LM7 engine computational design optimization techniques

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Design Evolution

The LM7 engine design has undergone significant evolution since its inception, driven by advancements in computational design optimization techniques. Initially developed as a successor to the LS series, the LM7 engine has seen continuous improvements in performance, efficiency, and reliability through iterative design processes.

In its early stages, the LM7 engine design relied heavily on traditional engineering methods, with limited use of computational tools. As computational power increased and simulation software became more sophisticated, engineers began incorporating basic finite element analysis (FEA) to optimize critical components such as the engine block and cylinder heads.

The next phase of evolution saw the introduction of more advanced computational fluid dynamics (CFD) simulations. These tools allowed engineers to model and optimize the engine's intake and exhaust systems, improving airflow characteristics and enhancing overall engine performance. CFD simulations also played a crucial role in refining combustion chamber designs, leading to more efficient fuel burning and reduced emissions.

As optimization techniques matured, multi-objective optimization algorithms were integrated into the design process. These algorithms enabled engineers to simultaneously consider multiple performance parameters, such as power output, fuel efficiency, and emissions, leading to more balanced and refined engine designs.

The advent of machine learning and artificial intelligence marked a significant leap in LM7 engine design optimization. These technologies allowed for rapid exploration of vast design spaces, identifying novel solutions that might have been overlooked by traditional methods. Genetic algorithms and neural networks were employed to evolve engine designs, iteratively improving performance metrics across generations of virtual prototypes.

Recent advancements in the LM7 engine design process have focused on integrating real-world data with computational models. By incorporating data from engine dynamometer tests and on-road performance metrics, engineers have been able to refine their simulation models, ensuring closer alignment between virtual predictions and real-world performance.

The latest iteration of LM7 engine design optimization techniques involves the use of digital twins. These virtual replicas of physical engines allow for continuous monitoring and optimization throughout the engine's lifecycle. By analyzing data from sensors embedded in production engines, engineers can identify areas for improvement and implement updates through over-the-air software modifications, ensuring that the LM7 engine continues to evolve even after leaving the factory.

In its early stages, the LM7 engine design relied heavily on traditional engineering methods, with limited use of computational tools. As computational power increased and simulation software became more sophisticated, engineers began incorporating basic finite element analysis (FEA) to optimize critical components such as the engine block and cylinder heads.

The next phase of evolution saw the introduction of more advanced computational fluid dynamics (CFD) simulations. These tools allowed engineers to model and optimize the engine's intake and exhaust systems, improving airflow characteristics and enhancing overall engine performance. CFD simulations also played a crucial role in refining combustion chamber designs, leading to more efficient fuel burning and reduced emissions.

As optimization techniques matured, multi-objective optimization algorithms were integrated into the design process. These algorithms enabled engineers to simultaneously consider multiple performance parameters, such as power output, fuel efficiency, and emissions, leading to more balanced and refined engine designs.

The advent of machine learning and artificial intelligence marked a significant leap in LM7 engine design optimization. These technologies allowed for rapid exploration of vast design spaces, identifying novel solutions that might have been overlooked by traditional methods. Genetic algorithms and neural networks were employed to evolve engine designs, iteratively improving performance metrics across generations of virtual prototypes.

Recent advancements in the LM7 engine design process have focused on integrating real-world data with computational models. By incorporating data from engine dynamometer tests and on-road performance metrics, engineers have been able to refine their simulation models, ensuring closer alignment between virtual predictions and real-world performance.

The latest iteration of LM7 engine design optimization techniques involves the use of digital twins. These virtual replicas of physical engines allow for continuous monitoring and optimization throughout the engine's lifecycle. By analyzing data from sensors embedded in production engines, engineers can identify areas for improvement and implement updates through over-the-air software modifications, ensuring that the LM7 engine continues to evolve even after leaving the factory.

Market Demand Analysis

The market demand for LM7 engine computational design optimization techniques has been steadily increasing in recent years, driven by the automotive industry's push for more efficient and environmentally friendly engines. As emission regulations become stricter worldwide, manufacturers are seeking advanced computational methods to optimize engine designs, reduce fuel consumption, and minimize emissions.

The global automotive engine market is projected to grow significantly, with a particular focus on advanced engine technologies. This growth directly correlates with the demand for sophisticated computational design optimization techniques for engines like the LM7. The market for these optimization tools is expected to expand as automotive companies invest heavily in research and development to maintain competitiveness and meet regulatory requirements.

