Cooling technology advancements in LM7 engine systems

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Cooling Tech Background and Objectives

The LM7 engine, a member of the GM Gen III small-block V8 family, has been a cornerstone in automotive engineering since its introduction in 1999. As vehicle performance demands have increased, cooling technology advancements have become crucial for maintaining engine efficiency and longevity. The evolution of cooling systems in LM7 engines reflects broader trends in automotive thermal management, addressing challenges posed by higher power outputs and stricter emissions standards.

Initially, LM7 engines utilized conventional cooling methods, primarily relying on a water-based coolant circulated through the engine block and radiator. However, as power outputs increased and engine designs became more compact, the need for more sophisticated cooling solutions became apparent. This led to a series of innovations aimed at improving heat dissipation and maintaining optimal operating temperatures across various engine components.

One significant advancement has been the implementation of precision cooling techniques. This approach involves targeted cooling of specific engine areas, such as cylinder heads and exhaust valves, which are prone to higher thermal stress. By directing coolant flow more efficiently, precision cooling has allowed for better temperature control and reduced overall coolant volume, contributing to improved engine performance and fuel efficiency.

Another key development has been the integration of advanced materials in cooling system components. High-performance alloys and composites have been introduced in radiators, water pumps, and engine blocks, offering enhanced heat transfer properties and reduced weight. These materials have enabled the design of more compact and efficient cooling systems, crucial for modern engine bay packaging requirements.

The objectives of cooling technology advancements in LM7 engine systems are multifaceted. Primarily, they aim to maintain optimal engine operating temperatures across a wide range of conditions, from idle to high-performance scenarios. This temperature control is essential for maximizing engine efficiency, reducing emissions, and extending component lifespan. Additionally, advanced cooling technologies seek to minimize parasitic losses associated with traditional cooling systems, thereby contributing to overall engine efficiency gains.

Furthermore, these advancements are driven by the need to meet increasingly stringent emissions regulations. Effective cooling plays a crucial role in controlling exhaust gas temperatures and ensuring optimal catalytic converter performance. As such, cooling technology innovations in LM7 engines are closely tied to broader efforts in emissions reduction and environmental compliance.

Looking ahead, the trajectory of cooling technology in LM7 engines points towards even more sophisticated solutions. This includes the potential integration of smart cooling systems that can adapt to real-time engine conditions, as well as the exploration of alternative cooling mediums beyond traditional water-based coolants. These future developments aim to push the boundaries of engine performance while meeting the ever-growing demands for efficiency and environmental responsibility.

Initially, LM7 engines utilized conventional cooling methods, primarily relying on a water-based coolant circulated through the engine block and radiator. However, as power outputs increased and engine designs became more compact, the need for more sophisticated cooling solutions became apparent. This led to a series of innovations aimed at improving heat dissipation and maintaining optimal operating temperatures across various engine components.

One significant advancement has been the implementation of precision cooling techniques. This approach involves targeted cooling of specific engine areas, such as cylinder heads and exhaust valves, which are prone to higher thermal stress. By directing coolant flow more efficiently, precision cooling has allowed for better temperature control and reduced overall coolant volume, contributing to improved engine performance and fuel efficiency.

Another key development has been the integration of advanced materials in cooling system components. High-performance alloys and composites have been introduced in radiators, water pumps, and engine blocks, offering enhanced heat transfer properties and reduced weight. These materials have enabled the design of more compact and efficient cooling systems, crucial for modern engine bay packaging requirements.

The objectives of cooling technology advancements in LM7 engine systems are multifaceted. Primarily, they aim to maintain optimal engine operating temperatures across a wide range of conditions, from idle to high-performance scenarios. This temperature control is essential for maximizing engine efficiency, reducing emissions, and extending component lifespan. Additionally, advanced cooling technologies seek to minimize parasitic losses associated with traditional cooling systems, thereby contributing to overall engine efficiency gains.

Furthermore, these advancements are driven by the need to meet increasingly stringent emissions regulations. Effective cooling plays a crucial role in controlling exhaust gas temperatures and ensuring optimal catalytic converter performance. As such, cooling technology innovations in LM7 engines are closely tied to broader efforts in emissions reduction and environmental compliance.

