How to Ensure Safety in 5.4 Triton Engine Modifications?

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton Engine Safety Objectives

The primary safety objectives for the 5.4 Triton engine modifications focus on maintaining and enhancing the engine's reliability, performance, and compliance with safety standards. These objectives are crucial to ensure the modified engine operates safely and efficiently in various applications.

One of the key safety objectives is to maintain the structural integrity of the engine components during the modification process. This involves careful analysis and reinforcement of critical parts to withstand increased stress and thermal loads that may result from performance enhancements. Engineers must ensure that modifications do not compromise the engine's durability or introduce potential failure points.

Another important objective is to optimize the engine's combustion process for improved efficiency and reduced emissions. This includes fine-tuning fuel injection systems, adjusting air-fuel ratios, and implementing advanced combustion control strategies. By achieving cleaner combustion, the modified engine can meet stringent environmental regulations while maintaining or improving performance.

Thermal management is a critical safety objective in the Triton engine modifications. Proper cooling system design and heat dissipation strategies must be implemented to prevent overheating and ensure consistent performance under various operating conditions. This may involve redesigning cooling passages, upgrading radiators, or incorporating advanced thermal management technologies.

Ensuring the reliability of the engine's control systems is another vital safety objective. This includes upgrading the engine control unit (ECU) software and hardware to accommodate new performance parameters and safety features. Robust fail-safe mechanisms and diagnostic capabilities must be integrated to detect and respond to potential issues promptly.

Vibration and noise reduction are important safety objectives that contribute to both operator comfort and long-term engine reliability. Engineers must analyze and mitigate vibration sources, implement improved damping solutions, and optimize engine mounts to reduce stress on components and minimize fatigue-related failures.

Compatibility with existing vehicle systems is a crucial safety objective for the modified Triton engine. This involves ensuring seamless integration with transmission systems, electrical components, and other vehicle subsystems. Proper calibration and testing are necessary to verify that the modified engine works harmoniously with all related vehicle functions.

Finally, comprehensive testing and validation form a critical safety objective in the modification process. This includes extensive bench testing, dynamometer runs, and real-world driving scenarios to verify the engine's performance, durability, and safety under various conditions. Rigorous quality control measures must be implemented throughout the modification process to ensure consistency and reliability in production.

One of the key safety objectives is to maintain the structural integrity of the engine components during the modification process. This involves careful analysis and reinforcement of critical parts to withstand increased stress and thermal loads that may result from performance enhancements. Engineers must ensure that modifications do not compromise the engine's durability or introduce potential failure points.

Another important objective is to optimize the engine's combustion process for improved efficiency and reduced emissions. This includes fine-tuning fuel injection systems, adjusting air-fuel ratios, and implementing advanced combustion control strategies. By achieving cleaner combustion, the modified engine can meet stringent environmental regulations while maintaining or improving performance.

Thermal management is a critical safety objective in the Triton engine modifications. Proper cooling system design and heat dissipation strategies must be implemented to prevent overheating and ensure consistent performance under various operating conditions. This may involve redesigning cooling passages, upgrading radiators, or incorporating advanced thermal management technologies.

Ensuring the reliability of the engine's control systems is another vital safety objective. This includes upgrading the engine control unit (ECU) software and hardware to accommodate new performance parameters and safety features. Robust fail-safe mechanisms and diagnostic capabilities must be integrated to detect and respond to potential issues promptly.

Vibration and noise reduction are important safety objectives that contribute to both operator comfort and long-term engine reliability. Engineers must analyze and mitigate vibration sources, implement improved damping solutions, and optimize engine mounts to reduce stress on components and minimize fatigue-related failures.

Compatibility with existing vehicle systems is a crucial safety objective for the modified Triton engine. This involves ensuring seamless integration with transmission systems, electrical components, and other vehicle subsystems. Proper calibration and testing are necessary to verify that the modified engine works harmoniously with all related vehicle functions.