In the United States, where the LM7 engine has been widely used in General Motors vehicles, there is a strong demand for optimization techniques to improve its performance and efficiency. This demand extends to aftermarket tuning and modification sectors, where enthusiasts and performance shops seek ways to enhance the LM7's capabilities while maintaining reliability and emissions compliance.

The trucking and commercial vehicle sectors also contribute significantly to the market demand for LM7 engine optimization techniques. Fleet operators are increasingly focused on reducing fuel costs and improving engine longevity, creating a substantial market for computational tools that can achieve these goals.

Furthermore, the rise of electric and hybrid vehicles has not diminished the demand for advanced combustion engine optimization. Instead, it has intensified the need for more efficient internal combustion engines to remain competitive, driving further interest in computational design optimization for engines like the LM7.

The academic and research sectors represent another significant market for these optimization techniques. Universities and research institutions are actively pursuing advanced computational methods for engine design, creating a demand for sophisticated software tools and expertise in this field.

Geographically, while North America remains a key market due to the LM7's prevalence in GM vehicles, there is growing interest from emerging automotive markets in Asia and South America. These regions are seeking to develop their own engine technologies and are looking to adopt advanced computational techniques to accelerate their progress.

The market for LM7 engine computational design optimization techniques is also being shaped by the broader trend towards digital transformation in the automotive industry. As manufacturers embrace concepts like digital twins and virtual testing, the demand for advanced computational tools for engine optimization is expected to grow further.

The global automotive engine market is projected to grow significantly, with a particular focus on advanced engine technologies. This growth directly correlates with the demand for sophisticated computational design optimization techniques for engines like the LM7. The market for these optimization tools is expected to expand as automotive companies invest heavily in research and development to maintain competitiveness and meet regulatory requirements.

In the United States, where the LM7 engine has been widely used in General Motors vehicles, there is a strong demand for optimization techniques to improve its performance and efficiency. This demand extends to aftermarket tuning and modification sectors, where enthusiasts and performance shops seek ways to enhance the LM7's capabilities while maintaining reliability and emissions compliance.

The trucking and commercial vehicle sectors also contribute significantly to the market demand for LM7 engine optimization techniques. Fleet operators are increasingly focused on reducing fuel costs and improving engine longevity, creating a substantial market for computational tools that can achieve these goals.

Furthermore, the rise of electric and hybrid vehicles has not diminished the demand for advanced combustion engine optimization. Instead, it has intensified the need for more efficient internal combustion engines to remain competitive, driving further interest in computational design optimization for engines like the LM7.

The academic and research sectors represent another significant market for these optimization techniques. Universities and research institutions are actively pursuing advanced computational methods for engine design, creating a demand for sophisticated software tools and expertise in this field.

Geographically, while North America remains a key market due to the LM7's prevalence in GM vehicles, there is growing interest from emerging automotive markets in Asia and South America. These regions are seeking to develop their own engine technologies and are looking to adopt advanced computational techniques to accelerate their progress.

The market for LM7 engine computational design optimization techniques is also being shaped by the broader trend towards digital transformation in the automotive industry. As manufacturers embrace concepts like digital twins and virtual testing, the demand for advanced computational tools for engine optimization is expected to grow further.

Current Optimization Challenges

The optimization of LM7 engine computational design faces several significant challenges in the current landscape. One of the primary obstacles is the complexity of the engine system, which involves numerous interrelated components and parameters. This complexity makes it difficult to accurately model and simulate the engine's behavior, leading to potential inaccuracies in optimization results.

Another major challenge is the computational cost associated with high-fidelity simulations. As engine designs become more sophisticated, the demand for more detailed and accurate simulations increases. However, these simulations often require substantial computational resources and time, which can slow down the optimization process and limit the number of design iterations that can be explored.

The multi-objective nature of engine design optimization also presents a significant hurdle. Engineers must balance various performance metrics such as fuel efficiency, power output, emissions, and durability. These objectives are often conflicting, making it challenging to find optimal solutions that satisfy all criteria simultaneously.

Data management and integration pose additional challenges in the optimization process. The vast amount of data generated during simulations and testing needs to be effectively stored, processed, and analyzed. Integrating data from various sources, including experimental results and historical designs, into the optimization workflow can be complex and time-consuming.

