Integration of smart technologies in LM7 engine for diagnostics

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Smart Tech Integration Background

The LM7 engine, a member of the GM Gen III small-block V8 family, has been a staple in various General Motors vehicles since its introduction in 1999. As automotive technology has advanced, there has been a growing trend towards integrating smart technologies into engine systems for enhanced diagnostics and performance monitoring. This integration represents a significant leap forward in engine management and maintenance capabilities.

The evolution of engine technology has seen a shift from purely mechanical systems to increasingly electronic and computerized control. The LM7 engine, while initially designed with basic electronic fuel injection and ignition control, now stands at the cusp of a new era of smart integration. This technological progression aims to address the increasing complexity of modern engines and the demand for more efficient, reliable, and environmentally friendly powertrains.

Smart technologies in engine diagnostics encompass a wide range of innovations, including advanced sensors, real-time data processing, and predictive analytics. These technologies enable continuous monitoring of engine performance parameters, early detection of potential issues, and more accurate diagnosis of problems when they occur. For the LM7 engine, this integration presents an opportunity to enhance its longevity, optimize performance, and reduce maintenance costs.

The primary goal of integrating smart technologies into the LM7 engine for diagnostics is to create a more intelligent and self-aware powertrain system. This involves implementing sensors that can monitor various aspects of engine operation, such as temperature, pressure, vibration, and emissions. These sensors feed data into sophisticated algorithms that can analyze patterns and detect anomalies, providing valuable insights into the engine's health and performance.

Furthermore, the integration of smart technologies aims to enable predictive maintenance capabilities. By continuously analyzing engine data, the system can forecast potential failures before they occur, allowing for proactive maintenance and reducing the likelihood of unexpected breakdowns. This not only improves vehicle reliability but also optimizes maintenance schedules, potentially reducing overall ownership costs.

Another key objective is to enhance the engine's adaptability to different operating conditions. Smart technologies can enable the LM7 engine to adjust its performance parameters in real-time based on driving conditions, environmental factors, and user preferences. This adaptability can lead to improved fuel efficiency, reduced emissions, and a more responsive driving experience.

In the broader context of automotive development, the integration of smart technologies into the LM7 engine aligns with the industry's move towards more connected and autonomous vehicles. As cars become increasingly networked, the ability to remotely monitor and diagnose engine performance becomes crucial. This integration lays the groundwork for future advancements in vehicle-to-vehicle and vehicle-to-infrastructure communication, further enhancing safety and efficiency.

The evolution of engine technology has seen a shift from purely mechanical systems to increasingly electronic and computerized control. The LM7 engine, while initially designed with basic electronic fuel injection and ignition control, now stands at the cusp of a new era of smart integration. This technological progression aims to address the increasing complexity of modern engines and the demand for more efficient, reliable, and environmentally friendly powertrains.

Smart technologies in engine diagnostics encompass a wide range of innovations, including advanced sensors, real-time data processing, and predictive analytics. These technologies enable continuous monitoring of engine performance parameters, early detection of potential issues, and more accurate diagnosis of problems when they occur. For the LM7 engine, this integration presents an opportunity to enhance its longevity, optimize performance, and reduce maintenance costs.

The primary goal of integrating smart technologies into the LM7 engine for diagnostics is to create a more intelligent and self-aware powertrain system. This involves implementing sensors that can monitor various aspects of engine operation, such as temperature, pressure, vibration, and emissions. These sensors feed data into sophisticated algorithms that can analyze patterns and detect anomalies, providing valuable insights into the engine's health and performance.

Furthermore, the integration of smart technologies aims to enable predictive maintenance capabilities. By continuously analyzing engine data, the system can forecast potential failures before they occur, allowing for proactive maintenance and reducing the likelihood of unexpected breakdowns. This not only improves vehicle reliability but also optimizes maintenance schedules, potentially reducing overall ownership costs.

Another key objective is to enhance the engine's adaptability to different operating conditions. Smart technologies can enable the LM7 engine to adjust its performance parameters in real-time based on driving conditions, environmental factors, and user preferences. This adaptability can lead to improved fuel efficiency, reduced emissions, and a more responsive driving experience.

