Computational modeling of LM7 engine thermodynamics

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Thermodynamics Background and Objectives

The LM7 engine, a member of the General Motors LS engine family, has been a cornerstone in automotive engineering since its introduction in the late 1990s. This 5.3-liter V8 engine has found widespread application in various GM vehicles, including trucks and SUVs, due to its robust performance and reliability. The computational modeling of LM7 engine thermodynamics represents a critical area of study in automotive engineering, aiming to optimize engine efficiency, reduce emissions, and enhance overall performance.

The evolution of computational modeling techniques has significantly advanced our understanding of engine thermodynamics. From early simplified models to today's complex, multi-dimensional simulations, the field has progressed rapidly. These advancements have enabled engineers to gain deeper insights into the intricate thermal processes occurring within the LM7 engine, including combustion dynamics, heat transfer, and fluid flow.

The primary objective of computational modeling in LM7 engine thermodynamics is to create accurate, predictive models that can simulate real-world engine behavior under various operating conditions. These models serve as powerful tools for engine design, optimization, and performance analysis. By leveraging computational fluid dynamics (CFD) and finite element analysis (FEA), engineers can visualize and analyze complex thermal phenomena that are challenging to observe through physical experimentation alone.

One of the key goals is to improve fuel efficiency while maintaining or enhancing engine power output. This involves optimizing combustion chamber design, valve timing, and fuel injection strategies. Computational models allow engineers to explore numerous design iterations virtually, significantly reducing the time and cost associated with physical prototyping and testing.

Another critical objective is to minimize harmful emissions. As environmental regulations become increasingly stringent, the ability to predict and control emissions through accurate thermodynamic modeling is paramount. This includes modeling the formation and reduction of pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter.

Furthermore, thermal management within the engine is a crucial aspect of the modeling process. Understanding and optimizing heat flow throughout the engine block, cylinder heads, and cooling system is essential for ensuring longevity and reliability. Computational models help in identifying potential hotspots and areas of thermal stress, allowing for targeted improvements in design and materials selection.

The ongoing development of computational modeling techniques for LM7 engine thermodynamics also aims to incorporate real-time simulation capabilities. This would enable more advanced engine control strategies, potentially leading to adaptive systems that can optimize performance on-the-fly based on current operating conditions and driver behavior.

The evolution of computational modeling techniques has significantly advanced our understanding of engine thermodynamics. From early simplified models to today's complex, multi-dimensional simulations, the field has progressed rapidly. These advancements have enabled engineers to gain deeper insights into the intricate thermal processes occurring within the LM7 engine, including combustion dynamics, heat transfer, and fluid flow.

The primary objective of computational modeling in LM7 engine thermodynamics is to create accurate, predictive models that can simulate real-world engine behavior under various operating conditions. These models serve as powerful tools for engine design, optimization, and performance analysis. By leveraging computational fluid dynamics (CFD) and finite element analysis (FEA), engineers can visualize and analyze complex thermal phenomena that are challenging to observe through physical experimentation alone.

One of the key goals is to improve fuel efficiency while maintaining or enhancing engine power output. This involves optimizing combustion chamber design, valve timing, and fuel injection strategies. Computational models allow engineers to explore numerous design iterations virtually, significantly reducing the time and cost associated with physical prototyping and testing.

Another critical objective is to minimize harmful emissions. As environmental regulations become increasingly stringent, the ability to predict and control emissions through accurate thermodynamic modeling is paramount. This includes modeling the formation and reduction of pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter.

Furthermore, thermal management within the engine is a crucial aspect of the modeling process. Understanding and optimizing heat flow throughout the engine block, cylinder heads, and cooling system is essential for ensuring longevity and reliability. Computational models help in identifying potential hotspots and areas of thermal stress, allowing for targeted improvements in design and materials selection.

The ongoing development of computational modeling techniques for LM7 engine thermodynamics also aims to incorporate real-time simulation capabilities. This would enable more advanced engine control strategies, potentially leading to adaptive systems that can optimize performance on-the-fly based on current operating conditions and driver behavior.

