designs. This ongoing innovation is likely to broaden the appeal of LM7-equipped vehicles across various market segments and geographies.

In the passenger vehicle segment, LM7-equipped models have seen a steady increase in market share. This growth can be attributed to the engine's ability to provide a balance between power output and aerodynamic efficiency. Consumers are increasingly prioritizing fuel economy and environmental considerations, making LM7-equipped vehicles an attractive option in the mid-range and premium markets.

The commercial vehicle sector has also witnessed a rising demand for LM7-equipped vehicles. Fleet operators and logistics companies are recognizing the long-term cost benefits of improved fuel efficiency and reduced aerodynamic drag. This has led to a notable uptick in the adoption of LM7 engines in light and medium-duty trucks, as well as in some specialized heavy-duty applications.

Geographically, North America and Europe have emerged as the primary markets for LM7-equipped vehicles. These regions' stringent emissions regulations and consumer preferences for fuel-efficient vehicles have created a favorable environment for the adoption of aerodynamically optimized powertrains. In Asia-Pacific, particularly in China and Japan, there is a growing interest in LM7 technology, driven by urbanization and increasing environmental awareness.

Market forecasts suggest a compound annual growth rate (CAGR) for LM7-equipped vehicles that outpaces the overall automotive market growth. This trend is expected to continue as automakers invest in research and development to further enhance the integration of LM7 engines with advanced aerodynamic designs.

The competitive landscape for LM7-equipped vehicles is characterized by a mix of established automotive manufacturers and emerging players specializing in aerodynamic technologies. Major automakers are forming strategic partnerships with aerodynamics experts to leverage the full potential of LM7 engines in their vehicle designs.

Looking ahead, the market for LM7-equipped vehicles is poised for further expansion. Advancements in materials science and computational fluid dynamics are expected to unlock new possibilities for integrating LM7 engines into even more aerodynamically efficient vehicle designs. This ongoing innovation is likely to broaden the appeal of LM7-equipped vehicles across various market segments and geographies.

Current Aerodynamic Challenges with LM7 Integration

The integration of the LM7 engine into vehicle designs presents several significant aerodynamic challenges that require careful consideration and innovative solutions. One of the primary issues is the engine's larger size and different shape compared to its predecessors, which can disrupt the carefully optimized airflow around the vehicle's body. This disruption can lead to increased drag, potentially reducing fuel efficiency and overall performance.

The LM7's increased power output also generates more heat, necessitating larger cooling systems. These larger radiators and air intakes can further complicate the vehicle's aerodynamic profile, creating additional areas of turbulence and drag. Engineers must find ways to efficiently channel air to these cooling systems without compromising the vehicle's overall aerodynamic efficiency.

Another challenge lies in managing the airflow underneath the vehicle. The LM7's different mounting position and underbody profile can alter the ground effect dynamics, potentially affecting vehicle stability at high speeds. This requires a reevaluation of underbody panels and diffuser designs to maintain optimal downforce and reduce lift.

The engine's exhaust system also poses aerodynamic challenges. The high-temperature exhaust gases exiting the vehicle can create localized areas of low pressure, potentially disrupting the carefully balanced airflow around the rear of the vehicle. This can affect stability and increase drag, particularly at higher speeds.

Furthermore, the LM7's integration may require modifications to the vehicle's front-end design. Changes to the hood profile or front fascia to accommodate the engine can significantly alter the vehicle's aerodynamic characteristics, potentially increasing frontal area and drag coefficient. Engineers must find creative ways to maintain an aerodynamically efficient front-end while accommodating the LM7's requirements.

The increased weight of the LM7 engine compared to smaller powerplants also impacts the vehicle's center of gravity and weight distribution. This shift can affect the vehicle's dynamic behavior, requiring adjustments to suspension settings and aerodynamic elements to maintain optimal handling characteristics.

