Tuning techniques for LM7 engines in competitive racing

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Evolution

The LM7 engine, a member of the GM Gen III small-block V8 family, has undergone significant evolution since its introduction in 1999. Initially designed for truck applications, this 5.3L powerplant has become a popular choice for performance enthusiasts due to its robust design and tuning potential.

In its early years, the LM7 was primarily focused on delivering reliable power for everyday use. However, as racing teams and tuners recognized its potential, the engine began to see more aggressive modifications. The first major evolution came with the introduction of aftermarket camshafts and valve springs, which allowed for higher RPMs and increased horsepower output.

As competitive racing demands grew, so did the sophistication of LM7 tuning techniques. The advent of programmable engine management systems marked a significant milestone in the engine's evolution. These systems allowed for precise control over fuel injection and ignition timing, enabling tuners to extract maximum performance while maintaining reliability.

The next phase of evolution saw the implementation of forced induction. Turbocharging and supercharging became popular methods to dramatically increase the LM7's power output. This necessitated further developments in engine internals, with forged pistons and strengthened connecting rods becoming common upgrades to handle the increased stress.

Cylinder head modifications also played a crucial role in the LM7's evolution. CNC porting and larger valves became standard practice for serious racers, improving airflow and combustion efficiency. These modifications, combined with high-flow intake manifolds and exhaust systems, pushed the boundaries of naturally aspirated performance.

In recent years, the focus has shifted towards advanced materials and manufacturing techniques. Lightweight, high-strength components such as titanium valves and carbon fiber intake manifolds have found their way into highly tuned LM7 engines. These innovations have not only increased power output but also improved durability under extreme racing conditions.

The latest frontier in LM7 evolution involves the integration of data acquisition and real-time tuning capabilities. Advanced sensors and telemetry systems now allow teams to monitor engine performance in real-time, making on-the-fly adjustments to maximize output and efficiency throughout a race.

As environmental concerns grow, recent developments have also explored ways to improve fuel efficiency and reduce emissions without sacrificing performance. This has led to experimentation with alternative fuels and hybrid technologies, potentially paving the way for the next generation of LM7-based racing engines.

In its early years, the LM7 was primarily focused on delivering reliable power for everyday use. However, as racing teams and tuners recognized its potential, the engine began to see more aggressive modifications. The first major evolution came with the introduction of aftermarket camshafts and valve springs, which allowed for higher RPMs and increased horsepower output.

As competitive racing demands grew, so did the sophistication of LM7 tuning techniques. The advent of programmable engine management systems marked a significant milestone in the engine's evolution. These systems allowed for precise control over fuel injection and ignition timing, enabling tuners to extract maximum performance while maintaining reliability.

The next phase of evolution saw the implementation of forced induction. Turbocharging and supercharging became popular methods to dramatically increase the LM7's power output. This necessitated further developments in engine internals, with forged pistons and strengthened connecting rods becoming common upgrades to handle the increased stress.

Cylinder head modifications also played a crucial role in the LM7's evolution. CNC porting and larger valves became standard practice for serious racers, improving airflow and combustion efficiency. These modifications, combined with high-flow intake manifolds and exhaust systems, pushed the boundaries of naturally aspirated performance.

In recent years, the focus has shifted towards advanced materials and manufacturing techniques. Lightweight, high-strength components such as titanium valves and carbon fiber intake manifolds have found their way into highly tuned LM7 engines. These innovations have not only increased power output but also improved durability under extreme racing conditions.

The latest frontier in LM7 evolution involves the integration of data acquisition and real-time tuning capabilities. Advanced sensors and telemetry systems now allow teams to monitor engine performance in real-time, making on-the-fly adjustments to maximize output and efficiency throughout a race.

As environmental concerns grow, recent developments have also explored ways to improve fuel efficiency and reduce emissions without sacrificing performance. This has led to experimentation with alternative fuels and hybrid technologies, potentially paving the way for the next generation of LM7-based racing engines.

Racing Market Analysis

The competitive racing market for LM7 engines has experienced significant growth in recent years, driven by the increasing popularity of motorsports and the rising demand for high-performance vehicles. This market segment is characterized by intense competition among racing teams, engine manufacturers, and aftermarket parts suppliers, all vying for a competitive edge through advanced tuning techniques.

The global racing market, including LM7 engine applications, is projected to reach a substantial value in the coming years, with North America and Europe being the primary regions for competitive racing events. The demand for LM7 engine tuning solutions is particularly strong in stock car racing, drag racing, and endurance racing categories, where the engine's reliability and power output are critical factors.