The selection of appropriate optimization algorithms is another critical challenge. Different algorithms may be more suitable for specific aspects of engine design, and choosing the right combination of methods to address various optimization problems can be difficult. Additionally, many traditional optimization techniques may struggle with the high-dimensional design spaces typical in engine optimization.

Uncertainty quantification and robust design optimization represent emerging challenges in the field. Accounting for manufacturing tolerances, material properties variations, and operating condition fluctuations in the optimization process is crucial for developing reliable engine designs. However, incorporating these uncertainties into the optimization framework adds another layer of complexity to an already demanding process.

Lastly, the need for rapid design iterations to meet market demands and regulatory requirements puts pressure on the optimization process. Balancing the trade-off between optimization accuracy and speed is an ongoing challenge, as engineers strive to deliver improved designs within increasingly tight development timelines.

Another major challenge is the computational cost associated with high-fidelity simulations. As engine designs become more sophisticated, the demand for more detailed and accurate simulations increases. However, these simulations often require substantial computational resources and time, which can slow down the optimization process and limit the number of design iterations that can be explored.

The multi-objective nature of engine design optimization also presents a significant hurdle. Engineers must balance various performance metrics such as fuel efficiency, power output, emissions, and durability. These objectives are often conflicting, making it challenging to find optimal solutions that satisfy all criteria simultaneously.

Data management and integration pose additional challenges in the optimization process. The vast amount of data generated during simulations and testing needs to be effectively stored, processed, and analyzed. Integrating data from various sources, including experimental results and historical designs, into the optimization workflow can be complex and time-consuming.

The selection of appropriate optimization algorithms is another critical challenge. Different algorithms may be more suitable for specific aspects of engine design, and choosing the right combination of methods to address various optimization problems can be difficult. Additionally, many traditional optimization techniques may struggle with the high-dimensional design spaces typical in engine optimization.

Uncertainty quantification and robust design optimization represent emerging challenges in the field. Accounting for manufacturing tolerances, material properties variations, and operating condition fluctuations in the optimization process is crucial for developing reliable engine designs. However, incorporating these uncertainties into the optimization framework adds another layer of complexity to an already demanding process.

Lastly, the need for rapid design iterations to meet market demands and regulatory requirements puts pressure on the optimization process. Balancing the trade-off between optimization accuracy and speed is an ongoing challenge, as engineers strive to deliver improved designs within increasingly tight development timelines.

Existing Optimization Methods

01 Combustion chamber optimization

Optimizing the combustion chamber design of the LM7 engine to improve fuel efficiency and power output. This includes refining the shape, size, and positioning of components within the chamber to enhance fuel mixture and combustion processes.- Combustion chamber optimization: Optimizing the combustion chamber design of the LM7 engine to improve fuel efficiency and power output. This includes refining the shape, size, and positioning of components within the chamber to enhance fuel mixture and combustion processes.

- Intake and exhaust system improvements: Enhancing the intake and exhaust systems of the LM7 engine to optimize airflow and exhaust gas management. This involves redesigning manifolds, valves, and ports to reduce restrictions and improve overall engine performance.

- Advanced materials integration: Incorporating advanced materials in the LM7 engine design to reduce weight, improve heat dissipation, and enhance durability. This includes the use of lightweight alloys and composite materials for various engine components.

- Fuel injection system optimization: Refining the fuel injection system of the LM7 engine to improve fuel atomization, distribution, and timing. This involves enhancing injector design, fuel pressure control, and electronic management systems for more precise fuel delivery.

- Thermal management enhancements: Improving the thermal management system of the LM7 engine to optimize operating temperatures and enhance overall efficiency. This includes redesigning cooling channels, implementing advanced heat exchangers, and optimizing coolant flow patterns.

02 Intake and exhaust system improvements

Enhancing the intake and exhaust systems of the LM7 engine to optimize airflow and exhaust gas management. This involves redesigning manifolds, valves, and ports to reduce restrictions and improve overall engine performance.Expand Specific Solutions03 Thermal management enhancements

Implementing advanced thermal management techniques to optimize the LM7 engine's operating temperature. This includes improving cooling systems, heat dissipation methods, and materials selection to enhance efficiency and longevity.Expand Specific Solutions04 Fuel injection system optimization

Refining the fuel injection system of the LM7 engine to improve fuel atomization, distribution, and timing. This involves enhancing injector design, fuel pressure control, and electronic management systems for better combustion efficiency.Expand Specific Solutions05 Engine control and management systems

