5.4 Triton Engine: Advances in Piston Ring Design

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton Engine Piston Ring Evolution and Objectives

The Triton Engine, a pinnacle of modern internal combustion technology, has undergone significant advancements in piston ring design over the years. These improvements have been driven by the ever-increasing demands for enhanced engine performance, fuel efficiency, and reduced emissions. The evolution of piston ring technology in the Triton Engine reflects a broader trend in the automotive industry towards more sophisticated and environmentally conscious powertrains.

Initially, piston rings in the Triton Engine were primarily focused on sealing the combustion chamber and controlling oil consumption. As engine designs progressed, the role of piston rings expanded to include heat management and friction reduction. This evolution has led to the development of multi-functional piston ring sets, each ring optimized for a specific purpose within the engine's operation.

The primary objectives in advancing piston ring design for the Triton Engine have been multifaceted. Firstly, there has been a concerted effort to minimize friction between the piston rings and cylinder walls, thereby improving fuel efficiency and reducing wear. This has led to the exploration of new materials and surface treatments that can withstand high temperatures and pressures while maintaining low friction characteristics.

Another key objective has been to enhance the sealing capabilities of the piston rings. Improved sealing not only increases engine compression and power output but also helps in reducing emissions by preventing blow-by gases from escaping into the crankcase. This has resulted in the development of more precise ring geometries and improved manufacturing techniques to ensure optimal conformability to cylinder walls.

Durability and longevity have also been critical focus areas in piston ring evolution. As engines are expected to perform reliably over longer periods, piston rings have been engineered to resist wear, corrosion, and thermal degradation. This has involved the use of advanced coatings and alloys that can maintain their properties under extreme operating conditions.

The trend towards engine downsizing and turbocharging has further influenced piston ring design objectives. These compact, high-output engines place greater demands on piston rings, requiring them to perform effectively under higher combustion pressures and temperatures. Consequently, research has been directed towards developing rings that can maintain their integrity and functionality in these more challenging environments.

Looking ahead, the objectives for future piston ring designs in the Triton Engine are likely to focus on further reducing friction, improving sealing under increasingly stringent emissions regulations, and adapting to alternative fuels and hybrid powertrains. The integration of smart materials and nanotechnology in piston ring design is also an area of growing interest, potentially leading to self-adjusting or self-lubricating rings that can optimize their performance in real-time based on engine operating conditions.

Initially, piston rings in the Triton Engine were primarily focused on sealing the combustion chamber and controlling oil consumption. As engine designs progressed, the role of piston rings expanded to include heat management and friction reduction. This evolution has led to the development of multi-functional piston ring sets, each ring optimized for a specific purpose within the engine's operation.

The primary objectives in advancing piston ring design for the Triton Engine have been multifaceted. Firstly, there has been a concerted effort to minimize friction between the piston rings and cylinder walls, thereby improving fuel efficiency and reducing wear. This has led to the exploration of new materials and surface treatments that can withstand high temperatures and pressures while maintaining low friction characteristics.

Another key objective has been to enhance the sealing capabilities of the piston rings. Improved sealing not only increases engine compression and power output but also helps in reducing emissions by preventing blow-by gases from escaping into the crankcase. This has resulted in the development of more precise ring geometries and improved manufacturing techniques to ensure optimal conformability to cylinder walls.

Durability and longevity have also been critical focus areas in piston ring evolution. As engines are expected to perform reliably over longer periods, piston rings have been engineered to resist wear, corrosion, and thermal degradation. This has involved the use of advanced coatings and alloys that can maintain their properties under extreme operating conditions.

The trend towards engine downsizing and turbocharging has further influenced piston ring design objectives. These compact, high-output engines place greater demands on piston rings, requiring them to perform effectively under higher combustion pressures and temperatures. Consequently, research has been directed towards developing rings that can maintain their integrity and functionality in these more challenging environments.

