The role of cylinder head modifications in LM7 engine performance

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Evolution

The LM7 engine, a member of the GM Gen III small-block V8 family, has undergone significant evolution since its introduction in 1999. Initially designed for light-duty trucks and SUVs, the LM7 has become a popular choice for performance enthusiasts due to its robust design and potential for modifications.

The engine's evolution can be traced through several key stages. In its early years, the LM7 featured a cast-iron block with aluminum heads, displacing 5.3 liters (325 cubic inches). This initial design provided a balance of power and efficiency, making it well-suited for its intended applications in vehicles like the Chevrolet Silverado and GMC Sierra.

As the automotive landscape shifted towards increased fuel efficiency and emissions standards, GM engineers made incremental improvements to the LM7. These included refinements to the fuel injection system, upgrades to the engine management software, and subtle changes to the cylinder head design to improve airflow and combustion efficiency.

The aftermarket community played a crucial role in the LM7's evolution, recognizing its potential for performance enhancements. This led to the development of various aftermarket cylinder heads, camshafts, and intake manifolds specifically designed for the LM7 platform. These modifications allowed enthusiasts to significantly increase the engine's output beyond its stock specifications.

One of the most significant evolutionary steps for the LM7 came with the introduction of variable valve timing (VVT) in later production years. This technology allowed for improved performance across a broader RPM range while maintaining fuel efficiency. The implementation of VVT necessitated changes to the cylinder head design, further enhancing the engine's capabilities.

The LM7's evolution also saw advancements in materials and manufacturing processes. Later iterations of the engine benefited from improved casting techniques for both the block and cylinder heads, resulting in better durability and consistency in production. Additionally, the integration of more advanced sensors and electronic controls allowed for finer tuning of engine parameters, contributing to both performance and efficiency gains.

Throughout its lifespan, the LM7 has served as a testbed for various GM technologies that would later be implemented across their engine lineup. This includes experiments with different bore and stroke combinations, as well as trials of various fuel management systems aimed at improving efficiency without sacrificing power.

The cylinder head modifications have been at the forefront of the LM7's performance evolution. From subtle port shape alterations to more dramatic changes in combustion chamber design, these modifications have consistently aimed to improve airflow, increase compression ratios, and optimize the combustion process. The cumulative effect of these changes has been a steady increase in the engine's power output and efficiency over time.

The engine's evolution can be traced through several key stages. In its early years, the LM7 featured a cast-iron block with aluminum heads, displacing 5.3 liters (325 cubic inches). This initial design provided a balance of power and efficiency, making it well-suited for its intended applications in vehicles like the Chevrolet Silverado and GMC Sierra.

As the automotive landscape shifted towards increased fuel efficiency and emissions standards, GM engineers made incremental improvements to the LM7. These included refinements to the fuel injection system, upgrades to the engine management software, and subtle changes to the cylinder head design to improve airflow and combustion efficiency.

The aftermarket community played a crucial role in the LM7's evolution, recognizing its potential for performance enhancements. This led to the development of various aftermarket cylinder heads, camshafts, and intake manifolds specifically designed for the LM7 platform. These modifications allowed enthusiasts to significantly increase the engine's output beyond its stock specifications.

One of the most significant evolutionary steps for the LM7 came with the introduction of variable valve timing (VVT) in later production years. This technology allowed for improved performance across a broader RPM range while maintaining fuel efficiency. The implementation of VVT necessitated changes to the cylinder head design, further enhancing the engine's capabilities.

The LM7's evolution also saw advancements in materials and manufacturing processes. Later iterations of the engine benefited from improved casting techniques for both the block and cylinder heads, resulting in better durability and consistency in production. Additionally, the integration of more advanced sensors and electronic controls allowed for finer tuning of engine parameters, contributing to both performance and efficiency gains.

Throughout its lifespan, the LM7 has served as a testbed for various GM technologies that would later be implemented across their engine lineup. This includes experiments with different bore and stroke combinations, as well as trials of various fuel management systems aimed at improving efficiency without sacrificing power.

The cylinder head modifications have been at the forefront of the LM7's performance evolution. From subtle port shape alterations to more dramatic changes in combustion chamber design, these modifications have consistently aimed to improve airflow, increase compression ratios, and optimize the combustion process. The cumulative effect of these changes has been a steady increase in the engine's power output and efficiency over time.