Market Demand for LM7 Engine Modeling

The market demand for computational modeling of LM7 engine thermodynamics has been steadily growing in recent years, driven by the automotive industry's push for more efficient and environmentally friendly engines. As emission regulations become increasingly stringent worldwide, manufacturers are seeking advanced tools to optimize engine performance while reducing fuel consumption and emissions.

The LM7 engine, a popular V8 engine used in various General Motors vehicles, has become a focal point for aftermarket modifications and performance enhancements. This has created a significant demand for accurate thermodynamic modeling tools that can predict engine behavior under various operating conditions and modifications.

Engine designers and automotive engineers are particularly interested in computational modeling solutions that can simulate the complex thermodynamic processes within the LM7 engine. These models allow for virtual testing of different design iterations, reducing the need for costly physical prototypes and accelerating the development cycle.

The aftermarket performance industry has also shown a keen interest in LM7 engine modeling tools. Tuning shops and performance parts manufacturers require accurate simulations to develop and optimize products such as intake manifolds, exhaust systems, and forced induction kits. This has led to a growing market for user-friendly software that can provide detailed insights into engine thermodynamics without requiring extensive engineering expertise.

Furthermore, the rise of electric and hybrid vehicles has not diminished the demand for LM7 engine modeling. Instead, it has created a new market segment focused on optimizing internal combustion engines for hybrid powertrains. Computational models that can accurately predict engine efficiency and emissions in various hybrid configurations are highly sought after by automotive manufacturers developing next-generation vehicles.

Educational institutions and research organizations have also contributed to the market demand for LM7 engine modeling tools. Universities and technical schools use these computational models to teach automotive engineering principles and conduct research into advanced combustion technologies.

The global nature of the automotive industry has expanded the market for LM7 engine modeling beyond North America. As General Motors vehicles featuring the LM7 engine have been exported worldwide, international markets have developed a need for localized modeling solutions that account for regional fuel qualities and environmental conditions.

In conclusion, the market demand for computational modeling of LM7 engine thermodynamics is robust and diverse, spanning multiple sectors of the automotive industry. From OEMs to aftermarket tuners, and from educational institutions to research facilities, the need for accurate and sophisticated modeling tools continues to drive innovation in this field.

The LM7 engine, a popular V8 engine used in various General Motors vehicles, has become a focal point for aftermarket modifications and performance enhancements. This has created a significant demand for accurate thermodynamic modeling tools that can predict engine behavior under various operating conditions and modifications.

Engine designers and automotive engineers are particularly interested in computational modeling solutions that can simulate the complex thermodynamic processes within the LM7 engine. These models allow for virtual testing of different design iterations, reducing the need for costly physical prototypes and accelerating the development cycle.

The aftermarket performance industry has also shown a keen interest in LM7 engine modeling tools. Tuning shops and performance parts manufacturers require accurate simulations to develop and optimize products such as intake manifolds, exhaust systems, and forced induction kits. This has led to a growing market for user-friendly software that can provide detailed insights into engine thermodynamics without requiring extensive engineering expertise.

Furthermore, the rise of electric and hybrid vehicles has not diminished the demand for LM7 engine modeling. Instead, it has created a new market segment focused on optimizing internal combustion engines for hybrid powertrains. Computational models that can accurately predict engine efficiency and emissions in various hybrid configurations are highly sought after by automotive manufacturers developing next-generation vehicles.

Educational institutions and research organizations have also contributed to the market demand for LM7 engine modeling tools. Universities and technical schools use these computational models to teach automotive engineering principles and conduct research into advanced combustion technologies.

The global nature of the automotive industry has expanded the market for LM7 engine modeling beyond North America. As General Motors vehicles featuring the LM7 engine have been exported worldwide, international markets have developed a need for localized modeling solutions that account for regional fuel qualities and environmental conditions.