Looking ahead, the trajectory of cooling technology in LM7 engines points towards even more sophisticated solutions. This includes the potential integration of smart cooling systems that can adapt to real-time engine conditions, as well as the exploration of alternative cooling mediums beyond traditional water-based coolants. These future developments aim to push the boundaries of engine performance while meeting the ever-growing demands for efficiency and environmental responsibility.

Market Demand for Advanced Engine Cooling

The market demand for advanced engine cooling technologies in LM7 engine systems has been steadily increasing due to several key factors driving the automotive industry. As vehicles become more powerful and efficient, the need for superior cooling solutions has become paramount to ensure optimal performance and longevity of engine components.

One of the primary drivers for this demand is the continuous push for improved fuel efficiency and reduced emissions. Advanced cooling technologies play a crucial role in maintaining ideal operating temperatures, which directly impacts engine efficiency and emissions output. By effectively managing heat dissipation, these systems allow engines to operate at higher temperatures without compromising performance or reliability.

The growing trend towards vehicle electrification and hybridization has also contributed to the increased demand for advanced cooling solutions. As hybrid and electric powertrains become more prevalent, the need for sophisticated thermal management systems that can handle both traditional internal combustion engines and electric components has risen significantly.

Furthermore, the automotive industry's focus on weight reduction and space optimization has created a need for more compact and efficient cooling systems. Advanced cooling technologies that can deliver superior performance while occupying less space and adding minimal weight to the vehicle are highly sought after by manufacturers.

The rise of high-performance vehicles and the increasing popularity of turbocharged engines have further fueled the demand for advanced cooling solutions. These high-output engines generate substantial heat, requiring more effective cooling systems to maintain optimal performance and prevent thermal-related issues.

Consumer expectations for improved vehicle reliability and longevity have also played a role in driving the demand for advanced cooling technologies. As customers seek vehicles with longer lifespans and reduced maintenance requirements, manufacturers are investing in cooling systems that can better protect engine components from heat-related wear and damage.

The market has also seen a growing interest in smart cooling systems that can adapt to various driving conditions and engine loads. These intelligent systems optimize cooling performance based on real-time data, further enhancing engine efficiency and reliability.

As environmental regulations become more stringent worldwide, the demand for cooling technologies that can help engines meet these standards without sacrificing performance continues to grow. Advanced cooling solutions are seen as a key enabler in achieving compliance with increasingly strict emissions and fuel efficiency requirements.

One of the primary drivers for this demand is the continuous push for improved fuel efficiency and reduced emissions. Advanced cooling technologies play a crucial role in maintaining ideal operating temperatures, which directly impacts engine efficiency and emissions output. By effectively managing heat dissipation, these systems allow engines to operate at higher temperatures without compromising performance or reliability.

The growing trend towards vehicle electrification and hybridization has also contributed to the increased demand for advanced cooling solutions. As hybrid and electric powertrains become more prevalent, the need for sophisticated thermal management systems that can handle both traditional internal combustion engines and electric components has risen significantly.

Furthermore, the automotive industry's focus on weight reduction and space optimization has created a need for more compact and efficient cooling systems. Advanced cooling technologies that can deliver superior performance while occupying less space and adding minimal weight to the vehicle are highly sought after by manufacturers.

The rise of high-performance vehicles and the increasing popularity of turbocharged engines have further fueled the demand for advanced cooling solutions. These high-output engines generate substantial heat, requiring more effective cooling systems to maintain optimal performance and prevent thermal-related issues.

Consumer expectations for improved vehicle reliability and longevity have also played a role in driving the demand for advanced cooling technologies. As customers seek vehicles with longer lifespans and reduced maintenance requirements, manufacturers are investing in cooling systems that can better protect engine components from heat-related wear and damage.

The market has also seen a growing interest in smart cooling systems that can adapt to various driving conditions and engine loads. These intelligent systems optimize cooling performance based on real-time data, further enhancing engine efficiency and reliability.

