Aerodynamic impact of LM7 engine in drag reduction

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Aerodynamics Background and Objectives

The LM7 engine, a member of the GM Gen III small-block V8 family, has been a significant player in the automotive industry since its introduction in 1999. As vehicle manufacturers increasingly focus on fuel efficiency and environmental impact, the aerodynamic properties of engines have become a crucial area of study. The LM7 engine's impact on drag reduction represents a critical juncture in the evolution of engine design, where performance meets aerodynamics.

The development of the LM7 engine's aerodynamics can be traced back to the late 1990s when General Motors began to prioritize fuel economy alongside power output. This shift in focus led to a comprehensive reevaluation of engine design principles, with particular attention paid to how the engine's physical structure interacts with airflow both under the hood and in relation to the vehicle's overall aerodynamic profile.

The primary objective in studying the aerodynamic impact of the LM7 engine in drag reduction is to understand how its design influences the vehicle's overall drag coefficient. This involves examining the engine's external geometry, its placement within the engine bay, and how it affects airflow around and through the vehicle. By optimizing these factors, engineers aim to minimize air resistance, thereby improving fuel efficiency and performance.

Another key goal is to investigate how the LM7 engine's aerodynamics contribute to engine cooling and thermal management. Efficient airflow around the engine is crucial for maintaining optimal operating temperatures, which in turn affects both performance and longevity. The study of the LM7's aerodynamic properties seeks to strike a balance between drag reduction and effective heat dissipation.

Furthermore, the research into the LM7 engine's aerodynamics aims to inform future engine designs. By identifying the most effective features for drag reduction, engineers can develop guidelines for creating more aerodynamic engines across various vehicle types. This forward-looking approach is essential for meeting increasingly stringent fuel efficiency standards and reducing overall vehicle emissions.

The technological evolution in this field has been marked by advancements in computational fluid dynamics (CFD) and wind tunnel testing. These tools have allowed for more precise modeling and analysis of airflow patterns around the LM7 engine, enabling engineers to make incremental improvements to its aerodynamic profile. The ongoing research continues to push the boundaries of what's possible in engine aerodynamics, with potential implications for the entire automotive industry.

The development of the LM7 engine's aerodynamics can be traced back to the late 1990s when General Motors began to prioritize fuel economy alongside power output. This shift in focus led to a comprehensive reevaluation of engine design principles, with particular attention paid to how the engine's physical structure interacts with airflow both under the hood and in relation to the vehicle's overall aerodynamic profile.

The primary objective in studying the aerodynamic impact of the LM7 engine in drag reduction is to understand how its design influences the vehicle's overall drag coefficient. This involves examining the engine's external geometry, its placement within the engine bay, and how it affects airflow around and through the vehicle. By optimizing these factors, engineers aim to minimize air resistance, thereby improving fuel efficiency and performance.

Another key goal is to investigate how the LM7 engine's aerodynamics contribute to engine cooling and thermal management. Efficient airflow around the engine is crucial for maintaining optimal operating temperatures, which in turn affects both performance and longevity. The study of the LM7's aerodynamic properties seeks to strike a balance between drag reduction and effective heat dissipation.

Furthermore, the research into the LM7 engine's aerodynamics aims to inform future engine designs. By identifying the most effective features for drag reduction, engineers can develop guidelines for creating more aerodynamic engines across various vehicle types. This forward-looking approach is essential for meeting increasingly stringent fuel efficiency standards and reducing overall vehicle emissions.

The technological evolution in this field has been marked by advancements in computational fluid dynamics (CFD) and wind tunnel testing. These tools have allowed for more precise modeling and analysis of airflow patterns around the LM7 engine, enabling engineers to make incremental improvements to its aerodynamic profile. The ongoing research continues to push the boundaries of what's possible in engine aerodynamics, with potential implications for the entire automotive industry.

Market Demand for Drag Reduction Technologies

The market demand for drag reduction technologies in the automotive industry has been steadily increasing over the past decade. This growth is primarily driven by stringent fuel efficiency regulations, consumer demand for improved vehicle performance, and the automotive industry's push towards more sustainable transportation solutions.

In the passenger vehicle segment, drag reduction technologies have become a critical factor in meeting Corporate Average Fuel Economy (CAFE) standards. These standards require manufacturers to achieve specific fleet-wide fuel efficiency targets, making aerodynamic improvements a key strategy. The market for drag reduction solutions in this segment is expected to grow as automakers seek to optimize vehicle designs and incorporate advanced materials and technologies.

