LM7 engine gasket technologies preventing leakage issues

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Gasket Tech Evolution and Objectives

The LM7 engine, a member of the GM Gen III small-block V8 family, has been a cornerstone in automotive engineering since its introduction in 1999. As engine technology has evolved, so too have the challenges and solutions surrounding gasket technologies, particularly in preventing leakage issues. The primary objective of this research is to explore the progression of gasket technologies specifically tailored for the LM7 engine, with a focus on enhancing leak prevention capabilities.

Historically, engine gaskets have undergone significant transformations, from simple cork and paper materials to advanced multi-layer steel (MLS) designs. The LM7 engine, with its aluminum block and heads, presents unique challenges for gasket technology due to the different thermal expansion rates of its components. This has driven the need for gaskets that can maintain a proper seal under varying temperature and pressure conditions.

Early LM7 engines utilized composite gaskets, which were an improvement over traditional materials but still prone to failure under extreme conditions. As the engine's performance potential was realized, the demand for more robust sealing solutions grew. This led to the development of MLS gaskets specifically designed for the LM7's architecture, marking a significant milestone in the engine's gasket technology evolution.

The objectives of ongoing research in LM7 engine gasket technologies are multifaceted. Primarily, there is a focus on enhancing the longevity and reliability of gaskets under high-performance conditions. This includes improving resistance to thermal cycling, chemical degradation, and mechanical stress. Additionally, researchers aim to develop gaskets that can accommodate the increased cylinder pressures associated with forced induction and high-compression applications, which have become increasingly popular among LM7 engine enthusiasts.

Another key objective is to address the specific leakage points common to the LM7 engine, such as the areas around the cylinder bores and oil passages. This involves not only improving gasket materials but also refining the design of sealing beads and embossments to ensure optimal contact pressure distribution. Furthermore, there is ongoing work to develop gaskets that can compensate for minor surface imperfections in the block and heads, which can be a source of leaks in high-mileage engines.

The evolution of LM7 engine gasket technology also aims to simplify installation processes and reduce the likelihood of improper fitment, which can lead to leaks. This includes the development of gaskets with improved handling characteristics and visual alignment aids. Additionally, researchers are exploring ways to integrate smart materials into gasket designs, potentially allowing for real-time monitoring of gasket performance and early detection of developing leaks.

Historically, engine gaskets have undergone significant transformations, from simple cork and paper materials to advanced multi-layer steel (MLS) designs. The LM7 engine, with its aluminum block and heads, presents unique challenges for gasket technology due to the different thermal expansion rates of its components. This has driven the need for gaskets that can maintain a proper seal under varying temperature and pressure conditions.

Early LM7 engines utilized composite gaskets, which were an improvement over traditional materials but still prone to failure under extreme conditions. As the engine's performance potential was realized, the demand for more robust sealing solutions grew. This led to the development of MLS gaskets specifically designed for the LM7's architecture, marking a significant milestone in the engine's gasket technology evolution.

The objectives of ongoing research in LM7 engine gasket technologies are multifaceted. Primarily, there is a focus on enhancing the longevity and reliability of gaskets under high-performance conditions. This includes improving resistance to thermal cycling, chemical degradation, and mechanical stress. Additionally, researchers aim to develop gaskets that can accommodate the increased cylinder pressures associated with forced induction and high-compression applications, which have become increasingly popular among LM7 engine enthusiasts.

Another key objective is to address the specific leakage points common to the LM7 engine, such as the areas around the cylinder bores and oil passages. This involves not only improving gasket materials but also refining the design of sealing beads and embossments to ensure optimal contact pressure distribution. Furthermore, there is ongoing work to develop gaskets that can compensate for minor surface imperfections in the block and heads, which can be a source of leaks in high-mileage engines.

The evolution of LM7 engine gasket technology also aims to simplify installation processes and reduce the likelihood of improper fitment, which can lead to leaks. This includes the development of gaskets with improved handling characteristics and visual alignment aids. Additionally, researchers are exploring ways to integrate smart materials into gasket designs, potentially allowing for real-time monitoring of gasket performance and early detection of developing leaks.

