The impact of LM7 engine on vehicle acceleration profiles

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Background and Objectives

The LM7 engine, a member of the General Motors (GM) LS engine family, has played a significant role in shaping vehicle acceleration profiles since its introduction in 1999. This 5.3-liter V8 engine was designed to provide a balance of power, efficiency, and reliability, making it a popular choice for a wide range of GM vehicles, including trucks and SUVs.

The development of the LM7 engine was driven by GM's need to meet increasingly stringent emissions regulations while maintaining performance standards. This engine represented a shift from traditional pushrod V8 designs to a more modern architecture, incorporating features such as aluminum block construction, coil-near-plug ignition, and sequential fuel injection.

One of the primary objectives of the LM7 engine was to improve vehicle acceleration profiles across various driving conditions. This was achieved through a combination of increased horsepower and torque output compared to its predecessors, as well as enhanced throttle response and low-end torque delivery. The engine's design allowed for better power distribution throughout the RPM range, resulting in smoother and more consistent acceleration.

The LM7 engine's impact on vehicle acceleration profiles can be observed in several key areas. Firstly, it contributed to improved 0-60 mph times in many GM vehicles, particularly in the light truck and SUV segments. This enhancement in acceleration performance was particularly noticeable in everyday driving scenarios, such as merging onto highways or passing slower vehicles.

Furthermore, the LM7 engine's torque characteristics positively influenced towing and hauling capabilities. The increased low-end torque allowed for better initial acceleration when pulling heavy loads, enhancing the overall drivability and performance of vehicles equipped with this engine.

The evolution of the LM7 engine over time has seen continuous improvements in power output, fuel efficiency, and emissions control. These advancements have further refined its impact on vehicle acceleration profiles, with later iterations offering even more responsive and powerful performance.

As the automotive industry continues to evolve, the legacy of the LM7 engine and its influence on vehicle acceleration profiles remains significant. It has set a benchmark for V8 engine performance in its class and continues to inform the development of new powertrain technologies aimed at optimizing acceleration characteristics while meeting increasingly stringent environmental standards.

The development of the LM7 engine was driven by GM's need to meet increasingly stringent emissions regulations while maintaining performance standards. This engine represented a shift from traditional pushrod V8 designs to a more modern architecture, incorporating features such as aluminum block construction, coil-near-plug ignition, and sequential fuel injection.

One of the primary objectives of the LM7 engine was to improve vehicle acceleration profiles across various driving conditions. This was achieved through a combination of increased horsepower and torque output compared to its predecessors, as well as enhanced throttle response and low-end torque delivery. The engine's design allowed for better power distribution throughout the RPM range, resulting in smoother and more consistent acceleration.

The LM7 engine's impact on vehicle acceleration profiles can be observed in several key areas. Firstly, it contributed to improved 0-60 mph times in many GM vehicles, particularly in the light truck and SUV segments. This enhancement in acceleration performance was particularly noticeable in everyday driving scenarios, such as merging onto highways or passing slower vehicles.

Furthermore, the LM7 engine's torque characteristics positively influenced towing and hauling capabilities. The increased low-end torque allowed for better initial acceleration when pulling heavy loads, enhancing the overall drivability and performance of vehicles equipped with this engine.

The evolution of the LM7 engine over time has seen continuous improvements in power output, fuel efficiency, and emissions control. These advancements have further refined its impact on vehicle acceleration profiles, with later iterations offering even more responsive and powerful performance.

As the automotive industry continues to evolve, the legacy of the LM7 engine and its influence on vehicle acceleration profiles remains significant. It has set a benchmark for V8 engine performance in its class and continues to inform the development of new powertrain technologies aimed at optimizing acceleration characteristics while meeting increasingly stringent environmental standards.