In conclusion, the market demand for computational modeling of LM7 engine thermodynamics is robust and diverse, spanning multiple sectors of the automotive industry. From OEMs to aftermarket tuners, and from educational institutions to research facilities, the need for accurate and sophisticated modeling tools continues to drive innovation in this field.

Current Challenges in LM7 Thermodynamic Modeling

The computational modeling of LM7 engine thermodynamics faces several significant challenges that hinder accurate simulation and prediction of engine performance. One of the primary obstacles is the complexity of the combustion process within the LM7 engine. The intricate interplay between fuel injection, air-fuel mixing, and combustion dynamics creates a highly non-linear system that is difficult to model accurately.

Another major challenge lies in the thermal management of the LM7 engine. The heat transfer processes occurring within the engine, including conduction through engine components, convection in coolant passages, and radiation from hot surfaces, are complex and interdependent. Accurately modeling these heat transfer mechanisms and their effects on engine performance requires sophisticated algorithms and significant computational resources.

The transient nature of engine operation poses additional difficulties for thermodynamic modeling. Rapid changes in engine speed, load, and operating conditions create dynamic thermal states that are challenging to capture in real-time simulations. This is particularly problematic when attempting to model start-up conditions, acceleration, and other non-steady-state scenarios.

Furthermore, the multi-scale nature of the thermodynamic processes in the LM7 engine presents a formidable challenge. Phenomena ranging from microscale fuel droplet evaporation to macroscale fluid dynamics within the engine cylinders must be accounted for, often requiring different modeling approaches at various scales. Integrating these multi-scale models into a cohesive simulation framework remains a significant hurdle.

The presence of turbulence in the combustion chamber and intake/exhaust systems adds another layer of complexity to the modeling process. Accurately predicting turbulent flow patterns and their impact on heat transfer and combustion efficiency is crucial for reliable thermodynamic simulations. However, current turbulence models often struggle to capture the full range of turbulent scales present in engine operation.

Additionally, the chemical kinetics of fuel combustion in the LM7 engine present a considerable challenge. The wide range of hydrocarbon species and intermediate compounds formed during combustion requires detailed chemical mechanisms to be incorporated into the thermodynamic models. Balancing the need for chemical accuracy with computational efficiency remains an ongoing challenge in engine simulation.

Lastly, the validation of computational models against experimental data poses significant difficulties. Obtaining high-fidelity experimental measurements from within operating engines is challenging, and discrepancies between simulated and measured results often arise due to uncertainties in both the modeling assumptions and experimental techniques. Bridging this gap between simulation and reality continues to be a key focus area for researchers in engine thermodynamics.

Another major challenge lies in the thermal management of the LM7 engine. The heat transfer processes occurring within the engine, including conduction through engine components, convection in coolant passages, and radiation from hot surfaces, are complex and interdependent. Accurately modeling these heat transfer mechanisms and their effects on engine performance requires sophisticated algorithms and significant computational resources.

The transient nature of engine operation poses additional difficulties for thermodynamic modeling. Rapid changes in engine speed, load, and operating conditions create dynamic thermal states that are challenging to capture in real-time simulations. This is particularly problematic when attempting to model start-up conditions, acceleration, and other non-steady-state scenarios.

Furthermore, the multi-scale nature of the thermodynamic processes in the LM7 engine presents a formidable challenge. Phenomena ranging from microscale fuel droplet evaporation to macroscale fluid dynamics within the engine cylinders must be accounted for, often requiring different modeling approaches at various scales. Integrating these multi-scale models into a cohesive simulation framework remains a significant hurdle.

The presence of turbulence in the combustion chamber and intake/exhaust systems adds another layer of complexity to the modeling process. Accurately predicting turbulent flow patterns and their impact on heat transfer and combustion efficiency is crucial for reliable thermodynamic simulations. However, current turbulence models often struggle to capture the full range of turbulent scales present in engine operation.