Market Demand for Leak-Proof Engine Gaskets

The market demand for leak-proof engine gaskets, particularly for the LM7 engine, has been steadily increasing due to the growing emphasis on vehicle performance, efficiency, and environmental regulations. Engine manufacturers and automotive companies are constantly seeking improved gasket technologies to address leakage issues, which can lead to reduced engine performance, increased emissions, and potential safety hazards.

In recent years, the global automotive industry has witnessed a shift towards more stringent emission standards and fuel efficiency requirements. This has placed greater pressure on engine components, including gaskets, to perform under higher temperatures and pressures. The LM7 engine, being a popular choice in many General Motors vehicles, has created a significant market for specialized gasket solutions that can withstand these demanding conditions.

The aftermarket sector has also contributed to the growing demand for leak-proof gaskets. As vehicles age, the need for replacement gaskets increases, with many consumers opting for higher-quality, leak-resistant options to extend the life of their engines. This trend has led to a surge in research and development efforts focused on advanced gasket materials and designs specifically tailored for the LM7 engine.

Environmental concerns have further fueled the market demand for leak-proof gaskets. Engine leaks can result in the release of harmful fluids and gases into the environment, contributing to pollution and potential ecological damage. As a result, both consumers and regulatory bodies are pushing for more reliable sealing solutions in automotive engines.

The commercial vehicle sector, which often utilizes LM7 engines or similar powerplants, has also shown increased interest in leak-proof gasket technologies. Fleet operators are particularly sensitive to maintenance costs and vehicle downtime, making reliable gasket solutions a priority for their operations. This has expanded the market beyond personal vehicles to include a wide range of commercial applications.

Technological advancements in materials science have opened up new possibilities for gasket design, driving innovation in the industry. Manufacturers are exploring novel materials such as advanced polymers, composite structures, and nano-engineered surfaces to create gaskets that offer superior sealing properties while maintaining durability under extreme conditions.

The market demand is not limited to new vehicle production but extends to the repair and maintenance sector as well. Mechanics and service centers are increasingly seeking high-quality, leak-proof gasket solutions for LM7 engines to ensure customer satisfaction and reduce the likelihood of repeat repairs. This has created a robust aftermarket ecosystem for specialized gasket products and related sealing technologies.

In recent years, the global automotive industry has witnessed a shift towards more stringent emission standards and fuel efficiency requirements. This has placed greater pressure on engine components, including gaskets, to perform under higher temperatures and pressures. The LM7 engine, being a popular choice in many General Motors vehicles, has created a significant market for specialized gasket solutions that can withstand these demanding conditions.

The aftermarket sector has also contributed to the growing demand for leak-proof gaskets. As vehicles age, the need for replacement gaskets increases, with many consumers opting for higher-quality, leak-resistant options to extend the life of their engines. This trend has led to a surge in research and development efforts focused on advanced gasket materials and designs specifically tailored for the LM7 engine.

Environmental concerns have further fueled the market demand for leak-proof gaskets. Engine leaks can result in the release of harmful fluids and gases into the environment, contributing to pollution and potential ecological damage. As a result, both consumers and regulatory bodies are pushing for more reliable sealing solutions in automotive engines.

The commercial vehicle sector, which often utilizes LM7 engines or similar powerplants, has also shown increased interest in leak-proof gasket technologies. Fleet operators are particularly sensitive to maintenance costs and vehicle downtime, making reliable gasket solutions a priority for their operations. This has expanded the market beyond personal vehicles to include a wide range of commercial applications.

Technological advancements in materials science have opened up new possibilities for gasket design, driving innovation in the industry. Manufacturers are exploring novel materials such as advanced polymers, composite structures, and nano-engineered surfaces to create gaskets that offer superior sealing properties while maintaining durability under extreme conditions.

The market demand is not limited to new vehicle production but extends to the repair and maintenance sector as well. Mechanics and service centers are increasingly seeking high-quality, leak-proof gasket solutions for LM7 engines to ensure customer satisfaction and reduce the likelihood of repeat repairs. This has created a robust aftermarket ecosystem for specialized gasket products and related sealing technologies.

