How to Enhance 5.4 Triton Engine Cooling Efficiency?

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

5.4 Triton Engine Cooling Background and Objectives

The 5.4 Triton engine, a V8 powerplant developed by Ford Motor Company, has been a cornerstone of their truck and SUV lineup since its introduction in the late 1990s. As vehicle performance demands and environmental regulations have evolved, the need for enhanced cooling efficiency in this engine has become increasingly critical. The primary objective of this technical research is to explore innovative methods to improve the cooling system of the 5.4 Triton engine, addressing both current limitations and future requirements.

Historically, the 5.4 Triton engine has undergone several iterations, each aiming to enhance performance and efficiency. However, as power output has increased over time, the cooling system has faced growing challenges in maintaining optimal operating temperatures across various driving conditions. This has led to a renewed focus on cooling efficiency as a key area for improvement.

The current cooling system in the 5.4 Triton engine utilizes a traditional liquid-cooled design, incorporating a water pump, radiator, thermostat, and coolant passages throughout the engine block and cylinder heads. While this system has been adequate for many years, emerging technologies and stricter emission standards necessitate a reevaluation of its effectiveness.

One of the primary goals in enhancing the cooling efficiency is to improve overall engine performance. By maintaining more consistent and optimal operating temperatures, the engine can achieve better fuel economy, reduced emissions, and increased longevity. Additionally, enhanced cooling can potentially allow for higher power outputs without compromising reliability.

Another crucial objective is to address specific issues that have been reported in some 5.4 Triton engines, such as overheating under heavy loads or in extreme climates. By improving the cooling efficiency, these problems can be mitigated, leading to increased customer satisfaction and reduced warranty claims.

The technological landscape surrounding engine cooling has evolved significantly in recent years. Advancements in materials science, computational fluid dynamics, and electronic control systems offer new possibilities for innovative cooling solutions. This research aims to explore these cutting-edge technologies and their potential application to the 5.4 Triton engine.

Furthermore, the automotive industry's shift towards electrification and hybrid powertrains presents both challenges and opportunities for traditional internal combustion engines like the 5.4 Triton. This research will also consider how enhanced cooling efficiency can contribute to the engine's relevance and competitiveness in an increasingly electrified market.

In summary, this technical research seeks to comprehensively analyze the current state of the 5.4 Triton engine's cooling system, identify areas for improvement, and explore innovative solutions to enhance its efficiency. The ultimate goal is to develop a cooling system that not only addresses current performance and reliability issues but also positions the engine for future technological and regulatory challenges in the automotive industry.

Historically, the 5.4 Triton engine has undergone several iterations, each aiming to enhance performance and efficiency. However, as power output has increased over time, the cooling system has faced growing challenges in maintaining optimal operating temperatures across various driving conditions. This has led to a renewed focus on cooling efficiency as a key area for improvement.

The current cooling system in the 5.4 Triton engine utilizes a traditional liquid-cooled design, incorporating a water pump, radiator, thermostat, and coolant passages throughout the engine block and cylinder heads. While this system has been adequate for many years, emerging technologies and stricter emission standards necessitate a reevaluation of its effectiveness.

One of the primary goals in enhancing the cooling efficiency is to improve overall engine performance. By maintaining more consistent and optimal operating temperatures, the engine can achieve better fuel economy, reduced emissions, and increased longevity. Additionally, enhanced cooling can potentially allow for higher power outputs without compromising reliability.

Another crucial objective is to address specific issues that have been reported in some 5.4 Triton engines, such as overheating under heavy loads or in extreme climates. By improving the cooling efficiency, these problems can be mitigated, leading to increased customer satisfaction and reduced warranty claims.

The technological landscape surrounding engine cooling has evolved significantly in recent years. Advancements in materials science, computational fluid dynamics, and electronic control systems offer new possibilities for innovative cooling solutions. This research aims to explore these cutting-edge technologies and their potential application to the 5.4 Triton engine.