Looking ahead, the objectives for future piston ring designs in the Triton Engine are likely to focus on further reducing friction, improving sealing under increasingly stringent emissions regulations, and adapting to alternative fuels and hybrid powertrains. The integration of smart materials and nanotechnology in piston ring design is also an area of growing interest, potentially leading to self-adjusting or self-lubricating rings that can optimize their performance in real-time based on engine operating conditions.

Market Demand for Advanced Piston Ring Technologies

The market demand for advanced piston ring technologies in the Triton engine sector has been steadily increasing, driven by the automotive industry's push for improved fuel efficiency, reduced emissions, and enhanced engine performance. As environmental regulations become more stringent worldwide, manufacturers are seeking innovative solutions to meet these challenges while maintaining competitive edge in the market.

Piston rings play a crucial role in engine efficiency by sealing the combustion chamber, controlling oil consumption, and transferring heat from the piston to the cylinder wall. Advanced piston ring designs for Triton engines are in high demand due to their potential to significantly improve these functions. The global market for piston rings is expected to grow substantially in the coming years, with a particular focus on technologies that can withstand higher temperatures and pressures associated with modern engine designs.

One of the key drivers of market demand is the automotive industry's shift towards downsized, turbocharged engines. These engines require piston rings that can perform under increased thermal and mechanical stress. Triton engine manufacturers are actively seeking piston ring technologies that offer improved wear resistance, reduced friction, and better sealing properties to meet the demands of these high-performance engines.

Another factor contributing to the market demand is the growing emphasis on reducing oil consumption and emissions. Advanced piston ring designs that minimize oil passage while maintaining effective sealing are highly sought after. This demand is further amplified by the need to comply with increasingly strict emissions standards, such as Euro 7 in Europe and Tier 3 in the United States.

The aftermarket segment also presents a significant opportunity for advanced piston ring technologies. As vehicle owners seek to improve the performance and longevity of their engines, there is a growing demand for high-quality replacement parts, including advanced piston rings. This trend is particularly pronounced in regions with a large number of aging vehicles.

In the commercial vehicle sector, the demand for advanced piston ring technologies is driven by the need for increased durability and extended service intervals. Fleet operators are looking for solutions that can reduce maintenance costs and improve vehicle uptime, making advanced piston rings an attractive investment.

The Asia-Pacific region, particularly countries like China and India, is expected to be a major growth market for advanced piston ring technologies. The rapid expansion of the automotive industry in these countries, coupled with increasing environmental awareness, is creating a substantial demand for high-performance engine components.

Piston rings play a crucial role in engine efficiency by sealing the combustion chamber, controlling oil consumption, and transferring heat from the piston to the cylinder wall. Advanced piston ring designs for Triton engines are in high demand due to their potential to significantly improve these functions. The global market for piston rings is expected to grow substantially in the coming years, with a particular focus on technologies that can withstand higher temperatures and pressures associated with modern engine designs.

One of the key drivers of market demand is the automotive industry's shift towards downsized, turbocharged engines. These engines require piston rings that can perform under increased thermal and mechanical stress. Triton engine manufacturers are actively seeking piston ring technologies that offer improved wear resistance, reduced friction, and better sealing properties to meet the demands of these high-performance engines.

Another factor contributing to the market demand is the growing emphasis on reducing oil consumption and emissions. Advanced piston ring designs that minimize oil passage while maintaining effective sealing are highly sought after. This demand is further amplified by the need to comply with increasingly strict emissions standards, such as Euro 7 in Europe and Tier 3 in the United States.

The aftermarket segment also presents a significant opportunity for advanced piston ring technologies. As vehicle owners seek to improve the performance and longevity of their engines, there is a growing demand for high-quality replacement parts, including advanced piston rings. This trend is particularly pronounced in regions with a large number of aging vehicles.

In the commercial vehicle sector, the demand for advanced piston ring technologies is driven by the need for increased durability and extended service intervals. Fleet operators are looking for solutions that can reduce maintenance costs and improve vehicle uptime, making advanced piston rings an attractive investment.

The Asia-Pacific region, particularly countries like China and India, is expected to be a major growth market for advanced piston ring technologies. The rapid expansion of the automotive industry in these countries, coupled with increasing environmental awareness, is creating a substantial demand for high-performance engine components.