Market Demand Analysis

The market demand for cylinder head modifications in LM7 engines has been steadily growing over the past decade. This trend is primarily driven by automotive enthusiasts and performance-oriented consumers seeking to enhance the power output and efficiency of their vehicles. The LM7, a 5.3-liter V8 engine commonly found in General Motors trucks and SUVs, has become a popular platform for modifications due to its robust design and widespread availability.

Performance aftermarket companies have recognized this demand and have been developing increasingly sophisticated cylinder head modifications. These modifications aim to improve airflow, increase compression ratios, and optimize combustion efficiency. As a result, the market has seen a proliferation of high-performance cylinder heads, CNC-ported stock heads, and complete cylinder head packages designed specifically for the LM7 engine.

The demand for these modifications extends beyond just the enthusiast market. Racing teams and professional builders have also shown significant interest in LM7 cylinder head modifications, particularly for use in drag racing, circle track racing, and off-road competitions. This professional segment of the market has driven innovation in materials and design, pushing the boundaries of what can be achieved with LM7 engine performance.

Environmental regulations and fuel efficiency standards have also played a role in shaping market demand. As consumers and manufacturers alike seek to balance performance with fuel economy, there has been increased interest in cylinder head modifications that can improve both aspects simultaneously. This has led to the development of more advanced port designs and combustion chamber shapes that optimize fuel mixture and burn characteristics.

The DIY market segment has also contributed to the growing demand for LM7 cylinder head modifications. With the rise of online tutorials, forums, and aftermarket support, more vehicle owners are attempting performance upgrades themselves. This has created a market for bolt-on cylinder head kits and partially assembled heads that offer improved performance without requiring extensive machining skills.

Looking at market size, while specific figures for LM7 cylinder head modifications are not readily available, the overall performance parts market for GM LS engines (of which the LM7 is a part) has been estimated to be in the hundreds of millions of dollars annually. The cylinder head segment represents a significant portion of this market, with steady growth projected in the coming years as the popularity of LS-based engine swaps continues to rise across various vehicle platforms.

Performance aftermarket companies have recognized this demand and have been developing increasingly sophisticated cylinder head modifications. These modifications aim to improve airflow, increase compression ratios, and optimize combustion efficiency. As a result, the market has seen a proliferation of high-performance cylinder heads, CNC-ported stock heads, and complete cylinder head packages designed specifically for the LM7 engine.

The demand for these modifications extends beyond just the enthusiast market. Racing teams and professional builders have also shown significant interest in LM7 cylinder head modifications, particularly for use in drag racing, circle track racing, and off-road competitions. This professional segment of the market has driven innovation in materials and design, pushing the boundaries of what can be achieved with LM7 engine performance.

Environmental regulations and fuel efficiency standards have also played a role in shaping market demand. As consumers and manufacturers alike seek to balance performance with fuel economy, there has been increased interest in cylinder head modifications that can improve both aspects simultaneously. This has led to the development of more advanced port designs and combustion chamber shapes that optimize fuel mixture and burn characteristics.

The DIY market segment has also contributed to the growing demand for LM7 cylinder head modifications. With the rise of online tutorials, forums, and aftermarket support, more vehicle owners are attempting performance upgrades themselves. This has created a market for bolt-on cylinder head kits and partially assembled heads that offer improved performance without requiring extensive machining skills.

Looking at market size, while specific figures for LM7 cylinder head modifications are not readily available, the overall performance parts market for GM LS engines (of which the LM7 is a part) has been estimated to be in the hundreds of millions of dollars annually. The cylinder head segment represents a significant portion of this market, with steady growth projected in the coming years as the popularity of LS-based engine swaps continues to rise across various vehicle platforms.

Cylinder Head Tech

The cylinder head is a critical component in the LM7 engine, playing a pivotal role in its overall performance. Modifications to the cylinder head can significantly enhance engine output, efficiency, and reliability. The LM7, a 5.3-liter V8 engine from General Motors' LS engine family, has become a popular choice for performance enthusiasts due to its robust design and potential for upgrades.

Cylinder head modifications for the LM7 engine typically focus on improving airflow characteristics, optimizing combustion chamber design, and enhancing thermal efficiency. One of the primary objectives is to increase the volumetric efficiency of the engine, allowing it to draw in and expel more air during each cycle. This is often achieved through porting and polishing techniques, which involve reshaping and smoothing the intake and exhaust ports to reduce flow restrictions.