Addressing these challenges requires a holistic approach to vehicle design, combining advanced computational fluid dynamics (CFD) simulations, wind tunnel testing, and on-road validation. Engineers must balance the aerodynamic requirements with other crucial factors such as cooling efficiency, structural integrity, and regulatory compliance. The goal is to create a harmonious integration that maximizes the LM7's performance potential while minimizing its impact on the vehicle's overall aerodynamic efficiency.

The LM7's increased power output also generates more heat, necessitating larger cooling systems. These larger radiators and air intakes can further complicate the vehicle's aerodynamic profile, creating additional areas of turbulence and drag. Engineers must find ways to efficiently channel air to these cooling systems without compromising the vehicle's overall aerodynamic efficiency.

Another challenge lies in managing the airflow underneath the vehicle. The LM7's different mounting position and underbody profile can alter the ground effect dynamics, potentially affecting vehicle stability at high speeds. This requires a reevaluation of underbody panels and diffuser designs to maintain optimal downforce and reduce lift.

The engine's exhaust system also poses aerodynamic challenges. The high-temperature exhaust gases exiting the vehicle can create localized areas of low pressure, potentially disrupting the carefully balanced airflow around the rear of the vehicle. This can affect stability and increase drag, particularly at higher speeds.

Furthermore, the LM7's integration may require modifications to the vehicle's front-end design. Changes to the hood profile or front fascia to accommodate the engine can significantly alter the vehicle's aerodynamic characteristics, potentially increasing frontal area and drag coefficient. Engineers must find creative ways to maintain an aerodynamically efficient front-end while accommodating the LM7's requirements.

The increased weight of the LM7 engine compared to smaller powerplants also impacts the vehicle's center of gravity and weight distribution. This shift can affect the vehicle's dynamic behavior, requiring adjustments to suspension settings and aerodynamic elements to maintain optimal handling characteristics.

Addressing these challenges requires a holistic approach to vehicle design, combining advanced computational fluid dynamics (CFD) simulations, wind tunnel testing, and on-road validation. Engineers must balance the aerodynamic requirements with other crucial factors such as cooling efficiency, structural integrity, and regulatory compliance. The goal is to create a harmonious integration that maximizes the LM7's performance potential while minimizing its impact on the vehicle's overall aerodynamic efficiency.

Existing Aerodynamic Solutions for LM7 Integration

01 Aerodynamic design improvements for LM7 engine

Various aerodynamic enhancements have been developed for the LM7 engine to improve its performance and efficiency. These improvements focus on reducing drag, optimizing airflow, and enhancing overall engine aerodynamics. Such modifications can lead to increased power output, better fuel efficiency, and improved engine cooling.- Aerodynamic design of LM7 engine components: The LM7 engine incorporates aerodynamic design principles in various components to improve overall performance. This includes optimized shapes for intake and exhaust systems, as well as streamlined engine covers and housings to reduce drag and improve airflow around the engine.

- Cooling system optimization for LM7 engine: Aerodynamic considerations are applied to the LM7 engine's cooling system to enhance heat dissipation and maintain optimal operating temperatures. This involves the design of efficient air intake pathways, strategically placed cooling fins, and aerodynamically shaped radiator components.

- Fuel efficiency improvements through aerodynamics: The LM7 engine utilizes aerodynamic principles to improve fuel efficiency. This includes the design of aerodynamic fuel injection systems, optimized combustion chamber shapes, and streamlined internal components to reduce energy losses due to air resistance within the engine.

- Noise reduction using aerodynamic techniques: Aerodynamic design elements are incorporated into the LM7 engine to reduce noise generation. This involves the use of specially shaped air intake and exhaust components, as well as aerodynamically optimized engine covers to minimize turbulence and acoustic resonance.

- Integration of LM7 engine aerodynamics with vehicle design: The aerodynamic characteristics of the LM7 engine are considered in the context of overall vehicle design. This includes optimizing the engine's placement and orientation within the vehicle, as well as designing complementary aerodynamic features in the surrounding vehicle structure to enhance overall performance and efficiency.