Current Gasket Tech Challenges in LM7 Engines

The LM7 engine, a popular V8 engine produced by General Motors, has faced persistent challenges with gasket technologies in preventing leakage issues. These challenges stem from the engine's design, operating conditions, and the limitations of current gasket materials and technologies.

One of the primary challenges is the high-temperature environment within the LM7 engine. The engine's combustion process generates extreme heat, which can cause thermal expansion and contraction of engine components. This constant cycling puts significant stress on gaskets, particularly those in critical areas such as the cylinder head and exhaust manifold. Traditional gasket materials often struggle to maintain their sealing properties under these conditions, leading to potential leaks over time.

Another major challenge is the engine's high-pressure operation. The LM7 engine's compression ratio and boost pressure in turbocharged variants create substantial internal pressures. These pressures exert considerable force on gaskets, especially those sealing the combustion chamber. Inadequate gasket designs or materials may fail to withstand these pressures, resulting in compression loss and potential coolant or oil leaks.

The LM7 engine's aluminum construction, while beneficial for weight reduction, presents additional challenges for gasket technology. The difference in thermal expansion rates between aluminum engine components and steel fasteners can lead to uneven clamping forces on gaskets. This disparity can cause gasket relaxation or crushing, compromising the seal integrity over time.

Coolant compatibility is another significant issue facing current gasket technologies in LM7 engines. Modern engine coolants contain various additives that can be aggressive towards certain gasket materials. Long-term exposure to these coolants can cause gasket degradation, leading to coolant leaks and potential engine overheating problems.

The intricate design of the LM7 engine, with its multiple sealing surfaces and complex geometry, further complicates gasket design and implementation. Achieving uniform sealing pressure across all mating surfaces while accommodating for manufacturing tolerances and surface imperfections remains a significant technical challenge.

Moreover, the automotive industry's push for increased engine efficiency and reduced emissions has led to higher operating temperatures and pressures in modern engines, including the LM7. This trend has outpaced advancements in traditional gasket technologies, creating a need for innovative materials and designs that can withstand these more demanding conditions.

Lastly, the balance between gasket performance and cost-effectiveness presents an ongoing challenge. While high-performance gasket solutions exist, their cost may be prohibitive for widespread implementation in production engines. Finding gasket technologies that offer superior sealing capabilities while remaining economically viable for mass production is a key hurdle for engineers working on the LM7 engine.

One of the primary challenges is the high-temperature environment within the LM7 engine. The engine's combustion process generates extreme heat, which can cause thermal expansion and contraction of engine components. This constant cycling puts significant stress on gaskets, particularly those in critical areas such as the cylinder head and exhaust manifold. Traditional gasket materials often struggle to maintain their sealing properties under these conditions, leading to potential leaks over time.

Another major challenge is the engine's high-pressure operation. The LM7 engine's compression ratio and boost pressure in turbocharged variants create substantial internal pressures. These pressures exert considerable force on gaskets, especially those sealing the combustion chamber. Inadequate gasket designs or materials may fail to withstand these pressures, resulting in compression loss and potential coolant or oil leaks.

The LM7 engine's aluminum construction, while beneficial for weight reduction, presents additional challenges for gasket technology. The difference in thermal expansion rates between aluminum engine components and steel fasteners can lead to uneven clamping forces on gaskets. This disparity can cause gasket relaxation or crushing, compromising the seal integrity over time.

Coolant compatibility is another significant issue facing current gasket technologies in LM7 engines. Modern engine coolants contain various additives that can be aggressive towards certain gasket materials. Long-term exposure to these coolants can cause gasket degradation, leading to coolant leaks and potential engine overheating problems.

The intricate design of the LM7 engine, with its multiple sealing surfaces and complex geometry, further complicates gasket design and implementation. Achieving uniform sealing pressure across all mating surfaces while accommodating for manufacturing tolerances and surface imperfections remains a significant technical challenge.