As environmental regulations become more stringent worldwide, the demand for cooling technologies that can help engines meet these standards without sacrificing performance continues to grow. Advanced cooling solutions are seen as a key enabler in achieving compliance with increasingly strict emissions and fuel efficiency requirements.

Current Cooling Challenges in LM7 Engines

The LM7 engine, a popular V8 engine developed by General Motors, faces several cooling challenges that require innovative solutions to maintain optimal performance and longevity. One of the primary issues is the management of heat distribution across the engine block. The V8 configuration, while powerful, creates uneven heat zones, with some cylinders experiencing higher temperatures than others. This temperature imbalance can lead to thermal stress and potential warping of engine components over time.

Another significant challenge is the cooling of high-stress areas, particularly around the combustion chambers and exhaust ports. These regions are subjected to extreme heat cycles, which can cause localized hot spots and accelerate wear on critical engine parts. The traditional cooling methods struggle to efficiently dissipate heat from these areas, potentially leading to reduced engine efficiency and increased emissions.

The LM7's high-performance nature also demands a more robust cooling system to handle increased thermal loads during peak operation. This is especially critical when the engine is used in high-performance applications or in vehicles subjected to heavy-duty use. The current cooling systems often struggle to maintain optimal operating temperatures under these conditions, which can result in reduced power output and increased fuel consumption.

Furthermore, the integration of modern emissions control systems has introduced additional heat management challenges. Components such as exhaust gas recirculation (EGR) systems and catalytic converters generate significant heat that must be effectively managed to prevent overheating and ensure compliance with stringent emissions regulations.

The cooling system's ability to respond quickly to varying engine loads and environmental conditions is another area of concern. Rapid temperature fluctuations during different driving scenarios can stress the cooling system, potentially leading to coolant pressure issues and reduced overall cooling efficiency.

Lastly, the pursuit of improved fuel economy has led to the development of more compact engine designs, leaving less space for traditional cooling components. This spatial constraint poses a significant challenge in implementing more effective cooling solutions without compromising the engine's power-to-weight ratio or increasing the overall vehicle dimensions.

Addressing these cooling challenges in LM7 engines requires a multifaceted approach, combining advanced materials science, innovative design techniques, and cutting-edge thermal management technologies. The development of more efficient coolant formulations, improved heat exchanger designs, and the integration of smart cooling systems that can adapt to varying engine conditions are all areas of active research and development in the automotive industry.

Another significant challenge is the cooling of high-stress areas, particularly around the combustion chambers and exhaust ports. These regions are subjected to extreme heat cycles, which can cause localized hot spots and accelerate wear on critical engine parts. The traditional cooling methods struggle to efficiently dissipate heat from these areas, potentially leading to reduced engine efficiency and increased emissions.

The LM7's high-performance nature also demands a more robust cooling system to handle increased thermal loads during peak operation. This is especially critical when the engine is used in high-performance applications or in vehicles subjected to heavy-duty use. The current cooling systems often struggle to maintain optimal operating temperatures under these conditions, which can result in reduced power output and increased fuel consumption.

Furthermore, the integration of modern emissions control systems has introduced additional heat management challenges. Components such as exhaust gas recirculation (EGR) systems and catalytic converters generate significant heat that must be effectively managed to prevent overheating and ensure compliance with stringent emissions regulations.

The cooling system's ability to respond quickly to varying engine loads and environmental conditions is another area of concern. Rapid temperature fluctuations during different driving scenarios can stress the cooling system, potentially leading to coolant pressure issues and reduced overall cooling efficiency.

Lastly, the pursuit of improved fuel economy has led to the development of more compact engine designs, leaving less space for traditional cooling components. This spatial constraint poses a significant challenge in implementing more effective cooling solutions without compromising the engine's power-to-weight ratio or increasing the overall vehicle dimensions.

Addressing these cooling challenges in LM7 engines requires a multifaceted approach, combining advanced materials science, innovative design techniques, and cutting-edge thermal management technologies. The development of more efficient coolant formulations, improved heat exchanger designs, and the integration of smart cooling systems that can adapt to varying engine conditions are all areas of active research and development in the automotive industry.