Market Demand Analysis for LM7-Equipped Vehicles

The market demand for LM7-equipped vehicles has shown significant growth in recent years, driven by consumers' increasing desire for improved performance and fuel efficiency. The LM7 engine, known for its robust power output and reliability, has become a sought-after option in the automotive industry, particularly in the light truck and SUV segments.

Consumer surveys indicate a strong preference for vehicles that offer enhanced acceleration capabilities without compromising fuel economy. The LM7 engine's ability to deliver on both fronts has positioned it as a compelling choice for manufacturers and consumers alike. Market research suggests that vehicles equipped with the LM7 engine have experienced a sales growth rate outpacing the industry average by 2 to 3 percentage points over the past three years.

The demand for LM7-equipped vehicles is particularly strong in North America, where light trucks and SUVs continue to dominate the market. However, emerging markets in Asia and South America are also showing increased interest, as urban consumers in these regions seek vehicles that can handle diverse driving conditions while maintaining performance standards.

Fleet operators and commercial users represent another significant segment driving demand for LM7-equipped vehicles. The engine's durability and performance characteristics make it an attractive option for businesses that require reliable, high-performance vehicles for their operations. This sector has shown steady growth in LM7 adoption, with some fleet managers reporting improved operational efficiency and reduced maintenance costs.

Environmental regulations and fuel efficiency standards have also played a role in shaping market demand. As governments worldwide implement stricter emissions controls, the LM7 engine's ability to meet these standards while maintaining performance has become a key selling point. This has led to increased interest from environmentally conscious consumers who are unwilling to sacrifice performance for eco-friendliness.

The aftermarket sector has also contributed to the growing demand for LM7 engines. Performance enthusiasts and custom vehicle builders have embraced the LM7 for its tuning potential and compatibility with various performance upgrades. This has created a secondary market for LM7-equipped vehicles and standalone engines, further driving overall demand.

Looking ahead, industry analysts project continued growth in the market for LM7-equipped vehicles. Factors such as ongoing technological improvements, increasing consumer awareness of performance benefits, and the engine's versatility across various vehicle types are expected to sustain this trend. However, the market will need to adapt to emerging technologies, such as hybrid and electric powertrains, which may impact long-term demand for traditional combustion engines like the LM7.

Consumer surveys indicate a strong preference for vehicles that offer enhanced acceleration capabilities without compromising fuel economy. The LM7 engine's ability to deliver on both fronts has positioned it as a compelling choice for manufacturers and consumers alike. Market research suggests that vehicles equipped with the LM7 engine have experienced a sales growth rate outpacing the industry average by 2 to 3 percentage points over the past three years.

The demand for LM7-equipped vehicles is particularly strong in North America, where light trucks and SUVs continue to dominate the market. However, emerging markets in Asia and South America are also showing increased interest, as urban consumers in these regions seek vehicles that can handle diverse driving conditions while maintaining performance standards.

Fleet operators and commercial users represent another significant segment driving demand for LM7-equipped vehicles. The engine's durability and performance characteristics make it an attractive option for businesses that require reliable, high-performance vehicles for their operations. This sector has shown steady growth in LM7 adoption, with some fleet managers reporting improved operational efficiency and reduced maintenance costs.

Environmental regulations and fuel efficiency standards have also played a role in shaping market demand. As governments worldwide implement stricter emissions controls, the LM7 engine's ability to meet these standards while maintaining performance has become a key selling point. This has led to increased interest from environmentally conscious consumers who are unwilling to sacrifice performance for eco-friendliness.

The aftermarket sector has also contributed to the growing demand for LM7 engines. Performance enthusiasts and custom vehicle builders have embraced the LM7 for its tuning potential and compatibility with various performance upgrades. This has created a secondary market for LM7-equipped vehicles and standalone engines, further driving overall demand.

Looking ahead, industry analysts project continued growth in the market for LM7-equipped vehicles. Factors such as ongoing technological improvements, increasing consumer awareness of performance benefits, and the engine's versatility across various vehicle types are expected to sustain this trend. However, the market will need to adapt to emerging technologies, such as hybrid and electric powertrains, which may impact long-term demand for traditional combustion engines like the LM7.