The commercial vehicle sector, particularly long-haul trucking, represents another significant market for drag reduction technologies. With fuel costs accounting for a substantial portion of operating expenses, fleet operators are increasingly investing in aerodynamic enhancements to improve fuel efficiency. This has led to a growing demand for aftermarket drag reduction products such as side skirts, boat tails, and gap reducers.

The racing industry continues to be a driving force in the development and adoption of cutting-edge drag reduction technologies. Formula 1, NASCAR, and other motorsports organizations are constantly pushing the boundaries of aerodynamic design, creating a trickle-down effect that benefits the broader automotive market.

The emergence of electric vehicles (EVs) has further amplified the importance of drag reduction. As range anxiety remains a concern for potential EV buyers, manufacturers are focusing on maximizing battery efficiency through improved aerodynamics. This trend is expected to create new opportunities for drag reduction technologies specifically tailored to the unique design challenges of electric powertrains.

In the aerospace sector, the demand for drag reduction technologies remains strong, particularly in commercial aviation. Airlines are continuously seeking ways to reduce fuel consumption and operating costs, making aerodynamic improvements a priority in aircraft design and retrofitting programs.

The global market for automotive aerodynamic components is projected to experience significant growth in the coming years. This growth is attributed to the increasing adoption of active aerodynamic systems, lightweight materials, and advanced manufacturing techniques that enable more complex and efficient designs.

As environmental concerns continue to shape consumer preferences and regulatory landscapes, the market for drag reduction technologies is expected to expand further. This trend is likely to drive innovation in areas such as smart surfaces, adaptive aerodynamics, and biomimetic designs inspired by nature's most efficient flyers and swimmers.

In the passenger vehicle segment, drag reduction technologies have become a critical factor in meeting Corporate Average Fuel Economy (CAFE) standards. These standards require manufacturers to achieve specific fleet-wide fuel efficiency targets, making aerodynamic improvements a key strategy. The market for drag reduction solutions in this segment is expected to grow as automakers seek to optimize vehicle designs and incorporate advanced materials and technologies.

The commercial vehicle sector, particularly long-haul trucking, represents another significant market for drag reduction technologies. With fuel costs accounting for a substantial portion of operating expenses, fleet operators are increasingly investing in aerodynamic enhancements to improve fuel efficiency. This has led to a growing demand for aftermarket drag reduction products such as side skirts, boat tails, and gap reducers.

The racing industry continues to be a driving force in the development and adoption of cutting-edge drag reduction technologies. Formula 1, NASCAR, and other motorsports organizations are constantly pushing the boundaries of aerodynamic design, creating a trickle-down effect that benefits the broader automotive market.

The emergence of electric vehicles (EVs) has further amplified the importance of drag reduction. As range anxiety remains a concern for potential EV buyers, manufacturers are focusing on maximizing battery efficiency through improved aerodynamics. This trend is expected to create new opportunities for drag reduction technologies specifically tailored to the unique design challenges of electric powertrains.

In the aerospace sector, the demand for drag reduction technologies remains strong, particularly in commercial aviation. Airlines are continuously seeking ways to reduce fuel consumption and operating costs, making aerodynamic improvements a priority in aircraft design and retrofitting programs.

The global market for automotive aerodynamic components is projected to experience significant growth in the coming years. This growth is attributed to the increasing adoption of active aerodynamic systems, lightweight materials, and advanced manufacturing techniques that enable more complex and efficient designs.

As environmental concerns continue to shape consumer preferences and regulatory landscapes, the market for drag reduction technologies is expected to expand further. This trend is likely to drive innovation in areas such as smart surfaces, adaptive aerodynamics, and biomimetic designs inspired by nature's most efficient flyers and swimmers.

Current State and Challenges in Engine Aerodynamics

The current state of engine aerodynamics in the context of drag reduction, particularly focusing on the LM7 engine, reflects significant advancements but also faces notable challenges. Recent developments have led to improved understanding of airflow dynamics around engine components, resulting in more efficient designs that contribute to overall vehicle drag reduction.

One of the primary areas of progress is the optimization of engine bay packaging. Engineers have made strides in creating more compact engine layouts that minimize frontal area exposure, thereby reducing aerodynamic drag. The LM7 engine, known for its V8 configuration, has been subject to extensive computational fluid dynamics (CFD) simulations to identify areas where airflow can be streamlined, both within the engine bay and around external components.