In the broader context of automotive development, the integration of smart technologies into the LM7 engine aligns with the industry's move towards more connected and autonomous vehicles. As cars become increasingly networked, the ability to remotely monitor and diagnose engine performance becomes crucial. This integration lays the groundwork for future advancements in vehicle-to-vehicle and vehicle-to-infrastructure communication, further enhancing safety and efficiency.

Market Demand Analysis

The integration of smart technologies in LM7 engines for diagnostics represents a significant market opportunity driven by increasing demand for advanced engine management systems. This trend is fueled by the automotive industry's push towards more efficient, reliable, and environmentally friendly vehicles. The market for smart engine diagnostics is expected to grow substantially in the coming years, as manufacturers and consumers alike recognize the benefits of real-time monitoring and predictive maintenance capabilities.

One of the primary drivers of market demand is the growing complexity of modern engines, which necessitates more sophisticated diagnostic tools. The LM7 engine, being a popular choice in many General Motors vehicles, presents a large installed base for potential upgrades and retrofits. This existing market provides a solid foundation for the adoption of smart diagnostic technologies.

Environmental regulations and fuel efficiency standards are also playing a crucial role in shaping market demand. As governments worldwide implement stricter emissions controls, there is an increased need for advanced engine management systems that can optimize performance while minimizing environmental impact. Smart diagnostics integrated into LM7 engines can help vehicle owners and fleet operators comply with these regulations by ensuring engines operate at peak efficiency and identifying potential issues before they lead to increased emissions.

The automotive aftermarket sector is another significant contributor to the demand for smart diagnostic technologies in LM7 engines. DIY enthusiasts and independent repair shops are seeking more advanced tools to diagnose and repair modern vehicles. This segment of the market values the ability to access detailed engine data and perform accurate diagnostics without the need for expensive proprietary equipment.

Fleet management companies represent a key market segment with high potential for adoption of smart diagnostic technologies. These companies manage large numbers of vehicles and are constantly looking for ways to reduce maintenance costs and vehicle downtime. The integration of smart diagnostics in LM7 engines can provide real-time monitoring of engine health, allowing for predictive maintenance and more efficient fleet operations.

Consumer demand for connected vehicles and enhanced user experiences is also driving the market for smart engine technologies. Vehicle owners are increasingly expecting their cars to provide detailed information about performance and maintenance needs. The integration of smart diagnostics in LM7 engines can meet this demand by offering features such as smartphone connectivity for engine health monitoring and maintenance alerts.

The insurance industry is showing interest in smart diagnostic technologies as a means to assess driver behavior and vehicle usage patterns. This could lead to new insurance models based on actual vehicle performance and maintenance habits, creating additional market demand for smart-enabled LM7 engines.

One of the primary drivers of market demand is the growing complexity of modern engines, which necessitates more sophisticated diagnostic tools. The LM7 engine, being a popular choice in many General Motors vehicles, presents a large installed base for potential upgrades and retrofits. This existing market provides a solid foundation for the adoption of smart diagnostic technologies.

Environmental regulations and fuel efficiency standards are also playing a crucial role in shaping market demand. As governments worldwide implement stricter emissions controls, there is an increased need for advanced engine management systems that can optimize performance while minimizing environmental impact. Smart diagnostics integrated into LM7 engines can help vehicle owners and fleet operators comply with these regulations by ensuring engines operate at peak efficiency and identifying potential issues before they lead to increased emissions.

The automotive aftermarket sector is another significant contributor to the demand for smart diagnostic technologies in LM7 engines. DIY enthusiasts and independent repair shops are seeking more advanced tools to diagnose and repair modern vehicles. This segment of the market values the ability to access detailed engine data and perform accurate diagnostics without the need for expensive proprietary equipment.

Fleet management companies represent a key market segment with high potential for adoption of smart diagnostic technologies. These companies manage large numbers of vehicles and are constantly looking for ways to reduce maintenance costs and vehicle downtime. The integration of smart diagnostics in LM7 engines can provide real-time monitoring of engine health, allowing for predictive maintenance and more efficient fleet operations.

