Role of LM7 engine in improving heavy-duty vehicle payload capacity

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Background and Objectives

The LM7 engine, a member of the GM Gen III small-block V8 family, has played a significant role in advancing heavy-duty vehicle performance since its introduction in 1999. Initially designed for light trucks and SUVs, the LM7's robust architecture and potential for modification have made it a popular choice for heavy-duty applications, particularly in improving payload capacity.

The development of the LM7 engine was driven by the increasing demand for more powerful and efficient engines in the commercial vehicle sector. As regulations tightened and customer expectations evolved, manufacturers sought innovative solutions to enhance vehicle capabilities without compromising fuel efficiency or environmental standards. The LM7 emerged as a versatile platform that could be adapted to meet these diverse requirements.

One of the primary objectives behind the LM7's design was to create a modular engine architecture that could be easily scaled and modified for various applications. This flexibility has been crucial in its adoption for heavy-duty vehicles, where payload capacity is a critical factor. The engine's ability to deliver high torque at low RPMs, coupled with its relatively lightweight design, has contributed significantly to improving the overall payload capacity of vehicles equipped with it.

The LM7's cast-iron block provides a sturdy foundation, capable of withstanding the increased stresses associated with heavy-duty applications. Its 5.3-liter displacement strikes a balance between power output and fuel efficiency, making it an attractive option for fleet operators looking to optimize their vehicles' performance and operating costs.

Over the years, the LM7 has undergone several iterations and improvements, each aimed at enhancing its capabilities in heavy-duty scenarios. These developments have focused on increasing durability, improving power delivery, and refining fuel management systems. The engine's compatibility with advanced technologies, such as variable valve timing and direct injection, has further extended its relevance in the evolving landscape of heavy-duty transportation.

The ongoing evolution of the LM7 engine reflects the broader trends in the automotive industry towards more efficient and powerful powertrains. As manufacturers continue to push the boundaries of what's possible in heavy-duty vehicle performance, the LM7 serves as a testament to the importance of adaptable and robust engine designs in meeting the challenges of modern transportation needs.

The development of the LM7 engine was driven by the increasing demand for more powerful and efficient engines in the commercial vehicle sector. As regulations tightened and customer expectations evolved, manufacturers sought innovative solutions to enhance vehicle capabilities without compromising fuel efficiency or environmental standards. The LM7 emerged as a versatile platform that could be adapted to meet these diverse requirements.

One of the primary objectives behind the LM7's design was to create a modular engine architecture that could be easily scaled and modified for various applications. This flexibility has been crucial in its adoption for heavy-duty vehicles, where payload capacity is a critical factor. The engine's ability to deliver high torque at low RPMs, coupled with its relatively lightweight design, has contributed significantly to improving the overall payload capacity of vehicles equipped with it.

The LM7's cast-iron block provides a sturdy foundation, capable of withstanding the increased stresses associated with heavy-duty applications. Its 5.3-liter displacement strikes a balance between power output and fuel efficiency, making it an attractive option for fleet operators looking to optimize their vehicles' performance and operating costs.

Over the years, the LM7 has undergone several iterations and improvements, each aimed at enhancing its capabilities in heavy-duty scenarios. These developments have focused on increasing durability, improving power delivery, and refining fuel management systems. The engine's compatibility with advanced technologies, such as variable valve timing and direct injection, has further extended its relevance in the evolving landscape of heavy-duty transportation.

The ongoing evolution of the LM7 engine reflects the broader trends in the automotive industry towards more efficient and powerful powertrains. As manufacturers continue to push the boundaries of what's possible in heavy-duty vehicle performance, the LM7 serves as a testament to the importance of adaptable and robust engine designs in meeting the challenges of modern transportation needs.

Market Demand Analysis for Increased Payload Capacity

The market demand for increased payload capacity in heavy-duty vehicles has been steadily growing, driven by various factors in the transportation and logistics industry. This demand is primarily fueled by the need for improved efficiency and cost-effectiveness in freight transportation. As companies seek to maximize their return on investment, the ability to transport larger loads per trip becomes increasingly crucial.