Advanced cooling systems have also played a crucial role in enhancing aerodynamic performance. By implementing more efficient heat exchangers and carefully designed air intakes, engineers have been able to reduce the size of cooling openings, which traditionally contribute significantly to drag. The LM7 engine's cooling requirements have been carefully balanced with aerodynamic considerations to achieve optimal performance.

Despite these advancements, several challenges persist in the field of engine aerodynamics. One major hurdle is the conflicting requirements between thermal management and aerodynamic efficiency. As engines become more powerful and compact, dissipating heat effectively while maintaining a streamlined profile becomes increasingly difficult. This challenge is particularly relevant for the LM7 engine, which generates substantial heat output.

Another significant challenge lies in the integration of aerodynamic features with other vehicle systems. The need for accessibility for maintenance, compliance with safety regulations, and accommodation of various powertrain configurations often limits the extent to which aerodynamic principles can be applied to engine design. Balancing these competing demands while achieving meaningful drag reduction remains a complex task for engineers working on the LM7 and similar engines.

The automotive industry's shift towards electrification also presents new challenges and opportunities in engine aerodynamics. While electric powertrains offer more flexibility in component placement, they introduce new considerations for battery cooling and overall vehicle thermal management. This transition affects how traditional combustion engines like the LM7 are optimized for aerodynamics, as manufacturers must consider the long-term relevance of their designs.

Lastly, the increasing focus on real-world performance versus laboratory or simulated conditions poses a challenge in engine aerodynamics. Variations in driving conditions, environmental factors, and vehicle loading can significantly impact the effectiveness of aerodynamic features. Developing solutions that provide consistent drag reduction across a wide range of operational scenarios remains an ongoing challenge for engineers working on the LM7 and other engine platforms.

One of the primary areas of progress is the optimization of engine bay packaging. Engineers have made strides in creating more compact engine layouts that minimize frontal area exposure, thereby reducing aerodynamic drag. The LM7 engine, known for its V8 configuration, has been subject to extensive computational fluid dynamics (CFD) simulations to identify areas where airflow can be streamlined, both within the engine bay and around external components.

Advanced cooling systems have also played a crucial role in enhancing aerodynamic performance. By implementing more efficient heat exchangers and carefully designed air intakes, engineers have been able to reduce the size of cooling openings, which traditionally contribute significantly to drag. The LM7 engine's cooling requirements have been carefully balanced with aerodynamic considerations to achieve optimal performance.

Despite these advancements, several challenges persist in the field of engine aerodynamics. One major hurdle is the conflicting requirements between thermal management and aerodynamic efficiency. As engines become more powerful and compact, dissipating heat effectively while maintaining a streamlined profile becomes increasingly difficult. This challenge is particularly relevant for the LM7 engine, which generates substantial heat output.

Another significant challenge lies in the integration of aerodynamic features with other vehicle systems. The need for accessibility for maintenance, compliance with safety regulations, and accommodation of various powertrain configurations often limits the extent to which aerodynamic principles can be applied to engine design. Balancing these competing demands while achieving meaningful drag reduction remains a complex task for engineers working on the LM7 and similar engines.

The automotive industry's shift towards electrification also presents new challenges and opportunities in engine aerodynamics. While electric powertrains offer more flexibility in component placement, they introduce new considerations for battery cooling and overall vehicle thermal management. This transition affects how traditional combustion engines like the LM7 are optimized for aerodynamics, as manufacturers must consider the long-term relevance of their designs.

Lastly, the increasing focus on real-world performance versus laboratory or simulated conditions poses a challenge in engine aerodynamics. Variations in driving conditions, environmental factors, and vehicle loading can significantly impact the effectiveness of aerodynamic features. Developing solutions that provide consistent drag reduction across a wide range of operational scenarios remains an ongoing challenge for engineers working on the LM7 and other engine platforms.

Existing LM7 Engine Drag Reduction Solutions

01 Engine control systems for drag reduction

Advanced control systems are implemented to optimize engine performance and reduce drag. These systems may include electronic throttle control, variable valve timing, and adaptive fuel injection strategies to improve efficiency and reduce aerodynamic drag during various driving conditions.- Engine control systems for drag reduction: Advanced control systems are implemented to optimize engine performance and reduce drag. These systems may include electronic throttle control, variable valve timing, and adaptive fuel injection strategies to improve efficiency and power output while minimizing resistance.

- Aerodynamic improvements for LM7 engines: Various aerodynamic enhancements are applied to LM7 engines to reduce drag. These may include streamlined engine covers, optimized air intake designs, and improved exhaust systems to minimize air resistance and enhance overall vehicle performance.

