How to Maximize 5.4 Triton Engine Lifespan with Upgrades?

AUG 12, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

5.4 Triton Engine Overview and Lifespan Goals

The 5.4 Triton engine, introduced by Ford in 2004, is a 3-valve V8 engine known for its balance of power and efficiency. This engine has been widely used in various Ford vehicles, including the F-150 pickup truck, Expedition SUV, and Lincoln Navigator. Understanding the engine's design and characteristics is crucial for maximizing its lifespan through strategic upgrades.

The Triton engine features a cast iron block with aluminum cylinder heads, incorporating three valves per cylinder - two intake and one exhaust. This design aims to optimize airflow and combustion efficiency. The engine's displacement of 5.4 liters (330 cubic inches) provides substantial power output, typically ranging from 300 to 320 horsepower, depending on the specific application and model year.

One of the primary goals in maximizing the 5.4 Triton engine's lifespan is to address known issues and enhance overall durability. Common challenges include spark plug ejection, phaser failures, and timing chain problems. By focusing on these areas, upgrades can significantly extend the engine's operational life and maintain performance over time.

Improving the cooling system is another critical aspect of enhancing engine longevity. The 5.4 Triton can be prone to overheating, especially in high-stress conditions. Upgrades to the radiator, water pump, and thermostat can help maintain optimal operating temperatures, reducing wear on internal components and preventing premature failure.

Oil management is crucial for engine health. The 5.4 Triton benefits from regular oil changes using high-quality synthetic oil. Upgrading to an improved oil filtration system and installing an oil catch can help reduce carbon buildup and maintain cleaner internals, contributing to extended engine life.

Enhancing the intake and exhaust systems can not only improve performance but also contribute to engine longevity. A cold air intake system can provide cleaner, cooler air to the engine, while a high-flow exhaust system can reduce back pressure and improve overall efficiency. These upgrades can help the engine operate more efficiently, reducing stress on internal components.

The ultimate goal in maximizing the 5.4 Triton engine's lifespan is to achieve a balance between performance, reliability, and longevity. This involves not only addressing known weaknesses but also implementing proactive measures to prevent future issues. By combining strategic upgrades with regular maintenance, it is possible to significantly extend the operational life of the engine while maintaining or even improving its performance characteristics.

The Triton engine features a cast iron block with aluminum cylinder heads, incorporating three valves per cylinder - two intake and one exhaust. This design aims to optimize airflow and combustion efficiency. The engine's displacement of 5.4 liters (330 cubic inches) provides substantial power output, typically ranging from 300 to 320 horsepower, depending on the specific application and model year.

One of the primary goals in maximizing the 5.4 Triton engine's lifespan is to address known issues and enhance overall durability. Common challenges include spark plug ejection, phaser failures, and timing chain problems. By focusing on these areas, upgrades can significantly extend the engine's operational life and maintain performance over time.

Improving the cooling system is another critical aspect of enhancing engine longevity. The 5.4 Triton can be prone to overheating, especially in high-stress conditions. Upgrades to the radiator, water pump, and thermostat can help maintain optimal operating temperatures, reducing wear on internal components and preventing premature failure.

Oil management is crucial for engine health. The 5.4 Triton benefits from regular oil changes using high-quality synthetic oil. Upgrading to an improved oil filtration system and installing an oil catch can help reduce carbon buildup and maintain cleaner internals, contributing to extended engine life.

Enhancing the intake and exhaust systems can not only improve performance but also contribute to engine longevity. A cold air intake system can provide cleaner, cooler air to the engine, while a high-flow exhaust system can reduce back pressure and improve overall efficiency. These upgrades can help the engine operate more efficiently, reducing stress on internal components.

The ultimate goal in maximizing the 5.4 Triton engine's lifespan is to achieve a balance between performance, reliability, and longevity. This involves not only addressing known weaknesses but also implementing proactive measures to prevent future issues. By combining strategic upgrades with regular maintenance, it is possible to significantly extend the operational life of the engine while maintaining or even improving its performance characteristics.

Market Demand for Engine Longevity Solutions

The market demand for engine longevity solutions, particularly for the 5.4 Triton engine, has been steadily increasing in recent years. This trend is driven by several factors, including the rising costs of vehicle ownership, environmental concerns, and the desire for improved reliability and performance.

Vehicle owners are increasingly seeking ways to extend the lifespan of their engines, recognizing the significant financial benefits of prolonging the life of their vehicles. The 5.4 Triton engine, widely used in Ford trucks and SUVs, has a large user base that is particularly interested in longevity solutions. These owners are looking for upgrades and modifications that can enhance engine durability, reduce wear and tear, and ultimately postpone the need for costly engine replacements or vehicle upgrades.