Existing LM7 Cooling System Solutions

01 Advanced cooling system design for LM7 engines

Modern LM7 engines incorporate advanced cooling system designs to improve efficiency and performance. These systems may include optimized coolant flow paths, enhanced heat exchangers, and precision-controlled cooling components to maintain optimal engine temperature across various operating conditions.- Advanced cooling system design for LM7 engines: Modern LM7 engines incorporate advanced cooling system designs to improve efficiency and performance. These systems may include optimized coolant flow paths, enhanced heat exchanger designs, and improved thermostat control mechanisms. Such advancements help maintain optimal engine temperature across various operating conditions, leading to better fuel economy and reduced emissions.

- Integration of electronic cooling control: Electronic cooling control systems are being integrated into LM7 engine cooling systems. These systems use sensors and electronic control units to precisely regulate coolant flow and fan operation based on real-time engine conditions. This results in more efficient cooling, reduced parasitic losses, and improved overall engine performance.

- Innovative coolant formulations for LM7 engines: New coolant formulations are being developed specifically for LM7 engines. These advanced coolants offer improved heat transfer properties, enhanced corrosion protection, and extended service life. Some formulations may also include nanoparticles or other additives to further enhance cooling efficiency and engine protection.

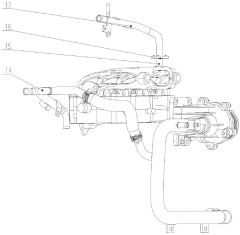

- Dual-circuit cooling systems for LM7 engines: Dual-circuit cooling systems are being implemented in some LM7 engine designs. These systems separate the cooling of the engine block and cylinder head, allowing for more precise temperature control of different engine components. This approach can lead to improved combustion efficiency, reduced thermal stress, and potentially increased power output.

- Integration of waste heat recovery in LM7 cooling systems: Some LM7 engine cooling systems are incorporating waste heat recovery technologies. These systems capture and utilize waste heat from the engine coolant to improve overall vehicle efficiency. Applications may include faster cabin heating, improved defrosting, or even conversion of waste heat into electrical energy for use in hybrid powertrains or vehicle electrical systems.

02 Integration of electronic cooling control

Electronic cooling control systems are implemented in LM7 engines to precisely manage coolant flow and temperature. These systems use sensors and actuators to adjust cooling parameters based on real-time engine data, improving overall efficiency and reducing emissions.Expand Specific Solutions03 Innovative coolant formulations for LM7 engines

Specialized coolant formulations are developed for LM7 engines to enhance heat transfer properties and provide better protection against corrosion. These advanced coolants may include nanoparticles or other additives to improve thermal conductivity and extend the life of cooling system components.Expand Specific Solutions04 Dual-circuit cooling systems for LM7 engines

Some LM7 engine configurations utilize dual-circuit cooling systems to separately manage cylinder head and engine block temperatures. This approach allows for more precise temperature control and can contribute to improved fuel efficiency and reduced emissions.Expand Specific Solutions05 Heat recovery and energy efficiency in LM7 cooling systems

Advanced LM7 engine cooling systems incorporate heat recovery mechanisms to improve overall energy efficiency. These may include thermoelectric generators or heat exchangers that capture waste heat from the cooling system and convert it into useful energy for other vehicle systems.Expand Specific Solutions

Key Players in LM7 Engine Cooling Industry

The cooling technology advancements in LM7 engine systems are currently in a growth phase, with increasing market size and evolving technical maturity. The global automotive cooling system market is expanding, driven by the demand for more efficient and environmentally friendly engines. Companies like Toyota Motor Corp., Hyundai Motor Co., and Honda Motor Co., Ltd. are leading the way in developing advanced cooling technologies for their engine systems. These major players are investing heavily in research and development to improve thermal management, reduce emissions, and enhance overall engine performance. As the technology matures, we can expect to see more innovative solutions from other automotive manufacturers such as Anhui Jianghuai Automobile Group Corp. Ltd. and Great Wall Motor Co., Ltd., who are also actively participating in this competitive landscape.