- Lightweight materials and components: The use of lightweight materials and components in LM7 engines helps reduce overall weight and, consequently, drag. This includes the incorporation of aluminum alloys, composite materials, and redesigned parts to achieve a better power-to-weight ratio.

- Friction reduction technologies: Various technologies are employed to reduce internal friction within the LM7 engine, thereby decreasing drag and improving efficiency. These may include advanced lubricants, low-friction coatings, and optimized bearing designs.

- Turbocharging and supercharging systems: Forced induction systems, such as turbochargers and superchargers, are utilized to enhance the power output of LM7 engines while minimizing drag. These systems improve volumetric efficiency and allow for better performance across a wide range of operating conditions.

02 Aerodynamic improvements for LM7 engine vehicles

Various aerodynamic enhancements are applied to vehicles equipped with LM7 engines to reduce drag. These may include modified body panels, underbody covers, and active aerodynamic elements that adjust based on speed and driving conditions to minimize air resistance.Expand Specific Solutions03 Lightweight materials and design for drag reduction

The use of lightweight materials and innovative design techniques in LM7 engine components and vehicle structures helps reduce overall weight, leading to decreased drag and improved fuel efficiency. This may involve the use of advanced alloys, composite materials, and optimized component designs.Expand Specific Solutions04 Cooling system optimization for reduced drag

Improvements in the cooling system design and management for LM7 engines contribute to reduced drag. This includes optimized radiator designs, intelligent cooling fan control, and advanced thermal management strategies that minimize unnecessary airflow and improve overall aerodynamic efficiency.Expand Specific Solutions05 Exhaust system design for drag reduction

Specialized exhaust system designs for LM7 engines focus on reducing backpressure and improving flow characteristics. This may include the use of larger diameter pipes, high-flow catalytic converters, and optimized muffler designs that contribute to reduced engine drag and improved performance.Expand Specific Solutions

Key Players in Automotive Aerodynamics

The aerodynamic impact of LM7 engine in drag reduction represents a competitive landscape in the mature automotive and aerospace industries. The market is characterized by established players like Toyota, Airbus, and Safran, alongside emerging companies such as Boom Technology and Aero Design Labs. The technology's maturity varies, with traditional automakers and aerospace giants leveraging decades of experience, while newer entrants focus on innovative approaches to drag reduction. The market size is substantial, driven by the automotive sector's push for fuel efficiency and the aerospace industry's pursuit of improved performance. Companies are investing heavily in R&D to optimize aerodynamics, with a focus on integrating advanced materials and computational fluid dynamics to achieve significant drag reduction.

Safran SA

Technical Solution: Safran SA, a leading aerospace propulsion company, has focused on optimizing the LM7 engine's aerodynamic impact through innovative nacelle designs and integration strategies. Their approach includes the development of slimline nacelles with advanced composite materials to reduce weight and drag. Safran has implemented variable geometry concepts in the nacelle design to optimize airflow characteristics across different flight regimes[4]. The company has also explored the use of active flow control technologies to manage boundary layer separation and reduce interference drag between the engine and airframe. Safran's research extends to thrust reverser systems that maintain aerodynamic efficiency during deployment while ensuring effective braking performance[5].

Strengths: Extensive experience in engine and nacelle design, strong integration capabilities with airframers. Weaknesses: Potential trade-offs between drag reduction and other performance parameters such as noise and maintenance accessibility.

Airbus Operations SAS

Technical Solution: Airbus Operations SAS has developed advanced computational fluid dynamics (CFD) models to analyze the aerodynamic impact of engine integration, including the LM7 engine, on drag reduction. Their approach combines high-fidelity simulations with wind tunnel testing to optimize engine placement and nacelle design. The company has implemented innovative pylon designs and engine-wing integration techniques to minimize interference drag. Airbus has also explored the use of boundary layer ingestion (BLI) concepts to further reduce drag associated with engine installation[1][3]. Their research includes the development of laminar flow nacelles and advanced acoustic liners to improve overall aerodynamic efficiency while maintaining noise reduction capabilities[2].

Strengths: Comprehensive CFD capabilities, extensive wind tunnel testing facilities, and expertise in aircraft systems integration. Weaknesses: High development costs and longer implementation timelines due to rigorous certification requirements.

Core Innovations in Engine Aerodynamics

Engine comprising a system for cooling the coolant using fuel

PatentActiveEP3112659A1

Innovation

- A cooling system that selectively cools the coolant using fuel through a heat exchanger, delaying the deactivation of aerodynamic drag reduction strategies by maintaining efficient engine cooling while reducing fuel consumption.