Current Challenges in Piston Ring Design

Piston ring design for the Triton engine faces several significant challenges in the current technological landscape. One of the primary issues is the need for improved sealing performance under increasingly demanding operating conditions. As engines become more powerful and efficient, piston rings must withstand higher temperatures and pressures while maintaining their sealing integrity. This requires advanced materials and coatings that can resist wear, reduce friction, and maintain their shape under extreme conditions.

Another challenge lies in the reduction of oil consumption and emissions. Stricter environmental regulations demand that piston rings not only seal effectively but also minimize oil passage into the combustion chamber. This necessitates precise control of ring tension and geometry, as well as the development of novel surface treatments that can enhance oil control without compromising sealing performance.

The pursuit of fuel efficiency presents an additional hurdle for piston ring designers. There is a constant drive to reduce friction between the piston rings and cylinder walls, as this friction accounts for a significant portion of mechanical losses in an engine. However, reducing friction must be balanced against the need for effective sealing and oil control, creating a complex optimization problem.

Durability and longevity of piston rings remain critical challenges, particularly in high-performance applications like the Triton engine. The rings must maintain their functionality over extended periods, resisting degradation from thermal cycling, chemical attack from combustion byproducts, and mechanical wear from constant reciprocation. This demands innovative material science solutions and surface engineering techniques.

The miniaturization trend in engine design also impacts piston ring development. As engines become more compact, piston rings must perform their functions within tighter spatial constraints. This requires careful consideration of ring thickness and profile, potentially leading to the exploration of multi-piece ring designs or unconventional geometries.

Lastly, manufacturability and cost-effectiveness pose ongoing challenges. Advanced piston ring designs often involve complex geometries and specialized materials, which can be difficult and expensive to produce at scale. Balancing performance improvements against manufacturing feasibility and cost considerations is a constant struggle for engineers working on Triton engine piston rings.

Another challenge lies in the reduction of oil consumption and emissions. Stricter environmental regulations demand that piston rings not only seal effectively but also minimize oil passage into the combustion chamber. This necessitates precise control of ring tension and geometry, as well as the development of novel surface treatments that can enhance oil control without compromising sealing performance.

The pursuit of fuel efficiency presents an additional hurdle for piston ring designers. There is a constant drive to reduce friction between the piston rings and cylinder walls, as this friction accounts for a significant portion of mechanical losses in an engine. However, reducing friction must be balanced against the need for effective sealing and oil control, creating a complex optimization problem.

Durability and longevity of piston rings remain critical challenges, particularly in high-performance applications like the Triton engine. The rings must maintain their functionality over extended periods, resisting degradation from thermal cycling, chemical attack from combustion byproducts, and mechanical wear from constant reciprocation. This demands innovative material science solutions and surface engineering techniques.

The miniaturization trend in engine design also impacts piston ring development. As engines become more compact, piston rings must perform their functions within tighter spatial constraints. This requires careful consideration of ring thickness and profile, potentially leading to the exploration of multi-piece ring designs or unconventional geometries.

Lastly, manufacturability and cost-effectiveness pose ongoing challenges. Advanced piston ring designs often involve complex geometries and specialized materials, which can be difficult and expensive to produce at scale. Balancing performance improvements against manufacturing feasibility and cost considerations is a constant struggle for engineers working on Triton engine piston rings.

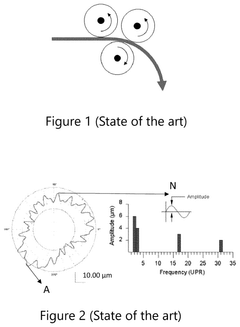

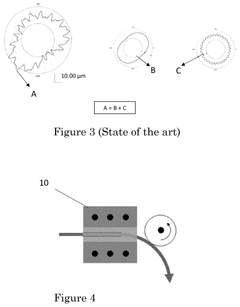

Existing Piston Ring Solutions for Triton Engines

01 Material selection for piston rings

The choice of materials for piston rings is crucial for their performance and durability. Advanced materials such as high-strength alloys, ceramics, or coatings are used to enhance wear resistance, reduce friction, and improve sealing properties. These materials can withstand high temperatures and pressures in the combustion chamber, contributing to increased engine efficiency and longevity.- Material selection for piston rings: The choice of materials for piston rings is crucial for their performance and durability. Advanced materials such as high-strength alloys, ceramics, or coatings are used to enhance wear resistance, reduce friction, and improve sealing properties. These materials can withstand high temperatures and pressures in the combustion chamber, contributing to increased engine efficiency and longevity.