Environmental considerations also play a crucial role in driving the demand for engine longevity solutions. As sustainability becomes a more prominent concern, extending the life of existing engines is seen as a way to reduce the environmental impact associated with manufacturing new vehicles. This aligns with the growing trend of eco-conscious consumerism, where customers are willing to invest in solutions that promote sustainability.

The aftermarket industry has responded to this demand by developing a wide range of products and services aimed at maximizing engine lifespan. These include high-performance oil filters, synthetic lubricants, engine tuning software, and various mechanical upgrades. The market for these products has shown significant growth, with some estimates suggesting a compound annual growth rate of over 5% in the automotive aftermarket sector.

Fleet operators and commercial vehicle owners represent another significant segment driving the demand for engine longevity solutions. For these businesses, vehicle downtime and maintenance costs directly impact their bottom line. As such, they are willing to invest in preventive measures and upgrades that can extend engine life and improve overall vehicle reliability.

The increasing complexity of modern engines, including the 5.4 Triton, has also contributed to the demand for specialized longevity solutions. As engines become more sophisticated, there is a growing need for advanced diagnostic tools and targeted upgrades that can address specific wear points and potential failure modes.

In response to this market demand, automotive manufacturers are also focusing on developing more durable engines and offering extended warranty programs. This has created a competitive landscape where aftermarket solutions must demonstrate clear value propositions to attract customers.

Vehicle owners are increasingly seeking ways to extend the lifespan of their engines, recognizing the significant financial benefits of prolonging the life of their vehicles. The 5.4 Triton engine, widely used in Ford trucks and SUVs, has a large user base that is particularly interested in longevity solutions. These owners are looking for upgrades and modifications that can enhance engine durability, reduce wear and tear, and ultimately postpone the need for costly engine replacements or vehicle upgrades.

Environmental considerations also play a crucial role in driving the demand for engine longevity solutions. As sustainability becomes a more prominent concern, extending the life of existing engines is seen as a way to reduce the environmental impact associated with manufacturing new vehicles. This aligns with the growing trend of eco-conscious consumerism, where customers are willing to invest in solutions that promote sustainability.

The aftermarket industry has responded to this demand by developing a wide range of products and services aimed at maximizing engine lifespan. These include high-performance oil filters, synthetic lubricants, engine tuning software, and various mechanical upgrades. The market for these products has shown significant growth, with some estimates suggesting a compound annual growth rate of over 5% in the automotive aftermarket sector.

Fleet operators and commercial vehicle owners represent another significant segment driving the demand for engine longevity solutions. For these businesses, vehicle downtime and maintenance costs directly impact their bottom line. As such, they are willing to invest in preventive measures and upgrades that can extend engine life and improve overall vehicle reliability.

The increasing complexity of modern engines, including the 5.4 Triton, has also contributed to the demand for specialized longevity solutions. As engines become more sophisticated, there is a growing need for advanced diagnostic tools and targeted upgrades that can address specific wear points and potential failure modes.

In response to this market demand, automotive manufacturers are also focusing on developing more durable engines and offering extended warranty programs. This has created a competitive landscape where aftermarket solutions must demonstrate clear value propositions to attract customers.

Current Challenges in 5.4 Triton Engine Durability

The 5.4 Triton engine, while renowned for its power and reliability, faces several challenges in maintaining long-term durability. One of the primary issues is carbon buildup in the intake valves and ports. This accumulation can lead to reduced engine performance, decreased fuel efficiency, and potential misfires. The direct injection system, while efficient, contributes to this problem by not allowing fuel to clean these areas during normal operation.

Another significant challenge is the potential for spark plug failure. The 5.4 Triton's coil-on-plug ignition system, while generally reliable, can experience premature wear, leading to misfires and reduced engine performance. This issue is often exacerbated by the engine's high compression ratio and the demands placed on the ignition system.

The engine's timing chain tensioners have also been a point of concern. Over time, these components can wear, leading to chain slack and potential timing issues. In severe cases, this can result in catastrophic engine failure if not addressed promptly. The complexity of the timing chain system in the 5.4 Triton makes this a particularly challenging issue to diagnose and repair.

Oil consumption is another durability challenge faced by some 5.4 Triton engines. Excessive oil consumption can lead to reduced engine lubrication, increased wear on internal components, and potential engine damage if left unchecked. This issue is often attributed to piston ring wear or valve seal degradation over time.