Finally, comprehensive testing and validation form a critical safety objective in the modification process. This includes extensive bench testing, dynamometer runs, and real-world driving scenarios to verify the engine's performance, durability, and safety under various conditions. Rigorous quality control measures must be implemented throughout the modification process to ensure consistency and reliability in production.

Market Analysis for Modified Engines

The market for modified engines, particularly those based on the 5.4 Triton engine, has shown significant growth in recent years. This trend is driven by automotive enthusiasts seeking improved performance and efficiency from their vehicles. The demand for modified engines spans various sectors, including off-road vehicles, racing applications, and high-performance street cars.

Safety considerations play a crucial role in the market dynamics of modified engines. As consumers become more aware of the potential risks associated with engine modifications, there is an increasing demand for safety-focused solutions. This has led to a growing market segment dedicated to safety equipment and technologies specifically designed for modified engines.

The global market for aftermarket automotive parts, which includes modified engines, was valued at $380 billion in 2021 and is projected to reach $522 billion by 2026, growing at a CAGR of 6.5%. Within this broader market, the segment for engine modifications and performance upgrades is experiencing even faster growth, driven by the rising popularity of customized vehicles and motorsports.

In the context of 5.4 Triton engine modifications, the market is characterized by a mix of professional tuning shops, aftermarket parts manufacturers, and DIY enthusiasts. The professional modification services market is estimated to account for about 60% of the total market share, while DIY modifications make up the remaining 40%.

Safety-related products and services for modified engines represent a rapidly expanding niche within this market. This includes advanced engine management systems, high-performance cooling solutions, and reinforced engine components designed to withstand increased power outputs. The market for these safety-oriented products is growing at an estimated rate of 8-10% annually, outpacing the overall modified engine market growth.

Geographically, North America dominates the market for 5.4 Triton engine modifications, accounting for approximately 45% of the global market share. This is largely due to the popularity of Ford vehicles equipped with these engines in the region. Europe and Asia-Pacific follow, with market shares of 30% and 20% respectively.

The competitive landscape is characterized by a mix of established automotive aftermarket companies and specialized performance tuning firms. Key players in this market include companies like Edelbrock, Borla Performance Industries, and SCT Performance, among others. These companies are increasingly focusing on developing products that not only enhance performance but also prioritize safety in modified engines.

Safety considerations play a crucial role in the market dynamics of modified engines. As consumers become more aware of the potential risks associated with engine modifications, there is an increasing demand for safety-focused solutions. This has led to a growing market segment dedicated to safety equipment and technologies specifically designed for modified engines.

The global market for aftermarket automotive parts, which includes modified engines, was valued at $380 billion in 2021 and is projected to reach $522 billion by 2026, growing at a CAGR of 6.5%. Within this broader market, the segment for engine modifications and performance upgrades is experiencing even faster growth, driven by the rising popularity of customized vehicles and motorsports.

In the context of 5.4 Triton engine modifications, the market is characterized by a mix of professional tuning shops, aftermarket parts manufacturers, and DIY enthusiasts. The professional modification services market is estimated to account for about 60% of the total market share, while DIY modifications make up the remaining 40%.

Safety-related products and services for modified engines represent a rapidly expanding niche within this market. This includes advanced engine management systems, high-performance cooling solutions, and reinforced engine components designed to withstand increased power outputs. The market for these safety-oriented products is growing at an estimated rate of 8-10% annually, outpacing the overall modified engine market growth.

Geographically, North America dominates the market for 5.4 Triton engine modifications, accounting for approximately 45% of the global market share. This is largely due to the popularity of Ford vehicles equipped with these engines in the region. Europe and Asia-Pacific follow, with market shares of 30% and 20% respectively.

The competitive landscape is characterized by a mix of established automotive aftermarket companies and specialized performance tuning firms. Key players in this market include companies like Edelbrock, Borla Performance Industries, and SCT Performance, among others. These companies are increasingly focusing on developing products that not only enhance performance but also prioritize safety in modified engines.