Furthermore, the automotive industry's shift towards electrification and hybrid powertrains presents both challenges and opportunities for traditional internal combustion engines like the 5.4 Triton. This research will also consider how enhanced cooling efficiency can contribute to the engine's relevance and competitiveness in an increasingly electrified market.

In summary, this technical research seeks to comprehensively analyze the current state of the 5.4 Triton engine's cooling system, identify areas for improvement, and explore innovative solutions to enhance its efficiency. The ultimate goal is to develop a cooling system that not only addresses current performance and reliability issues but also positions the engine for future technological and regulatory challenges in the automotive industry.

Market Demand for Improved Engine Cooling Systems

The market demand for improved engine cooling systems, particularly for the 5.4 Triton engine, has been steadily increasing due to several factors. As automotive technologies advance, engines are becoming more powerful and compact, leading to higher heat generation and the need for more efficient cooling solutions. The 5.4 Triton engine, widely used in Ford vehicles, has been a focus of attention for both manufacturers and consumers seeking enhanced performance and longevity.

Consumer expectations for vehicle reliability and durability have risen significantly, driving the demand for more effective cooling systems. Engine overheating issues can lead to costly repairs and reduced vehicle lifespan, making improved cooling efficiency a priority for vehicle owners. This demand is further amplified by the growing trend of using vehicles for heavy-duty applications, such as towing and off-road activities, which put additional stress on engine cooling systems.

Environmental regulations and fuel efficiency standards have also played a crucial role in shaping the market demand. As automakers strive to meet stricter emissions requirements, they are exploring ways to optimize engine performance, including enhancing cooling efficiency. Improved cooling systems contribute to better fuel economy and reduced emissions, aligning with both regulatory demands and consumer preferences for eco-friendly vehicles.

The aftermarket sector has seen a surge in demand for upgraded cooling components for the 5.4 Triton engine. This includes high-performance radiators, electric fans, and coolant additives designed to improve heat dissipation. The DIY automotive community and performance enthusiasts have shown particular interest in these products, seeking ways to enhance their vehicles' cooling capabilities beyond factory specifications.

Fleet operators and commercial users of vehicles equipped with the 5.4 Triton engine have also contributed to the market demand. These users require reliable and efficient cooling systems to minimize downtime and maintenance costs associated with engine overheating. The potential for improved fuel efficiency through better cooling management has made this a key consideration for businesses looking to optimize their vehicle operations.

Technological advancements in materials science and thermal management have opened new possibilities for cooling system improvements. This has created a market for innovative solutions such as advanced heat exchangers, smart cooling systems with precise temperature control, and the integration of cooling systems with other vehicle subsystems for optimized performance.

As the automotive industry moves towards electrification and hybrid technologies, the lessons learned from improving traditional engine cooling systems are being applied to new vehicle architectures. This cross-pollination of technologies is driving further innovation in thermal management across various powertrain types, expanding the market for advanced cooling solutions beyond conventional internal combustion engines.

Consumer expectations for vehicle reliability and durability have risen significantly, driving the demand for more effective cooling systems. Engine overheating issues can lead to costly repairs and reduced vehicle lifespan, making improved cooling efficiency a priority for vehicle owners. This demand is further amplified by the growing trend of using vehicles for heavy-duty applications, such as towing and off-road activities, which put additional stress on engine cooling systems.

Environmental regulations and fuel efficiency standards have also played a crucial role in shaping the market demand. As automakers strive to meet stricter emissions requirements, they are exploring ways to optimize engine performance, including enhancing cooling efficiency. Improved cooling systems contribute to better fuel economy and reduced emissions, aligning with both regulatory demands and consumer preferences for eco-friendly vehicles.

The aftermarket sector has seen a surge in demand for upgraded cooling components for the 5.4 Triton engine. This includes high-performance radiators, electric fans, and coolant additives designed to improve heat dissipation. The DIY automotive community and performance enthusiasts have shown particular interest in these products, seeking ways to enhance their vehicles' cooling capabilities beyond factory specifications.

Fleet operators and commercial users of vehicles equipped with the 5.4 Triton engine have also contributed to the market demand. These users require reliable and efficient cooling systems to minimize downtime and maintenance costs associated with engine overheating. The potential for improved fuel efficiency through better cooling management has made this a key consideration for businesses looking to optimize their vehicle operations.