Developing advanced engine control and management systems for the LM7 engine to optimize performance, fuel efficiency, and emissions. This includes implementing sophisticated algorithms, sensors, and adaptive control strategies to fine-tune engine operation in real-time.Expand Specific Solutions

Key Industry Players

The LM7 engine computational design optimization techniques market is in a growth phase, driven by increasing demand for fuel-efficient and high-performance engines. The global market size is estimated to be in the billions, with steady expansion projected. Technologically, the field is rapidly evolving, with advancements in AI, machine learning, and high-performance computing pushing the boundaries of optimization capabilities. Key players like GM Global Technology Operations, FEV Motorentechnik, and Aisin are at the forefront, investing heavily in R&D. Academic institutions such as Tsinghua University and Northwestern Polytechnical University are also contributing significantly to technological progress through research collaborations and talent development.

GM Global Technology Operations LLC

Technical Solution: GM employs advanced computational design optimization techniques for the LM7 engine, utilizing multi-objective optimization algorithms to enhance performance, fuel efficiency, and emissions reduction. Their approach integrates Computational Fluid Dynamics (CFD) simulations with Finite Element Analysis (FEA) to optimize combustion chamber geometry, intake and exhaust port designs, and overall engine structure[1]. GM's method incorporates machine learning algorithms to predict engine performance based on design parameters, significantly reducing the time and cost of physical prototyping[3]. The company also utilizes Design of Experiments (DoE) methodologies to efficiently explore the vast design space and identify optimal configurations for the LM7 engine[5].

Strengths: Comprehensive integration of multiple simulation techniques, advanced machine learning implementation, and efficient design space exploration. Weaknesses: High computational resource requirements and potential over-reliance on simulations versus real-world testing.

FEV Motorentechnik GmbH & Co. KG

Technical Solution: FEV specializes in engine development and optimization, applying cutting-edge computational techniques to the LM7 engine design. Their approach utilizes a combination of 1D and 3D simulation tools to model and optimize engine performance across various operating conditions[2]. FEV employs genetic algorithms and neural networks to enhance the efficiency of their optimization process, allowing for rapid iteration and refinement of engine designs[4]. The company's methodology includes detailed modeling of combustion processes, heat transfer, and structural dynamics to ensure a holistic approach to engine optimization. FEV also incorporates real-time engine control optimization strategies to maximize performance and efficiency in real-world driving conditions[6].

Strengths: Comprehensive simulation capabilities, advanced optimization algorithms, and integration of real-time control strategies. Weaknesses: Potential complexity in model calibration and validation against real-world data.

Core Optimization Algorithms

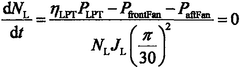

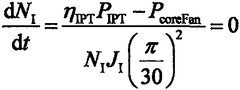

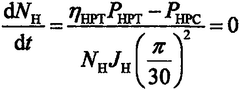

Aero-engine model optimization iteration solving method based on LM algorithm and quasi-Newton method

PatentPendingCN119442965A

Innovation

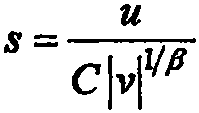

- The optimization iterative solution method combined with the Levenberg-Marquardt (LM) algorithm and the quasi-Newtonian method is used. By calculating the LM step and two approximate LM steps, the algorithm has four convergence speeds under the local error boundary conditions, and the objective function value is used. The information of f and the first derivative g constructs the curvature approximation of the objective function.

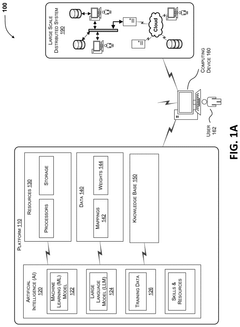

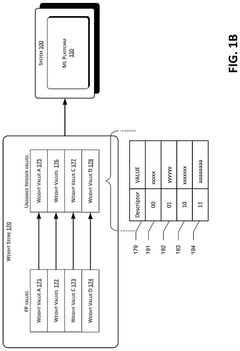

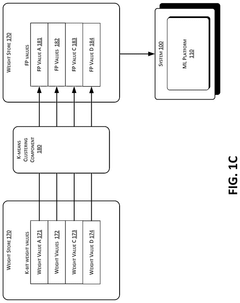

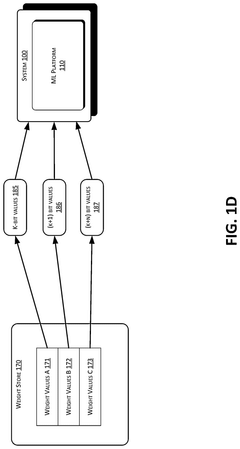

Distribution encoding for quantizing model weights

PatentPendingUS20250077945A1

Innovation

- The distribution encoding technique optimizes the rounding process in LLMs by exploiting the non-uniform distribution of model weights, improving numerical accuracy and compression, and reducing the number of GPUs required for inferencing.