One of the key drivers of this demand is the e-commerce boom, which has led to a surge in last-mile deliveries and long-haul transportation. With the rise of online shopping, there is a growing need for vehicles that can carry more goods while maintaining fuel efficiency and adhering to regulatory weight limits. This trend is expected to continue, with the global e-commerce market projected to expand significantly in the coming years.

Additionally, the construction and infrastructure sectors contribute significantly to the demand for increased payload capacity. As urbanization accelerates and large-scale infrastructure projects become more common, the need for heavy-duty vehicles capable of transporting heavier loads of materials and equipment has intensified. This is particularly evident in emerging economies where rapid development is taking place.

The agriculture and mining industries also play a crucial role in driving this market demand. These sectors require vehicles that can handle substantial loads of raw materials, crops, and minerals. As global population growth continues to drive demand for food and resources, the need for more efficient transportation solutions in these industries is likely to increase.

Environmental concerns and regulatory pressures are also shaping the market demand for increased payload capacity. Stricter emissions regulations and a push towards sustainability have led to a growing interest in vehicles that can transport more goods with fewer trips, thereby reducing overall carbon emissions. This aligns with the global trend towards greener transportation solutions and has become a significant factor in fleet management decisions.

From a financial perspective, the potential for cost savings through increased payload capacity is substantial. By reducing the number of trips required to transport a given volume of goods, companies can significantly lower their operational costs, including fuel consumption, maintenance expenses, and labor costs. This economic incentive is a powerful driver for businesses to invest in vehicles with higher payload capacities.

Market analysis indicates that the demand for heavy-duty vehicles with increased payload capacity is not limited to a specific region but is a global phenomenon. Developing markets in Asia, Africa, and South America show particularly strong growth potential as their economies expand and infrastructure needs increase. Meanwhile, mature markets in North America and Europe continue to seek innovative solutions to optimize their transportation networks.

One of the key drivers of this demand is the e-commerce boom, which has led to a surge in last-mile deliveries and long-haul transportation. With the rise of online shopping, there is a growing need for vehicles that can carry more goods while maintaining fuel efficiency and adhering to regulatory weight limits. This trend is expected to continue, with the global e-commerce market projected to expand significantly in the coming years.

Additionally, the construction and infrastructure sectors contribute significantly to the demand for increased payload capacity. As urbanization accelerates and large-scale infrastructure projects become more common, the need for heavy-duty vehicles capable of transporting heavier loads of materials and equipment has intensified. This is particularly evident in emerging economies where rapid development is taking place.

The agriculture and mining industries also play a crucial role in driving this market demand. These sectors require vehicles that can handle substantial loads of raw materials, crops, and minerals. As global population growth continues to drive demand for food and resources, the need for more efficient transportation solutions in these industries is likely to increase.

Environmental concerns and regulatory pressures are also shaping the market demand for increased payload capacity. Stricter emissions regulations and a push towards sustainability have led to a growing interest in vehicles that can transport more goods with fewer trips, thereby reducing overall carbon emissions. This aligns with the global trend towards greener transportation solutions and has become a significant factor in fleet management decisions.

From a financial perspective, the potential for cost savings through increased payload capacity is substantial. By reducing the number of trips required to transport a given volume of goods, companies can significantly lower their operational costs, including fuel consumption, maintenance expenses, and labor costs. This economic incentive is a powerful driver for businesses to invest in vehicles with higher payload capacities.

Market analysis indicates that the demand for heavy-duty vehicles with increased payload capacity is not limited to a specific region but is a global phenomenon. Developing markets in Asia, Africa, and South America show particularly strong growth potential as their economies expand and infrastructure needs increase. Meanwhile, mature markets in North America and Europe continue to seek innovative solutions to optimize their transportation networks.

Current State and Challenges in Heavy-Duty Vehicle Engines

The current state of heavy-duty vehicle engines is characterized by a continuous push for improved efficiency, reduced emissions, and increased payload capacity. Traditional diesel engines have long dominated this sector, but they face mounting challenges in meeting stringent environmental regulations and performance demands.