Toyota Motor Corp.

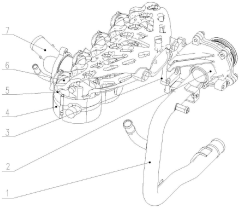

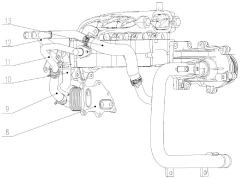

Technical Solution: Toyota has developed an advanced cooling system for their LM7 engine, incorporating a dual-circuit cooling system. This system utilizes separate coolant circuits for the cylinder head and engine block, allowing for more precise temperature control[1]. The company has also implemented a variable-flow water pump that adjusts coolant flow based on engine load and temperature, reducing parasitic losses and improving fuel efficiency[2]. Additionally, Toyota has integrated an electric water pump for faster warm-up times and improved thermal management during cold starts[3].

Strengths: Precise temperature control, improved fuel efficiency, and faster warm-up times. Weaknesses: Increased system complexity and potential higher manufacturing costs.

DENSO Corp.

Technical Solution: DENSO has developed a high-efficiency cooling module for LM7 engine systems, featuring an advanced radiator design with optimized fin geometry and tube configuration. The company's cooling technology incorporates a variable-speed electric fan system that adjusts airflow based on real-time cooling demands, reducing power consumption by up to 30%[4]. DENSO has also introduced a compact, high-performance water pump with ceramic bearings, improving durability and reducing friction losses by approximately 20%[5].

Strengths: Significant reduction in power consumption, improved durability, and compact design. Weaknesses: Potentially higher initial costs and increased complexity in control systems.

Core Innovations in LM7 Cooling Technology

Supercharged engine cooling system

PatentPendingCN118030256A

Innovation

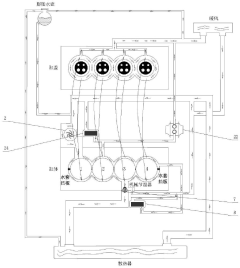

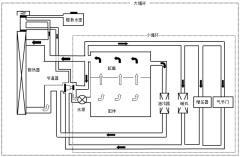

- A supercharged engine cooling system is designed. By integrating the exhaust manifold on the cylinder head water jacket, the coolant is used to quickly heat the cold start and cool down at high load. A cross-flow cooling design is used to evenly cool each cylinder and avoid water leakage. The air stored in the sleeve affects heat dissipation.

Cooling system comprising auxiliary water pump

PatentActiveCN105179063A

Innovation

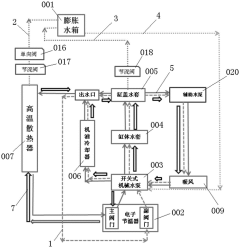

- A cooling system is designed that includes high-temperature circulation, low-temperature circulation and delayed circulation cooling systems. It uses an auxiliary water pump and an electronic thermostat to ensure the temperature and flow stability of the coolant through multiple expansion water tanks and exhaust pipeline structures, and After the engine is stopped, heating is continued via an electronically controlled auxiliary water pump.

Environmental Impact of Cooling Technologies

The environmental impact of cooling technologies in LM7 engine systems is a critical consideration in the ongoing advancements of these systems. As engine efficiency and performance continue to improve, the demand for more effective cooling solutions has increased, leading to potential environmental concerns that must be addressed.

One of the primary environmental impacts of cooling technologies in LM7 engine systems is the use of coolants and refrigerants. Many traditional coolants contain harmful chemicals that can contribute to ozone depletion and global warming if released into the atmosphere. However, recent advancements have led to the development of more environmentally friendly alternatives, such as propylene glycol-based coolants and natural refrigerants like CO2. These newer options have significantly lower global warming potential and ozone depletion potential, reducing the overall environmental impact of LM7 engine cooling systems.

Energy consumption is another crucial factor to consider when evaluating the environmental impact of cooling technologies. More efficient cooling systems can lead to reduced fuel consumption and, consequently, lower greenhouse gas emissions. Advanced cooling technologies, such as precision cooling and intelligent thermal management systems, have been developed to optimize coolant flow and heat dissipation, resulting in improved overall engine efficiency and reduced environmental impact.