Technological advancements in materials science and thermal management have opened new possibilities for cooling system improvements. This has created a market for innovative solutions such as advanced heat exchangers, smart cooling systems with precise temperature control, and the integration of cooling systems with other vehicle subsystems for optimized performance.

As the automotive industry moves towards electrification and hybrid technologies, the lessons learned from improving traditional engine cooling systems are being applied to new vehicle architectures. This cross-pollination of technologies is driving further innovation in thermal management across various powertrain types, expanding the market for advanced cooling solutions beyond conventional internal combustion engines.

Current Cooling Challenges in 5.4 Triton Engines

The 5.4 Triton engine, a popular powerplant in Ford's lineup, faces several cooling challenges that impact its overall efficiency and performance. One of the primary issues is the engine's tendency to overheat under high-load conditions, particularly when towing or during extended periods of operation in hot climates. This overheating problem can lead to reduced engine life, decreased performance, and potential engine damage if not addressed properly.

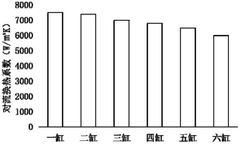

Another significant challenge is the cooling system's inability to maintain consistent temperatures across all cylinders. This uneven cooling can result in thermal stress on engine components, leading to premature wear and potential failure of critical parts such as head gaskets and cylinder liners. The inconsistent temperature distribution also affects combustion efficiency, potentially reducing fuel economy and increasing emissions.

The current cooling system design struggles to cope with the heat generated by modern high-performance variants of the 5.4 Triton engine. As power outputs have increased over time, the cooling capacity has not always kept pace, leading to a mismatch between heat generation and dissipation capabilities. This discrepancy is particularly noticeable in aftermarket-modified engines or those used in high-performance applications.

Coolant flow distribution is another area of concern. The complex engine architecture of the 5.4 Triton can create coolant flow restrictions or dead spots, where heat accumulation becomes problematic. These areas of restricted flow can lead to localized hot spots within the engine, potentially causing warping or other heat-related damage to critical components.

The cooling system's efficiency is further compromised by the accumulation of scale and deposits over time. As the engine ages, these buildups can reduce the heat transfer efficiency of the radiator and other cooling components, exacerbating the overall cooling challenges. This issue is particularly prevalent in engines that have not received regular maintenance or have been operated in harsh environments.

Lastly, the integration of advanced technologies such as variable valve timing and direct injection in newer versions of the 5.4 Triton engine has introduced additional heat management complexities. These systems generate more localized heat and require more precise temperature control to function optimally, putting further strain on the cooling system's capabilities.

Addressing these cooling challenges is crucial for enhancing the 5.4 Triton engine's efficiency, reliability, and longevity. Innovative solutions that can overcome these obstacles will be key to improving the engine's performance and meeting the increasingly stringent demands of modern automotive applications.

Another significant challenge is the cooling system's inability to maintain consistent temperatures across all cylinders. This uneven cooling can result in thermal stress on engine components, leading to premature wear and potential failure of critical parts such as head gaskets and cylinder liners. The inconsistent temperature distribution also affects combustion efficiency, potentially reducing fuel economy and increasing emissions.

The current cooling system design struggles to cope with the heat generated by modern high-performance variants of the 5.4 Triton engine. As power outputs have increased over time, the cooling capacity has not always kept pace, leading to a mismatch between heat generation and dissipation capabilities. This discrepancy is particularly noticeable in aftermarket-modified engines or those used in high-performance applications.

Coolant flow distribution is another area of concern. The complex engine architecture of the 5.4 Triton can create coolant flow restrictions or dead spots, where heat accumulation becomes problematic. These areas of restricted flow can lead to localized hot spots within the engine, potentially causing warping or other heat-related damage to critical components.