Environmental Impact Assessment

The environmental impact assessment of LM7 engine computational design optimization techniques is a critical aspect of modern engine development. These techniques, while primarily focused on improving engine performance and efficiency, also play a significant role in reducing the environmental footprint of automotive engines.

Computational design optimization for the LM7 engine allows for more precise control over combustion processes, leading to reduced emissions of harmful pollutants. By optimizing parameters such as fuel injection timing, valve timing, and combustion chamber geometry, engineers can minimize the production of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons. This results in cleaner exhaust emissions, contributing to improved air quality and reduced environmental impact.

Furthermore, these optimization techniques enable the development of more fuel-efficient engines. By fine-tuning the engine's design and operating parameters, fuel consumption can be significantly reduced. This not only leads to cost savings for consumers but also translates to lower carbon dioxide (CO2) emissions, a major contributor to global warming. The reduction in fuel consumption also means less reliance on fossil fuels, helping to conserve non-renewable resources.

The use of computational design optimization in LM7 engine development also contributes to the reduction of engine weight. Through advanced modeling and simulation, engineers can identify areas where material can be removed without compromising structural integrity. Lighter engines result in overall vehicle weight reduction, leading to improved fuel economy and further reductions in emissions.

Additionally, these techniques allow for the exploration of alternative materials and manufacturing processes that may have less environmental impact. For example, optimizing designs for additive manufacturing can reduce material waste and energy consumption during production. This holistic approach to engine design considers the entire lifecycle of the engine, from manufacturing to end-of-life disposal.

The environmental benefits of LM7 engine computational design optimization extend beyond direct emissions and fuel consumption. By improving engine durability and longevity, these techniques can reduce the frequency of engine replacements and repairs. This, in turn, decreases the demand for raw materials and energy required for manufacturing replacement parts, further minimizing the overall environmental impact of the automotive industry.

In conclusion, the application of computational design optimization techniques to the LM7 engine demonstrates a significant positive impact on environmental sustainability. By enabling more efficient, cleaner, and longer-lasting engines, these techniques contribute to reducing air pollution, conserving resources, and mitigating climate change effects associated with automotive emissions.

Computational design optimization for the LM7 engine allows for more precise control over combustion processes, leading to reduced emissions of harmful pollutants. By optimizing parameters such as fuel injection timing, valve timing, and combustion chamber geometry, engineers can minimize the production of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons. This results in cleaner exhaust emissions, contributing to improved air quality and reduced environmental impact.

Furthermore, these optimization techniques enable the development of more fuel-efficient engines. By fine-tuning the engine's design and operating parameters, fuel consumption can be significantly reduced. This not only leads to cost savings for consumers but also translates to lower carbon dioxide (CO2) emissions, a major contributor to global warming. The reduction in fuel consumption also means less reliance on fossil fuels, helping to conserve non-renewable resources.

The use of computational design optimization in LM7 engine development also contributes to the reduction of engine weight. Through advanced modeling and simulation, engineers can identify areas where material can be removed without compromising structural integrity. Lighter engines result in overall vehicle weight reduction, leading to improved fuel economy and further reductions in emissions.

Additionally, these techniques allow for the exploration of alternative materials and manufacturing processes that may have less environmental impact. For example, optimizing designs for additive manufacturing can reduce material waste and energy consumption during production. This holistic approach to engine design considers the entire lifecycle of the engine, from manufacturing to end-of-life disposal.

The environmental benefits of LM7 engine computational design optimization extend beyond direct emissions and fuel consumption. By improving engine durability and longevity, these techniques can reduce the frequency of engine replacements and repairs. This, in turn, decreases the demand for raw materials and energy required for manufacturing replacement parts, further minimizing the overall environmental impact of the automotive industry.