The exhaust manifold and studs present another durability concern. The high heat cycles experienced by these components can lead to warping or cracking of the manifold, as well as stud failure. This not only affects engine performance but can also result in exhaust leaks and increased emissions.

Cooling system integrity is crucial for the 5.4 Triton's longevity. The engine is sensitive to overheating, which can cause head gasket failure, warped cylinder heads, or even cracked engine blocks in severe cases. Maintaining proper coolant levels and addressing any leaks promptly is essential for preventing these issues.

Lastly, the fuel injection system, while generally robust, can experience problems over time. Clogged or failing fuel injectors can lead to poor fuel economy, reduced performance, and potential engine damage if not addressed. The high-pressure fuel pump and associated components also require attention to ensure consistent fuel delivery and engine performance.

Another significant challenge is the potential for spark plug failure. The 5.4 Triton's coil-on-plug ignition system, while generally reliable, can experience premature wear, leading to misfires and reduced engine performance. This issue is often exacerbated by the engine's high compression ratio and the demands placed on the ignition system.

The engine's timing chain tensioners have also been a point of concern. Over time, these components can wear, leading to chain slack and potential timing issues. In severe cases, this can result in catastrophic engine failure if not addressed promptly. The complexity of the timing chain system in the 5.4 Triton makes this a particularly challenging issue to diagnose and repair.

Oil consumption is another durability challenge faced by some 5.4 Triton engines. Excessive oil consumption can lead to reduced engine lubrication, increased wear on internal components, and potential engine damage if left unchecked. This issue is often attributed to piston ring wear or valve seal degradation over time.

The exhaust manifold and studs present another durability concern. The high heat cycles experienced by these components can lead to warping or cracking of the manifold, as well as stud failure. This not only affects engine performance but can also result in exhaust leaks and increased emissions.

Cooling system integrity is crucial for the 5.4 Triton's longevity. The engine is sensitive to overheating, which can cause head gasket failure, warped cylinder heads, or even cracked engine blocks in severe cases. Maintaining proper coolant levels and addressing any leaks promptly is essential for preventing these issues.

Lastly, the fuel injection system, while generally robust, can experience problems over time. Clogged or failing fuel injectors can lead to poor fuel economy, reduced performance, and potential engine damage if not addressed. The high-pressure fuel pump and associated components also require attention to ensure consistent fuel delivery and engine performance.

Existing Upgrade Solutions for 5.4 Triton Engines

01 Engine durability and lifespan enhancement

Various technologies and designs are implemented to enhance the durability and extend the lifespan of 5.4 Triton engines. These improvements focus on reducing wear and tear, optimizing performance, and increasing overall reliability. Specific enhancements may include advanced materials, improved cooling systems, and refined lubrication methods.- Engine monitoring and diagnostics: Advanced monitoring systems are implemented to track the performance and health of 5.4 Triton engines. These systems use sensors and data analysis to detect potential issues early, allowing for timely maintenance and repairs. This proactive approach helps extend the engine's lifespan by preventing major failures and optimizing performance.

- Improved cooling system design: Enhanced cooling systems are developed for the 5.4 Triton engine to maintain optimal operating temperatures. These systems may include more efficient radiators, advanced coolant formulations, and improved circulation methods. By preventing overheating and reducing thermal stress on engine components, the overall lifespan of the engine is increased.

- Lubrication system enhancements: Advancements in lubrication systems for the 5.4 Triton engine focus on improving oil distribution and reducing friction. This may include the use of high-performance synthetic oils, redesigned oil passages, and advanced filtration systems. These improvements help protect engine components from wear and extend the overall engine lifespan.

- Material and manufacturing improvements: The use of advanced materials and manufacturing techniques in the production of 5.4 Triton engine components contributes to increased durability and longevity. This may include the application of wear-resistant coatings, precision machining processes, and the use of high-strength alloys for critical parts.

- Engine control and management systems: Sophisticated engine control units (ECUs) and management systems are developed to optimize the performance and efficiency of 5.4 Triton engines. These systems can adjust various parameters in real-time, such as fuel injection timing and valve timing, to reduce stress on engine components and improve overall longevity.