Additionally, the chemical kinetics of fuel combustion in the LM7 engine present a considerable challenge. The wide range of hydrocarbon species and intermediate compounds formed during combustion requires detailed chemical mechanisms to be incorporated into the thermodynamic models. Balancing the need for chemical accuracy with computational efficiency remains an ongoing challenge in engine simulation.

Lastly, the validation of computational models against experimental data poses significant difficulties. Obtaining high-fidelity experimental measurements from within operating engines is challenging, and discrepancies between simulated and measured results often arise due to uncertainties in both the modeling assumptions and experimental techniques. Bridging this gap between simulation and reality continues to be a key focus area for researchers in engine thermodynamics.

Existing LM7 Computational Modeling Approaches

01 Thermodynamic cycle optimization

Optimization of the thermodynamic cycle in LM7 engines focuses on improving efficiency and performance. This involves analyzing and adjusting various parameters such as compression ratio, fuel injection timing, and exhaust gas recirculation to maximize power output while minimizing fuel consumption. Advanced modeling techniques and simulations are used to predict and enhance the engine's thermodynamic behavior under different operating conditions.- Thermodynamic cycle optimization: Optimization of the thermodynamic cycle in LM7 engines involves improving efficiency through various methods such as adjusting compression ratios, enhancing heat recovery systems, and refining combustion processes. These optimizations aim to increase power output while reducing fuel consumption and emissions.

- Exhaust gas recirculation (EGR) systems: Implementation of EGR systems in LM7 engines helps to reduce emissions and improve fuel efficiency. These systems recirculate a portion of the exhaust gases back into the combustion chamber, lowering peak combustion temperatures and reducing the formation of nitrogen oxides.

- Turbocharging and supercharging: Forced induction systems such as turbochargers and superchargers are used to enhance the thermodynamic performance of LM7 engines. These systems increase the air density entering the combustion chamber, allowing for more fuel to be burned and resulting in higher power output and improved efficiency.

- Thermal management and cooling systems: Advanced thermal management and cooling systems are crucial for maintaining optimal operating temperatures in LM7 engines. These systems help to improve overall engine efficiency, reduce thermal stress on components, and enhance durability by effectively managing heat dissipation.

- Combustion analysis and modeling: Sophisticated combustion analysis and modeling techniques are employed to optimize the thermodynamic processes within LM7 engines. These methods involve computer simulations, real-time monitoring, and advanced sensors to fine-tune combustion parameters for improved performance and reduced emissions.

02 Heat recovery systems

Implementation of heat recovery systems in LM7 engines aims to capture and utilize waste heat, improving overall thermal efficiency. These systems may include thermoelectric generators, Rankine cycle systems, or other heat exchangers that convert thermal energy from exhaust gases into useful power. By recovering waste heat, the engine's fuel efficiency can be significantly improved, reducing emissions and operating costs.Expand Specific Solutions03 Combustion chamber design

Optimizing the combustion chamber design in LM7 engines is crucial for enhancing thermodynamic efficiency. This involves careful consideration of factors such as chamber geometry, piston crown shape, and valve positioning. Advanced computational fluid dynamics (CFD) simulations are used to analyze and improve fuel-air mixing, flame propagation, and heat transfer within the combustion chamber, leading to more complete combustion and reduced energy losses.Expand Specific Solutions04 Turbocharging and supercharging

Integration of turbocharging or supercharging systems in LM7 engines enhances thermodynamic performance by increasing the air density in the combustion chamber. This allows for more fuel to be burned efficiently, resulting in higher power output and improved thermal efficiency. Advanced control strategies and variable geometry turbochargers are employed to optimize boost pressure across different engine operating conditions.Expand Specific Solutions05 Thermal management and cooling systems

Effective thermal management and cooling systems are essential for maintaining optimal thermodynamic performance in LM7 engines. This includes advanced coolant flow designs, precision temperature control, and innovative materials for improved heat dissipation. Efficient cooling systems help maintain ideal operating temperatures, reduce thermal stress on engine components, and contribute to overall engine efficiency and longevity.Expand Specific Solutions