The cooling system's efficiency is further compromised by the accumulation of scale and deposits over time. As the engine ages, these buildups can reduce the heat transfer efficiency of the radiator and other cooling components, exacerbating the overall cooling challenges. This issue is particularly prevalent in engines that have not received regular maintenance or have been operated in harsh environments.

Lastly, the integration of advanced technologies such as variable valve timing and direct injection in newer versions of the 5.4 Triton engine has introduced additional heat management complexities. These systems generate more localized heat and require more precise temperature control to function optimally, putting further strain on the cooling system's capabilities.

Addressing these cooling challenges is crucial for enhancing the 5.4 Triton engine's efficiency, reliability, and longevity. Innovative solutions that can overcome these obstacles will be key to improving the engine's performance and meeting the increasingly stringent demands of modern automotive applications.

Existing Solutions for 5.4 Triton Engine Cooling

01 Improved cooling system design

Enhanced cooling efficiency for the 5.4 Triton engine can be achieved through improved cooling system design. This includes optimizing coolant flow paths, redesigning radiator configurations, and implementing advanced heat exchanger technologies. These improvements help to dissipate heat more effectively, maintaining optimal engine temperature and performance.- Improved cooling system design: Enhanced cooling efficiency for the 5.4 Triton engine can be achieved through improved cooling system design. This includes optimizing coolant flow paths, increasing radiator capacity, and implementing advanced thermostat control mechanisms. These improvements help to maintain optimal engine temperature and prevent overheating during various operating conditions.

- Advanced heat exchanger technology: Utilizing advanced heat exchanger technology can significantly improve the cooling efficiency of the 5.4 Triton engine. This may involve the use of high-performance materials, innovative fin designs, and enhanced surface area for better heat dissipation. These advancements contribute to more effective heat transfer between the coolant and the surrounding air.

- Electronic cooling fan control: Implementing electronic cooling fan control systems can optimize the cooling efficiency of the 5.4 Triton engine. These systems use sensors to monitor engine temperature and adjust fan speed accordingly, ensuring precise cooling when needed and reducing unnecessary power consumption when full cooling is not required.

- Coolant composition and additives: Improving the coolant composition and incorporating advanced additives can enhance the cooling efficiency of the 5.4 Triton engine. This may include using specialized coolant formulations with improved heat transfer properties, corrosion inhibitors, and additives that prevent scale buildup in the cooling system.

- Integrated thermal management systems: Developing integrated thermal management systems can optimize the overall cooling efficiency of the 5.4 Triton engine. These systems may incorporate multiple cooling circuits, intelligent valve control, and heat recovery mechanisms to manage engine temperature more effectively across various operating conditions and improve fuel efficiency.

02 Advanced coolant formulations

Utilizing advanced coolant formulations can significantly enhance the cooling efficiency of the 5.4 Triton engine. These specialized coolants may have improved heat transfer properties, better corrosion resistance, and longer service life. By optimizing the coolant composition, the overall cooling performance of the engine can be improved.Expand Specific Solutions03 Electronic cooling control systems

Implementing electronic cooling control systems can enhance the cooling efficiency of the 5.4 Triton engine. These systems use sensors and advanced algorithms to monitor engine temperature and adjust coolant flow, fan speed, and other parameters in real-time. This dynamic approach to cooling management helps maintain optimal engine temperature under various operating conditions.Expand Specific Solutions04 Innovative heat dissipation methods

Incorporating innovative heat dissipation methods can improve the cooling efficiency of the 5.4 Triton engine. These may include the use of advanced materials with high thermal conductivity, implementation of phase-change cooling technologies, or the integration of thermoelectric cooling elements. Such innovations can help manage engine heat more effectively, especially in high-performance applications.Expand Specific Solutions05 Optimized engine block and cylinder head design

Enhancing the cooling efficiency of the 5.4 Triton engine can be achieved through optimized engine block and cylinder head design. This may involve redesigning coolant passages, improving the distribution of cooling jackets, and optimizing the overall thermal management within the engine structure. These design improvements can lead to more uniform cooling and better heat dissipation.Expand Specific Solutions

Key Players in Automotive Cooling Systems

The competition landscape for enhancing 5.4 Triton Engine cooling efficiency is characterized by a mature market with established players and ongoing innovation. Major automotive manufacturers like Honda, Hyundai, and Ford are actively involved, alongside specialized cooling system suppliers such as MAHLE and Behr. The market is driven by increasing demands for fuel efficiency and emissions reduction. Companies are focusing on advanced thermal management technologies, integrating smart cooling systems, and exploring novel materials. With global players like Rolls-Royce and emerging contenders from China, the field is highly competitive, pushing for continuous improvements in engine cooling performance and efficiency.