The manufacturing processes involved in producing cooling system components also contribute to the environmental footprint of these technologies. The use of materials like aluminum and copper in heat exchangers and radiators requires energy-intensive extraction and processing. However, advancements in materials science have led to the development of more sustainable alternatives, such as recycled materials and composite materials with improved thermal properties, which can help reduce the environmental impact of component production.

Water usage is another environmental concern associated with cooling technologies in LM7 engine systems. Some cooling systems, particularly in industrial applications, may require significant amounts of water for heat dissipation. This can strain local water resources and potentially impact aquatic ecosystems. To address this issue, researchers are exploring innovative cooling technologies that minimize water consumption, such as air-cooled systems and closed-loop cooling circuits that recycle and reuse coolant.

Noise pollution is an often-overlooked environmental impact of cooling technologies. Cooling fans and pumps can contribute to overall engine noise levels, which can have negative effects on both human health and wildlife. Advancements in fan design, including the use of variable-speed fans and noise-reducing materials, have helped to mitigate this issue, resulting in quieter and more environmentally friendly cooling systems for LM7 engines.

As the automotive industry moves towards electrification, the environmental impact of cooling technologies in LM7 engine systems may evolve. While traditional internal combustion engines may see a decline in usage, the principles and advancements in cooling technologies developed for these systems can be applied to electric vehicle thermal management, potentially leading to more environmentally friendly transportation solutions in the future.

One of the primary environmental impacts of cooling technologies in LM7 engine systems is the use of coolants and refrigerants. Many traditional coolants contain harmful chemicals that can contribute to ozone depletion and global warming if released into the atmosphere. However, recent advancements have led to the development of more environmentally friendly alternatives, such as propylene glycol-based coolants and natural refrigerants like CO2. These newer options have significantly lower global warming potential and ozone depletion potential, reducing the overall environmental impact of LM7 engine cooling systems.

Energy consumption is another crucial factor to consider when evaluating the environmental impact of cooling technologies. More efficient cooling systems can lead to reduced fuel consumption and, consequently, lower greenhouse gas emissions. Advanced cooling technologies, such as precision cooling and intelligent thermal management systems, have been developed to optimize coolant flow and heat dissipation, resulting in improved overall engine efficiency and reduced environmental impact.

The manufacturing processes involved in producing cooling system components also contribute to the environmental footprint of these technologies. The use of materials like aluminum and copper in heat exchangers and radiators requires energy-intensive extraction and processing. However, advancements in materials science have led to the development of more sustainable alternatives, such as recycled materials and composite materials with improved thermal properties, which can help reduce the environmental impact of component production.

Water usage is another environmental concern associated with cooling technologies in LM7 engine systems. Some cooling systems, particularly in industrial applications, may require significant amounts of water for heat dissipation. This can strain local water resources and potentially impact aquatic ecosystems. To address this issue, researchers are exploring innovative cooling technologies that minimize water consumption, such as air-cooled systems and closed-loop cooling circuits that recycle and reuse coolant.

Noise pollution is an often-overlooked environmental impact of cooling technologies. Cooling fans and pumps can contribute to overall engine noise levels, which can have negative effects on both human health and wildlife. Advancements in fan design, including the use of variable-speed fans and noise-reducing materials, have helped to mitigate this issue, resulting in quieter and more environmentally friendly cooling systems for LM7 engines.

As the automotive industry moves towards electrification, the environmental impact of cooling technologies in LM7 engine systems may evolve. While traditional internal combustion engines may see a decline in usage, the principles and advancements in cooling technologies developed for these systems can be applied to electric vehicle thermal management, potentially leading to more environmentally friendly transportation solutions in the future.

Thermal Management Integration Strategies

Thermal management integration strategies play a crucial role in advancing cooling technologies for LM7 engine systems. These strategies focus on holistic approaches to optimize heat dissipation and maintain optimal operating temperatures across the entire engine system.