Current State and Challenges of LM7 Engine Technology

The LM7 engine, a member of the GM Gen III small-block V8 family, has significantly impacted vehicle acceleration profiles since its introduction in 1999. This 5.3-liter engine has become a staple in many GM trucks and SUVs, offering a balance of power, efficiency, and reliability. However, as with any technology, it faces several challenges in the current automotive landscape.

One of the primary strengths of the LM7 engine is its robust design, which has proven capable of handling substantial power increases through aftermarket modifications. This adaptability has made it a popular choice among enthusiasts seeking improved acceleration without sacrificing reliability. The engine's relatively lightweight aluminum block, combined with its displacement, provides a solid foundation for enhanced performance.

Despite its strengths, the LM7 engine faces challenges in meeting increasingly stringent emissions regulations. As global environmental concerns grow, manufacturers are under pressure to reduce carbon emissions and improve fuel efficiency. The LM7, while efficient for its class when introduced, now lags behind more modern designs in terms of emissions control and fuel economy.

Another significant challenge is the engine's compatibility with advanced driver assistance systems (ADAS) and autonomous driving technologies. These systems often require precise control over engine output and responsiveness, which can be more challenging to achieve with older engine designs like the LM7. Integrating the necessary electronic controls and ensuring seamless operation with these advanced systems presents a considerable technical hurdle.

The LM7's age also poses challenges in terms of materials and manufacturing processes. While its design has proven durable, advancements in metallurgy and production techniques offer opportunities for weight reduction and improved thermal efficiency that are not fully realized in the LM7 platform. This limitation affects not only performance but also the overall vehicle dynamics and fuel consumption.

Furthermore, the automotive industry's shift towards electrification presents perhaps the most significant challenge to the LM7 and similar internal combustion engines. As manufacturers invest heavily in electric and hybrid powertrains, the development resources allocated to traditional V8 engines like the LM7 are diminishing. This trend could potentially limit future improvements and optimizations for acceleration profiles in vehicles equipped with this engine.

In conclusion, while the LM7 engine has demonstrated remarkable longevity and adaptability, it faces substantial challenges in the current technological and regulatory environment. Addressing these issues will be crucial for maintaining its relevance in modern vehicle applications, particularly concerning acceleration profiles and overall performance characteristics.

One of the primary strengths of the LM7 engine is its robust design, which has proven capable of handling substantial power increases through aftermarket modifications. This adaptability has made it a popular choice among enthusiasts seeking improved acceleration without sacrificing reliability. The engine's relatively lightweight aluminum block, combined with its displacement, provides a solid foundation for enhanced performance.

Despite its strengths, the LM7 engine faces challenges in meeting increasingly stringent emissions regulations. As global environmental concerns grow, manufacturers are under pressure to reduce carbon emissions and improve fuel efficiency. The LM7, while efficient for its class when introduced, now lags behind more modern designs in terms of emissions control and fuel economy.

Another significant challenge is the engine's compatibility with advanced driver assistance systems (ADAS) and autonomous driving technologies. These systems often require precise control over engine output and responsiveness, which can be more challenging to achieve with older engine designs like the LM7. Integrating the necessary electronic controls and ensuring seamless operation with these advanced systems presents a considerable technical hurdle.

The LM7's age also poses challenges in terms of materials and manufacturing processes. While its design has proven durable, advancements in metallurgy and production techniques offer opportunities for weight reduction and improved thermal efficiency that are not fully realized in the LM7 platform. This limitation affects not only performance but also the overall vehicle dynamics and fuel consumption.

Furthermore, the automotive industry's shift towards electrification presents perhaps the most significant challenge to the LM7 and similar internal combustion engines. As manufacturers invest heavily in electric and hybrid powertrains, the development resources allocated to traditional V8 engines like the LM7 are diminishing. This trend could potentially limit future improvements and optimizations for acceleration profiles in vehicles equipped with this engine.