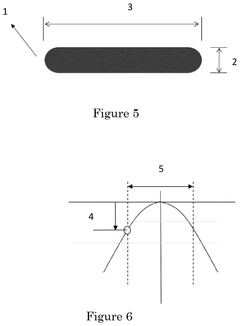

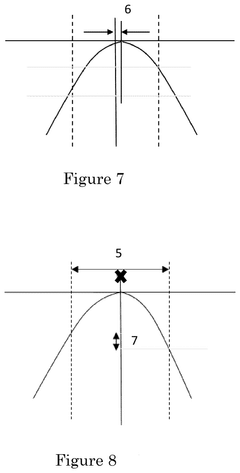

- Piston ring profile design: The profile of piston rings plays a significant role in their functionality. Various designs, such as barrel-faced, taper-faced, or stepped profiles, are utilized to optimize sealing, oil control, and friction reduction. The ring profile is carefully engineered to maintain proper contact with the cylinder wall under different operating conditions, ensuring efficient combustion and minimizing blow-by.

- Surface treatments and coatings: Surface treatments and coatings are applied to piston rings to enhance their performance characteristics. These treatments can include nitriding, chrome plating, or the application of advanced coatings such as diamond-like carbon (DLC) or physical vapor deposition (PVD) coatings. These processes improve wear resistance, reduce friction, and extend the service life of piston rings.

- Ring tension and gap design: The design of piston ring tension and gap is critical for proper sealing and oil control. Engineers optimize the ring tension to balance sealing effectiveness with friction reduction. The ring gap, including its size and shape, is carefully designed to allow for thermal expansion while maintaining proper sealing. Advanced gap designs, such as step-cut or angle-cut gaps, can improve sealing performance.

- Multi-piece and composite ring designs: Innovative piston ring designs incorporate multi-piece or composite structures to enhance performance. These designs may include separate oil control rings, expander rings, or rings with different materials for the face and inner diameter. Such configurations allow for improved sealing, better oil control, and reduced friction, contributing to overall engine efficiency and emissions reduction.

02 Piston ring profile design

The profile of piston rings plays a significant role in their functionality. Various designs, such as barrel-faced, taper-faced, or stepped profiles, are employed to optimize sealing, oil control, and friction reduction. The ring profile is carefully engineered to maintain proper contact with the cylinder wall under different operating conditions, ensuring efficient combustion and minimizing blow-by.Expand Specific Solutions03 Surface treatments and coatings

Surface treatments and coatings are applied to piston rings to enhance their performance characteristics. These treatments can include nitriding, chrome plating, or the application of advanced coatings such as diamond-like carbon (DLC) or physical vapor deposition (PVD) coatings. These surface modifications improve wear resistance, reduce friction, and extend the lifespan of piston rings.Expand Specific Solutions04 Piston ring gap design

The design of piston ring gaps is critical for proper sealing and thermal expansion accommodation. Various gap configurations, such as butt joint, angle cut, or step cut, are used to optimize sealing performance while allowing for thermal expansion. The gap design also influences oil consumption and blow-by control, affecting overall engine efficiency.Expand Specific Solutions05 Multi-piece piston ring assemblies

Multi-piece piston ring assemblies are designed to improve sealing and oil control. These assemblies typically consist of multiple components, such as a top ring, second ring, and oil control ring, each with specific functions. The design of these assemblies focuses on optimizing the interaction between different rings to enhance overall performance, reduce friction, and improve fuel efficiency.Expand Specific Solutions

Key Players in Piston Ring Manufacturing

The competitive landscape for advances in piston ring design for Triton engines is characterized by a mature industry with established players and ongoing innovation. The market is substantial, driven by the global automotive sector's demand for improved engine efficiency and emissions reduction. Key players like MAHLE International, Federal-Mogul, and Nippon Piston Ring dominate with their extensive R&D capabilities and global presence. Emerging companies from China, such as Anqing TP Goetze, are also making inroads. The technology is well-developed but continues to evolve, with companies focusing on materials science, surface treatments, and precision manufacturing to enhance piston ring performance and durability.