Current Safety Challenges in Engine Modifications

Engine modifications, particularly for high-performance vehicles like those equipped with the 5.4 Triton engine, present significant safety challenges that require careful consideration and mitigation strategies. One of the primary concerns is the potential for increased stress on engine components due to enhanced power output. As modifications often push the engine beyond its original design parameters, there is an elevated risk of component failure, which can lead to catastrophic engine damage or even accidents.

Another critical safety challenge lies in the alteration of the engine's thermal characteristics. Modified engines typically generate more heat, potentially exceeding the cooling system's capacity. This can result in overheating, which not only compromises engine performance but also poses serious safety risks, including the possibility of engine fires or sudden power loss during operation.

Fuel system modifications present their own set of safety concerns. Increased fuel flow rates and pressures can strain fuel lines, pumps, and injectors beyond their design limits. This may lead to fuel leaks, which in turn create fire hazards and potential for engine damage. Additionally, improper fuel-air mixture ratios resulting from modifications can cause engine knock or pre-ignition, potentially damaging pistons, valves, and other critical components.

The integration of aftermarket parts introduces compatibility issues that can compromise safety. Not all aftermarket components are designed to the same standards as original equipment, and their interaction with stock parts may lead to unexpected failures. This is particularly concerning for safety-critical systems such as brakes and suspension, which may need to be upgraded to handle the increased power and performance.

Emissions control is another significant challenge in engine modifications. Alterations that bypass or modify emissions control systems not only violate environmental regulations but can also lead to the release of harmful pollutants. This poses health risks to both the vehicle occupants and the general public, and may result in legal consequences for non-compliance with emissions standards.

Lastly, the complexity of modern engine management systems presents a unique challenge. Modifications often require recalibration of the engine control unit (ECU) to optimize performance and ensure safe operation. Improper tuning can lead to a range of issues, from poor drivability to severe engine damage. The intricate nature of these systems demands expertise that may be beyond the capabilities of many enthusiasts or even some professional tuners.

Another critical safety challenge lies in the alteration of the engine's thermal characteristics. Modified engines typically generate more heat, potentially exceeding the cooling system's capacity. This can result in overheating, which not only compromises engine performance but also poses serious safety risks, including the possibility of engine fires or sudden power loss during operation.

Fuel system modifications present their own set of safety concerns. Increased fuel flow rates and pressures can strain fuel lines, pumps, and injectors beyond their design limits. This may lead to fuel leaks, which in turn create fire hazards and potential for engine damage. Additionally, improper fuel-air mixture ratios resulting from modifications can cause engine knock or pre-ignition, potentially damaging pistons, valves, and other critical components.

The integration of aftermarket parts introduces compatibility issues that can compromise safety. Not all aftermarket components are designed to the same standards as original equipment, and their interaction with stock parts may lead to unexpected failures. This is particularly concerning for safety-critical systems such as brakes and suspension, which may need to be upgraded to handle the increased power and performance.

Emissions control is another significant challenge in engine modifications. Alterations that bypass or modify emissions control systems not only violate environmental regulations but can also lead to the release of harmful pollutants. This poses health risks to both the vehicle occupants and the general public, and may result in legal consequences for non-compliance with emissions standards.

Lastly, the complexity of modern engine management systems presents a unique challenge. Modifications often require recalibration of the engine control unit (ECU) to optimize performance and ensure safe operation. Improper tuning can lead to a range of issues, from poor drivability to severe engine damage. The intricate nature of these systems demands expertise that may be beyond the capabilities of many enthusiasts or even some professional tuners.

Existing Safety Solutions for 5.4 Triton Engine

01 Safety systems for Triton engine

Various safety systems are implemented in Triton engines to ensure safe operation. These include monitoring systems for temperature, pressure, and vibration, as well as emergency shutdown mechanisms. Advanced sensors and control units are utilized to detect abnormal conditions and initiate appropriate safety responses.- Safety systems for Triton engine: Various safety systems are implemented in Triton engines to ensure safe operation. These include monitoring systems for temperature, pressure, and vibration, as well as emergency shutdown mechanisms. Advanced sensors and control units are utilized to detect abnormal conditions and initiate appropriate safety responses.