One of the primary challenges is the need to balance power output with fuel efficiency. Heavy-duty vehicles require substantial torque and horsepower to move large loads, but this often comes at the cost of increased fuel consumption. Engine manufacturers are investing heavily in technologies such as advanced fuel injection systems, turbocharging, and exhaust gas recirculation to optimize combustion processes and improve overall efficiency.

Emissions reduction remains a critical challenge for heavy-duty vehicle engines. With tightening regulations worldwide, particularly regarding NOx and particulate matter, engine designers are implementing sophisticated aftertreatment systems. These include selective catalytic reduction (SCR), diesel particulate filters (DPF), and exhaust gas recirculation (EGR) systems. However, these technologies often add weight and complexity to the vehicle, potentially impacting payload capacity.

The pursuit of alternative fuel technologies presents both opportunities and challenges. Natural gas engines, particularly those using liquefied natural gas (LNG), have gained traction in certain markets due to their lower emissions profile. However, challenges persist in terms of infrastructure development and energy density compared to diesel fuel.

Weight reduction is another significant focus area. Engine manufacturers are exploring the use of lightweight materials and compact designs to reduce the overall weight of the powertrain. This effort directly contributes to increasing the vehicle's payload capacity, a key factor in improving operational efficiency for fleet operators.

Durability and reliability remain paramount in heavy-duty applications. Engines must withstand long operating hours under high-stress conditions. This requirement often conflicts with the goals of weight reduction and increased power density, necessitating innovative engineering solutions and advanced materials.

The integration of advanced electronics and control systems is reshaping engine design. Engine control units (ECUs) are becoming more sophisticated, enabling precise management of fuel injection, air intake, and exhaust processes. This trend towards "smart" engines offers improved performance and efficiency but also introduces new complexities in maintenance and diagnostics.

In the context of these challenges, the LM7 engine represents a significant development in heavy-duty vehicle propulsion. Its design aims to address many of the aforementioned issues, particularly in terms of power-to-weight ratio and efficiency. By potentially offering increased power output in a more compact and lighter package, the LM7 engine could play a crucial role in improving payload capacity without compromising on performance or environmental standards.

One of the primary challenges is the need to balance power output with fuel efficiency. Heavy-duty vehicles require substantial torque and horsepower to move large loads, but this often comes at the cost of increased fuel consumption. Engine manufacturers are investing heavily in technologies such as advanced fuel injection systems, turbocharging, and exhaust gas recirculation to optimize combustion processes and improve overall efficiency.

Emissions reduction remains a critical challenge for heavy-duty vehicle engines. With tightening regulations worldwide, particularly regarding NOx and particulate matter, engine designers are implementing sophisticated aftertreatment systems. These include selective catalytic reduction (SCR), diesel particulate filters (DPF), and exhaust gas recirculation (EGR) systems. However, these technologies often add weight and complexity to the vehicle, potentially impacting payload capacity.

The pursuit of alternative fuel technologies presents both opportunities and challenges. Natural gas engines, particularly those using liquefied natural gas (LNG), have gained traction in certain markets due to their lower emissions profile. However, challenges persist in terms of infrastructure development and energy density compared to diesel fuel.

Weight reduction is another significant focus area. Engine manufacturers are exploring the use of lightweight materials and compact designs to reduce the overall weight of the powertrain. This effort directly contributes to increasing the vehicle's payload capacity, a key factor in improving operational efficiency for fleet operators.

Durability and reliability remain paramount in heavy-duty applications. Engines must withstand long operating hours under high-stress conditions. This requirement often conflicts with the goals of weight reduction and increased power density, necessitating innovative engineering solutions and advanced materials.

The integration of advanced electronics and control systems is reshaping engine design. Engine control units (ECUs) are becoming more sophisticated, enabling precise management of fuel injection, air intake, and exhaust processes. This trend towards "smart" engines offers improved performance and efficiency but also introduces new complexities in maintenance and diagnostics.