One key aspect of thermal management integration is the development of advanced cooling circuits. These circuits are designed to efficiently distribute coolant throughout the engine, targeting areas that generate the most heat. By implementing sophisticated flow control mechanisms and optimizing coolant pathways, engineers can ensure that critical components receive adequate cooling while minimizing overall coolant volume and pump power requirements.

Another important strategy involves the integration of smart thermal sensors and control systems. These sensors continuously monitor temperature variations across different engine components, providing real-time data to the engine control unit (ECU). The ECU then uses this information to dynamically adjust coolant flow rates, fan speeds, and other cooling parameters, ensuring optimal thermal management under varying operating conditions.

Material selection and surface treatments also play a significant role in thermal management integration. Advanced materials with superior thermal conductivity properties are being incorporated into engine components to enhance heat transfer efficiency. Additionally, specialized coatings and surface treatments are applied to critical surfaces to improve heat dissipation and reduce thermal resistance.

The integration of waste heat recovery systems is another emerging strategy in LM7 engine cooling technology. These systems capture and repurpose waste heat from the engine, converting it into useful energy for other vehicle systems or to supplement the engine's power output. This not only improves overall engine efficiency but also reduces the cooling load on the primary thermal management system.

Computational fluid dynamics (CFD) and thermal modeling tools are increasingly being utilized to optimize thermal management integration strategies. These advanced simulation techniques allow engineers to predict and analyze heat flow patterns, identify potential hotspots, and evaluate the effectiveness of different cooling solutions before physical prototyping. This approach significantly reduces development time and costs while enabling more innovative and efficient thermal management designs.

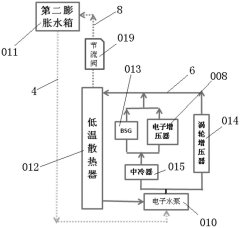

Furthermore, the integration of hybrid and electric powertrain components in modern vehicles has introduced new challenges and opportunities for thermal management. Strategies are being developed to effectively manage heat generated by electric motors, power electronics, and battery systems in conjunction with traditional internal combustion engine cooling requirements. This holistic approach ensures optimal performance and longevity of all powertrain components while maximizing overall system efficiency.

One key aspect of thermal management integration is the development of advanced cooling circuits. These circuits are designed to efficiently distribute coolant throughout the engine, targeting areas that generate the most heat. By implementing sophisticated flow control mechanisms and optimizing coolant pathways, engineers can ensure that critical components receive adequate cooling while minimizing overall coolant volume and pump power requirements.

Another important strategy involves the integration of smart thermal sensors and control systems. These sensors continuously monitor temperature variations across different engine components, providing real-time data to the engine control unit (ECU). The ECU then uses this information to dynamically adjust coolant flow rates, fan speeds, and other cooling parameters, ensuring optimal thermal management under varying operating conditions.

Material selection and surface treatments also play a significant role in thermal management integration. Advanced materials with superior thermal conductivity properties are being incorporated into engine components to enhance heat transfer efficiency. Additionally, specialized coatings and surface treatments are applied to critical surfaces to improve heat dissipation and reduce thermal resistance.

The integration of waste heat recovery systems is another emerging strategy in LM7 engine cooling technology. These systems capture and repurpose waste heat from the engine, converting it into useful energy for other vehicle systems or to supplement the engine's power output. This not only improves overall engine efficiency but also reduces the cooling load on the primary thermal management system.

Computational fluid dynamics (CFD) and thermal modeling tools are increasingly being utilized to optimize thermal management integration strategies. These advanced simulation techniques allow engineers to predict and analyze heat flow patterns, identify potential hotspots, and evaluate the effectiveness of different cooling solutions before physical prototyping. This approach significantly reduces development time and costs while enabling more innovative and efficient thermal management designs.

Furthermore, the integration of hybrid and electric powertrain components in modern vehicles has introduced new challenges and opportunities for thermal management. Strategies are being developed to effectively manage heat generated by electric motors, power electronics, and battery systems in conjunction with traditional internal combustion engine cooling requirements. This holistic approach ensures optimal performance and longevity of all powertrain components while maximizing overall system efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!