- Cooling and lubrication improvements: Enhanced cooling and lubrication systems are developed for Triton engines to prevent overheating and reduce wear. These improvements include advanced coolant circulation designs, efficient oil distribution mechanisms, and thermal management solutions to maintain optimal operating temperatures and extend engine life.

- Exhaust gas treatment and emission control: Triton engines incorporate advanced exhaust gas treatment and emission control technologies to reduce harmful emissions. These systems may include catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems to meet stringent environmental regulations and improve overall engine safety.

- Fuel injection and combustion optimization: Improved fuel injection systems and combustion chamber designs are implemented in Triton engines to enhance efficiency and safety. These advancements include precise fuel metering, optimized spray patterns, and advanced ignition timing control to ensure complete combustion and reduce the risk of engine knock or misfire.

- Structural reinforcement and vibration reduction: Triton engines feature enhanced structural designs and vibration dampening technologies to improve durability and safety. These improvements include reinforced engine blocks, optimized crankshaft and bearing designs, and advanced mounting systems to reduce stress on components and minimize the risk of mechanical failures.

02 Cooling and lubrication improvements

Enhanced cooling and lubrication systems are developed for Triton engines to prevent overheating and reduce wear. These improvements include advanced coolant circulation designs, efficient oil distribution mechanisms, and temperature-regulated lubrication systems. Such enhancements contribute to increased engine longevity and safer operation.Expand Specific Solutions03 Exhaust gas management

Triton engines incorporate advanced exhaust gas management systems to reduce emissions and improve safety. These systems include catalytic converters, particulate filters, and exhaust gas recirculation technologies. Proper management of exhaust gases helps in maintaining engine efficiency and reducing environmental impact.Expand Specific Solutions04 Fuel injection and combustion control

Improved fuel injection and combustion control mechanisms are implemented in Triton engines to enhance safety and efficiency. These include precise electronic fuel injection systems, advanced ignition timing control, and combustion chamber designs that optimize fuel-air mixture. Such improvements lead to more stable engine operation and reduced risk of misfires or fuel-related issues.Expand Specific Solutions05 Structural reinforcements and vibration damping

Triton engines feature enhanced structural reinforcements and vibration damping technologies to improve overall safety and reliability. These include strengthened engine blocks, improved mounting systems, and advanced materials for vibration absorption. Such measures help in reducing mechanical stress and preventing potential failures during operation.Expand Specific Solutions

Key Players in Engine Modification Industry

The safety of 5.4 Triton engine modifications is a critical concern in the automotive industry, currently in a mature stage with a substantial market size. The technology's maturity varies among key players, with established companies like Toyota Motor Corp. and Dana Automotive Systems Group LLC likely having advanced safety protocols. Emerging players such as Weichai Power and Contemporary Amperex Technology Co., Ltd. are also contributing to the field, potentially introducing innovative safety measures. The competitive landscape is diverse, with traditional automotive manufacturers competing alongside specialized engine and power system developers, driving continuous improvements in safety standards and technologies for engine modifications.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology Co., Ltd. (CATL) has applied its expertise in battery technology to address safety concerns in 5.4 Triton engine modifications, particularly for hybrid and electric powertrains. They have developed advanced battery management systems (BMS) that integrate seamlessly with modified engine control units[1]. CATL's approach includes the implementation of high-performance lithium-ion batteries with enhanced thermal management capabilities, crucial for handling the increased power demands of modified engines[3]. They have also introduced smart power distribution modules that optimize energy flow between the engine and electric systems, enhancing overall efficiency and safety[5]. Additionally, CATL has developed specialized insulation and shielding technologies to protect battery components from the increased heat and vibration associated with modified engines[7]. The company has also implemented advanced diagnostic systems that continuously monitor battery health and performance, providing early warning of potential issues[9].

Strengths: Advanced battery management systems, specialized thermal management, and smart power distribution. Weaknesses: Primary focus on hybrid and electric applications may limit relevance to purely combustion-based modifications.