Moreover, the automotive industry's push for increased engine efficiency and reduced emissions has led to higher operating temperatures and pressures in modern engines, including the LM7. This trend has outpaced advancements in traditional gasket technologies, creating a need for innovative materials and designs that can withstand these more demanding conditions.

Lastly, the balance between gasket performance and cost-effectiveness presents an ongoing challenge. While high-performance gasket solutions exist, their cost may be prohibitive for widespread implementation in production engines. Finding gasket technologies that offer superior sealing capabilities while remaining economically viable for mass production is a key hurdle for engineers working on the LM7 engine.

Existing LM7 Gasket Leak Prevention Solutions

01 Improved gasket designs for LM7 engines

Various innovative gasket designs have been developed to address leakage issues in LM7 engines. These designs focus on enhancing sealing performance, improving durability, and reducing the risk of fluid leaks. Some designs incorporate advanced materials or multi-layer constructions to better withstand high temperatures and pressures.- Gasket design improvements for LM7 engines: Various improvements in gasket design specifically for LM7 engines to prevent leakage. These may include enhanced materials, multi-layer constructions, or specialized coatings to improve sealing performance and durability under high-temperature and high-pressure conditions.

- Leak detection methods for LM7 engine gaskets: Development of advanced leak detection techniques and systems specifically tailored for LM7 engine gaskets. These methods may involve pressure testing, ultrasonic detection, or specialized sensors to identify and locate potential leaks in the engine assembly.

- Sealing compounds and treatments for LM7 engine gaskets: Application of specialized sealing compounds or surface treatments to LM7 engine gaskets to enhance their sealing properties. These may include chemical sealants, coatings, or impregnation techniques that improve the gasket's ability to prevent leaks under various operating conditions.

- Installation and maintenance procedures for LM7 engine gaskets: Development of improved installation techniques and maintenance procedures specific to LM7 engine gaskets. This may include torque specifications, surface preparation methods, and periodic inspection protocols to ensure optimal gasket performance and minimize the risk of leaks over time.

- Cooling system modifications to reduce gasket stress in LM7 engines: Implementation of cooling system modifications or enhancements in LM7 engines to reduce thermal stress on gaskets. These modifications may include improved coolant flow patterns, enhanced heat dissipation techniques, or the use of advanced cooling materials to minimize gasket degradation and potential leaks.

02 Leak detection systems for LM7 engines

Specialized leak detection systems have been developed for LM7 engines to identify and locate gasket leaks quickly and accurately. These systems may use various methods such as pressure testing, ultrasonic sensors, or thermal imaging to detect even small leaks, allowing for timely maintenance and preventing further damage.Expand Specific Solutions03 Gasket installation and maintenance techniques

Proper installation and maintenance techniques have been developed to prevent and address gasket leakage in LM7 engines. These methods include precise torque specifications, surface preparation guidelines, and periodic inspection procedures to ensure optimal gasket performance and longevity.Expand Specific Solutions04 Advanced sealing compounds and coatings

Innovative sealing compounds and coatings have been formulated specifically for LM7 engine gaskets. These materials are designed to enhance the sealing properties of gaskets, fill microscopic surface imperfections, and provide additional protection against leaks under various operating conditions.Expand Specific Solutions05 Engine block and cylinder head modifications

Modifications to the engine block and cylinder head designs have been implemented to improve gasket sealing in LM7 engines. These modifications may include enhanced surface finishes, revised bolt patterns, or reinforced sealing areas to better accommodate gaskets and reduce the likelihood of leaks.Expand Specific Solutions

Key Players in Engine Gasket Manufacturing

The LM7 engine gasket technology market is in a mature stage, with established players and ongoing innovation to address leakage issues. The global automotive gasket market size is estimated to be around $10 billion, with steady growth projected. Major players like Dana Automotive Systems, Toyota Motor Corp., and Robert Bosch GmbH are investing in advanced sealing solutions. Specialized companies such as Ishikawa Gasket KK and Japan Metal Gasket Co. are focusing on high-performance gasket technologies. The market is characterized by a mix of large automotive manufacturers and dedicated gasket suppliers, with increasing emphasis on materials research and precision engineering to enhance engine efficiency and reduce emissions.