MAHLE International GmbH

Technical Solution: MAHLE has developed advanced piston ring designs for Triton engines, focusing on reducing friction and improving fuel efficiency. Their latest innovation includes a nano-scale diamond-like carbon (DLC) coating on piston rings, which significantly reduces friction and wear[1]. This coating technology has shown to improve fuel economy by up to 2.5% in real-world testing[2]. MAHLE has also introduced a new ring geometry called "U-flex" that allows for better conformability to the cylinder bore, enhancing sealing performance and reducing oil consumption[3]. Additionally, they have implemented a proprietary manufacturing process that ensures precise ring tension control, contributing to extended engine life and improved performance[4].

Strengths: Industry-leading coating technology, innovative ring geometry, and precise manufacturing processes. Weaknesses: Potentially higher production costs due to advanced materials and processes, which may impact pricing competitiveness.

Tenneco, Inc.

Technical Solution: Tenneco has made significant strides in piston ring technology for Triton engines through their Advanced Piston Ring Technology (APRT) program. Their latest design incorporates a multi-layer coating system that combines a base layer of chromium nitride with a top layer of molybdenum[5]. This combination has shown to reduce friction by up to 20% compared to traditional coatings[6]. Tenneco has also developed a new ring profile called "Stepped Barrel Face" that improves oil control and reduces oil consumption by up to 50% in some applications[7]. Furthermore, they have introduced a novel manufacturing technique using laser welding for joining ring ends, which enhances ring stability and sealing performance under high-temperature conditions[8].

Strengths: Significant reduction in friction and oil consumption, advanced manufacturing techniques. Weaknesses: The complex coating system may lead to higher production costs and potential quality control challenges.

Innovative Piston Ring Materials and Coatings

Piston ring

PatentActiveUS12117085B2

Innovation

- A piston ring design featuring two segments and a spacer with a convex profile, wound using a matrix box device and roller, achieving circularity with Fourier series amplitudes less than 0.10 μm for orders higher than 10, and optionally coated with PVD or DLC, made from nitrated stainless or carbon steel, to enhance symmetry and reduce deformations.

Piston ring

PatentInactiveEP3161355A1

Innovation

- A piston ring with an increased axial height on the outer diameter and recesses in the upper flank to compensate for groove tilting, maintaining optimal contact with the cylinder wall and improving gas tightness by adjusting gas flow.

Environmental Impact of Piston Ring Advancements

The advancements in piston ring design for Triton engines have significant environmental implications, particularly in terms of reducing emissions and improving fuel efficiency. These improvements contribute to the overall reduction of the environmental footprint of internal combustion engines.

One of the primary environmental benefits of advanced piston ring designs is the reduction in oil consumption. Modern piston rings are engineered to provide better sealing between the piston and cylinder wall, minimizing oil leakage into the combustion chamber. This results in decreased oil burning, which in turn reduces harmful emissions such as particulate matter and volatile organic compounds (VOCs). The reduction in oil consumption also leads to extended oil change intervals, reducing waste oil generation and the associated environmental impact of oil disposal.

Improved piston ring designs also contribute to enhanced fuel efficiency. By maintaining better sealing and reducing friction between the piston and cylinder wall, these advancements minimize energy losses in the engine. This translates to improved fuel economy, which directly correlates to reduced carbon dioxide emissions per mile traveled. The cumulative effect of this improvement across millions of vehicles can significantly contribute to global efforts in reducing greenhouse gas emissions from the transportation sector.