Transportation IP Holdings LLC

Technical Solution: Transportation IP Holdings LLC has developed a suite of intellectual property solutions aimed at enhancing safety in 5.4 Triton engine modifications. Their approach includes patented technologies for advanced fuel management systems that optimize fuel delivery and combustion processes in modified engines[2]. They have also developed innovative sensor technologies that provide more accurate and responsive monitoring of engine parameters[4]. Transportation IP Holdings has created algorithms for predictive maintenance, which analyze engine data to forecast potential issues before they occur[6]. Additionally, they have patented designs for reinforced engine mounts and supports that better distribute the increased stresses associated with modified engines[8]. The company has also developed intellectual property around advanced exhaust gas recirculation (EGR) systems, which help manage emissions and temperatures in high-performance applications[10].

Strengths: Innovative fuel management and sensor technologies, predictive maintenance algorithms. Weaknesses: Reliance on licensing agreements for implementation, potential compatibility issues with existing systems.

Core Innovations in Engine Safety Systems

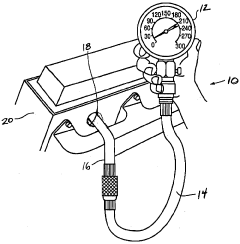

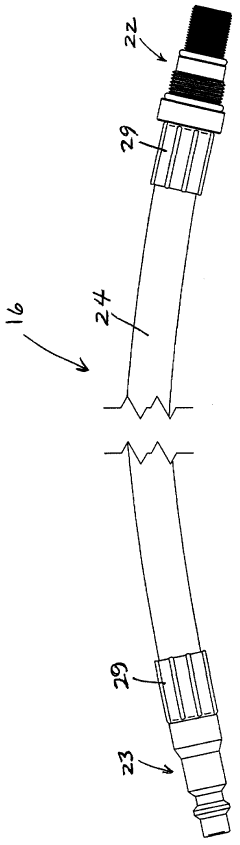

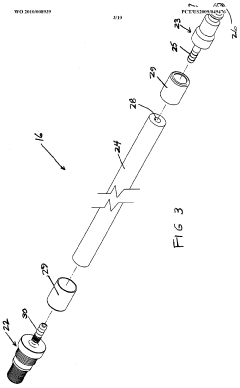

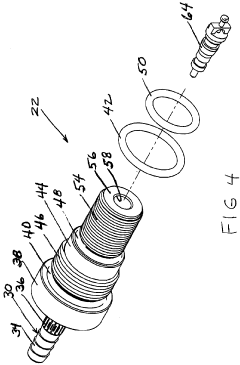

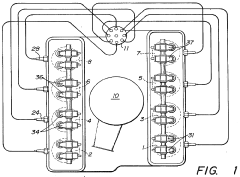

Dual application compression tester adapter assembly and method

PatentWO2010008939A1

Innovation

- A dual-purpose adapter assembly with a leading cylindrical portion having 12 mm external threads and a trailing cylindrical portion with 16 mm external threads, featuring axial spacing between full threads within the range of .636-.737 inches, along with gasket seats for sealing and a hose connector for uninterrupted fluid communication, allowing engagement with both socket sizes.

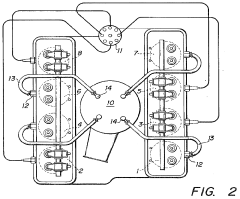

Engine modification

PatentInactiveUS3945367A

Innovation

- A method to convert an N-cylinder engine to an (N/2)-cylinder engine by deactivating every other cylinder by replacing spark plugs with fittings, connecting conduits to prevent debris and vacuum passage, and removing rocker arm assemblies to maintain valve closure, thereby eliminating power-robbing friction and fuel flow.

Regulatory Compliance for Modified Engines

Regulatory compliance is a critical aspect of ensuring safety in 5.4 Triton engine modifications. The process of modifying engines must adhere to strict guidelines set forth by various regulatory bodies to maintain safety standards and legal requirements. In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) play pivotal roles in regulating engine modifications.