02 Intake and exhaust system optimization

Advancements in the intake and exhaust systems of the LM7 engine have been made to enhance aerodynamic performance. These improvements include redesigned air intake manifolds, optimized exhaust flow paths, and advanced filtration systems. Such modifications contribute to better air-fuel mixture, reduced backpressure, and improved overall engine efficiency.Expand Specific Solutions03 Cooling system enhancements

Innovative cooling system designs have been implemented to improve the aerodynamic performance of the LM7 engine. These enhancements include optimized radiator designs, advanced coolant flow management, and improved heat dissipation techniques. Such improvements contribute to better thermal management, reduced drag, and enhanced overall engine efficiency.Expand Specific Solutions04 Aerodynamic component integration

Integration of aerodynamic components into the LM7 engine design has been a focus of recent developments. This includes the incorporation of streamlined covers, optimized engine bay layouts, and aerodynamic underbody panels. These integrations help reduce turbulence, improve airflow management, and enhance the overall aerodynamic performance of the engine and vehicle.Expand Specific Solutions05 Computational fluid dynamics (CFD) optimization

Advanced computational fluid dynamics techniques have been employed to optimize the aerodynamics of the LM7 engine. These methods allow for detailed analysis and simulation of airflow patterns, enabling engineers to identify and address areas of inefficiency. The use of CFD has led to refined designs that maximize aerodynamic performance and engine efficiency.Expand Specific Solutions

Key Players in LM7 Engine and Vehicle Aerodynamics

The LM7 engine's influence on vehicle aerodynamics represents a competitive landscape in the mature automotive industry. With a global market size exceeding $2 trillion, major players like Toyota, Honda, and Mercedes-Benz are investing heavily in aerodynamic innovations to improve fuel efficiency and performance. The technology's maturity varies, with established manufacturers like GM and Nissan leveraging extensive R&D capabilities, while newer entrants such as Rivian and Zoox focus on integrating aerodynamics into electric vehicle designs. Collaboration between automakers and specialized firms like Hitachi Automotive Systems is accelerating progress in this field.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced aerodynamic package for their LM7 engine-equipped vehicles, focusing on reducing drag and improving fuel efficiency. Their approach includes a redesigned front grille with active shutters that automatically close at high speeds to reduce air resistance[1]. The underbody has been optimized with smooth panels and air deflectors to guide airflow efficiently. Toyota has also implemented a unique rear diffuser design that helps manage air separation at the vehicle's rear, reducing turbulence and drag[2]. Additionally, they have integrated small vortex generators on the roof and side mirrors to control airflow separation, further enhancing overall aerodynamics[3].

Strengths: Comprehensive approach to aerodynamics, innovative active grille shutters, and attention to underbody airflow management. Weaknesses: Potential increased complexity and cost of manufacturing, possible maintenance challenges for active components.

GM Global Technology Operations LLC

Technical Solution: GM has implemented a holistic aerodynamic strategy for vehicles equipped with the LM7 engine, focusing on both passive and active aerodynamic features. Their approach includes an advanced front air dam that automatically lowers at highway speeds to reduce underbody airflow[1]. They have also developed a system of active aero shutters in the front grille that close when additional engine cooling is not needed, significantly reducing frontal area drag[2]. GM's design incorporates specially shaped side mirrors and A-pillars to minimize wind noise and drag. Furthermore, they have implemented an innovative rear spoiler design that adapts its angle based on vehicle speed and driving conditions, optimizing downforce and reducing drag at higher speeds[3].

Strengths: Combination of active and passive aerodynamic features, adaptive rear spoiler for optimized performance. Weaknesses: Increased vehicle complexity and potential reliability issues with multiple active systems.