In the context of these challenges, the LM7 engine represents a significant development in heavy-duty vehicle propulsion. Its design aims to address many of the aforementioned issues, particularly in terms of power-to-weight ratio and efficiency. By potentially offering increased power output in a more compact and lighter package, the LM7 engine could play a crucial role in improving payload capacity without compromising on performance or environmental standards.

Existing Solutions for Payload Capacity Enhancement

01 LM7 engine specifications and performance

The LM7 engine is a V8 engine known for its reliability and performance. It has a displacement of 5.3 liters and is commonly used in various General Motors vehicles. The engine's design allows for a good balance between power output and fuel efficiency, making it suitable for a range of applications including trucks and SUVs.- LM7 engine specifications and performance: The LM7 engine is a V8 engine known for its reliability and performance. It has a displacement of 5.3 liters and is commonly used in various General Motors vehicles. The engine's design allows for a balance between power output and fuel efficiency, making it suitable for a range of applications including trucks and SUVs.

- Payload capacity optimization for LM7-equipped vehicles: Vehicles equipped with the LM7 engine can be optimized for increased payload capacity through various modifications and enhancements. These may include suspension upgrades, chassis reinforcements, and weight distribution improvements. Such optimizations can significantly increase the vehicle's ability to carry heavier loads while maintaining performance and safety.

- Engine management systems for payload optimization: Advanced engine management systems can be implemented to optimize the LM7 engine's performance for varying payload conditions. These systems can adjust fuel injection, timing, and other parameters to ensure optimal power delivery and efficiency across different load scenarios, thereby enhancing the overall payload capacity of the vehicle.

- Transmission and drivetrain enhancements: Improvements in transmission and drivetrain components can contribute to increased payload capacity for LM7-equipped vehicles. This may include upgraded gearboxes, stronger driveshafts, and enhanced differential systems designed to handle higher torque loads and improve power distribution, ultimately allowing for greater payload capacities.

- Aerodynamic considerations for payload efficiency: Aerodynamic modifications can be applied to vehicles with LM7 engines to improve payload efficiency. These changes may include streamlined body designs, air deflectors, and underbody panels that reduce drag and improve stability under heavy load conditions, thereby indirectly increasing the effective payload capacity by enhancing overall vehicle performance.

02 Payload capacity optimization for LM7-equipped vehicles

Vehicles equipped with the LM7 engine can be optimized for increased payload capacity through various modifications and enhancements. These may include suspension upgrades, reinforced chassis components, and advanced weight distribution systems. Such optimizations can significantly improve the vehicle's ability to carry heavier loads while maintaining performance and safety.Expand Specific Solutions03 Engine management systems for payload optimization

Advanced engine management systems can be implemented to optimize the LM7 engine's performance when carrying heavy payloads. These systems can adjust fuel injection, timing, and other parameters to ensure optimal power delivery and efficiency under various load conditions. This results in improved payload capacity without compromising engine longevity or fuel economy.Expand Specific Solutions04 Transmission and drivetrain enhancements

To maximize payload capacity in LM7-equipped vehicles, transmission and drivetrain components can be upgraded. This may include stronger gearboxes, enhanced cooling systems, and reinforced driveshafts. These improvements allow the vehicle to handle increased loads more effectively, distributing power efficiently and reducing strain on the engine.Expand Specific Solutions05 Aerodynamic improvements for payload efficiency

Aerodynamic enhancements can be applied to vehicles with LM7 engines to improve payload capacity and efficiency. These may include redesigned body panels, air deflectors, and underbody treatments. By reducing drag and improving airflow, these modifications can help maintain performance and fuel efficiency even when carrying heavy loads.Expand Specific Solutions

Key Players in Heavy-Duty Vehicle Engine Industry

The LM7 engine's role in improving heavy-duty vehicle payload capacity is situated within a competitive landscape characterized by ongoing technological advancements in the commercial vehicle sector. The market for enhanced payload capacity solutions is expanding, driven by the increasing demand for more efficient transportation and logistics operations. Major players in this field include established manufacturers like Komatsu Ltd., Caterpillar, Inc., and Volvo Construction Equipment AB, who are investing heavily in research and development to improve engine performance and vehicle efficiency. The technology is still evolving, with companies such as Weichai Power and Yanmar Co., Ltd. making significant strides in engine innovation. As the industry progresses, collaboration between engine manufacturers and vehicle producers is becoming increasingly crucial to optimize overall system performance and payload capacity.