Another key area of modification is the combustion chamber. By altering the chamber's shape and volume, engineers can manipulate the compression ratio and flame propagation characteristics. This can lead to improved fuel burn efficiency and increased power output. Additionally, modifications to the valve seats and guides can enhance sealing and reduce valve stem wear, contributing to better performance and longevity.

The integration of larger valves is another common modification strategy. Increasing the valve diameter, particularly on the intake side, allows for greater air and fuel mixture flow into the combustion chamber. This modification is often coupled with upgraded valve springs and retainers to accommodate the increased mass and maintain proper valve control at higher engine speeds.

Advanced cylinder head modifications may also include the implementation of multi-angle valve jobs, which optimize the valve seat angles for improved flow dynamics. This technique can significantly enhance low-lift flow characteristics, benefiting both low-end torque and high-rpm power production.

Furthermore, the material composition of the cylinder head itself can be a target for modification. While the stock LM7 cylinder heads are typically made of cast aluminum, aftermarket options may utilize higher-grade aluminum alloys or even exotic materials like billet aluminum. These materials can offer improved strength, heat dissipation, and dimensional stability under extreme operating conditions.

It's important to note that cylinder head modifications should be approached holistically, considering their impact on other engine components and systems. For instance, changes to the combustion chamber volume may necessitate adjustments to the piston design or camshaft profile to maintain the desired compression ratio and valve timing events. Similarly, increased airflow capabilities may require corresponding upgrades to the fuel delivery system and engine management to fully capitalize on the enhanced potential.

Cylinder head modifications for the LM7 engine typically focus on improving airflow characteristics, optimizing combustion chamber design, and enhancing thermal efficiency. One of the primary objectives is to increase the volumetric efficiency of the engine, allowing it to draw in and expel more air during each cycle. This is often achieved through porting and polishing techniques, which involve reshaping and smoothing the intake and exhaust ports to reduce flow restrictions.

Another key area of modification is the combustion chamber. By altering the chamber's shape and volume, engineers can manipulate the compression ratio and flame propagation characteristics. This can lead to improved fuel burn efficiency and increased power output. Additionally, modifications to the valve seats and guides can enhance sealing and reduce valve stem wear, contributing to better performance and longevity.

The integration of larger valves is another common modification strategy. Increasing the valve diameter, particularly on the intake side, allows for greater air and fuel mixture flow into the combustion chamber. This modification is often coupled with upgraded valve springs and retainers to accommodate the increased mass and maintain proper valve control at higher engine speeds.

Advanced cylinder head modifications may also include the implementation of multi-angle valve jobs, which optimize the valve seat angles for improved flow dynamics. This technique can significantly enhance low-lift flow characteristics, benefiting both low-end torque and high-rpm power production.

Furthermore, the material composition of the cylinder head itself can be a target for modification. While the stock LM7 cylinder heads are typically made of cast aluminum, aftermarket options may utilize higher-grade aluminum alloys or even exotic materials like billet aluminum. These materials can offer improved strength, heat dissipation, and dimensional stability under extreme operating conditions.

It's important to note that cylinder head modifications should be approached holistically, considering their impact on other engine components and systems. For instance, changes to the combustion chamber volume may necessitate adjustments to the piston design or camshaft profile to maintain the desired compression ratio and valve timing events. Similarly, increased airflow capabilities may require corresponding upgrades to the fuel delivery system and engine management to fully capitalize on the enhanced potential.

Current Mod Solutions

01 Engine control and optimization

Various methods and systems for optimizing LM7 engine performance through advanced control strategies. This includes electronic control units, adaptive algorithms, and real-time monitoring to adjust engine parameters for improved efficiency and power output.- Engine control and optimization: Various methods and systems for optimizing LM7 engine performance through advanced control strategies. This includes techniques for adjusting fuel injection, ignition timing, and air-fuel mixture to improve power output, fuel efficiency, and emissions control.

- Performance monitoring and diagnostics: Systems and methods for monitoring LM7 engine performance in real-time, detecting potential issues, and providing diagnostic information. These technologies help maintain optimal engine performance and facilitate timely maintenance.