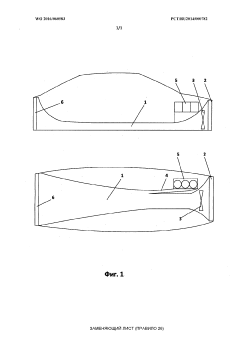

Method for reducing the aerodynamic drag of a moving automotive vehicle

PatentWO2016060583A1

Innovation

- The method involves compressing oncoming air flow using an engine cooling fan or supercharger in a narrowing duct and expanding it at the rear, utilizing a thermodynamic cycle to reduce drag forces, and integrating this system with the exhaust system to enhance engine efficiency.

Environmental Impact of Improved Aerodynamics

The improved aerodynamics resulting from the LM7 engine's drag reduction capabilities have significant positive environmental impacts. By reducing air resistance and improving overall vehicle efficiency, these advancements contribute to decreased fuel consumption and lower emissions. Studies have shown that aerodynamic improvements can lead to fuel savings of up to 5-10% in highway driving conditions, translating to a proportional reduction in greenhouse gas emissions.

The reduced drag also allows vehicles to maintain higher speeds with less energy input, potentially leading to shorter travel times and reduced overall emissions from transportation. This is particularly impactful for long-haul trucking and commercial transportation, where even small efficiency gains can result in substantial cumulative environmental benefits across large fleets.

Furthermore, the improved aerodynamics can contribute to noise reduction. As vehicles encounter less air resistance, there is a decrease in wind noise and turbulence, leading to a quieter driving experience and reduced noise pollution in urban and highway environments. This has positive implications for both human health and wildlife habitats near transportation corridors.

The LM7 engine's aerodynamic enhancements may also indirectly benefit the environment by influencing vehicle design trends. As manufacturers strive to meet increasingly stringent fuel efficiency and emissions standards, innovations in engine aerodynamics can drive the development of more streamlined and efficient vehicle shapes. This ripple effect can lead to industry-wide improvements in vehicle efficiency and environmental performance.

Additionally, the reduced drag can potentially extend the range of electric vehicles, making them more viable for longer journeys and potentially accelerating the adoption of zero-emission vehicles. This could have far-reaching implications for reducing transportation-related carbon emissions and improving air quality in urban areas.

However, it is important to consider potential trade-offs. The materials and manufacturing processes required for advanced aerodynamic components may have their own environmental impacts, which should be carefully assessed in a full lifecycle analysis. Additionally, the improved efficiency might lead to increased vehicle usage, potentially offsetting some of the environmental gains through a rebound effect.

In conclusion, while the environmental benefits of improved aerodynamics are significant and multifaceted, a comprehensive assessment should consider both direct and indirect impacts across the entire lifecycle of vehicles and transportation systems.

The reduced drag also allows vehicles to maintain higher speeds with less energy input, potentially leading to shorter travel times and reduced overall emissions from transportation. This is particularly impactful for long-haul trucking and commercial transportation, where even small efficiency gains can result in substantial cumulative environmental benefits across large fleets.

Furthermore, the improved aerodynamics can contribute to noise reduction. As vehicles encounter less air resistance, there is a decrease in wind noise and turbulence, leading to a quieter driving experience and reduced noise pollution in urban and highway environments. This has positive implications for both human health and wildlife habitats near transportation corridors.

The LM7 engine's aerodynamic enhancements may also indirectly benefit the environment by influencing vehicle design trends. As manufacturers strive to meet increasingly stringent fuel efficiency and emissions standards, innovations in engine aerodynamics can drive the development of more streamlined and efficient vehicle shapes. This ripple effect can lead to industry-wide improvements in vehicle efficiency and environmental performance.

Additionally, the reduced drag can potentially extend the range of electric vehicles, making them more viable for longer journeys and potentially accelerating the adoption of zero-emission vehicles. This could have far-reaching implications for reducing transportation-related carbon emissions and improving air quality in urban areas.

However, it is important to consider potential trade-offs. The materials and manufacturing processes required for advanced aerodynamic components may have their own environmental impacts, which should be carefully assessed in a full lifecycle analysis. Additionally, the improved efficiency might lead to increased vehicle usage, potentially offsetting some of the environmental gains through a rebound effect.