Core Innovations in LM7-Vehicle Aerodynamics

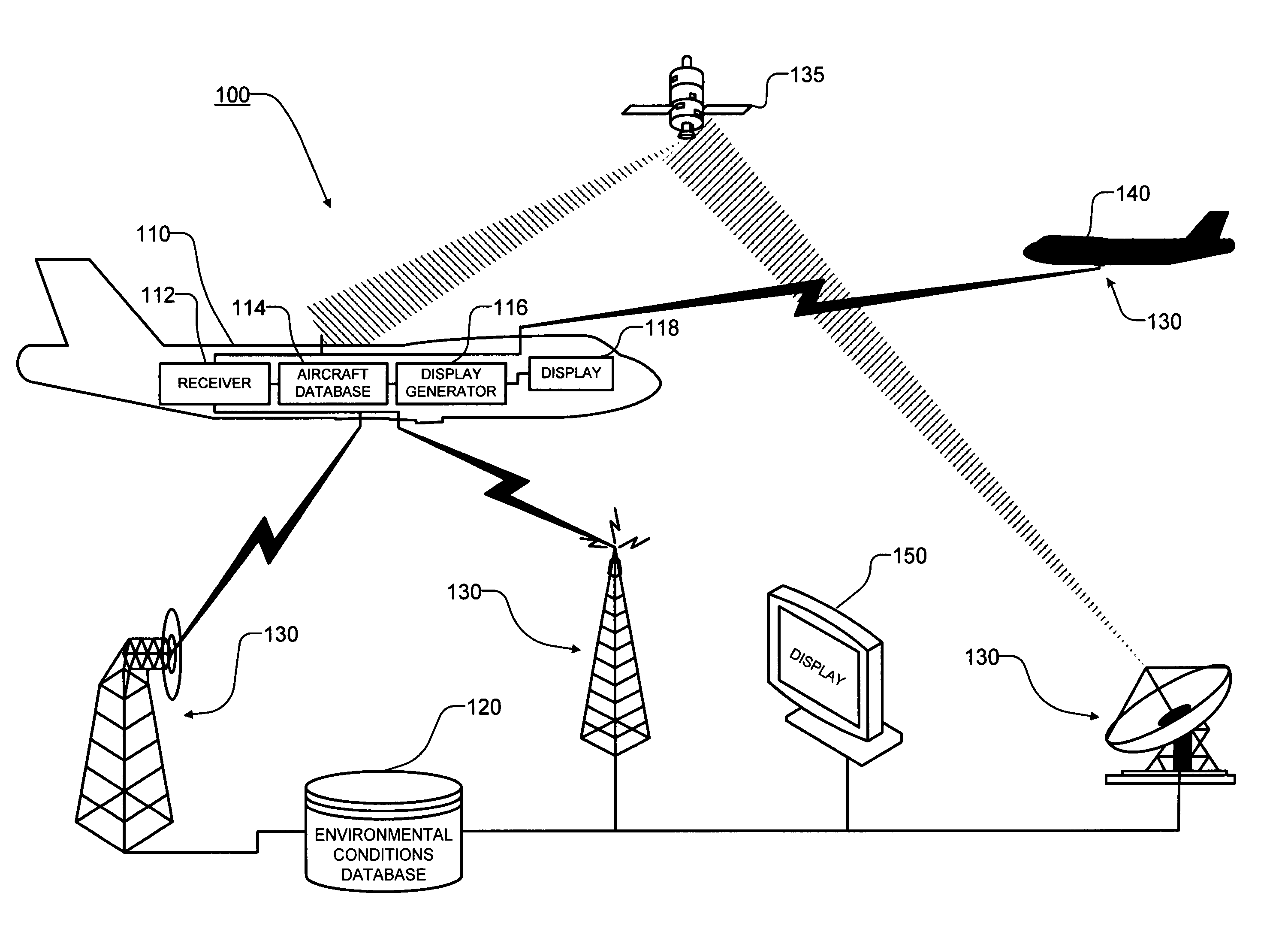

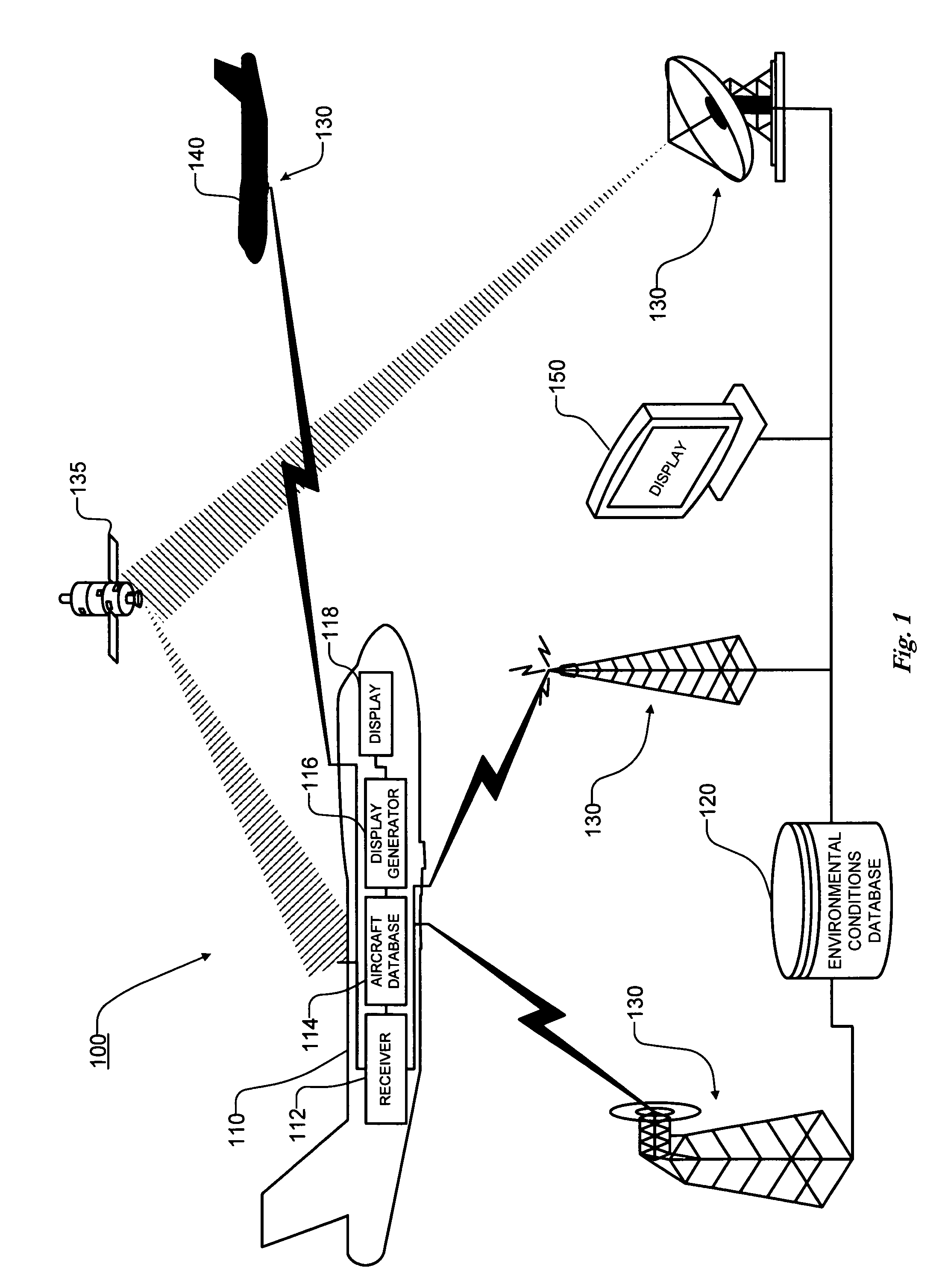

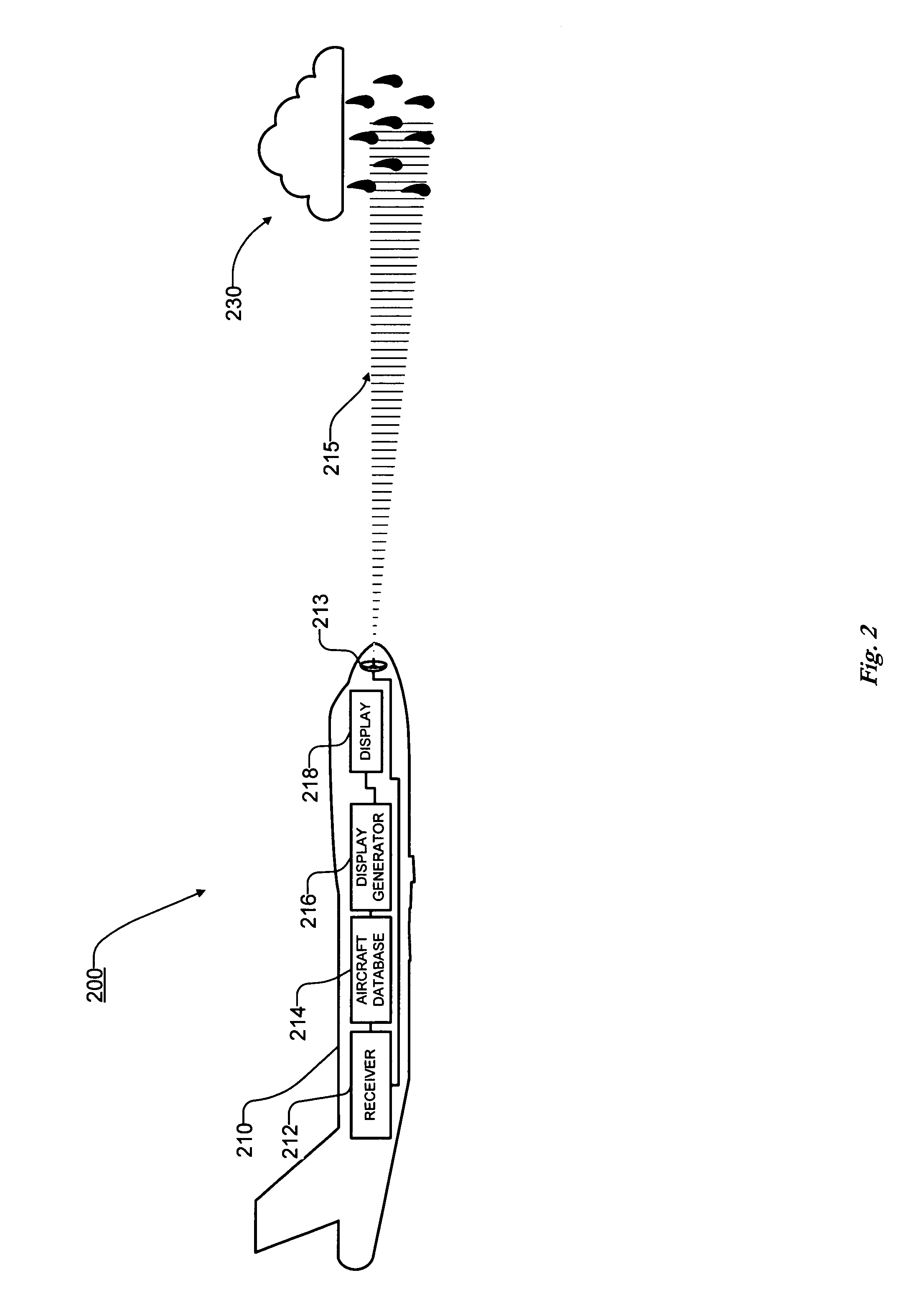

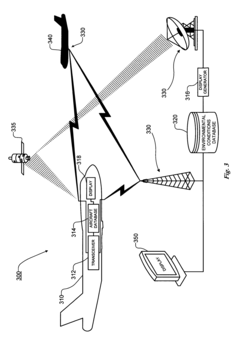

Transmission, receipt, combination, sorting, and presentation of vehicle specific environmental conditions and hazards information

PatentInactiveUS7471995B1

Innovation

- A system that combines environmental conditions information with aircraft-specific data to provide a simplified display map, optimizing travel routes based on both factors, and updating routes in real-time according to changing conditions or aircraft characteristics.