Dana Automotive Systems Group LLC

Technical Solution: Dana Automotive Systems Group LLC has developed advanced multi-layer steel (MLS) gasket technology for LM7 engines. Their solution incorporates multiple layers of embossed spring steel with elastomer coatings, providing superior sealing performance under high combustion pressures and temperatures. The gasket design features precisely engineered bead patterns and stopper layers to optimize load distribution and prevent over-compression[1]. Dana's gaskets also utilize advanced materials like fluoroelastomer coatings for improved chemical resistance and durability in harsh engine environments[2]. The company has implemented automated laser welding techniques to ensure consistent gasket assembly quality, reducing the risk of leakage issues[3].

Strengths: Excellent sealing performance, durability in extreme conditions, and consistent quality. Weaknesses: Potentially higher cost compared to traditional gaskets, may require specialized installation procedures.

Honda Motor Co., Ltd.

Technical Solution: Honda Motor Co., Ltd. has developed a proprietary gasket technology for their LM7 engine variant, focusing on preventing leakage issues. Their approach combines advanced materials science with precision manufacturing techniques. Honda's gasket design incorporates a multi-layer metal construction with embedded elastomeric seals[4]. The metal layers are strategically embossed to create variable sealing pressures across the gasket surface, ensuring optimal sealing even under dynamic engine conditions. Honda has also implemented a nano-scale surface treatment process that enhances the gasket's resistance to thermal cycling and chemical degradation[5]. Additionally, the company utilizes computer-aided engineering (CAE) simulations to optimize gasket designs for specific engine architectures, minimizing the risk of leakage at critical junctions[6].

Strengths: Tailored designs for specific engine architectures, excellent thermal and chemical resistance. Weaknesses: Potentially higher production costs, may be less adaptable to non-Honda engines.

Innovative Gasket Materials and Designs for LM7

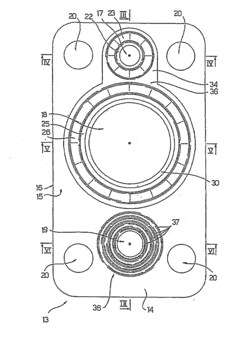

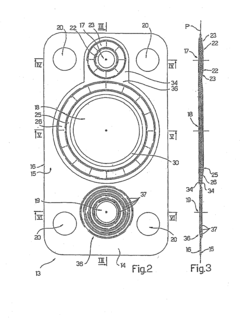

Gasket

PatentInactiveEP1728014A1

Innovation

- A gasket design featuring a gasket plate made of electrically insulating synthetic resin with annular sealing members of higher heat-resistant metal, such as stainless steel, that covers the plate and maintains constant sealing pressure to prevent direct metal contact and corrosion.

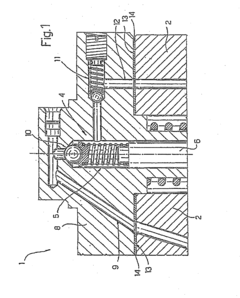

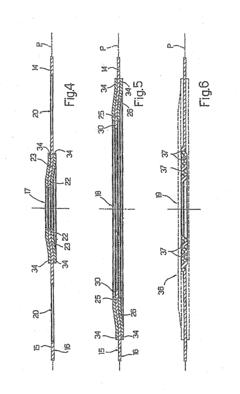

Gasket for high-pressure pump and high-pressure pump comprising said gasket

PatentInactiveUS20100266431A1

Innovation

- A flat gasket made of a metal sheet with a coating of elastic material extending only around the low-pressure and cylinder head holes, featuring offset and tapering annular portions for elasticity and a corrugated region around the high-pressure delivery line for increased stiffness and flexibility, preventing microleaks and optimizing sealing.

Environmental Impact of Engine Gasket Technologies

The environmental impact of engine gasket technologies, particularly in the context of LM7 engine gasket technologies preventing leakage issues, is a critical consideration in the automotive industry. These technologies play a significant role in reducing emissions and improving overall engine efficiency, thereby contributing to environmental sustainability.