Consumer demand for connected vehicles and enhanced user experiences is also driving the market for smart engine technologies. Vehicle owners are increasingly expecting their cars to provide detailed information about performance and maintenance needs. The integration of smart diagnostics in LM7 engines can meet this demand by offering features such as smartphone connectivity for engine health monitoring and maintenance alerts.

The insurance industry is showing interest in smart diagnostic technologies as a means to assess driver behavior and vehicle usage patterns. This could lead to new insurance models based on actual vehicle performance and maintenance habits, creating additional market demand for smart-enabled LM7 engines.

Current Challenges in Engine Diagnostics

The integration of smart technologies in LM7 engine diagnostics faces several significant challenges that need to be addressed for effective implementation. One of the primary obstacles is the complexity of modern engine systems, which require sophisticated diagnostic tools capable of interpreting vast amounts of data from multiple sensors and components simultaneously. This complexity often leads to difficulties in accurately identifying and isolating specific issues within the engine.

Another challenge lies in the real-time processing and analysis of diagnostic data. As engines become more advanced, the volume of data generated during operation increases exponentially. Developing algorithms and systems that can process this information in real-time, while the engine is running, presents a significant technical hurdle. This challenge is further compounded by the need for these systems to be both highly accurate and responsive to ensure timely detection of potential problems.

The integration of smart technologies also faces obstacles related to the reliability and durability of sensors and diagnostic equipment in harsh engine environments. High temperatures, vibrations, and exposure to various fluids can compromise the longevity and accuracy of diagnostic tools, necessitating the development of more robust and resilient technologies.

Standardization and compatibility issues present another set of challenges. With various manufacturers and suppliers involved in engine production, ensuring that diagnostic systems can seamlessly integrate and communicate across different platforms and protocols is crucial. This lack of standardization can lead to inconsistencies in diagnostic results and difficulties in implementing universal diagnostic solutions.

Cybersecurity concerns have also emerged as a significant challenge in the era of connected and smart engines. As diagnostic systems become more interconnected and reliant on data transmission, protecting these systems from potential cyber threats and ensuring the integrity of diagnostic data becomes paramount.

The cost-effectiveness of implementing advanced diagnostic technologies in LM7 engines is another hurdle. Balancing the benefits of improved diagnostics with the additional costs associated with developing, integrating, and maintaining these systems is a critical consideration for manufacturers and end-users alike.

Lastly, there is the challenge of training and adapting the workforce to effectively utilize these advanced diagnostic technologies. As systems become more complex, there is a growing need for specialized skills and knowledge to interpret diagnostic data and perform maintenance based on smart technology insights. This necessitates ongoing education and training programs to keep pace with technological advancements in engine diagnostics.

Another challenge lies in the real-time processing and analysis of diagnostic data. As engines become more advanced, the volume of data generated during operation increases exponentially. Developing algorithms and systems that can process this information in real-time, while the engine is running, presents a significant technical hurdle. This challenge is further compounded by the need for these systems to be both highly accurate and responsive to ensure timely detection of potential problems.

The integration of smart technologies also faces obstacles related to the reliability and durability of sensors and diagnostic equipment in harsh engine environments. High temperatures, vibrations, and exposure to various fluids can compromise the longevity and accuracy of diagnostic tools, necessitating the development of more robust and resilient technologies.

Standardization and compatibility issues present another set of challenges. With various manufacturers and suppliers involved in engine production, ensuring that diagnostic systems can seamlessly integrate and communicate across different platforms and protocols is crucial. This lack of standardization can lead to inconsistencies in diagnostic results and difficulties in implementing universal diagnostic solutions.

Cybersecurity concerns have also emerged as a significant challenge in the era of connected and smart engines. As diagnostic systems become more interconnected and reliant on data transmission, protecting these systems from potential cyber threats and ensuring the integrity of diagnostic data becomes paramount.

The cost-effectiveness of implementing advanced diagnostic technologies in LM7 engines is another hurdle. Balancing the benefits of improved diagnostics with the additional costs associated with developing, integrating, and maintaining these systems is a critical consideration for manufacturers and end-users alike.