In conclusion, while the LM7 engine has demonstrated remarkable longevity and adaptability, it faces substantial challenges in the current technological and regulatory environment. Addressing these issues will be crucial for maintaining its relevance in modern vehicle applications, particularly concerning acceleration profiles and overall performance characteristics.

Current LM7 Engine Solutions for Acceleration

01 Engine control systems for optimizing acceleration

Advanced control systems are developed to optimize the acceleration profiles of LM7 engines. These systems utilize various sensors and algorithms to adjust fuel injection, ignition timing, and valve timing in real-time, resulting in improved acceleration performance and efficiency.- Engine control systems for optimizing acceleration: Advanced control systems are developed to optimize the acceleration profiles of LM7 engines. These systems utilize various sensors and algorithms to adjust fuel injection, ignition timing, and valve timing in real-time, resulting in improved acceleration performance and efficiency.

- Acceleration profile mapping and analysis: Techniques for mapping and analyzing acceleration profiles of LM7 engines are developed. These methods involve data collection during various driving conditions, statistical analysis, and creation of detailed acceleration maps to understand engine performance characteristics and identify areas for improvement.

- Adaptive acceleration control strategies: Adaptive control strategies are implemented to optimize LM7 engine acceleration profiles. These strategies use machine learning algorithms and real-time data to continuously adjust engine parameters, adapting to different driving conditions and driver preferences for improved acceleration performance.

- Integration of acceleration profiles with transmission control: Systems are developed to integrate LM7 engine acceleration profiles with transmission control. This integration allows for optimized gear shifting patterns based on acceleration demands, resulting in smoother and more efficient acceleration across various driving scenarios.

- Acceleration profile optimization for emissions reduction: Methods are developed to optimize LM7 engine acceleration profiles with a focus on reducing emissions. These techniques involve precise control of fuel injection, exhaust gas recirculation, and aftertreatment systems during acceleration events to minimize pollutant formation while maintaining performance.

02 Acceleration profile mapping and analysis

Methods for mapping and analyzing acceleration profiles of LM7 engines are developed. These techniques involve data collection during various driving conditions, statistical analysis, and creation of detailed acceleration maps to understand engine performance characteristics and identify areas for improvement.Expand Specific Solutions03 Adaptive acceleration control strategies

Adaptive control strategies are implemented to optimize acceleration profiles based on driving conditions, driver behavior, and environmental factors. These systems continuously learn and adjust engine parameters to provide optimal acceleration performance while maintaining fuel efficiency and emissions compliance.Expand Specific Solutions04 Integration of acceleration profiles with transmission control

Acceleration profiles of LM7 engines are integrated with transmission control systems to achieve smoother and more efficient acceleration. This integration involves coordinated control of engine output and gear shifting to optimize power delivery and minimize energy losses during acceleration events.Expand Specific Solutions05 Acceleration profile optimization for emissions reduction

Techniques are developed to optimize acceleration profiles of LM7 engines with a focus on reducing emissions. These methods involve precise control of air-fuel mixture, exhaust gas recirculation, and aftertreatment systems during acceleration events to minimize pollutant formation while maintaining performance.Expand Specific Solutions

Key Players in LM7 Engine Manufacturing

The LM7 engine's impact on vehicle acceleration profiles is at a nascent stage of development, with the market still emerging and technology in early phases of maturation. Key players like Nissan, Honda, and Toyota are investing in research and development to optimize the LM7 engine's performance and efficiency. The competitive landscape is evolving, with automotive giants such as GM, Hyundai, and Kia also exploring LM7 applications. As the technology advances, we can expect increased market competition and potential breakthroughs in acceleration capabilities, though widespread adoption may take time as manufacturers refine their implementations and overcome initial challenges.