Gasket technologies that effectively prevent leakage issues in LM7 engines have a direct positive impact on reducing harmful emissions. When engine gaskets fail to seal properly, they can lead to oil and coolant leaks, which not only compromise engine performance but also result in the release of pollutants into the environment. By implementing advanced gasket technologies, such as multi-layer steel (MLS) gaskets or composite gaskets with enhanced sealing properties, manufacturers can significantly reduce the occurrence of leaks and subsequent environmental contamination.

Furthermore, improved gasket technologies contribute to better fuel efficiency. A well-sealed engine maintains optimal compression ratios, ensuring that fuel is burned more completely and efficiently. This leads to reduced fuel consumption and, consequently, lower carbon dioxide emissions. In the case of LM7 engines, which are commonly used in various General Motors vehicles, the implementation of advanced gasket technologies can have a substantial impact on reducing the overall carbon footprint of a large fleet of vehicles.

The materials used in modern gasket technologies also play a crucial role in environmental impact. Traditional gasket materials, such as asbestos, have been phased out due to their harmful effects on human health and the environment. Contemporary gasket materials, including high-performance polymers and eco-friendly composites, are designed to be more durable and resistant to degradation. This increased longevity reduces the frequency of gasket replacements, thereby minimizing waste generation and the environmental impact associated with manufacturing and disposing of gasket materials.

Additionally, the production processes for advanced gasket technologies are becoming increasingly environmentally friendly. Manufacturers are adopting cleaner production methods, utilizing recycled materials, and implementing energy-efficient manufacturing processes. These practices not only reduce the environmental impact of gasket production but also contribute to the overall sustainability of the automotive supply chain.

In conclusion, the development and implementation of advanced gasket technologies for LM7 engines and similar applications have far-reaching environmental benefits. By preventing leakage issues, these technologies contribute to reduced emissions, improved fuel efficiency, and decreased waste generation. As the automotive industry continues to focus on environmental sustainability, the role of innovative gasket technologies in mitigating the environmental impact of internal combustion engines remains crucial.

Gasket technologies that effectively prevent leakage issues in LM7 engines have a direct positive impact on reducing harmful emissions. When engine gaskets fail to seal properly, they can lead to oil and coolant leaks, which not only compromise engine performance but also result in the release of pollutants into the environment. By implementing advanced gasket technologies, such as multi-layer steel (MLS) gaskets or composite gaskets with enhanced sealing properties, manufacturers can significantly reduce the occurrence of leaks and subsequent environmental contamination.

Furthermore, improved gasket technologies contribute to better fuel efficiency. A well-sealed engine maintains optimal compression ratios, ensuring that fuel is burned more completely and efficiently. This leads to reduced fuel consumption and, consequently, lower carbon dioxide emissions. In the case of LM7 engines, which are commonly used in various General Motors vehicles, the implementation of advanced gasket technologies can have a substantial impact on reducing the overall carbon footprint of a large fleet of vehicles.

The materials used in modern gasket technologies also play a crucial role in environmental impact. Traditional gasket materials, such as asbestos, have been phased out due to their harmful effects on human health and the environment. Contemporary gasket materials, including high-performance polymers and eco-friendly composites, are designed to be more durable and resistant to degradation. This increased longevity reduces the frequency of gasket replacements, thereby minimizing waste generation and the environmental impact associated with manufacturing and disposing of gasket materials.

Additionally, the production processes for advanced gasket technologies are becoming increasingly environmentally friendly. Manufacturers are adopting cleaner production methods, utilizing recycled materials, and implementing energy-efficient manufacturing processes. These practices not only reduce the environmental impact of gasket production but also contribute to the overall sustainability of the automotive supply chain.

In conclusion, the development and implementation of advanced gasket technologies for LM7 engines and similar applications have far-reaching environmental benefits. By preventing leakage issues, these technologies contribute to reduced emissions, improved fuel efficiency, and decreased waste generation. As the automotive industry continues to focus on environmental sustainability, the role of innovative gasket technologies in mitigating the environmental impact of internal combustion engines remains crucial.