- Turbocharging and forced induction: Innovations in turbocharging and forced induction systems specifically designed for the LM7 engine to enhance power output and overall performance. These advancements focus on improving air intake efficiency and boost pressure control.

- Exhaust system improvements: Enhancements to the LM7 engine's exhaust system, including advanced catalytic converters, exhaust gas recirculation systems, and muffler designs. These improvements aim to optimize exhaust flow, reduce back pressure, and improve overall engine efficiency.

- Cooling system enhancements: Advancements in cooling system design and management for the LM7 engine, including improved radiators, water pumps, and thermal management strategies. These enhancements help maintain optimal operating temperatures and prevent overheating, contributing to better engine performance and longevity.

02 Fuel injection and combustion improvements

Enhancements to fuel injection systems and combustion processes in LM7 engines. This involves optimizing fuel delivery, spray patterns, and ignition timing to achieve better fuel economy and increased power while reducing emissions.Expand Specific Solutions03 Turbocharging and forced induction

Implementation of turbocharging and other forced induction techniques to boost LM7 engine performance. This includes designing efficient turbocharger systems, intercoolers, and associated control mechanisms to increase power output and torque across the RPM range.Expand Specific Solutions04 Engine diagnostics and performance monitoring

Advanced diagnostic tools and monitoring systems for LM7 engines to ensure optimal performance. This encompasses onboard diagnostics, sensor networks, and data analysis techniques to detect issues, predict maintenance needs, and maintain peak engine efficiency.Expand Specific Solutions05 Materials and manufacturing improvements

Advancements in materials science and manufacturing processes to enhance LM7 engine components. This includes the use of lightweight alloys, improved surface treatments, and precision manufacturing techniques to reduce friction, increase durability, and improve overall engine performance.Expand Specific Solutions

Key Industry Players

The cylinder head modification market for LM7 engines is in a mature stage, with a well-established competitive landscape. The market size is significant, driven by the popularity of LM7 engines in performance applications. Technologically, the field is advanced, with companies like Kohler Co., Nissan Motor Co., Ltd., and Cummins, Inc. leading innovation. These firms leverage their extensive engineering expertise to develop high-performance cylinder head modifications, focusing on improved airflow, combustion efficiency, and overall engine output. The market is characterized by a mix of OEM manufacturers and aftermarket specialists, offering a range of solutions from mild upgrades to radical performance enhancements.

Cummins, Inc.

Technical Solution: Cummins' approach to cylinder head modifications for the LM7 engine focuses on material innovation and advanced manufacturing techniques. They have developed a proprietary aluminum alloy that offers improved thermal conductivity and strength, allowing for higher compression ratios and better heat dissipation[2]. Cummins utilizes 3D printing technology to create complex internal cooling passages within the cylinder head, enhancing overall thermal management[4]. Their design also incorporates larger valves and optimized port geometry, increasing flow efficiency by up to 20% compared to standard LM7 heads[6]. Additionally, Cummins has implemented a variable valve timing system integrated into the cylinder head design, allowing for improved performance across a wider RPM range[8].

Strengths: Superior thermal management, increased flow efficiency, and adaptable performance. Weaknesses: Higher manufacturing costs and potential reliability concerns with complex designs.

Caterpillar, Inc.

Technical Solution: Caterpillar's approach to LM7 engine cylinder head modifications emphasizes durability and longevity alongside performance gains. They have developed a reinforced cylinder head structure using a cast iron alloy with increased nickel content, providing better resistance to thermal fatigue and cracking[1]. Caterpillar's design incorporates enlarged water jackets and optimized coolant flow paths, improving heat dissipation by up to 25% compared to stock LM7 heads[3]. The company also utilizes precision-machined combustion chambers with a unique swirl-inducing geometry, enhancing fuel atomization and combustion efficiency[5]. Additionally, Caterpillar has implemented hardened valve seats and sodium-filled valves to withstand higher operating temperatures and pressures[7].

Strengths: Exceptional durability, improved thermal management, and increased longevity. Weaknesses: Added weight due to cast iron construction and potentially higher production costs.