Kubota Corp.

Technical Solution: Kubota Corporation has adapted LM7 engine technology for use in a range of heavy-duty vehicles, with a particular focus on agricultural and industrial applications. Their approach to improving payload capacity centers on developing compact, high-output engines that maximize power density. Kubota's LM7 engines feature advanced common rail systems and precise electronic fuel injection control to optimize combustion efficiency[10]. The company has implemented innovative cooling systems and lightweight materials to reduce overall engine weight without compromising durability. Kubota's LM7 engines also incorporate advanced exhaust gas recirculation (EGR) systems and diesel particulate filters (DPF) to meet stringent emissions standards while maintaining performance. The compact design of Kubota's LM7 engines allows for more flexible vehicle layouts, potentially increasing available space for payload[11].

Strengths: Expertise in compact, high-efficiency engines, strong presence in agricultural and industrial markets, and reputation for reliability. Weaknesses: May have limited experience with larger heavy-duty applications compared to some competitors, and potentially narrower range of engine sizes.

Caterpillar, Inc.

Technical Solution: Caterpillar has developed advanced LM7 engine technology for heavy-duty vehicles, focusing on improving payload capacity while maintaining fuel efficiency. Their LM7 engine utilizes a high-pressure common rail fuel system and advanced turbocharging to optimize power output and torque[1]. The engine's compact design allows for better weight distribution, contributing to increased payload capacity. Caterpillar has also implemented advanced materials and manufacturing techniques to reduce the engine's overall weight without compromising durability[2]. The LM7 engine incorporates sophisticated electronic controls and sensors to continuously adjust performance based on load and operating conditions, ensuring optimal efficiency across various applications[3].

Strengths: Industry-leading power-to-weight ratio, advanced electronic control systems, and proven durability. Weaknesses: Potentially higher initial cost compared to simpler engine designs, and may require specialized maintenance.

Core Innovations in LM7 Engine Technology

Engine

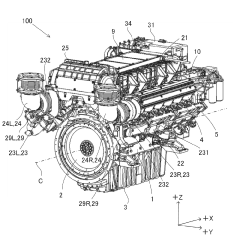

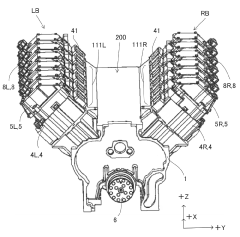

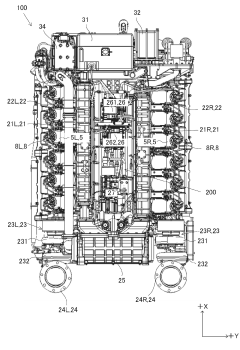

PatentActiveJP2023131944A

Innovation

- A liquid-cooled engine design with a coolant flow path that directs coolant through the exhaust connecting pipe and exhaust manifold, cooling the supercharger by prioritizing the parts prone to high temperatures, such as the exhaust manifold and supercharger, using a compact and efficient coolant flow path configuration.

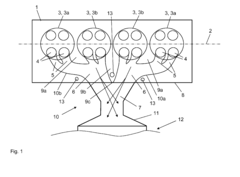

Liquid cooled multi cylinder internal combustion engine and method to operate such an engine

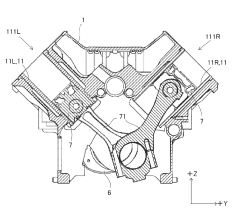

PatentInactiveEP2660452A1

Innovation

- The engine design incorporates a lower and upper coolant jacket with connections between them, adjacent to the exhaust pipes, allowing for both longitudinal and transverse coolant flow to enhance heat dissipation, and the exhaust gas lines are merged within the cylinder head to form partial manifolds before combining outside, reducing the overall exhaust gas system volume and thermal inertia.