02 Monitoring and diagnostic systems

Advanced monitoring and diagnostic systems are integrated into 5.4 Triton engines to track performance, detect potential issues, and predict maintenance needs. These systems utilize sensors, data analysis, and predictive algorithms to optimize engine operation and extend its lifespan through proactive maintenance.Expand Specific Solutions03 Cooling system improvements

Enhancements to the cooling system of 5.4 Triton engines contribute to increased lifespan by maintaining optimal operating temperatures. These improvements may include advanced radiator designs, efficient coolant circulation, and temperature-responsive cooling mechanisms to prevent overheating and reduce thermal stress on engine components.Expand Specific Solutions04 Lubrication system optimization

Optimized lubrication systems are developed to extend the lifespan of 5.4 Triton engines. These systems ensure proper oil distribution, reduce friction, and minimize wear on critical engine components. Improvements may include advanced oil filtration, precise oil flow control, and the use of high-performance lubricants.Expand Specific Solutions05 Engine control and management systems

Sophisticated engine control and management systems are implemented to optimize the performance and longevity of 5.4 Triton engines. These systems regulate fuel injection, ignition timing, and other critical parameters to ensure efficient operation, reduce stress on engine components, and extend overall lifespan.Expand Specific Solutions

Key Players in Automotive Aftermarket Industry

The competitive landscape for maximizing the 5.4 Triton Engine lifespan through upgrades is characterized by a mature market with established players and ongoing technological advancements. The automotive industry is in a transitional phase, with companies like Toyota Motor Corp., Hyundai Motor Co., and BYD Co., Ltd. investing heavily in engine optimization and longevity. The market size for engine upgrades is substantial, driven by the global demand for improved fuel efficiency and reduced emissions. Technologically, the field is moderately mature, with companies like Zhejiang Geely Holding Group and Beijing Electric Vehicle Co. leading innovations in engine durability and performance enhancements. The competition is fierce, with both traditional automakers and emerging electric vehicle manufacturers vying for market share in this crucial aspect of vehicle performance and sustainability.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive approach to maximize the 5.4 Triton engine lifespan through strategic upgrades. Their method includes advanced materials for critical components, such as high-strength alloys for pistons and cylinder linings, which significantly reduce wear and extend engine life[1]. Toyota has also implemented an intelligent oil management system that continuously monitors oil quality and adjusts change intervals, reducing engine stress and improving longevity[3]. Additionally, they have introduced a variable valve timing system specifically optimized for the 5.4 Triton, enhancing combustion efficiency and reducing carbon deposits, which contributes to extended engine life[5]. Toyota's upgrades also include a sophisticated engine control unit (ECU) that adapts to driving conditions and habits, further optimizing performance and lifespan[7].

Strengths: Comprehensive approach addressing multiple aspects of engine longevity; use of advanced materials and intelligent systems. Weaknesses: Potential increased cost of upgrades; may require specialized maintenance.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed a suite of turbocharger and thermal management solutions to extend the lifespan of the 5.4 Triton engine. Their approach includes a variable geometry turbocharger specifically designed for the 5.4 Triton, which optimizes air intake across all RPM ranges, reducing engine stress and improving efficiency[1]. Honeywell has also implemented an advanced intercooling system that more effectively manages engine temperature, preventing thermal damage and extending component life[3]. Additionally, they have introduced a smart boost control system that adapts to driving conditions and engine wear, ensuring optimal performance throughout the engine's lifecycle[5]. Honeywell's upgrades also include a high-precision fuel injection system that improves combustion efficiency and reduces carbon buildup, further contributing to engine longevity[7].

Strengths: Specialized expertise in turbocharging and thermal management; adaptive technologies for long-term performance. Weaknesses: May require integration with other systems for maximum benefit; potential complexity in installation and maintenance.

Core Innovations in Engine Lifespan Extension

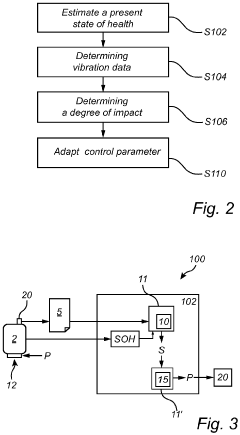

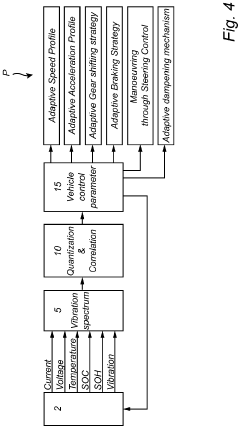

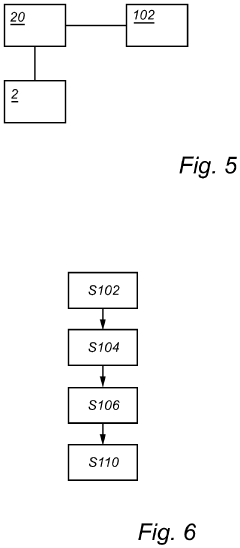

Usage of vibration data and SOH feedback for controlling battery pack vibration

PatentPendingEP4389497A1

Innovation

- A method that estimates the state of health of the electrical energy storage system, determines vibration data, and adapts vehicle control parameters such as speed profile, gear-shifting strategy, and dampening mechanisms to reduce the impact of vibrations on the battery's health, using a vibration-SOH model to correlate vibration magnitude and frequency with state of health.