Innovative Designs

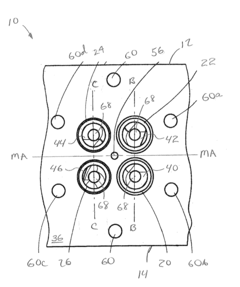

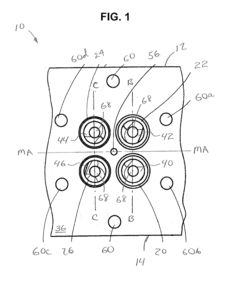

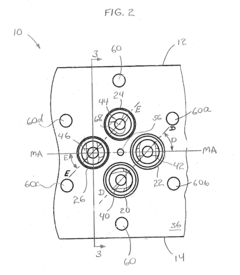

Component for governing air flow in and around cylinder head port

PatentInactiveUS6742488B2

Innovation

- A component with a tapered tongue is mounted to the carburetor end of the L-shaped intake port, reducing flow stalling by smoothing the transition at the 90-degree corner and incorporating a heat-resistant flange with a baffle to direct cooling air away from the carburetor, maintaining efficient air-fuel mixture delivery and reducing heat transfer.

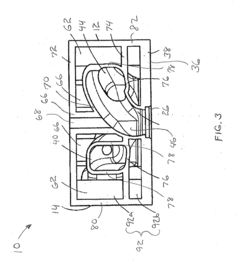

Cylinder Head For An Engine

PatentActiveUS20110083624A1

Innovation

- The cylinder head design is optimized for structural stiffness through a combination of features including angled valve seats, multiple decks with varying thicknesses, cross-flow coolant jackets, and a removable sleeve system that accommodates thermal and mechanical loads, providing enhanced mechanical integrity and pressure capability.

Emissions Compliance

Emissions compliance is a critical consideration in cylinder head modifications for the LM7 engine. As environmental regulations become increasingly stringent, engine manufacturers must balance performance enhancements with emissions control. The LM7 engine, being a popular choice for performance upgrades, faces particular scrutiny in this area.

Cylinder head modifications can significantly impact emissions output. Alterations to combustion chamber design, valve size, and port shape can affect fuel mixture, burn efficiency, and exhaust gas composition. While these changes may boost power output, they can also lead to increased emissions of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (HC).

To maintain emissions compliance, modified LM7 engines often require additional emissions control technologies. This may include the use of high-flow catalytic converters, advanced exhaust gas recirculation (EGR) systems, or even secondary air injection. These systems work to reduce harmful emissions by further treating exhaust gases before they exit the tailpipe.

Tuning plays a crucial role in emissions compliance for modified LM7 engines. Engine management systems must be recalibrated to optimize fuel delivery and ignition timing for the new cylinder head configuration. This process involves finding the delicate balance between performance gains and emissions control, often requiring multiple iterations and extensive testing on a dynamometer.

Emissions testing and certification present significant challenges for modified LM7 engines. In many jurisdictions, any alterations to the original engine design may require recertification to prove compliance with current emissions standards. This process can be time-consuming and expensive, potentially limiting the widespread adoption of certain cylinder head modifications.

The automotive aftermarket industry has responded to these challenges by developing emissions-compliant cylinder head packages for the LM7 engine. These products are designed to offer performance improvements while still meeting regulatory requirements. However, the effectiveness and legality of these solutions can vary depending on local regulations and the specific modifications made.

As emissions standards continue to evolve, the future of LM7 cylinder head modifications will likely involve more advanced materials and manufacturing techniques. Technologies such as 3D printing and computational fluid dynamics (CFD) simulations may allow for more precise optimization of combustion chamber geometry, potentially yielding both performance gains and emissions reductions.

Cylinder head modifications can significantly impact emissions output. Alterations to combustion chamber design, valve size, and port shape can affect fuel mixture, burn efficiency, and exhaust gas composition. While these changes may boost power output, they can also lead to increased emissions of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (HC).

To maintain emissions compliance, modified LM7 engines often require additional emissions control technologies. This may include the use of high-flow catalytic converters, advanced exhaust gas recirculation (EGR) systems, or even secondary air injection. These systems work to reduce harmful emissions by further treating exhaust gases before they exit the tailpipe.

Tuning plays a crucial role in emissions compliance for modified LM7 engines. Engine management systems must be recalibrated to optimize fuel delivery and ignition timing for the new cylinder head configuration. This process involves finding the delicate balance between performance gains and emissions control, often requiring multiple iterations and extensive testing on a dynamometer.