MAHLE International GmbH

Technical Solution: MAHLE has developed an innovative cooling system for 5.4 Triton engines that utilizes advanced thermal management techniques. Their solution incorporates a smart coolant flow control system that optimizes coolant distribution based on real-time engine temperature data. This system employs electronically controlled valves and pumps to precisely regulate coolant flow to different engine components[1]. Additionally, MAHLE has integrated high-efficiency heat exchangers and improved radiator designs to enhance heat dissipation. The company has also implemented advanced materials with superior thermal conductivity in critical engine components to facilitate more efficient heat transfer[2]. MAHLE's cooling solution is complemented by intelligent software algorithms that predict cooling needs based on driving conditions and engine load, allowing for proactive thermal management[3].

Strengths: Precise coolant control, advanced materials, and predictive cooling algorithms. Weaknesses: Potentially higher initial cost and complexity compared to traditional cooling systems.

Honda Motor Co., Ltd.

Technical Solution: Honda has engineered a cutting-edge cooling system for the 5.4 Triton engine, focusing on optimizing coolant flow and heat dissipation. Their approach includes a variable-speed electric water pump that adjusts coolant flow rate based on engine demand, reducing parasitic losses and improving overall efficiency[4]. Honda has also implemented a split cooling system that separates the cylinder head and engine block circuits, allowing for more precise temperature control in different engine regions[5]. The company has incorporated advanced ceramic coatings on engine components to enhance heat resistance and reduce thermal stress. Furthermore, Honda's system utilizes a sophisticated electronic control unit that monitors multiple temperature sensors throughout the engine, enabling dynamic adjustments to the cooling strategy[6].

Strengths: Energy-efficient variable-speed pump, precise temperature control, and advanced thermal coatings. Weaknesses: Increased system complexity may lead to higher maintenance requirements.

Core Innovations in Engine Cooling Efficiency

Engine assembly

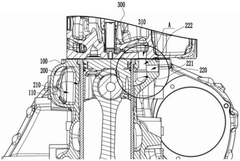

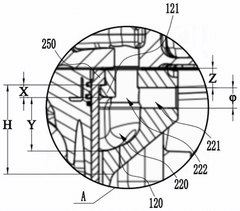

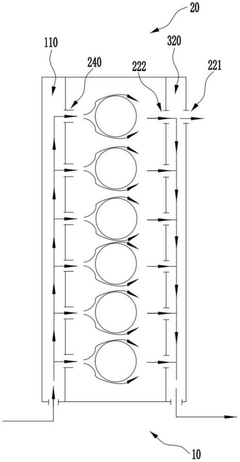

PatentPendingCN119532055A

Innovation

- A first cooling flow channel is provided on the outer wall of the cylinder liner, so that the cylinder liner is in direct contact with the cooling water for heat exchange, and a cooling water cycle is formed through the outlet passage, the water separator and the second cooling flow channel to enhance the flow rate and cooling effect of the cooling water.

Environmental Impact of Cooling System Improvements

The enhancement of the 5.4 Triton Engine cooling efficiency has significant environmental implications that extend beyond the immediate performance improvements. As cooling systems become more efficient, they contribute to reduced fuel consumption and lower emissions, aligning with global efforts to mitigate climate change and improve air quality.

One of the primary environmental benefits of improved cooling efficiency is the reduction in greenhouse gas emissions. A more efficient cooling system allows the engine to operate at optimal temperatures, reducing the need for excess fuel consumption to compensate for heat-related inefficiencies. This translates to lower carbon dioxide emissions per mile driven, contributing to a decrease in the overall carbon footprint of vehicles equipped with the 5.4 Triton Engine.