Lastly, there is the challenge of training and adapting the workforce to effectively utilize these advanced diagnostic technologies. As systems become more complex, there is a growing need for specialized skills and knowledge to interpret diagnostic data and perform maintenance based on smart technology insights. This necessitates ongoing education and training programs to keep pace with technological advancements in engine diagnostics.

Existing Smart Diagnostic Solutions

01 Engine Control Unit (ECU) Diagnostics

Advanced diagnostic systems for LM7 engines utilize the Engine Control Unit (ECU) to monitor and analyze various engine parameters. These systems can detect and report issues related to fuel injection, ignition timing, and emissions control. They often employ machine learning algorithms to improve accuracy and predictive capabilities.- Engine Control Unit (ECU) Diagnostics: Advanced diagnostic systems for LM7 engines utilize the Engine Control Unit (ECU) to monitor and analyze various engine parameters. These systems can detect and report issues related to fuel injection, ignition timing, and emissions control. They often employ sophisticated algorithms to interpret sensor data and provide accurate diagnostic information.

- On-Board Diagnostic (OBD) Systems: LM7 engines are equipped with On-Board Diagnostic systems that continuously monitor engine performance and emissions. These systems can identify malfunctions, store diagnostic trouble codes, and activate warning indicators. OBD systems for LM7 engines often include features for real-time data streaming and remote diagnostics.

- Sensor-based Diagnostics: LM7 engine diagnostics rely heavily on various sensors to monitor engine conditions. These may include oxygen sensors, mass airflow sensors, and temperature sensors. Advanced diagnostic techniques involve analyzing sensor data patterns to identify potential issues before they become critical, improving overall engine reliability and performance.

- Predictive Maintenance Algorithms: Modern LM7 engine diagnostic systems incorporate predictive maintenance algorithms. These algorithms use machine learning and data analytics to predict potential failures based on historical data and current engine performance metrics. This approach allows for proactive maintenance, reducing downtime and extending engine life.

- Remote Diagnostics and Telematics: LM7 engine diagnostics have evolved to include remote diagnostics and telematics capabilities. These systems allow for real-time monitoring of engine performance from a distance, enabling quick response to issues and facilitating fleet management. They often integrate with mobile applications and cloud-based platforms for comprehensive engine health tracking.

02 On-Board Diagnostic (OBD) Systems

LM7 engines are equipped with On-Board Diagnostic systems that continuously monitor engine performance and emissions. These systems can identify malfunctions, store diagnostic trouble codes, and activate warning indicators. They also provide real-time data for technicians to diagnose and troubleshoot engine issues efficiently.Expand Specific Solutions03 Sensor-Based Diagnostics

LM7 engine diagnostics rely heavily on various sensors to gather data on engine performance. These sensors monitor parameters such as oxygen levels, temperature, pressure, and exhaust composition. Advanced diagnostic systems integrate and analyze data from multiple sensors to provide comprehensive engine health assessments.Expand Specific Solutions04 Remote Diagnostics and Telematics

Modern LM7 engine diagnostic systems incorporate remote diagnostics and telematics capabilities. These features allow for real-time monitoring of engine performance, remote troubleshooting, and predictive maintenance. They enable technicians to diagnose issues and provide guidance without physical access to the vehicle.Expand Specific Solutions05 Diagnostic Software and Tools

Specialized diagnostic software and tools have been developed for LM7 engines. These include advanced scanning tools, data analysis software, and interactive diagnostic guides. Such tools assist technicians in interpreting complex diagnostic data, performing system checks, and identifying potential issues quickly and accurately.Expand Specific Solutions

Key Players in Engine Diagnostics

The integration of smart technologies in LM7 engines for diagnostics represents a rapidly evolving field in the automotive industry. This market is in its growth phase, with increasing adoption across major manufacturers. The global market size for smart engine diagnostics is projected to expand significantly in the coming years, driven by the demand for improved vehicle performance and maintenance. Technologically, the field is advancing quickly, with companies like Scania CV AB, Chery Automobile, and Johnson Controls leading the way in developing sophisticated diagnostic systems. IBM and Northrop Grumman are also contributing their expertise in data analytics and systems integration, pushing the boundaries of what's possible in engine diagnostics.