A key trend in the racing market is the growing emphasis on sustainability and environmental considerations. This has led to increased interest in tuning techniques that not only enhance performance but also improve fuel efficiency and reduce emissions. As a result, there is a rising demand for advanced engine management systems and eco-friendly tuning solutions for LM7 engines.

The market for LM7 engine tuning is also influenced by technological advancements in data analytics and simulation tools. Racing teams and tuning specialists are increasingly adopting sophisticated software and hardware solutions to optimize engine performance, analyze real-time data, and make precise adjustments during races.

Another significant factor shaping the market is the evolving regulatory landscape in competitive racing. Governing bodies are implementing stricter rules regarding engine modifications and performance enhancements, which directly impact the development and application of tuning techniques for LM7 engines. This has created a need for innovative tuning solutions that can maximize performance within the constraints of racing regulations.

The aftermarket parts and accessories segment for LM7 engines is experiencing robust growth, with a wide range of products available for performance enhancement. This includes specialized camshafts, high-flow intake systems, performance exhaust systems, and advanced fuel injection components. The market for these products is highly competitive, with both established manufacturers and niche suppliers competing for market share.

In terms of customer segments, professional racing teams represent a significant portion of the market for LM7 engine tuning. However, there is also a growing market among amateur racers and enthusiasts who participate in local and regional racing events. This diverse customer base has led to the development of a wide range of tuning solutions, from high-end, custom-engineered packages to more accessible, off-the-shelf performance upgrades.

The global racing market, including LM7 engine applications, is projected to reach a substantial value in the coming years, with North America and Europe being the primary regions for competitive racing events. The demand for LM7 engine tuning solutions is particularly strong in stock car racing, drag racing, and endurance racing categories, where the engine's reliability and power output are critical factors.

A key trend in the racing market is the growing emphasis on sustainability and environmental considerations. This has led to increased interest in tuning techniques that not only enhance performance but also improve fuel efficiency and reduce emissions. As a result, there is a rising demand for advanced engine management systems and eco-friendly tuning solutions for LM7 engines.

The market for LM7 engine tuning is also influenced by technological advancements in data analytics and simulation tools. Racing teams and tuning specialists are increasingly adopting sophisticated software and hardware solutions to optimize engine performance, analyze real-time data, and make precise adjustments during races.

Another significant factor shaping the market is the evolving regulatory landscape in competitive racing. Governing bodies are implementing stricter rules regarding engine modifications and performance enhancements, which directly impact the development and application of tuning techniques for LM7 engines. This has created a need for innovative tuning solutions that can maximize performance within the constraints of racing regulations.

The aftermarket parts and accessories segment for LM7 engines is experiencing robust growth, with a wide range of products available for performance enhancement. This includes specialized camshafts, high-flow intake systems, performance exhaust systems, and advanced fuel injection components. The market for these products is highly competitive, with both established manufacturers and niche suppliers competing for market share.

In terms of customer segments, professional racing teams represent a significant portion of the market for LM7 engine tuning. However, there is also a growing market among amateur racers and enthusiasts who participate in local and regional racing events. This diverse customer base has led to the development of a wide range of tuning solutions, from high-end, custom-engineered packages to more accessible, off-the-shelf performance upgrades.

Current Tuning Challenges

The current tuning challenges for LM7 engines in competitive racing are multifaceted and require a deep understanding of engine dynamics and performance optimization. One of the primary challenges is achieving the delicate balance between power output and engine reliability. As racers push these engines to their limits, the risk of component failure increases significantly, necessitating careful consideration of material strengths and thermal management.

Another significant challenge lies in the realm of fuel management. Optimizing fuel delivery and combustion efficiency is crucial for maximizing power while maintaining acceptable fuel economy. This involves precise tuning of fuel injectors, adjusting air-fuel ratios, and implementing advanced fuel mapping strategies. The complexity of modern engine management systems adds another layer of difficulty, requiring tuners to possess a high level of expertise in both mechanical and electronic aspects of engine control.

Emissions regulations pose an additional hurdle for competitive racing tuners. Even in racing environments, there is increasing pressure to reduce harmful emissions without sacrificing performance. This necessitates the development of innovative solutions that can meet stringent environmental standards while still delivering the power output required for competitive racing.