Key Players in Engine Simulation Software

The computational modeling of LM7 engine thermodynamics is in a mature stage of development, with significant market potential in the automotive and aerospace industries. The technology's maturity is evident from the involvement of established players like Chery Automobile Co., Ltd., GM Global Technology Operations LLC, and China FAW Co., Ltd. These companies are likely leveraging advanced modeling techniques to optimize engine performance and efficiency. The market size is substantial, driven by the increasing demand for fuel-efficient and low-emission engines. Universities such as Beihang University and Northwestern Polytechnical University are contributing to research and development, indicating a strong academic-industry collaboration in this field. The competitive landscape is diverse, with both automotive manufacturers and specialized technology firms actively participating in advancing LM7 engine thermodynamics modeling capabilities.

Robert Bosch GmbH

Technical Solution: Bosch's computational modeling approach for LM7 engine thermodynamics focuses on high-fidelity simulations coupled with extensive experimental validation. They employ a multi-physics modeling framework that integrates combustion chemistry, spray dynamics, and heat transfer models[1]. Bosch's simulations incorporate detailed models for fuel injection systems, including nozzle flow and cavitation effects. They utilize advanced turbulence models such as Large Eddy Simulation (LES) for improved accuracy in predicting in-cylinder flow structures[3]. Bosch has developed specialized sub-models for phenomena like wall heat transfer and piston oil jet cooling. Their approach also includes co-simulation capabilities to integrate powertrain control models with thermodynamic simulations[5].

Strengths: High-fidelity modeling with extensive experimental validation; Specialized sub-models for critical phenomena; Integration with powertrain control simulations. Weaknesses: High computational cost for detailed simulations; Potential limitations in real-time applications due to model complexity.

Combustion Science & Engineering, Inc.

Technical Solution: Combustion Science & Engineering (CSE) specializes in advanced computational modeling of engine thermodynamics, with a focus on the LM7 engine. Their approach utilizes high-fidelity Large Eddy Simulation (LES) coupled with detailed chemical kinetics models[2]. CSE has developed proprietary algorithms for adaptive mesh refinement, allowing for efficient resolution of critical flow and combustion phenomena. Their models incorporate advanced spray breakup and evaporation models, crucial for accurate prediction of fuel-air mixing in direct injection systems[4]. CSE employs a novel approach to turbulence-chemistry interaction modeling, improving the accuracy of emissions predictions. They have also developed specialized models for cycle-to-cycle variations and abnormal combustion phenomena like knock and pre-ignition[6].

Strengths: Cutting-edge LES modeling with detailed chemistry; Advanced algorithms for computational efficiency; Specialized models for critical phenomena. Weaknesses: High computational requirements may limit applicability in real-time applications; Potential over-specialization in high-fidelity modeling at the expense of system-level integration.

Core Innovations in Engine Thermodynamics Simulation

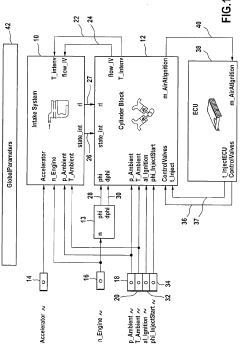

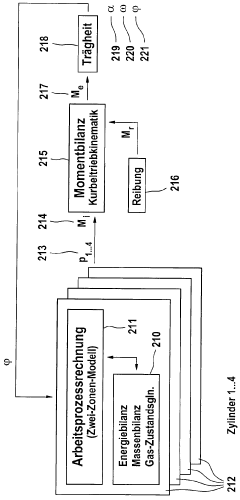

Combustion process simulating method for internal combustion engine, involves creating simulation model by considering energy and mass balances, and issuing controlling and/or adjustment parameter of engine by inputting input parameter

PatentInactiveDE102004044814A1

Innovation

- A thermodynamic engine simulation model considering energy and mass balances, along with a gas equation of state, is used to simulate combustion processes in each cylinder, incorporating one- or two-zone models and accounting for wall heat losses, leakage, and gas exchange, enabling accurate simulation across all speeds, including zero and reverse rotation.