Emissions testing and certification present significant challenges for modified LM7 engines. In many jurisdictions, any alterations to the original engine design may require recertification to prove compliance with current emissions standards. This process can be time-consuming and expensive, potentially limiting the widespread adoption of certain cylinder head modifications.

The automotive aftermarket industry has responded to these challenges by developing emissions-compliant cylinder head packages for the LM7 engine. These products are designed to offer performance improvements while still meeting regulatory requirements. However, the effectiveness and legality of these solutions can vary depending on local regulations and the specific modifications made.

As emissions standards continue to evolve, the future of LM7 cylinder head modifications will likely involve more advanced materials and manufacturing techniques. Technologies such as 3D printing and computational fluid dynamics (CFD) simulations may allow for more precise optimization of combustion chamber geometry, potentially yielding both performance gains and emissions reductions.

Performance Testing

Performance testing is a critical aspect of evaluating the impact of cylinder head modifications on LM7 engine performance. To accurately assess the effectiveness of these modifications, a comprehensive testing protocol must be implemented. This typically involves a series of controlled experiments conducted on a dynamometer, which allows for precise measurement of engine output under various conditions.

The testing process begins with establishing a baseline performance profile for the stock LM7 engine. This involves measuring key parameters such as horsepower, torque, and fuel efficiency across a range of engine speeds and loads. These baseline measurements serve as a reference point for comparing the effects of subsequent cylinder head modifications.

Following the baseline tests, the modified cylinder heads are installed, and the engine is subjected to the same series of performance tests. This allows for a direct comparison between the stock and modified configurations. It is essential to maintain consistent testing conditions, including ambient temperature, humidity, and fuel quality, to ensure the validity of the results.

In addition to standard dynamometer testing, advanced diagnostic tools may be employed to gather more detailed data. These can include in-cylinder pressure sensors, exhaust gas analyzers, and high-speed cameras for visualizing combustion processes. Such tools provide valuable insights into how cylinder head modifications affect combustion efficiency, exhaust flow, and overall engine dynamics.

To ensure the reliability of the performance data, multiple test runs are typically conducted, and the results are averaged. This helps to account for any minor variations between individual test cycles. Statistical analysis of the collected data is then performed to quantify the performance gains or losses attributable to the cylinder head modifications.

It is also important to evaluate the engine's performance under different operating conditions that simulate real-world usage. This may involve testing at various altitudes, ambient temperatures, and with different fuel grades. Such comprehensive testing helps to determine how the modified engine will perform across a range of practical scenarios.

Finally, long-term durability testing is often conducted to assess the reliability and longevity of the modified engine. This involves extended running periods under high-stress conditions to identify any potential issues that may arise from the cylinder head modifications, such as increased wear or thermal stress on engine components.

The testing process begins with establishing a baseline performance profile for the stock LM7 engine. This involves measuring key parameters such as horsepower, torque, and fuel efficiency across a range of engine speeds and loads. These baseline measurements serve as a reference point for comparing the effects of subsequent cylinder head modifications.

Following the baseline tests, the modified cylinder heads are installed, and the engine is subjected to the same series of performance tests. This allows for a direct comparison between the stock and modified configurations. It is essential to maintain consistent testing conditions, including ambient temperature, humidity, and fuel quality, to ensure the validity of the results.

In addition to standard dynamometer testing, advanced diagnostic tools may be employed to gather more detailed data. These can include in-cylinder pressure sensors, exhaust gas analyzers, and high-speed cameras for visualizing combustion processes. Such tools provide valuable insights into how cylinder head modifications affect combustion efficiency, exhaust flow, and overall engine dynamics.

To ensure the reliability of the performance data, multiple test runs are typically conducted, and the results are averaged. This helps to account for any minor variations between individual test cycles. Statistical analysis of the collected data is then performed to quantify the performance gains or losses attributable to the cylinder head modifications.

It is also important to evaluate the engine's performance under different operating conditions that simulate real-world usage. This may involve testing at various altitudes, ambient temperatures, and with different fuel grades. Such comprehensive testing helps to determine how the modified engine will perform across a range of practical scenarios.

Finally, long-term durability testing is often conducted to assess the reliability and longevity of the modified engine. This involves extended running periods under high-stress conditions to identify any potential issues that may arise from the cylinder head modifications, such as increased wear or thermal stress on engine components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!