Environmental Impact and Emissions Regulations

The introduction of the LM7 engine in heavy-duty vehicles has significant implications for environmental impact and emissions regulations. As governments worldwide tighten emissions standards, the automotive industry faces increasing pressure to develop cleaner and more efficient powertrains. The LM7 engine, with its advanced technology and improved fuel efficiency, plays a crucial role in addressing these environmental concerns while enhancing payload capacity.

One of the primary environmental benefits of the LM7 engine is its reduced fuel consumption. By optimizing combustion processes and incorporating advanced fuel injection systems, the engine achieves better fuel economy compared to its predecessors. This improvement directly translates to lower carbon dioxide emissions, a key greenhouse gas contributing to climate change. The reduced fuel consumption also means fewer emissions of other pollutants, such as nitrogen oxides (NOx) and particulate matter (PM), which are heavily regulated in many countries.

The LM7 engine's design incorporates several features that help meet stringent emissions regulations. Advanced exhaust gas recirculation (EGR) systems and selective catalytic reduction (SCR) technology work in tandem to minimize NOx emissions. Additionally, the engine's improved thermal management and combustion control contribute to lower PM emissions, addressing another critical aspect of emissions regulations.

Furthermore, the LM7 engine's ability to improve payload capacity indirectly contributes to environmental benefits. By allowing heavy-duty vehicles to carry larger loads, it potentially reduces the number of trips required for freight transportation. This efficiency gain can lead to an overall reduction in fleet emissions and fuel consumption on a per-ton-mile basis, aligning with broader sustainability goals in the transportation sector.

However, the implementation of the LM7 engine also presents challenges in meeting evolving emissions standards. As regulations become more stringent, manufacturers must continuously innovate to ensure compliance. This may involve further refinements to the engine's design, integration with hybrid or electric powertrains, or the development of advanced aftertreatment systems. The ongoing evolution of emissions regulations, such as the introduction of real-world driving emissions (RDE) tests, requires engine manufacturers to adapt their technologies to perform optimally across a wide range of operating conditions.

In conclusion, the LM7 engine represents a significant step forward in balancing the need for increased payload capacity with environmental responsibility. Its role in improving heavy-duty vehicle performance while addressing emissions concerns underscores the importance of technological innovation in meeting the dual challenges of economic efficiency and environmental sustainability in the transportation sector.

One of the primary environmental benefits of the LM7 engine is its reduced fuel consumption. By optimizing combustion processes and incorporating advanced fuel injection systems, the engine achieves better fuel economy compared to its predecessors. This improvement directly translates to lower carbon dioxide emissions, a key greenhouse gas contributing to climate change. The reduced fuel consumption also means fewer emissions of other pollutants, such as nitrogen oxides (NOx) and particulate matter (PM), which are heavily regulated in many countries.

The LM7 engine's design incorporates several features that help meet stringent emissions regulations. Advanced exhaust gas recirculation (EGR) systems and selective catalytic reduction (SCR) technology work in tandem to minimize NOx emissions. Additionally, the engine's improved thermal management and combustion control contribute to lower PM emissions, addressing another critical aspect of emissions regulations.

Furthermore, the LM7 engine's ability to improve payload capacity indirectly contributes to environmental benefits. By allowing heavy-duty vehicles to carry larger loads, it potentially reduces the number of trips required for freight transportation. This efficiency gain can lead to an overall reduction in fleet emissions and fuel consumption on a per-ton-mile basis, aligning with broader sustainability goals in the transportation sector.

However, the implementation of the LM7 engine also presents challenges in meeting evolving emissions standards. As regulations become more stringent, manufacturers must continuously innovate to ensure compliance. This may involve further refinements to the engine's design, integration with hybrid or electric powertrains, or the development of advanced aftertreatment systems. The ongoing evolution of emissions regulations, such as the introduction of real-world driving emissions (RDE) tests, requires engine manufacturers to adapt their technologies to perform optimally across a wide range of operating conditions.