In conclusion, the application of computational design optimization techniques to the LM7 engine demonstrates a significant positive impact on environmental sustainability. By enabling more efficient, cleaner, and longer-lasting engines, these techniques contribute to reducing air pollution, conserving resources, and mitigating climate change effects associated with automotive emissions.

Regulatory Compliance Strategies

Regulatory compliance is a critical aspect of LM7 engine computational design optimization techniques. As engine manufacturers strive to improve performance and efficiency, they must also navigate a complex landscape of emissions regulations and safety standards. The optimization process must consider these regulatory requirements from the outset to ensure that the final engine design meets all applicable standards.

One key strategy for regulatory compliance is the integration of emissions modeling into the computational design process. Advanced simulation tools can predict engine emissions under various operating conditions, allowing engineers to optimize combustion parameters and aftertreatment systems simultaneously. This approach helps identify potential compliance issues early in the design phase, reducing the need for costly redesigns later in development.

Another important strategy is the use of multi-objective optimization algorithms that explicitly include regulatory constraints. These algorithms can balance performance goals with emissions targets, ensuring that the optimized design remains within legal limits. By incorporating regulatory requirements as optimization objectives, engineers can explore design spaces that are inherently compliant, streamlining the certification process.

Collaboration with regulatory bodies is also crucial for successful compliance strategies. Engaging with agencies such as the Environmental Protection Agency (EPA) or the European Union Aviation Safety Agency (EASA) during the early stages of engine development can provide valuable insights into upcoming regulatory changes. This foresight allows manufacturers to anticipate future requirements and incorporate them into their optimization techniques proactively.

Furthermore, the development of robust design methodologies is essential for maintaining compliance across a range of operating conditions and manufacturing tolerances. Stochastic optimization techniques can account for uncertainties in material properties, manufacturing processes, and operating environments, ensuring that the engine design remains compliant even under worst-case scenarios.

Lastly, the implementation of comprehensive validation and verification protocols is critical for demonstrating regulatory compliance. These protocols should include both computational and experimental methods to validate the accuracy of optimization results. Advanced data analytics and machine learning techniques can be employed to process large volumes of test data, identifying potential compliance risks and guiding further optimization efforts.

By adopting these regulatory compliance strategies, engine manufacturers can ensure that their computational design optimization techniques not only yield high-performance engines but also meet the stringent regulatory requirements of the aviation industry. This holistic approach to optimization helps balance innovation with compliance, paving the way for more efficient and environmentally friendly aircraft engines.

One key strategy for regulatory compliance is the integration of emissions modeling into the computational design process. Advanced simulation tools can predict engine emissions under various operating conditions, allowing engineers to optimize combustion parameters and aftertreatment systems simultaneously. This approach helps identify potential compliance issues early in the design phase, reducing the need for costly redesigns later in development.

Another important strategy is the use of multi-objective optimization algorithms that explicitly include regulatory constraints. These algorithms can balance performance goals with emissions targets, ensuring that the optimized design remains within legal limits. By incorporating regulatory requirements as optimization objectives, engineers can explore design spaces that are inherently compliant, streamlining the certification process.

Collaboration with regulatory bodies is also crucial for successful compliance strategies. Engaging with agencies such as the Environmental Protection Agency (EPA) or the European Union Aviation Safety Agency (EASA) during the early stages of engine development can provide valuable insights into upcoming regulatory changes. This foresight allows manufacturers to anticipate future requirements and incorporate them into their optimization techniques proactively.

Furthermore, the development of robust design methodologies is essential for maintaining compliance across a range of operating conditions and manufacturing tolerances. Stochastic optimization techniques can account for uncertainties in material properties, manufacturing processes, and operating environments, ensuring that the engine design remains compliant even under worst-case scenarios.

Lastly, the implementation of comprehensive validation and verification protocols is critical for demonstrating regulatory compliance. These protocols should include both computational and experimental methods to validate the accuracy of optimization results. Advanced data analytics and machine learning techniques can be employed to process large volumes of test data, identifying potential compliance risks and guiding further optimization efforts.

By adopting these regulatory compliance strategies, engine manufacturers can ensure that their computational design optimization techniques not only yield high-performance engines but also meet the stringent regulatory requirements of the aviation industry. This holistic approach to optimization helps balance innovation with compliance, paving the way for more efficient and environmentally friendly aircraft engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!