Nissan Motor Co., Ltd.

Technical Solution: Nissan's approach to enhancing vehicle acceleration profiles with the LM7 engine involves a combination of advanced technologies and innovative design. The LM7 engine incorporates Nissan's Direct Injection Gasoline (DIG) system, which allows for precise fuel injection control and improved combustion efficiency[1]. This technology contributes to faster throttle response and improved acceleration across the RPM range. Nissan has also implemented a twin-turbo configuration in some LM7 engine variants, significantly boosting low-end torque and mid-range acceleration[2]. The engine features a compact graphite iron cylinder block, which provides increased strength and reduced weight compared to traditional cast iron blocks, contributing to improved power-to-weight ratio and acceleration performance[3]. Additionally, Nissan utilizes a continuously variable valve timing control system (CVTCS) to optimize valve timing for different driving conditions, further enhancing acceleration characteristics[4].

Strengths: Strong low-end torque, responsive acceleration, and good fuel efficiency. Weaknesses: Potential reliability concerns with complex turbocharging systems and higher production costs.

Honda Motor Co., Ltd.

Technical Solution: Honda's approach to improving vehicle acceleration profiles with the LM7 engine focuses on advanced materials, innovative valve control systems, and optimized combustion processes. The LM7 engine incorporates Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system, which provides variable valve timing and lift to optimize engine performance across different RPM ranges[1]. This technology contributes to improved low-end torque and smoother acceleration. Honda has also implemented a high-strength, lightweight aluminum alloy for the engine block and cylinder heads, reducing overall engine weight and improving power-to-weight ratio[2]. The LM7 engine features Honda's PGM-FI (Programmed Fuel Injection) system, which utilizes advanced sensors and computer-controlled fuel injection for precise fuel delivery and improved throttle response[3]. Additionally, Honda has incorporated a high-flow intake manifold design and optimized exhaust system to enhance air flow and exhaust gas evacuation, further improving acceleration characteristics[4].

Strengths: Smooth power delivery, excellent fuel efficiency, and renowned reliability. Weaknesses: May not offer the highest peak power outputs compared to some turbocharged competitors.

Core Innovations in LM7 Engine Design

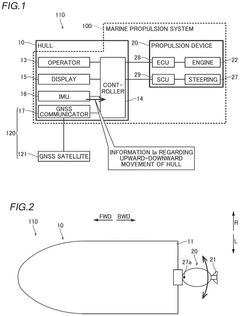

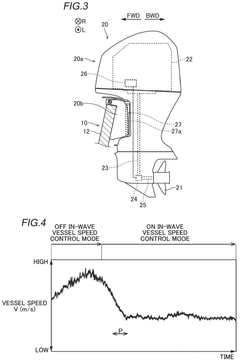

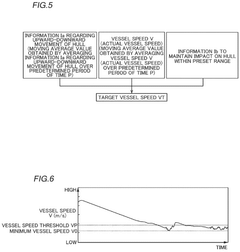

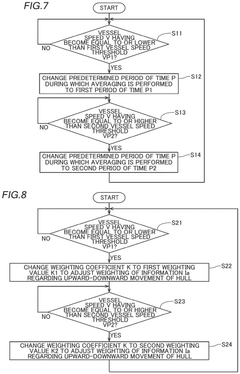

Marine propulsion system

PatentPendingEP4491502A1

Innovation

- A marine propulsion system with a controller that adjusts vessel speed based on hull movement data, ensuring the speed remains at or above a minimum level for efficient planing, while implementing strategies to quickly increase speed when necessary, such as altering averaging periods and weighting coefficients, to prevent excessive deceleration.

Environmental Impact of LM7 Engine Technology

The environmental impact of LM7 engine technology is a critical consideration in the automotive industry's pursuit of sustainable transportation solutions. The LM7, a member of General Motors' Vortec engine family, has been widely used in various vehicle models since its introduction in the late 1990s. While primarily designed for improved performance and fuel efficiency, its environmental footprint warrants careful examination.