The integration of aftermarket components presents its own set of challenges. Tuners must ensure compatibility between various aftermarket parts and the stock LM7 engine, often requiring custom solutions and extensive testing. This includes addressing issues such as altered airflow dynamics, changes in compression ratios, and the need for recalibration of engine management systems to accommodate these modifications.

Heat management remains a persistent challenge in high-performance tuning. The increased power output of a tuned LM7 engine generates significantly more heat, which can lead to reduced performance and potential engine damage if not properly managed. Developing effective cooling solutions that can withstand the rigors of competitive racing while maintaining optimal engine temperatures is a complex task.

Lastly, the ever-evolving nature of racing technology and regulations presents a continuous challenge for tuners. Staying ahead of the competition requires constant innovation and adaptation to new rules, materials, and technologies. This demands ongoing research and development efforts, as well as the ability to quickly implement and fine-tune new strategies on the track.

Another significant challenge lies in the realm of fuel management. Optimizing fuel delivery and combustion efficiency is crucial for maximizing power while maintaining acceptable fuel economy. This involves precise tuning of fuel injectors, adjusting air-fuel ratios, and implementing advanced fuel mapping strategies. The complexity of modern engine management systems adds another layer of difficulty, requiring tuners to possess a high level of expertise in both mechanical and electronic aspects of engine control.

Emissions regulations pose an additional hurdle for competitive racing tuners. Even in racing environments, there is increasing pressure to reduce harmful emissions without sacrificing performance. This necessitates the development of innovative solutions that can meet stringent environmental standards while still delivering the power output required for competitive racing.

The integration of aftermarket components presents its own set of challenges. Tuners must ensure compatibility between various aftermarket parts and the stock LM7 engine, often requiring custom solutions and extensive testing. This includes addressing issues such as altered airflow dynamics, changes in compression ratios, and the need for recalibration of engine management systems to accommodate these modifications.

Heat management remains a persistent challenge in high-performance tuning. The increased power output of a tuned LM7 engine generates significantly more heat, which can lead to reduced performance and potential engine damage if not properly managed. Developing effective cooling solutions that can withstand the rigors of competitive racing while maintaining optimal engine temperatures is a complex task.

Lastly, the ever-evolving nature of racing technology and regulations presents a continuous challenge for tuners. Staying ahead of the competition requires constant innovation and adaptation to new rules, materials, and technologies. This demands ongoing research and development efforts, as well as the ability to quickly implement and fine-tune new strategies on the track.

Advanced Tuning Methods

01 Engine control and optimization

Advanced control systems and algorithms are used to optimize LM7 engine performance. These systems monitor various parameters and adjust engine settings in real-time to improve efficiency, power output, and fuel economy. Techniques include adaptive learning, predictive modeling, and intelligent control strategies.- Engine control and optimization: Advanced control systems and algorithms are used to optimize LM7 engine performance. These systems monitor various parameters and adjust engine settings in real-time to improve efficiency, power output, and fuel economy. Techniques include adaptive learning, predictive modeling, and intelligent control strategies.

- Fuel injection and combustion improvements: Enhancements to fuel injection systems and combustion processes contribute to improved LM7 engine performance. This includes precise fuel metering, optimized injection timing, and advanced combustion chamber designs. These improvements lead to better fuel atomization, more complete combustion, and reduced emissions.

- Turbocharging and forced induction: Implementation of turbocharging and other forced induction methods significantly boost LM7 engine performance. These systems increase air intake, allowing for more fuel to be burned and resulting in higher power output. Advanced designs focus on reducing turbo lag and improving overall engine responsiveness.

- Engine diagnostics and performance monitoring: Sophisticated diagnostic tools and performance monitoring systems are employed to maintain optimal LM7 engine performance. These systems use sensors and data analysis to detect issues, predict maintenance needs, and provide real-time performance feedback. This enables proactive maintenance and performance tuning.

- Materials and design optimization: Advanced materials and optimized component designs are utilized to enhance LM7 engine performance. This includes lightweight alloys, improved piston and cylinder designs, and optimized cooling systems. These advancements contribute to reduced friction, better heat management, and overall improved engine efficiency.