Scania CV AB

Technical Solution: Scania has developed an advanced diagnostic system for their LM7 engine, integrating smart technologies to enhance performance and reliability. The system utilizes a network of sensors throughout the engine to continuously monitor key parameters such as temperature, pressure, and vibration. This data is processed in real-time by an onboard AI algorithm that can detect anomalies and predict potential failures before they occur[1]. The system also incorporates machine learning capabilities, allowing it to improve its diagnostic accuracy over time based on accumulated data from multiple engines[3]. Additionally, Scania has implemented a secure telematics solution that enables remote diagnostics and over-the-air updates, reducing downtime and maintenance costs for fleet operators[5].

Strengths: Predictive maintenance capabilities, real-time monitoring, and remote diagnostics. Weaknesses: High initial implementation cost and potential cybersecurity risks associated with connected systems.

Johnson Controls, Inc.

Technical Solution: Johnson Controls has integrated its smart technologies into the LM7 engine diagnostic system, focusing on energy efficiency and environmental sustainability. Their solution incorporates a network of smart sensors that monitor not only traditional engine parameters but also environmental factors such as ambient temperature and air quality. This holistic approach allows for more context-aware diagnostics and optimization[13]. The system utilizes Johnson Controls' proprietary energy management algorithms to optimize engine performance and reduce fuel consumption. Additionally, they have developed a unique emissions monitoring module that provides real-time data on engine emissions, helping to ensure compliance with increasingly stringent environmental regulations[14]. The diagnostic system also features an intuitive user interface and mobile app integration, allowing for easy access to engine health data and maintenance recommendations[15].

Strengths: Focus on energy efficiency and emissions monitoring, user-friendly interface. Weaknesses: May require additional sensors and equipment, potentially increasing complexity and cost.

Core Innovations in LM7 Smart Integration

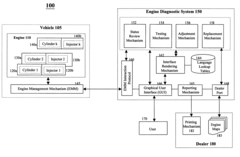

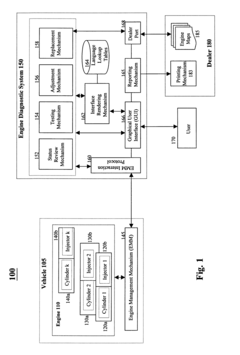

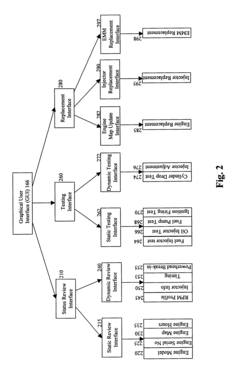

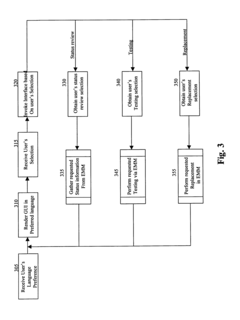

Engine diagnostic via PDA

PatentInactiveUS6801849B2

Innovation

- A portable engine diagnostic system implemented on a personal data assistant (PDA) or other handheld devices, featuring a graphical user interface, interaction protocols with engine management modules, and mechanisms for status review, testing, adjustment, and component replacement, allowing wireless communication and essential operations like injector adjustments and engine map updates.

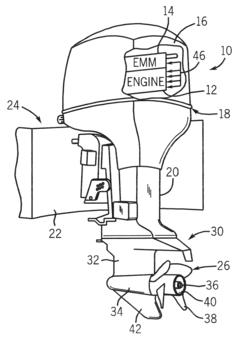

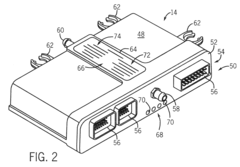

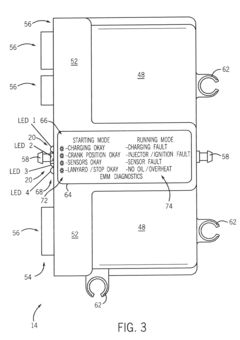

Engine mounted fault indicators

PatentInactiveUS7449994B1

Innovation

- An apparatus with a control unit mounted to the engine, featuring an array of operational indicators that provide diagnostic feedback directly to the user or technician, including LEDs that illuminate based on engine operating modes to indicate faults, accompanied by a label for quick reference.