In conclusion, while the environmental benefits of improved aerodynamics are significant and multifaceted, a comprehensive assessment should consider both direct and indirect impacts across the entire lifecycle of vehicles and transportation systems.

Cost-Benefit Analysis of LM7 Drag Reduction

The cost-benefit analysis of LM7 drag reduction is a critical aspect of evaluating the aerodynamic impact of this engine technology. The implementation of LM7 engine modifications for drag reduction involves both initial investment costs and potential long-term benefits. The primary costs associated with this technology include research and development expenses, manufacturing and installation costs, and potential increases in maintenance requirements.

On the investment side, significant resources are typically allocated to the design and testing phases of LM7 drag reduction features. This includes wind tunnel testing, computational fluid dynamics simulations, and prototype development. The manufacturing process may require retooling or new production lines, adding to the initial capital expenditure. Additionally, the integration of drag reduction components into existing engine designs might necessitate modifications to other systems, further increasing implementation costs.

However, the benefits of LM7 drag reduction can be substantial and multifaceted. The most direct advantage is improved fuel efficiency, which translates to reduced operating costs for aircraft operators. Even small reductions in drag can lead to significant fuel savings over the lifespan of an aircraft, particularly for commercial airlines with high utilization rates. This improved efficiency also contributes to extended range capabilities, potentially opening up new route possibilities and enhancing operational flexibility.

Environmental benefits are another crucial factor in the cost-benefit equation. Reduced fuel consumption directly correlates with lower greenhouse gas emissions, aligning with increasingly stringent environmental regulations and corporate sustainability goals. This can result in both tangible benefits, such as reduced carbon offset costs, and intangible advantages like improved brand perception and compliance with future environmental standards.

From a performance perspective, drag reduction can lead to improved aircraft speed and climb rates. While these enhancements may be marginal, they can contribute to reduced flight times and increased payload capacity, both of which have economic value for operators. Furthermore, the technology may offer noise reduction benefits, which is increasingly important for airport operations and community relations.

The long-term cost savings and performance improvements must be weighed against the initial investment and any ongoing maintenance costs. The break-even point for this technology will vary depending on factors such as aircraft type, utilization patterns, and fuel prices. For high-frequency operators or those with large fleets, the cumulative benefits are likely to outweigh the costs more quickly.

In conclusion, while the implementation of LM7 drag reduction technology requires significant upfront investment, the potential for long-term cost savings, improved operational efficiency, and environmental benefits presents a compelling case for its adoption. The exact cost-benefit ratio will depend on specific operational contexts and market conditions, necessitating careful analysis for each potential application.

On the investment side, significant resources are typically allocated to the design and testing phases of LM7 drag reduction features. This includes wind tunnel testing, computational fluid dynamics simulations, and prototype development. The manufacturing process may require retooling or new production lines, adding to the initial capital expenditure. Additionally, the integration of drag reduction components into existing engine designs might necessitate modifications to other systems, further increasing implementation costs.

However, the benefits of LM7 drag reduction can be substantial and multifaceted. The most direct advantage is improved fuel efficiency, which translates to reduced operating costs for aircraft operators. Even small reductions in drag can lead to significant fuel savings over the lifespan of an aircraft, particularly for commercial airlines with high utilization rates. This improved efficiency also contributes to extended range capabilities, potentially opening up new route possibilities and enhancing operational flexibility.

Environmental benefits are another crucial factor in the cost-benefit equation. Reduced fuel consumption directly correlates with lower greenhouse gas emissions, aligning with increasingly stringent environmental regulations and corporate sustainability goals. This can result in both tangible benefits, such as reduced carbon offset costs, and intangible advantages like improved brand perception and compliance with future environmental standards.

From a performance perspective, drag reduction can lead to improved aircraft speed and climb rates. While these enhancements may be marginal, they can contribute to reduced flight times and increased payload capacity, both of which have economic value for operators. Furthermore, the technology may offer noise reduction benefits, which is increasingly important for airport operations and community relations.

The long-term cost savings and performance improvements must be weighed against the initial investment and any ongoing maintenance costs. The break-even point for this technology will vary depending on factors such as aircraft type, utilization patterns, and fuel prices. For high-frequency operators or those with large fleets, the cumulative benefits are likely to outweigh the costs more quickly.

In conclusion, while the implementation of LM7 drag reduction technology requires significant upfront investment, the potential for long-term cost savings, improved operational efficiency, and environmental benefits presents a compelling case for its adoption. The exact cost-benefit ratio will depend on specific operational contexts and market conditions, necessitating careful analysis for each potential application.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!