02 Fuel injection and combustion improvements

Enhancements to fuel injection systems and combustion processes contribute to improved LM7 engine performance. This includes precise fuel metering, optimized injection timing, and advanced combustion chamber designs. These improvements lead to better fuel atomization, more complete combustion, and increased power output.Expand Specific Solutions03 Turbocharging and forced induction

Implementation of turbocharging or other forced induction methods significantly boosts LM7 engine performance. These systems increase air intake, allowing for more fuel to be burned and resulting in higher power output. Advanced designs focus on reducing turbo lag and optimizing boost pressure across different operating conditions.Expand Specific Solutions04 Thermal management and cooling systems

Improved thermal management and cooling systems enhance LM7 engine performance by maintaining optimal operating temperatures. This includes advanced coolant circulation, efficient heat exchangers, and intelligent temperature control strategies. Better thermal management leads to increased reliability, efficiency, and power output.Expand Specific Solutions05 Performance monitoring and diagnostics

Advanced monitoring and diagnostic systems are employed to assess and maintain LM7 engine performance. These systems use sensors, data analysis, and predictive algorithms to detect potential issues, optimize maintenance schedules, and ensure peak performance. Real-time monitoring allows for immediate adjustments and proactive maintenance.Expand Specific Solutions

Key Racing Teams & Tuners

The competitive landscape for tuning techniques in LM7 engines for racing is characterized by a mature market with established players and ongoing innovation. The industry is in a growth phase, driven by the continuous demand for performance enhancements in competitive racing. Major automotive manufacturers like Ford, General Motors, and Mercedes-Benz, along with specialized racing technology companies, dominate the field. These companies leverage their extensive R&D capabilities and racing heritage to develop advanced tuning solutions. The market size is significant, catering to professional racing teams and enthusiasts alike. Technological maturity varies, with companies like Bosch and Continental Automotive leading in engine management systems, while Ford Global Technologies and Mercedes-Benz Group push boundaries in overall engine performance and efficiency.

Ford Global Technologies LLC

Technical Solution: Ford's approach to tuning LM7 engines for competitive racing focuses on advanced electronic control unit (ECU) programming and hardware modifications. They utilize sophisticated engine mapping techniques to optimize fuel injection timing and ignition timing across various RPM ranges and load conditions. Ford has developed a proprietary algorithm that dynamically adjusts these parameters based on real-time sensor data, allowing for maximum power output while maintaining engine reliability[1]. Additionally, they have implemented a two-stage forced induction system, combining a supercharger for low-end torque with a turbocharger for high-end power, effectively eliminating turbo lag[3]. This system is complemented by a high-flow intake manifold and a custom exhaust system designed to reduce back pressure and improve scavenging effects.

Strengths: Cutting-edge ECU programming, innovative dual forced induction system, and comprehensive approach to engine optimization. Weaknesses: Complexity of the system may lead to higher maintenance requirements and potential reliability issues in extended high-stress racing conditions.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed a multi-faceted approach to tuning LM7 engines for competitive racing, focusing on both software and hardware enhancements. Their strategy includes advanced combustion modeling using computational fluid dynamics (CFD) to optimize piston and combustion chamber designs[2]. This is coupled with a variable valve timing system that allows for precise control of valve lift and duration, maximizing volumetric efficiency across the entire RPM range[4]. Mercedes has also implemented a sophisticated thermal management system, utilizing nanomaterial-based coolants and precision-controlled electric water pumps to maintain optimal engine temperatures under extreme racing conditions. Their ECU programming incorporates machine learning algorithms that continuously adapt to driving conditions and track characteristics, fine-tuning engine parameters in real-time for peak performance[5].

Strengths: Cutting-edge combustion modeling, adaptive ECU programming, and advanced thermal management. Weaknesses: High development costs and potential over-reliance on complex electronic systems that could be prone to failure in harsh racing environments.

Breakthrough Innovations

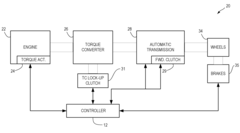

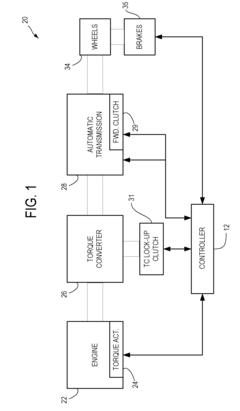

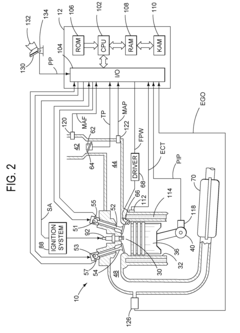

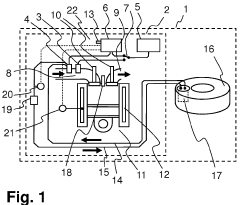

System and methods for assisted direct start control

PatentInactiveUS20100174465A1

Innovation

- A method that adjusts engine torque and transmission forward clutch/wheel brake settings based on vehicle grade and brake caliper wear during automatic re-starts, using engine torque modulation on lower grades and coordinated adjustments on steeper grades to reduce wear and improve launch consistency.