Environmental Impact of LM7 Aerodynamic Integration

The integration of the LM7 engine into vehicle design has significant implications for overall aerodynamics, which in turn affects environmental performance. The LM7's compact size and efficient design contribute to reduced frontal area and improved airflow management, potentially leading to decreased drag coefficients. This aerodynamic enhancement can result in lower fuel consumption and reduced emissions, aligning with increasingly stringent environmental regulations.

The LM7's integration often necessitates modifications to the vehicle's underbody and engine bay layout. These changes can facilitate smoother airflow underneath the vehicle, reducing turbulence and lift. Consequently, this may lead to improved stability at high speeds and reduced wind noise, enhancing both safety and comfort while minimizing energy loss due to aerodynamic inefficiencies.

Furthermore, the LM7's design allows for more effective heat management. Improved cooling system layouts and optimized air intake configurations can enhance thermal efficiency, potentially reducing the need for additional cooling mechanisms. This streamlined approach not only contributes to better aerodynamics but also helps in maintaining optimal engine performance, which is crucial for minimizing emissions and maximizing fuel efficiency.

The aerodynamic integration of the LM7 engine also influences the vehicle's overall weight distribution. By optimizing the engine's placement and surrounding components, designers can achieve a more balanced weight distribution, potentially improving handling characteristics. This balance can lead to reduced tire wear and more efficient power transfer to the road, indirectly contributing to lower environmental impact through reduced material consumption and improved overall vehicle efficiency.

Additionally, the LM7's integration often prompts innovations in body panel design and material selection. Manufacturers may opt for lightweight materials or aerodynamically optimized shapes to complement the engine's efficiency. These choices can further reduce vehicle weight and improve aerodynamic performance, culminating in lower energy requirements for propulsion and, consequently, reduced environmental footprint.

The environmental benefits of LM7 aerodynamic integration extend beyond direct emissions reduction. Improved aerodynamics can lead to reduced wind resistance, potentially allowing for smaller, more efficient batteries in electric or hybrid variants. This cascading effect can result in lighter vehicles overall, further enhancing energy efficiency and reducing the environmental impact associated with battery production and disposal.

The LM7's integration often necessitates modifications to the vehicle's underbody and engine bay layout. These changes can facilitate smoother airflow underneath the vehicle, reducing turbulence and lift. Consequently, this may lead to improved stability at high speeds and reduced wind noise, enhancing both safety and comfort while minimizing energy loss due to aerodynamic inefficiencies.

Furthermore, the LM7's design allows for more effective heat management. Improved cooling system layouts and optimized air intake configurations can enhance thermal efficiency, potentially reducing the need for additional cooling mechanisms. This streamlined approach not only contributes to better aerodynamics but also helps in maintaining optimal engine performance, which is crucial for minimizing emissions and maximizing fuel efficiency.

The aerodynamic integration of the LM7 engine also influences the vehicle's overall weight distribution. By optimizing the engine's placement and surrounding components, designers can achieve a more balanced weight distribution, potentially improving handling characteristics. This balance can lead to reduced tire wear and more efficient power transfer to the road, indirectly contributing to lower environmental impact through reduced material consumption and improved overall vehicle efficiency.

Additionally, the LM7's integration often prompts innovations in body panel design and material selection. Manufacturers may opt for lightweight materials or aerodynamically optimized shapes to complement the engine's efficiency. These choices can further reduce vehicle weight and improve aerodynamic performance, culminating in lower energy requirements for propulsion and, consequently, reduced environmental footprint.

The environmental benefits of LM7 aerodynamic integration extend beyond direct emissions reduction. Improved aerodynamics can lead to reduced wind resistance, potentially allowing for smaller, more efficient batteries in electric or hybrid variants. This cascading effect can result in lighter vehicles overall, further enhancing energy efficiency and reducing the environmental impact associated with battery production and disposal.