The EPA's regulations focus on emissions control and fuel economy standards. Any modifications to the 5.4 Triton engine must not compromise the vehicle's ability to meet these standards. This includes maintaining or improving the engine's emissions output and fuel efficiency. Modifications that alter the engine's performance characteristics must be thoroughly tested and certified to ensure compliance with EPA regulations.

CARB regulations are particularly stringent, especially for vehicles registered in California. CARB requires that all aftermarket parts and modifications be approved through their Executive Order (EO) process. This process involves rigorous testing to ensure that the modified engine does not increase emissions or compromise the vehicle's overall environmental performance. Manufacturers of aftermarket parts for the 5.4 Triton engine must obtain CARB EO numbers for their products to be legally used in California and states that follow CARB standards.

Safety compliance extends beyond emissions and includes structural integrity and operational safety. The National Highway Traffic Safety Administration (NHTSA) sets standards for vehicle safety, which must be considered when modifying the 5.4 Triton engine. Any modifications that affect the engine's mounting, power output, or heat generation must not compromise the vehicle's crash safety or increase the risk of mechanical failure.

For commercial vehicles utilizing the 5.4 Triton engine, additional regulations from the Department of Transportation (DOT) and the Federal Motor Carrier Safety Administration (FMCSA) may apply. These regulations cover aspects such as engine performance, durability, and safety features specific to commercial use.

Internationally, engine modifications must comply with regulations in the target markets. The European Union, for instance, has its own set of emissions standards and safety regulations that may differ from those in the United States. Manufacturers and modifiers must ensure that their 5.4 Triton engine modifications meet these diverse international standards if the vehicles are intended for global markets.

To ensure regulatory compliance, manufacturers and modifiers should implement a comprehensive testing and certification process. This process should include emissions testing, durability testing, and safety evaluations. Documentation of all modifications, test results, and certifications should be meticulously maintained to demonstrate compliance to regulatory bodies and consumers.

The EPA's regulations focus on emissions control and fuel economy standards. Any modifications to the 5.4 Triton engine must not compromise the vehicle's ability to meet these standards. This includes maintaining or improving the engine's emissions output and fuel efficiency. Modifications that alter the engine's performance characteristics must be thoroughly tested and certified to ensure compliance with EPA regulations.

CARB regulations are particularly stringent, especially for vehicles registered in California. CARB requires that all aftermarket parts and modifications be approved through their Executive Order (EO) process. This process involves rigorous testing to ensure that the modified engine does not increase emissions or compromise the vehicle's overall environmental performance. Manufacturers of aftermarket parts for the 5.4 Triton engine must obtain CARB EO numbers for their products to be legally used in California and states that follow CARB standards.

Safety compliance extends beyond emissions and includes structural integrity and operational safety. The National Highway Traffic Safety Administration (NHTSA) sets standards for vehicle safety, which must be considered when modifying the 5.4 Triton engine. Any modifications that affect the engine's mounting, power output, or heat generation must not compromise the vehicle's crash safety or increase the risk of mechanical failure.

For commercial vehicles utilizing the 5.4 Triton engine, additional regulations from the Department of Transportation (DOT) and the Federal Motor Carrier Safety Administration (FMCSA) may apply. These regulations cover aspects such as engine performance, durability, and safety features specific to commercial use.

Internationally, engine modifications must comply with regulations in the target markets. The European Union, for instance, has its own set of emissions standards and safety regulations that may differ from those in the United States. Manufacturers and modifiers must ensure that their 5.4 Triton engine modifications meet these diverse international standards if the vehicles are intended for global markets.

To ensure regulatory compliance, manufacturers and modifiers should implement a comprehensive testing and certification process. This process should include emissions testing, durability testing, and safety evaluations. Documentation of all modifications, test results, and certifications should be meticulously maintained to demonstrate compliance to regulatory bodies and consumers.

Environmental Impact of Engine Modifications

Engine modifications, while aimed at improving performance and efficiency, can have significant environmental implications. The 5.4 Triton engine modifications must be carefully evaluated for their potential impact on emissions, fuel consumption, and overall ecological footprint. These alterations can affect the engine's combustion process, potentially leading to changes in the composition and quantity of exhaust gases.