Regulatory Compliance for Smart Engines

The integration of smart technologies in LM7 engines for diagnostics necessitates careful consideration of regulatory compliance. As these advanced engines incorporate sophisticated sensors, data processing capabilities, and connectivity features, they must adhere to a complex web of regulations spanning multiple domains.

Engine manufacturers must ensure compliance with emissions standards set by environmental protection agencies. Smart engines with advanced diagnostic capabilities can continuously monitor and optimize combustion processes, potentially reducing emissions. However, these systems must be rigorously tested and certified to meet stringent regulatory requirements, such as those outlined in the US EPA's Clean Air Act or the European Union's Euro emissions standards.

Safety regulations also play a crucial role in the development of smart engines. Diagnostic systems that can detect potential failures or performance issues in real-time must be designed to meet safety standards set by organizations like the National Highway Traffic Safety Administration (NHTSA) in the United States or the European New Car Assessment Programme (Euro NCAP). These regulations often require fail-safe mechanisms and redundancies to ensure that engine diagnostics do not compromise vehicle safety.

Data privacy and cybersecurity regulations present another layer of compliance challenges for smart engine technologies. As these systems collect and transmit sensitive data about engine performance and vehicle usage, they must comply with data protection laws such as the General Data Protection Regulation (GDPR) in the European Union or the California Consumer Privacy Act (CCPA) in the United States. Manufacturers must implement robust data encryption, secure communication protocols, and user consent mechanisms to ensure compliance with these regulations.

Electromagnetic compatibility (EMC) regulations are also critical for smart engines. The integration of multiple electronic systems and wireless communication technologies in engines must not interfere with other vehicle systems or external devices. Compliance with EMC standards, such as those set by the International Special Committee on Radio Interference (CISPR), is essential to ensure the reliable operation of smart engine diagnostics without causing electromagnetic disturbances.

As smart engines evolve, regulatory bodies are likely to introduce new standards specifically addressing the unique challenges posed by these technologies. Engine manufacturers must stay abreast of emerging regulations and actively participate in industry working groups to shape future compliance requirements. This proactive approach can help ensure that regulatory frameworks keep pace with technological advancements while maintaining safety, environmental protection, and consumer privacy standards.

Engine manufacturers must ensure compliance with emissions standards set by environmental protection agencies. Smart engines with advanced diagnostic capabilities can continuously monitor and optimize combustion processes, potentially reducing emissions. However, these systems must be rigorously tested and certified to meet stringent regulatory requirements, such as those outlined in the US EPA's Clean Air Act or the European Union's Euro emissions standards.

Safety regulations also play a crucial role in the development of smart engines. Diagnostic systems that can detect potential failures or performance issues in real-time must be designed to meet safety standards set by organizations like the National Highway Traffic Safety Administration (NHTSA) in the United States or the European New Car Assessment Programme (Euro NCAP). These regulations often require fail-safe mechanisms and redundancies to ensure that engine diagnostics do not compromise vehicle safety.

Data privacy and cybersecurity regulations present another layer of compliance challenges for smart engine technologies. As these systems collect and transmit sensitive data about engine performance and vehicle usage, they must comply with data protection laws such as the General Data Protection Regulation (GDPR) in the European Union or the California Consumer Privacy Act (CCPA) in the United States. Manufacturers must implement robust data encryption, secure communication protocols, and user consent mechanisms to ensure compliance with these regulations.

Electromagnetic compatibility (EMC) regulations are also critical for smart engines. The integration of multiple electronic systems and wireless communication technologies in engines must not interfere with other vehicle systems or external devices. Compliance with EMC standards, such as those set by the International Special Committee on Radio Interference (CISPR), is essential to ensure the reliable operation of smart engine diagnostics without causing electromagnetic disturbances.