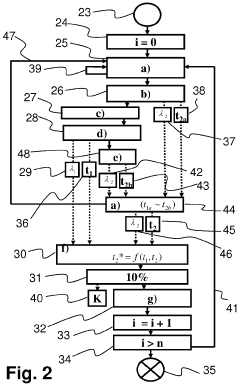

Method and device for injecting an alternative fuel

PatentWO2011061062A1

Innovation

- A method that determines a balanced operating condition, adjusts injection durations for alternative fuels based on regular fuel injection durations, and corrects these adjustments to maintain optimal lambda values, using separate control units for regular and alternative fuel injectors.

Performance Regulations

Performance regulations play a crucial role in shaping the landscape of competitive racing, particularly when it comes to tuning techniques for LM7 engines. These regulations are designed to ensure fair competition, maintain safety standards, and promote technological innovation within specified boundaries.

In the context of LM7 engine tuning, performance regulations typically cover a wide range of aspects. Engine displacement limits are often imposed to maintain parity among competitors. For the LM7, which is a 5.3-liter V8 engine, regulations may specify maximum allowable displacement or restrict modifications that could significantly alter the engine's capacity.

Fuel restrictions are another key component of performance regulations. Sanctioning bodies may mandate the use of specific fuel types or impose limitations on fuel additives. This not only ensures a level playing field but also addresses environmental concerns and promotes the development of more efficient engine tuning techniques.

Boost pressure limits are particularly relevant for forced induction applications of the LM7 engine. Regulations often specify maximum allowable boost pressures or may require the use of specific turbocharger or supercharger configurations. These restrictions challenge tuners to optimize engine performance within the prescribed limits.

Electronic control unit (ECU) regulations are becoming increasingly important in modern racing. For LM7 engines, regulations may dictate the type of ECU that can be used or impose restrictions on ECU programming capabilities. Some series may require the use of standardized ECUs to prevent unfair advantages through sophisticated engine mapping techniques.

Intake and exhaust system regulations also impact LM7 engine tuning. Restrictions on intake manifold design, air filter types, or exhaust system configurations are common. These regulations often aim to limit the effectiveness of certain tuning techniques while encouraging innovation in other areas.

Durability and reliability requirements are integral to performance regulations. Rules may specify minimum engine life or impose penalties for frequent engine changes. This encourages tuners to balance performance gains with longevity, leading to the development of more robust tuning solutions for LM7 engines.

Weight regulations, while not directly related to engine tuning, can significantly influence the approach to LM7 engine modifications. Minimum weight requirements or weight penalties for certain modifications may affect decisions on engine tuning strategies, balancing power output with overall vehicle performance.

In the context of LM7 engine tuning, performance regulations typically cover a wide range of aspects. Engine displacement limits are often imposed to maintain parity among competitors. For the LM7, which is a 5.3-liter V8 engine, regulations may specify maximum allowable displacement or restrict modifications that could significantly alter the engine's capacity.

Fuel restrictions are another key component of performance regulations. Sanctioning bodies may mandate the use of specific fuel types or impose limitations on fuel additives. This not only ensures a level playing field but also addresses environmental concerns and promotes the development of more efficient engine tuning techniques.

Boost pressure limits are particularly relevant for forced induction applications of the LM7 engine. Regulations often specify maximum allowable boost pressures or may require the use of specific turbocharger or supercharger configurations. These restrictions challenge tuners to optimize engine performance within the prescribed limits.

Electronic control unit (ECU) regulations are becoming increasingly important in modern racing. For LM7 engines, regulations may dictate the type of ECU that can be used or impose restrictions on ECU programming capabilities. Some series may require the use of standardized ECUs to prevent unfair advantages through sophisticated engine mapping techniques.

Intake and exhaust system regulations also impact LM7 engine tuning. Restrictions on intake manifold design, air filter types, or exhaust system configurations are common. These regulations often aim to limit the effectiveness of certain tuning techniques while encouraging innovation in other areas.