One of the key environmental aspects of the LM7 engine is its emissions profile. As a V8 gasoline engine, it inherently produces carbon dioxide and other greenhouse gases during combustion. However, the LM7's design incorporates several features aimed at reducing harmful emissions. The engine's sequential fuel injection system and advanced engine control module work in tandem to optimize fuel delivery and combustion, potentially lowering overall emissions compared to its predecessors.

The LM7's impact on air quality extends beyond tailpipe emissions. Its manufacturing process, including the sourcing of raw materials and component production, contributes to the engine's overall environmental footprint. The use of aluminum for the engine block, while beneficial for weight reduction and fuel efficiency, has implications for resource extraction and energy-intensive production processes.

Fuel consumption is another crucial environmental factor associated with the LM7 engine. While it offers improved efficiency over earlier V8 designs, its fuel economy still lags behind smaller displacement engines and alternative powertrains. This higher fuel consumption translates to increased carbon emissions over the vehicle's lifetime, contributing to the transportation sector's significant share of global greenhouse gas emissions.

The LM7's durability and longevity also play a role in its environmental impact. The engine's robust design and reliability can lead to extended vehicle lifespans, potentially reducing the frequency of vehicle replacements and associated manufacturing emissions. However, this longevity may also delay the adoption of newer, more environmentally friendly technologies in the vehicle fleet.

End-of-life considerations for LM7-equipped vehicles are an important aspect of their environmental impact. The recyclability of engine components, particularly the aluminum block and various metal parts, can help mitigate some of the environmental costs associated with production. However, proper disposal and recycling infrastructure are crucial to realizing these benefits and minimizing the engine's long-term environmental footprint.

In conclusion, while the LM7 engine represents an improvement over its predecessors in terms of performance and efficiency, its environmental impact remains significant. As the automotive industry continues to evolve towards more sustainable technologies, the lessons learned from the LM7's environmental profile can inform the development of future powertrains with reduced ecological footprints.

One of the key environmental aspects of the LM7 engine is its emissions profile. As a V8 gasoline engine, it inherently produces carbon dioxide and other greenhouse gases during combustion. However, the LM7's design incorporates several features aimed at reducing harmful emissions. The engine's sequential fuel injection system and advanced engine control module work in tandem to optimize fuel delivery and combustion, potentially lowering overall emissions compared to its predecessors.

The LM7's impact on air quality extends beyond tailpipe emissions. Its manufacturing process, including the sourcing of raw materials and component production, contributes to the engine's overall environmental footprint. The use of aluminum for the engine block, while beneficial for weight reduction and fuel efficiency, has implications for resource extraction and energy-intensive production processes.

Fuel consumption is another crucial environmental factor associated with the LM7 engine. While it offers improved efficiency over earlier V8 designs, its fuel economy still lags behind smaller displacement engines and alternative powertrains. This higher fuel consumption translates to increased carbon emissions over the vehicle's lifetime, contributing to the transportation sector's significant share of global greenhouse gas emissions.

The LM7's durability and longevity also play a role in its environmental impact. The engine's robust design and reliability can lead to extended vehicle lifespans, potentially reducing the frequency of vehicle replacements and associated manufacturing emissions. However, this longevity may also delay the adoption of newer, more environmentally friendly technologies in the vehicle fleet.

End-of-life considerations for LM7-equipped vehicles are an important aspect of their environmental impact. The recyclability of engine components, particularly the aluminum block and various metal parts, can help mitigate some of the environmental costs associated with production. However, proper disposal and recycling infrastructure are crucial to realizing these benefits and minimizing the engine's long-term environmental footprint.

In conclusion, while the LM7 engine represents an improvement over its predecessors in terms of performance and efficiency, its environmental impact remains significant. As the automotive industry continues to evolve towards more sustainable technologies, the lessons learned from the LM7's environmental profile can inform the development of future powertrains with reduced ecological footprints.