Furthermore, the durability enhancements in modern piston ring designs lead to extended engine life. This longevity reduces the frequency of engine replacements and overhauls, thereby decreasing the environmental impact associated with manufacturing and disposing of engine components. The reduced wear also maintains engine performance over time, ensuring that emissions control systems remain effective throughout the engine's lifespan.

Advanced coating technologies used in piston ring manufacturing, such as diamond-like carbon (DLC) coatings, not only improve performance but also offer environmental benefits. These coatings often replace traditional chrome plating processes, which can involve the use of hexavalent chromium, a known environmental pollutant. The shift towards more environmentally friendly coating processes reduces the release of harmful substances during manufacturing.

The optimization of piston ring geometry and materials also contributes to noise reduction in engines. This improvement in noise pollution is particularly significant in urban environments, where vehicle noise is a major contributor to overall environmental noise levels. The reduction in engine noise can lead to improved quality of life in densely populated areas and potentially reduce the need for noise barriers along highways.

In conclusion, the advancements in piston ring design for Triton engines demonstrate how targeted improvements in engine components can yield substantial environmental benefits. These innovations play a crucial role in the automotive industry's efforts to meet increasingly stringent environmental regulations and contribute to global sustainability goals.

One of the primary environmental benefits of advanced piston ring designs is the reduction in oil consumption. Modern piston rings are engineered to provide better sealing between the piston and cylinder wall, minimizing oil leakage into the combustion chamber. This results in decreased oil burning, which in turn reduces harmful emissions such as particulate matter and volatile organic compounds (VOCs). The reduction in oil consumption also leads to extended oil change intervals, reducing waste oil generation and the associated environmental impact of oil disposal.

Improved piston ring designs also contribute to enhanced fuel efficiency. By maintaining better sealing and reducing friction between the piston and cylinder wall, these advancements minimize energy losses in the engine. This translates to improved fuel economy, which directly correlates to reduced carbon dioxide emissions per mile traveled. The cumulative effect of this improvement across millions of vehicles can significantly contribute to global efforts in reducing greenhouse gas emissions from the transportation sector.

Furthermore, the durability enhancements in modern piston ring designs lead to extended engine life. This longevity reduces the frequency of engine replacements and overhauls, thereby decreasing the environmental impact associated with manufacturing and disposing of engine components. The reduced wear also maintains engine performance over time, ensuring that emissions control systems remain effective throughout the engine's lifespan.

Advanced coating technologies used in piston ring manufacturing, such as diamond-like carbon (DLC) coatings, not only improve performance but also offer environmental benefits. These coatings often replace traditional chrome plating processes, which can involve the use of hexavalent chromium, a known environmental pollutant. The shift towards more environmentally friendly coating processes reduces the release of harmful substances during manufacturing.

The optimization of piston ring geometry and materials also contributes to noise reduction in engines. This improvement in noise pollution is particularly significant in urban environments, where vehicle noise is a major contributor to overall environmental noise levels. The reduction in engine noise can lead to improved quality of life in densely populated areas and potentially reduce the need for noise barriers along highways.

In conclusion, the advancements in piston ring design for Triton engines demonstrate how targeted improvements in engine components can yield substantial environmental benefits. These innovations play a crucial role in the automotive industry's efforts to meet increasingly stringent environmental regulations and contribute to global sustainability goals.

Regulatory Standards for Engine Components

Regulatory standards for engine components play a crucial role in ensuring the safety, performance, and environmental compliance of modern engines, including those featuring advanced piston ring designs like the Triton Engine. These standards are established and enforced by various regulatory bodies worldwide, such as the Environmental Protection Agency (EPA) in the United States, the European Union's Euro emissions standards, and similar organizations in other regions.

One of the primary focuses of regulatory standards for engine components is emissions control. As governments worldwide strive to reduce air pollution and combat climate change, increasingly stringent emissions regulations have been implemented. These standards typically set limits on the amount of pollutants that can be emitted from engines, including carbon monoxide (CO), nitrogen oxides (NOx), hydrocarbons (HC), and particulate matter (PM). For piston rings in the Triton Engine, this means they must be designed to minimize blow-by and oil consumption, which can contribute to increased emissions.