In conclusion, the LM7 engine represents a significant step forward in balancing the need for increased payload capacity with environmental responsibility. Its role in improving heavy-duty vehicle performance while addressing emissions concerns underscores the importance of technological innovation in meeting the dual challenges of economic efficiency and environmental sustainability in the transportation sector.

Cost-Benefit Analysis of LM7 Engine Implementation

The implementation of the LM7 engine in heavy-duty vehicles represents a significant investment for fleet operators and manufacturers. To fully understand the financial implications, a comprehensive cost-benefit analysis is essential. This analysis should consider both the immediate expenses and long-term advantages associated with the LM7 engine adoption.

Initial costs include the purchase price of vehicles equipped with LM7 engines or the expense of retrofitting existing vehicles. These upfront investments are typically higher than those for conventional engines due to the advanced technology incorporated in the LM7. However, the increased payload capacity offered by the LM7 engine can potentially offset these costs over time.

Operational expenses form a crucial part of the cost-benefit equation. The LM7 engine's improved fuel efficiency can lead to substantial savings in fuel costs, especially for long-haul operations. Maintenance costs should also be evaluated, considering the engine's durability and potential for reduced wear and tear due to its advanced design.

The increased payload capacity enabled by the LM7 engine directly impacts revenue potential. Vehicles equipped with this engine can transport larger loads, potentially reducing the number of trips required for a given volume of goods. This efficiency can translate into increased profits per journey and improved overall fleet productivity.

Environmental considerations play a role in the cost-benefit analysis as well. The LM7 engine's reduced emissions may result in lower environmental compliance costs and potentially qualify operators for green incentives or tax benefits in certain jurisdictions.

Long-term benefits should be projected over the expected lifespan of the vehicles. This includes factors such as the engine's durability, which may extend the operational life of the vehicle, and its potential resale value. The analysis should also consider the evolving regulatory landscape and how the LM7 engine positions fleet operators for future compliance requirements.

Market competitiveness is another critical factor. The ability to offer increased payload capacity can provide a significant advantage in securing contracts and expanding market share. This potential for business growth should be quantified and included in the overall cost-benefit assessment.

In conclusion, while the initial investment in LM7 engine technology may be substantial, the long-term benefits in terms of operational efficiency, increased revenue potential, and environmental compliance could provide a compelling return on investment for many heavy-duty vehicle operators.

Initial costs include the purchase price of vehicles equipped with LM7 engines or the expense of retrofitting existing vehicles. These upfront investments are typically higher than those for conventional engines due to the advanced technology incorporated in the LM7. However, the increased payload capacity offered by the LM7 engine can potentially offset these costs over time.

Operational expenses form a crucial part of the cost-benefit equation. The LM7 engine's improved fuel efficiency can lead to substantial savings in fuel costs, especially for long-haul operations. Maintenance costs should also be evaluated, considering the engine's durability and potential for reduced wear and tear due to its advanced design.

The increased payload capacity enabled by the LM7 engine directly impacts revenue potential. Vehicles equipped with this engine can transport larger loads, potentially reducing the number of trips required for a given volume of goods. This efficiency can translate into increased profits per journey and improved overall fleet productivity.

Environmental considerations play a role in the cost-benefit analysis as well. The LM7 engine's reduced emissions may result in lower environmental compliance costs and potentially qualify operators for green incentives or tax benefits in certain jurisdictions.

Long-term benefits should be projected over the expected lifespan of the vehicles. This includes factors such as the engine's durability, which may extend the operational life of the vehicle, and its potential resale value. The analysis should also consider the evolving regulatory landscape and how the LM7 engine positions fleet operators for future compliance requirements.

Market competitiveness is another critical factor. The ability to offer increased payload capacity can provide a significant advantage in securing contracts and expanding market share. This potential for business growth should be quantified and included in the overall cost-benefit assessment.

In conclusion, while the initial investment in LM7 engine technology may be substantial, the long-term benefits in terms of operational efficiency, increased revenue potential, and environmental compliance could provide a compelling return on investment for many heavy-duty vehicle operators.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!