Moreover, enhanced cooling efficiency can lead to a reduction in the use of coolants and other potentially harmful fluids. Many traditional coolants contain chemicals that can be detrimental to the environment if leaked or improperly disposed of. By improving the cooling system's efficiency, the volume of coolant required may be reduced, minimizing the risk of environmental contamination.

The improved thermal management resulting from enhanced cooling efficiency also contributes to the longevity of engine components. This increased durability reduces the frequency of part replacements and repairs, which in turn decreases the demand for new parts production and the associated environmental impacts of manufacturing and transportation.

Additionally, more efficient cooling systems can lead to a reduction in noise pollution. As engines operate more efficiently and at more stable temperatures, they tend to produce less noise, contributing to a quieter urban environment and reducing the negative impacts of noise on wildlife and human health.

The advancements in cooling technology may also pave the way for the use of more environmentally friendly materials in engine construction. As thermal management improves, it may become feasible to incorporate lighter or recycled materials that were previously unsuitable due to heat-related constraints, further reducing the environmental impact of vehicle production.

Lastly, the improvements in cooling efficiency can contribute to the overall sustainability of the automotive industry. By demonstrating a commitment to environmental stewardship through technological advancements, manufacturers can inspire broader adoption of eco-friendly practices across the sector, potentially leading to industry-wide reductions in environmental impact.

One of the primary environmental benefits of improved cooling efficiency is the reduction in greenhouse gas emissions. A more efficient cooling system allows the engine to operate at optimal temperatures, reducing the need for excess fuel consumption to compensate for heat-related inefficiencies. This translates to lower carbon dioxide emissions per mile driven, contributing to a decrease in the overall carbon footprint of vehicles equipped with the 5.4 Triton Engine.

Moreover, enhanced cooling efficiency can lead to a reduction in the use of coolants and other potentially harmful fluids. Many traditional coolants contain chemicals that can be detrimental to the environment if leaked or improperly disposed of. By improving the cooling system's efficiency, the volume of coolant required may be reduced, minimizing the risk of environmental contamination.

The improved thermal management resulting from enhanced cooling efficiency also contributes to the longevity of engine components. This increased durability reduces the frequency of part replacements and repairs, which in turn decreases the demand for new parts production and the associated environmental impacts of manufacturing and transportation.

Additionally, more efficient cooling systems can lead to a reduction in noise pollution. As engines operate more efficiently and at more stable temperatures, they tend to produce less noise, contributing to a quieter urban environment and reducing the negative impacts of noise on wildlife and human health.

The advancements in cooling technology may also pave the way for the use of more environmentally friendly materials in engine construction. As thermal management improves, it may become feasible to incorporate lighter or recycled materials that were previously unsuitable due to heat-related constraints, further reducing the environmental impact of vehicle production.

Lastly, the improvements in cooling efficiency can contribute to the overall sustainability of the automotive industry. By demonstrating a commitment to environmental stewardship through technological advancements, manufacturers can inspire broader adoption of eco-friendly practices across the sector, potentially leading to industry-wide reductions in environmental impact.

Cost-Benefit Analysis of Enhanced Cooling Solutions

Enhancing the cooling efficiency of the 5.4 Triton engine requires a comprehensive cost-benefit analysis of various cooling solutions. This analysis is crucial for determining the most effective and economically viable options for improving engine performance and longevity.

The primary costs associated with enhanced cooling solutions include research and development expenses, material costs, manufacturing processes, and potential redesigns of existing engine components. These costs can vary significantly depending on the complexity of the proposed cooling enhancements. For instance, implementing advanced heat-dissipating materials or redesigning the coolant flow system may incur substantial upfront costs but could lead to long-term benefits.

On the benefit side, improved cooling efficiency can result in numerous advantages. Firstly, it can lead to increased engine performance, allowing for higher power output without compromising reliability. This performance boost can translate into improved vehicle acceleration and towing capacity, which are particularly valuable for trucks and SUVs equipped with the 5.4 Triton engine.