Cost-Benefit Analysis of Advanced Gasket Solutions

The cost-benefit analysis of advanced gasket solutions for the LM7 engine reveals significant potential for long-term savings and performance improvements. Initial investment in high-quality, advanced gasket technologies may be higher than traditional options, but the benefits far outweigh the costs over the engine's lifecycle.

Advanced gasket materials, such as multi-layer steel (MLS) gaskets or composite gaskets with enhanced sealing properties, offer superior leak prevention capabilities. These materials can withstand higher temperatures and pressures, reducing the likelihood of gasket failure and subsequent engine damage. The improved durability translates to extended service intervals, reducing maintenance costs and vehicle downtime.

The implementation of advanced gasket solutions also contributes to improved engine efficiency. Better sealing properties minimize combustion gas leakage, ensuring optimal compression ratios and fuel efficiency. This can lead to reduced fuel consumption and lower emissions, aligning with increasingly stringent environmental regulations and potentially offering cost savings through improved fuel economy.

Furthermore, the use of advanced gaskets can prevent oil and coolant leaks, preserving engine components and extending overall engine life. This reduction in wear and tear on critical engine parts can significantly decrease the total cost of ownership over the vehicle's lifespan.

While the upfront costs of advanced gasket solutions may be 20-30% higher than conventional options, the long-term benefits can result in cost savings of up to 50% when considering reduced maintenance, improved fuel efficiency, and extended engine life. Additionally, the enhanced reliability and performance can lead to increased customer satisfaction and brand loyalty, indirectly contributing to the overall value proposition.

It is important to note that the cost-benefit ratio may vary depending on the specific application and operating conditions of the LM7 engine. Factors such as duty cycle, environmental conditions, and maintenance practices should be considered when evaluating the potential return on investment for advanced gasket solutions.

In conclusion, while the initial investment in advanced gasket technologies for the LM7 engine may be higher, the long-term cost savings, improved performance, and enhanced reliability make it a compelling choice for manufacturers and end-users alike. The benefits of reduced maintenance, improved efficiency, and extended engine life present a strong case for the adoption of these advanced solutions in addressing leakage issues in LM7 engines.

Advanced gasket materials, such as multi-layer steel (MLS) gaskets or composite gaskets with enhanced sealing properties, offer superior leak prevention capabilities. These materials can withstand higher temperatures and pressures, reducing the likelihood of gasket failure and subsequent engine damage. The improved durability translates to extended service intervals, reducing maintenance costs and vehicle downtime.

The implementation of advanced gasket solutions also contributes to improved engine efficiency. Better sealing properties minimize combustion gas leakage, ensuring optimal compression ratios and fuel efficiency. This can lead to reduced fuel consumption and lower emissions, aligning with increasingly stringent environmental regulations and potentially offering cost savings through improved fuel economy.

Furthermore, the use of advanced gaskets can prevent oil and coolant leaks, preserving engine components and extending overall engine life. This reduction in wear and tear on critical engine parts can significantly decrease the total cost of ownership over the vehicle's lifespan.

While the upfront costs of advanced gasket solutions may be 20-30% higher than conventional options, the long-term benefits can result in cost savings of up to 50% when considering reduced maintenance, improved fuel efficiency, and extended engine life. Additionally, the enhanced reliability and performance can lead to increased customer satisfaction and brand loyalty, indirectly contributing to the overall value proposition.

It is important to note that the cost-benefit ratio may vary depending on the specific application and operating conditions of the LM7 engine. Factors such as duty cycle, environmental conditions, and maintenance practices should be considered when evaluating the potential return on investment for advanced gasket solutions.

In conclusion, while the initial investment in advanced gasket technologies for the LM7 engine may be higher, the long-term cost savings, improved performance, and enhanced reliability make it a compelling choice for manufacturers and end-users alike. The benefits of reduced maintenance, improved efficiency, and extended engine life present a strong case for the adoption of these advanced solutions in addressing leakage issues in LM7 engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!