As smart engines evolve, regulatory bodies are likely to introduce new standards specifically addressing the unique challenges posed by these technologies. Engine manufacturers must stay abreast of emerging regulations and actively participate in industry working groups to shape future compliance requirements. This proactive approach can help ensure that regulatory frameworks keep pace with technological advancements while maintaining safety, environmental protection, and consumer privacy standards.

Cybersecurity in Smart Engine Systems

The integration of smart technologies in engine systems has revolutionized diagnostics and performance monitoring, but it has also introduced new cybersecurity vulnerabilities. As LM7 engines incorporate advanced sensors, connectivity features, and data processing capabilities, they become potential targets for cyber attacks. These attacks could compromise engine performance, safety, and data integrity.

To address these challenges, a multi-layered cybersecurity approach is essential. At the hardware level, secure boot processes and trusted platform modules (TPMs) can ensure the integrity of the engine control unit (ECU) and prevent unauthorized modifications. Encryption of data at rest and in transit protects sensitive information from interception or tampering.

Network segmentation and firewalls are crucial for isolating critical engine systems from potentially compromised components. Implementing secure communication protocols, such as TLS/SSL, for data transmission between engine components and external systems adds an extra layer of protection.

Robust authentication and access control mechanisms are necessary to prevent unauthorized access to engine diagnostics and control systems. This includes multi-factor authentication for maintenance personnel and role-based access control to limit system exposure.

Continuous monitoring and intrusion detection systems (IDS) can identify anomalous behavior or potential security breaches in real-time. Machine learning algorithms can be employed to detect patterns indicative of cyber attacks and trigger appropriate responses.

Regular security audits and penetration testing should be conducted to identify and address vulnerabilities in the smart engine system. This proactive approach helps maintain the system's resilience against evolving cyber threats.

Over-the-air (OTA) update capabilities are essential for deploying security patches and firmware updates promptly. However, these update mechanisms must themselves be secured to prevent them from becoming attack vectors.

Cybersecurity awareness training for personnel involved in engine maintenance and operation is crucial. This ensures that human factors do not compromise the overall security posture of the smart engine system.

As the threat landscape evolves, cybersecurity measures for smart engine systems must adapt. This requires ongoing research and development to stay ahead of potential vulnerabilities and attack methods. Collaboration between engine manufacturers, cybersecurity experts, and regulatory bodies is essential to establish and maintain robust security standards for smart engine technologies.

To address these challenges, a multi-layered cybersecurity approach is essential. At the hardware level, secure boot processes and trusted platform modules (TPMs) can ensure the integrity of the engine control unit (ECU) and prevent unauthorized modifications. Encryption of data at rest and in transit protects sensitive information from interception or tampering.

Network segmentation and firewalls are crucial for isolating critical engine systems from potentially compromised components. Implementing secure communication protocols, such as TLS/SSL, for data transmission between engine components and external systems adds an extra layer of protection.

Robust authentication and access control mechanisms are necessary to prevent unauthorized access to engine diagnostics and control systems. This includes multi-factor authentication for maintenance personnel and role-based access control to limit system exposure.

Continuous monitoring and intrusion detection systems (IDS) can identify anomalous behavior or potential security breaches in real-time. Machine learning algorithms can be employed to detect patterns indicative of cyber attacks and trigger appropriate responses.

Regular security audits and penetration testing should be conducted to identify and address vulnerabilities in the smart engine system. This proactive approach helps maintain the system's resilience against evolving cyber threats.

Over-the-air (OTA) update capabilities are essential for deploying security patches and firmware updates promptly. However, these update mechanisms must themselves be secured to prevent them from becoming attack vectors.

Cybersecurity awareness training for personnel involved in engine maintenance and operation is crucial. This ensures that human factors do not compromise the overall security posture of the smart engine system.

As the threat landscape evolves, cybersecurity measures for smart engine systems must adapt. This requires ongoing research and development to stay ahead of potential vulnerabilities and attack methods. Collaboration between engine manufacturers, cybersecurity experts, and regulatory bodies is essential to establish and maintain robust security standards for smart engine technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!