Enhanced cooling efficiency also contributes to extended engine life and reduced maintenance costs. By maintaining optimal operating temperatures, the engine components experience less thermal stress, reducing wear and tear. This can lead to fewer breakdowns, longer intervals between major services, and an overall increase in the engine's lifespan.

Fuel efficiency improvements are another potential benefit of enhanced cooling solutions. A more efficiently cooled engine operates closer to its ideal temperature range, potentially reducing fuel consumption. While the fuel savings may seem marginal on a per-vehicle basis, when applied across a large fleet or production run, the cumulative savings can be substantial.

Environmental benefits should also be considered in the cost-benefit analysis. Improved cooling efficiency can lead to reduced emissions, as the engine operates more cleanly and efficiently. This aspect is increasingly important given stricter environmental regulations and growing consumer demand for eco-friendly vehicles.

When evaluating specific cooling solutions, it's essential to consider their scalability and compatibility with existing manufacturing processes. Solutions that can be easily integrated into current production lines without significant retooling may offer a better cost-benefit ratio compared to those requiring extensive modifications to manufacturing facilities.

The long-term market positioning of vehicles equipped with enhanced cooling systems should also factor into the analysis. Improved engine reliability and performance can boost brand reputation, potentially leading to increased sales and market share. This indirect benefit, while challenging to quantify precisely, can have a significant impact on the overall cost-benefit equation.

In conclusion, a thorough cost-benefit analysis of enhanced cooling solutions for the 5.4 Triton engine must weigh the initial investment against long-term gains in performance, reliability, efficiency, and market position. The most promising solutions will likely offer a balance of immediate improvements and long-term value, aligning with both engineering goals and business objectives.

The primary costs associated with enhanced cooling solutions include research and development expenses, material costs, manufacturing processes, and potential redesigns of existing engine components. These costs can vary significantly depending on the complexity of the proposed cooling enhancements. For instance, implementing advanced heat-dissipating materials or redesigning the coolant flow system may incur substantial upfront costs but could lead to long-term benefits.

On the benefit side, improved cooling efficiency can result in numerous advantages. Firstly, it can lead to increased engine performance, allowing for higher power output without compromising reliability. This performance boost can translate into improved vehicle acceleration and towing capacity, which are particularly valuable for trucks and SUVs equipped with the 5.4 Triton engine.

Enhanced cooling efficiency also contributes to extended engine life and reduced maintenance costs. By maintaining optimal operating temperatures, the engine components experience less thermal stress, reducing wear and tear. This can lead to fewer breakdowns, longer intervals between major services, and an overall increase in the engine's lifespan.

Fuel efficiency improvements are another potential benefit of enhanced cooling solutions. A more efficiently cooled engine operates closer to its ideal temperature range, potentially reducing fuel consumption. While the fuel savings may seem marginal on a per-vehicle basis, when applied across a large fleet or production run, the cumulative savings can be substantial.

Environmental benefits should also be considered in the cost-benefit analysis. Improved cooling efficiency can lead to reduced emissions, as the engine operates more cleanly and efficiently. This aspect is increasingly important given stricter environmental regulations and growing consumer demand for eco-friendly vehicles.

When evaluating specific cooling solutions, it's essential to consider their scalability and compatibility with existing manufacturing processes. Solutions that can be easily integrated into current production lines without significant retooling may offer a better cost-benefit ratio compared to those requiring extensive modifications to manufacturing facilities.

The long-term market positioning of vehicles equipped with enhanced cooling systems should also factor into the analysis. Improved engine reliability and performance can boost brand reputation, potentially leading to increased sales and market share. This indirect benefit, while challenging to quantify precisely, can have a significant impact on the overall cost-benefit equation.

In conclusion, a thorough cost-benefit analysis of enhanced cooling solutions for the 5.4 Triton engine must weigh the initial investment against long-term gains in performance, reliability, efficiency, and market position. The most promising solutions will likely offer a balance of immediate improvements and long-term value, aligning with both engineering goals and business objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!