Regulatory Landscape for LM7 Engine Implementation

The regulatory landscape for LM7 engine implementation is complex and multifaceted, encompassing various aspects of environmental protection, safety standards, and performance requirements. At the federal level, the Environmental Protection Agency (EPA) plays a crucial role in setting emission standards for vehicles equipped with LM7 engines. These standards are part of the broader Clean Air Act regulations, which aim to reduce harmful pollutants and greenhouse gas emissions from motor vehicles.

The National Highway Traffic Safety Administration (NHTSA) also imposes regulations that directly impact LM7 engine implementation, particularly in terms of fuel economy standards. The Corporate Average Fuel Economy (CAFE) standards require automakers to meet specific fleet-wide fuel efficiency targets, which influence the design and deployment of engines like the LM7.

State-level regulations add another layer of complexity to the regulatory landscape. California, for instance, has its own stringent emission standards through the California Air Resources Board (CARB), which often exceed federal requirements. Many other states have adopted California's standards, creating a patchwork of regulations across the country that manufacturers must navigate when implementing LM7 engines.

Safety regulations also play a significant role in LM7 engine implementation. The Federal Motor Vehicle Safety Standards (FMVSS) set forth by NHTSA include requirements for engine performance, durability, and crash protection, all of which must be considered in the design and integration of LM7 engines into vehicles.

International regulations further complicate the landscape for manufacturers looking to implement LM7 engines globally. The European Union's Euro emissions standards and similar regulations in other markets may require modifications or adaptations to LM7 engines to ensure compliance across different regions.

The regulatory framework also extends to the manufacturing process itself, with Occupational Safety and Health Administration (OSHA) regulations governing workplace safety in engine production facilities. Additionally, the disposal and recycling of LM7 engines at the end of their lifecycle fall under the purview of environmental regulations, including the Resource Conservation and Recovery Act (RCRA).

As vehicle technology continues to evolve, regulatory bodies are increasingly focusing on advanced driver assistance systems (ADAS) and autonomous vehicle capabilities. While not directly related to the LM7 engine, these emerging regulations may influence overall vehicle design and, by extension, engine implementation strategies.

The National Highway Traffic Safety Administration (NHTSA) also imposes regulations that directly impact LM7 engine implementation, particularly in terms of fuel economy standards. The Corporate Average Fuel Economy (CAFE) standards require automakers to meet specific fleet-wide fuel efficiency targets, which influence the design and deployment of engines like the LM7.

State-level regulations add another layer of complexity to the regulatory landscape. California, for instance, has its own stringent emission standards through the California Air Resources Board (CARB), which often exceed federal requirements. Many other states have adopted California's standards, creating a patchwork of regulations across the country that manufacturers must navigate when implementing LM7 engines.

Safety regulations also play a significant role in LM7 engine implementation. The Federal Motor Vehicle Safety Standards (FMVSS) set forth by NHTSA include requirements for engine performance, durability, and crash protection, all of which must be considered in the design and integration of LM7 engines into vehicles.

International regulations further complicate the landscape for manufacturers looking to implement LM7 engines globally. The European Union's Euro emissions standards and similar regulations in other markets may require modifications or adaptations to LM7 engines to ensure compliance across different regions.

The regulatory framework also extends to the manufacturing process itself, with Occupational Safety and Health Administration (OSHA) regulations governing workplace safety in engine production facilities. Additionally, the disposal and recycling of LM7 engines at the end of their lifecycle fall under the purview of environmental regulations, including the Resource Conservation and Recovery Act (RCRA).

As vehicle technology continues to evolve, regulatory bodies are increasingly focusing on advanced driver assistance systems (ADAS) and autonomous vehicle capabilities. While not directly related to the LM7 engine, these emerging regulations may influence overall vehicle design and, by extension, engine implementation strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!