Durability and reliability requirements are integral to performance regulations. Rules may specify minimum engine life or impose penalties for frequent engine changes. This encourages tuners to balance performance gains with longevity, leading to the development of more robust tuning solutions for LM7 engines.

Weight regulations, while not directly related to engine tuning, can significantly influence the approach to LM7 engine modifications. Minimum weight requirements or weight penalties for certain modifications may affect decisions on engine tuning strategies, balancing power output with overall vehicle performance.

Environmental Considerations

Environmental considerations play a crucial role in the tuning of LM7 engines for competitive racing. As motorsports face increasing pressure to reduce their environmental impact, engine tuners must balance performance optimization with ecological responsibility.

One of the primary environmental concerns in LM7 engine tuning is emissions control. While racing vehicles are often exempt from standard emissions regulations, many racing series are implementing stricter guidelines to reduce harmful exhaust gases. Tuners must explore innovative ways to maintain high performance while minimizing pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. This may involve the use of advanced catalytic converters, exhaust gas recirculation systems, or even the integration of hybrid technologies.

Fuel efficiency is another critical environmental factor in LM7 engine tuning. Although racing traditionally prioritizes power over efficiency, the push for sustainability has led to a greater focus on maximizing fuel economy without sacrificing performance. Tuners are experimenting with advanced fuel injection systems, variable valve timing, and cylinder deactivation technologies to optimize fuel consumption during different racing conditions.

The choice of fuel itself is becoming an increasingly important environmental consideration. Many racing series are exploring the use of biofuels or synthetic fuels as alternatives to traditional petroleum-based products. Tuners must adapt their strategies to accommodate these new fuel types, which may have different combustion characteristics and energy densities compared to conventional racing fuels.

Noise pollution is another environmental aspect that cannot be overlooked in LM7 engine tuning. Many racing venues face restrictions on noise levels, requiring tuners to develop innovative exhaust systems that balance performance with sound reduction. This may involve the use of advanced muffler designs, resonators, or even active noise cancellation technologies.

The lifecycle impact of racing engines is also gaining attention from an environmental perspective. Tuners are increasingly considering the durability and longevity of engine components to reduce waste and resource consumption. This involves selecting materials and designing systems that can withstand the extreme conditions of competitive racing while minimizing the need for frequent replacements.

As environmental regulations in motorsports continue to evolve, LM7 engine tuners must stay ahead of the curve by incorporating eco-friendly technologies and practices into their work. This may include the use of sustainable materials in engine components, the implementation of energy recovery systems, or the development of more efficient cooling solutions to reduce overall energy consumption during races.

One of the primary environmental concerns in LM7 engine tuning is emissions control. While racing vehicles are often exempt from standard emissions regulations, many racing series are implementing stricter guidelines to reduce harmful exhaust gases. Tuners must explore innovative ways to maintain high performance while minimizing pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. This may involve the use of advanced catalytic converters, exhaust gas recirculation systems, or even the integration of hybrid technologies.

Fuel efficiency is another critical environmental factor in LM7 engine tuning. Although racing traditionally prioritizes power over efficiency, the push for sustainability has led to a greater focus on maximizing fuel economy without sacrificing performance. Tuners are experimenting with advanced fuel injection systems, variable valve timing, and cylinder deactivation technologies to optimize fuel consumption during different racing conditions.

The choice of fuel itself is becoming an increasingly important environmental consideration. Many racing series are exploring the use of biofuels or synthetic fuels as alternatives to traditional petroleum-based products. Tuners must adapt their strategies to accommodate these new fuel types, which may have different combustion characteristics and energy densities compared to conventional racing fuels.

Noise pollution is another environmental aspect that cannot be overlooked in LM7 engine tuning. Many racing venues face restrictions on noise levels, requiring tuners to develop innovative exhaust systems that balance performance with sound reduction. This may involve the use of advanced muffler designs, resonators, or even active noise cancellation technologies.

The lifecycle impact of racing engines is also gaining attention from an environmental perspective. Tuners are increasingly considering the durability and longevity of engine components to reduce waste and resource consumption. This involves selecting materials and designing systems that can withstand the extreme conditions of competitive racing while minimizing the need for frequent replacements.

As environmental regulations in motorsports continue to evolve, LM7 engine tuners must stay ahead of the curve by incorporating eco-friendly technologies and practices into their work. This may include the use of sustainable materials in engine components, the implementation of energy recovery systems, or the development of more efficient cooling solutions to reduce overall energy consumption during races.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!