Durability and reliability standards are also critical aspects of regulatory requirements for engine components. Piston rings, being crucial components in the engine's combustion system, must meet specific longevity and performance criteria. Regulatory bodies often mandate minimum service life expectations for engine components, ensuring that they maintain their effectiveness throughout the engine's intended lifespan. This necessitates the use of advanced materials and coatings in piston ring design to withstand the harsh operating conditions within the engine.

Fuel efficiency standards have become increasingly important in recent years, driven by both environmental concerns and consumer demand for more economical vehicles. Regulatory bodies have established corporate average fuel economy (CAFE) standards or similar measures to encourage manufacturers to improve overall fleet efficiency. For piston rings in the Triton Engine, this translates to a need for designs that minimize friction and improve sealing, thereby enhancing fuel economy.

Safety standards also play a significant role in the regulatory landscape for engine components. While piston rings may not be directly related to vehicle safety systems, their failure can lead to engine damage or malfunction, potentially compromising vehicle safety. As such, regulatory standards often include requirements for component integrity, resistance to extreme operating conditions, and fail-safe mechanisms.

Compliance with these regulatory standards requires extensive testing and certification processes. Manufacturers must demonstrate that their engine components, including piston rings, meet or exceed the prescribed standards through rigorous testing procedures. This often involves both laboratory testing and real-world driving cycles to validate performance across a range of operating conditions.

As technology advances and environmental concerns grow, regulatory standards for engine components continue to evolve. Manufacturers must stay abreast of these changes and adapt their designs accordingly. For the Triton Engine's piston rings, this may involve ongoing research into novel materials, surface treatments, and geometries to meet increasingly stringent regulatory requirements while maintaining or improving engine performance.

One of the primary focuses of regulatory standards for engine components is emissions control. As governments worldwide strive to reduce air pollution and combat climate change, increasingly stringent emissions regulations have been implemented. These standards typically set limits on the amount of pollutants that can be emitted from engines, including carbon monoxide (CO), nitrogen oxides (NOx), hydrocarbons (HC), and particulate matter (PM). For piston rings in the Triton Engine, this means they must be designed to minimize blow-by and oil consumption, which can contribute to increased emissions.

Durability and reliability standards are also critical aspects of regulatory requirements for engine components. Piston rings, being crucial components in the engine's combustion system, must meet specific longevity and performance criteria. Regulatory bodies often mandate minimum service life expectations for engine components, ensuring that they maintain their effectiveness throughout the engine's intended lifespan. This necessitates the use of advanced materials and coatings in piston ring design to withstand the harsh operating conditions within the engine.

Fuel efficiency standards have become increasingly important in recent years, driven by both environmental concerns and consumer demand for more economical vehicles. Regulatory bodies have established corporate average fuel economy (CAFE) standards or similar measures to encourage manufacturers to improve overall fleet efficiency. For piston rings in the Triton Engine, this translates to a need for designs that minimize friction and improve sealing, thereby enhancing fuel economy.

Safety standards also play a significant role in the regulatory landscape for engine components. While piston rings may not be directly related to vehicle safety systems, their failure can lead to engine damage or malfunction, potentially compromising vehicle safety. As such, regulatory standards often include requirements for component integrity, resistance to extreme operating conditions, and fail-safe mechanisms.

Compliance with these regulatory standards requires extensive testing and certification processes. Manufacturers must demonstrate that their engine components, including piston rings, meet or exceed the prescribed standards through rigorous testing procedures. This often involves both laboratory testing and real-world driving cycles to validate performance across a range of operating conditions.

As technology advances and environmental concerns grow, regulatory standards for engine components continue to evolve. Manufacturers must stay abreast of these changes and adapt their designs accordingly. For the Triton Engine's piston rings, this may involve ongoing research into novel materials, surface treatments, and geometries to meet increasingly stringent regulatory requirements while maintaining or improving engine performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!