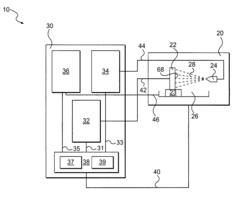

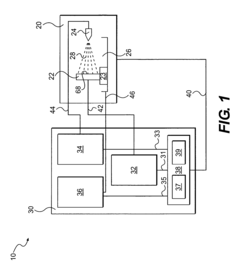

Systems and methods for simulating an engine environment

PatentInactiveUS8082775B2

Innovation

- A system and method that include a chamber with a surface for condensation, a liquid delivery device, and a temperature controller to simulate engine conditions, allowing for the analysis of lubricant composition and emulsion formation by controlling parameters such as humidity, temperature, and fluid composition.

Environmental Impact of LM7 Engine Optimization

The optimization of the LM7 engine through computational modeling of its thermodynamics has significant implications for environmental impact. As engine efficiency improves, fuel consumption decreases, leading to reduced emissions of greenhouse gases and other pollutants. The LM7, a 5.3-liter V8 engine commonly used in General Motors vehicles, has been a target for optimization due to its widespread use and potential for improvement.

Computational modeling allows for precise analysis of combustion processes, heat transfer, and fluid dynamics within the engine. By optimizing these factors, engineers can achieve better fuel economy and lower emissions without sacrificing performance. For instance, improvements in combustion chamber design can lead to more complete fuel burning, reducing unburned hydrocarbon emissions.

The environmental benefits of LM7 engine optimization extend beyond direct emissions reduction. Enhanced efficiency translates to less fuel consumption over the vehicle's lifetime, reducing the overall carbon footprint associated with fuel production and distribution. Additionally, optimized engines may require less frequent maintenance, potentially reducing waste from replacement parts and fluids.

However, it is crucial to consider the entire lifecycle of the engine when assessing environmental impact. While operational improvements are significant, the manufacturing process for more advanced engine components may have its own environmental costs. These could include increased energy consumption in production or the use of rare or difficult-to-recycle materials.

The optimization process also has implications for existing vehicles. Retrofitting older LM7 engines with optimized components or control systems could extend the useful life of vehicles, delaying the need for replacement and the associated environmental costs of new vehicle production. This approach could be particularly impactful given the large number of LM7-equipped vehicles already on the road.

Furthermore, the knowledge gained from LM7 optimization can be applied to the development of future engine designs, potentially leading to even greater environmental benefits in next-generation vehicles. This transfer of technology and understanding contributes to a broader trend of increasing automotive efficiency and reduced environmental impact across the industry.

Computational modeling allows for precise analysis of combustion processes, heat transfer, and fluid dynamics within the engine. By optimizing these factors, engineers can achieve better fuel economy and lower emissions without sacrificing performance. For instance, improvements in combustion chamber design can lead to more complete fuel burning, reducing unburned hydrocarbon emissions.

The environmental benefits of LM7 engine optimization extend beyond direct emissions reduction. Enhanced efficiency translates to less fuel consumption over the vehicle's lifetime, reducing the overall carbon footprint associated with fuel production and distribution. Additionally, optimized engines may require less frequent maintenance, potentially reducing waste from replacement parts and fluids.

However, it is crucial to consider the entire lifecycle of the engine when assessing environmental impact. While operational improvements are significant, the manufacturing process for more advanced engine components may have its own environmental costs. These could include increased energy consumption in production or the use of rare or difficult-to-recycle materials.

The optimization process also has implications for existing vehicles. Retrofitting older LM7 engines with optimized components or control systems could extend the useful life of vehicles, delaying the need for replacement and the associated environmental costs of new vehicle production. This approach could be particularly impactful given the large number of LM7-equipped vehicles already on the road.