One primary concern is the potential increase in greenhouse gas emissions, particularly carbon dioxide (CO2). Modifications that enhance engine power or alter fuel-to-air ratios may result in higher fuel consumption, directly correlating to increased CO2 output. This is especially critical given the global focus on reducing carbon emissions to combat climate change. Conversely, some modifications aimed at improving fuel efficiency could potentially reduce overall emissions, presenting a positive environmental outcome.

Nitrogen oxides (NOx) emissions are another crucial factor to consider. Engine modifications that increase combustion temperatures or alter timing can lead to higher NOx production. These compounds contribute to smog formation and acid rain, posing risks to both human health and the environment. Ensuring that any modifications comply with or exceed current emission standards is essential for minimizing these negative impacts.

Particulate matter emissions, particularly relevant in diesel engines, must also be addressed. Modifications that affect fuel injection or combustion characteristics can influence the amount and size of particulates released. These microscopic particles can have severe respiratory health implications and contribute to air pollution. Implementing or maintaining effective particulate filters becomes crucial when considering engine modifications.

The lifecycle environmental impact of the materials used in modifications should not be overlooked. New components or technologies introduced during the modification process may have their own environmental footprint, from production to eventual disposal. Selecting materials and technologies with minimal environmental impact throughout their lifecycle can help mitigate these concerns.

Noise pollution is another environmental aspect affected by engine modifications. Changes to the exhaust system or engine components can alter the acoustic profile of the vehicle. While this may not directly impact emissions or fuel consumption, it can have significant effects on urban environments and wildlife habitats. Ensuring that modifications do not excessively increase noise levels is important for maintaining environmental and community standards.

In conclusion, a comprehensive environmental assessment of 5.4 Triton engine modifications is crucial. This should include analysis of emissions changes, fuel efficiency impacts, material lifecycle considerations, and noise pollution effects. Balancing performance enhancements with environmental responsibility is key to ensuring that modifications are not only safe but also sustainable in the long term.

One primary concern is the potential increase in greenhouse gas emissions, particularly carbon dioxide (CO2). Modifications that enhance engine power or alter fuel-to-air ratios may result in higher fuel consumption, directly correlating to increased CO2 output. This is especially critical given the global focus on reducing carbon emissions to combat climate change. Conversely, some modifications aimed at improving fuel efficiency could potentially reduce overall emissions, presenting a positive environmental outcome.

Nitrogen oxides (NOx) emissions are another crucial factor to consider. Engine modifications that increase combustion temperatures or alter timing can lead to higher NOx production. These compounds contribute to smog formation and acid rain, posing risks to both human health and the environment. Ensuring that any modifications comply with or exceed current emission standards is essential for minimizing these negative impacts.

Particulate matter emissions, particularly relevant in diesel engines, must also be addressed. Modifications that affect fuel injection or combustion characteristics can influence the amount and size of particulates released. These microscopic particles can have severe respiratory health implications and contribute to air pollution. Implementing or maintaining effective particulate filters becomes crucial when considering engine modifications.

The lifecycle environmental impact of the materials used in modifications should not be overlooked. New components or technologies introduced during the modification process may have their own environmental footprint, from production to eventual disposal. Selecting materials and technologies with minimal environmental impact throughout their lifecycle can help mitigate these concerns.

Noise pollution is another environmental aspect affected by engine modifications. Changes to the exhaust system or engine components can alter the acoustic profile of the vehicle. While this may not directly impact emissions or fuel consumption, it can have significant effects on urban environments and wildlife habitats. Ensuring that modifications do not excessively increase noise levels is important for maintaining environmental and community standards.

In conclusion, a comprehensive environmental assessment of 5.4 Triton engine modifications is crucial. This should include analysis of emissions changes, fuel efficiency impacts, material lifecycle considerations, and noise pollution effects. Balancing performance enhancements with environmental responsibility is key to ensuring that modifications are not only safe but also sustainable in the long term.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!