Regulatory Landscape for Vehicle Aerodynamics

The regulatory landscape for vehicle aerodynamics has become increasingly complex and stringent in recent years, driven by the global push for improved fuel efficiency and reduced emissions. Governments and regulatory bodies worldwide have implemented various standards and guidelines to ensure that vehicles meet specific aerodynamic performance criteria.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a significant driver for aerodynamic improvements. These standards require automakers to achieve specific fleet-wide fuel economy targets, indirectly encouraging the development of more aerodynamic vehicles. The Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) jointly administer these regulations, which have been progressively tightened over the years.

The European Union has implemented its own set of regulations, including the New European Driving Cycle (NEDC) and more recently, the Worldwide Harmonized Light Vehicles Test Procedure (WLTP). These testing procedures take into account aerodynamic performance as part of overall vehicle efficiency assessments. The EU has also set ambitious CO2 emission reduction targets, which have spurred innovation in vehicle aerodynamics.

China, as the world's largest automotive market, has introduced its own fuel consumption regulations and new energy vehicle (NEV) mandates. These regulations have led to increased focus on aerodynamic efficiency in vehicle design, particularly for electric vehicles where range optimization is crucial.

Specific aerodynamic regulations often focus on drag coefficient targets, with many regions requiring manufacturers to achieve certain thresholds. For instance, some jurisdictions mandate that passenger vehicles must achieve a drag coefficient below a specified value, typically in the range of 0.30 to 0.35, depending on the vehicle class.

The influence of engines like the LM7 on overall vehicle aerodynamics has become a subject of regulatory scrutiny. Regulators are increasingly considering the holistic impact of powertrain components on aerodynamic performance. This has led to requirements for integrated design approaches that consider engine placement, cooling systems, and underbody airflow management.

Safety regulations also intersect with aerodynamic considerations. For example, pedestrian protection standards in various regions have influenced front-end designs, which in turn affect overall aerodynamics. Balancing these safety requirements with aerodynamic efficiency has become a key challenge for automotive engineers and designers.

As the automotive industry moves towards electrification, regulatory bodies are adapting their frameworks to address the unique aerodynamic challenges and opportunities presented by electric vehicles. This includes considerations for battery cooling, reduced engine bay requirements, and the potential for more streamlined designs.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a significant driver for aerodynamic improvements. These standards require automakers to achieve specific fleet-wide fuel economy targets, indirectly encouraging the development of more aerodynamic vehicles. The Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) jointly administer these regulations, which have been progressively tightened over the years.

The European Union has implemented its own set of regulations, including the New European Driving Cycle (NEDC) and more recently, the Worldwide Harmonized Light Vehicles Test Procedure (WLTP). These testing procedures take into account aerodynamic performance as part of overall vehicle efficiency assessments. The EU has also set ambitious CO2 emission reduction targets, which have spurred innovation in vehicle aerodynamics.

China, as the world's largest automotive market, has introduced its own fuel consumption regulations and new energy vehicle (NEV) mandates. These regulations have led to increased focus on aerodynamic efficiency in vehicle design, particularly for electric vehicles where range optimization is crucial.

Specific aerodynamic regulations often focus on drag coefficient targets, with many regions requiring manufacturers to achieve certain thresholds. For instance, some jurisdictions mandate that passenger vehicles must achieve a drag coefficient below a specified value, typically in the range of 0.30 to 0.35, depending on the vehicle class.

The influence of engines like the LM7 on overall vehicle aerodynamics has become a subject of regulatory scrutiny. Regulators are increasingly considering the holistic impact of powertrain components on aerodynamic performance. This has led to requirements for integrated design approaches that consider engine placement, cooling systems, and underbody airflow management.

Safety regulations also intersect with aerodynamic considerations. For example, pedestrian protection standards in various regions have influenced front-end designs, which in turn affect overall aerodynamics. Balancing these safety requirements with aerodynamic efficiency has become a key challenge for automotive engineers and designers.

As the automotive industry moves towards electrification, regulatory bodies are adapting their frameworks to address the unique aerodynamic challenges and opportunities presented by electric vehicles. This includes considerations for battery cooling, reduced engine bay requirements, and the potential for more streamlined designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!