Furthermore, the knowledge gained from LM7 optimization can be applied to the development of future engine designs, potentially leading to even greater environmental benefits in next-generation vehicles. This transfer of technology and understanding contributes to a broader trend of increasing automotive efficiency and reduced environmental impact across the industry.

Integration with Powertrain Control Systems

The integration of computational modeling for LM7 engine thermodynamics with powertrain control systems represents a critical advancement in automotive engineering. This integration enables real-time optimization of engine performance, fuel efficiency, and emissions control based on accurate thermodynamic predictions.

One of the primary benefits of this integration is the ability to implement model-based control strategies. By incorporating thermodynamic models into the powertrain control unit (PCU), engineers can develop more sophisticated control algorithms that anticipate and respond to changes in engine operating conditions. This proactive approach allows for finer adjustments to fuel injection timing, valve timing, and other critical parameters.

The integration process typically involves embedding simplified versions of the computational models within the PCU's software architecture. These models must be optimized for real-time execution while maintaining sufficient accuracy to inform control decisions. Techniques such as model reduction, look-up tables, and neural network approximations are often employed to achieve the necessary balance between computational speed and predictive power.

A key challenge in this integration is managing the increased computational demands on the PCU. As thermodynamic models become more complex, they require greater processing power and memory resources. This necessitates careful optimization of the control system hardware and software to ensure reliable real-time performance under all operating conditions.

Data communication between the thermodynamic model and other powertrain subsystems is another critical aspect of the integration. High-speed CAN (Controller Area Network) buses or more advanced automotive ethernet systems are typically used to facilitate rapid data exchange. This allows the thermodynamic predictions to be quickly disseminated to relevant subsystems, such as the fuel injection system or turbocharger control module.

The integration also enables more advanced diagnostic capabilities. By comparing real-time sensor data with the predictions of the thermodynamic model, the control system can detect anomalies that may indicate component wear, system faults, or the need for maintenance. This predictive maintenance approach can significantly improve vehicle reliability and reduce downtime.

Looking forward, the integration of computational modeling with powertrain control systems is expected to play a crucial role in the development of next-generation engines. As regulations on emissions and fuel efficiency become increasingly stringent, the ability to precisely control engine thermodynamics in real-time will be essential for meeting these challenges while maintaining or improving performance.

One of the primary benefits of this integration is the ability to implement model-based control strategies. By incorporating thermodynamic models into the powertrain control unit (PCU), engineers can develop more sophisticated control algorithms that anticipate and respond to changes in engine operating conditions. This proactive approach allows for finer adjustments to fuel injection timing, valve timing, and other critical parameters.

The integration process typically involves embedding simplified versions of the computational models within the PCU's software architecture. These models must be optimized for real-time execution while maintaining sufficient accuracy to inform control decisions. Techniques such as model reduction, look-up tables, and neural network approximations are often employed to achieve the necessary balance between computational speed and predictive power.

A key challenge in this integration is managing the increased computational demands on the PCU. As thermodynamic models become more complex, they require greater processing power and memory resources. This necessitates careful optimization of the control system hardware and software to ensure reliable real-time performance under all operating conditions.

Data communication between the thermodynamic model and other powertrain subsystems is another critical aspect of the integration. High-speed CAN (Controller Area Network) buses or more advanced automotive ethernet systems are typically used to facilitate rapid data exchange. This allows the thermodynamic predictions to be quickly disseminated to relevant subsystems, such as the fuel injection system or turbocharger control module.

The integration also enables more advanced diagnostic capabilities. By comparing real-time sensor data with the predictions of the thermodynamic model, the control system can detect anomalies that may indicate component wear, system faults, or the need for maintenance. This predictive maintenance approach can significantly improve vehicle reliability and reduce downtime.

Looking forward, the integration of computational modeling with powertrain control systems is expected to play a crucial role in the development of next-generation engines. As regulations on emissions and fuel efficiency become increasingly stringent, the ability to precisely control engine thermodynamics in real-time will be essential for meeting these challenges while maintaining or improving performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!