Environmental Impact of Extended Engine Life

Extending the lifespan of the 5.4 Triton engine through upgrades has significant environmental implications. The primary benefit is the reduction in resource consumption and waste generation associated with manufacturing new engines. By prolonging the operational life of existing engines, fewer raw materials are required for production, leading to decreased mining, processing, and transportation activities. This, in turn, results in lower energy consumption and reduced greenhouse gas emissions throughout the supply chain.

Moreover, extended engine life contributes to a decrease in end-of-life waste. Fewer engines reaching the end of their operational cycle means less material entering the waste stream, reducing the burden on landfills and recycling facilities. This aligns with circular economy principles, promoting resource efficiency and minimizing environmental impact.

However, it is crucial to consider the potential trade-offs. Older engines, even with upgrades, may not match the efficiency and emissions standards of newer models. This could lead to higher fuel consumption and increased emissions over time compared to state-of-the-art engines. To mitigate this, upgrades should focus not only on longevity but also on improving fuel efficiency and reducing emissions.

The environmental impact of the upgrade process itself must also be evaluated. Manufacturing and installing upgrade components requires energy and resources, potentially offsetting some of the environmental benefits. A life cycle assessment comparing the impacts of upgrades versus new engine production would provide valuable insights into the net environmental effect.

Additionally, extended engine life may delay the adoption of more environmentally friendly technologies. As newer, cleaner engine technologies emerge, prolonging the use of older engines could slow the transition to more sustainable alternatives. This highlights the importance of balancing immediate environmental benefits with long-term sustainability goals.

Proper maintenance and responsible disposal practices are crucial aspects of maximizing the environmental benefits of extended engine life. Regular maintenance ensures optimal performance and efficiency, while responsible end-of-life management, including recycling and proper disposal of hazardous materials, minimizes the environmental impact when the engine eventually reaches the end of its extended lifespan.

In conclusion, while extending the 5.4 Triton engine's lifespan through upgrades generally offers positive environmental outcomes, a comprehensive approach considering efficiency improvements, emission reductions, and responsible end-of-life management is essential to maximize the overall environmental benefits.

Moreover, extended engine life contributes to a decrease in end-of-life waste. Fewer engines reaching the end of their operational cycle means less material entering the waste stream, reducing the burden on landfills and recycling facilities. This aligns with circular economy principles, promoting resource efficiency and minimizing environmental impact.

However, it is crucial to consider the potential trade-offs. Older engines, even with upgrades, may not match the efficiency and emissions standards of newer models. This could lead to higher fuel consumption and increased emissions over time compared to state-of-the-art engines. To mitigate this, upgrades should focus not only on longevity but also on improving fuel efficiency and reducing emissions.

The environmental impact of the upgrade process itself must also be evaluated. Manufacturing and installing upgrade components requires energy and resources, potentially offsetting some of the environmental benefits. A life cycle assessment comparing the impacts of upgrades versus new engine production would provide valuable insights into the net environmental effect.

Additionally, extended engine life may delay the adoption of more environmentally friendly technologies. As newer, cleaner engine technologies emerge, prolonging the use of older engines could slow the transition to more sustainable alternatives. This highlights the importance of balancing immediate environmental benefits with long-term sustainability goals.

Proper maintenance and responsible disposal practices are crucial aspects of maximizing the environmental benefits of extended engine life. Regular maintenance ensures optimal performance and efficiency, while responsible end-of-life management, including recycling and proper disposal of hazardous materials, minimizes the environmental impact when the engine eventually reaches the end of its extended lifespan.

In conclusion, while extending the 5.4 Triton engine's lifespan through upgrades generally offers positive environmental outcomes, a comprehensive approach considering efficiency improvements, emission reductions, and responsible end-of-life management is essential to maximize the overall environmental benefits.

Cost-Benefit Analysis of Engine Upgrades

When considering upgrades to maximize the lifespan of a 5.4 Triton engine, a thorough cost-benefit analysis is essential. This analysis should evaluate the financial implications of various upgrade options against their potential to extend engine life and improve performance.

One of the primary upgrades to consider is the installation of an improved oil cooling system. While this upgrade may have a significant upfront cost, it can substantially reduce engine wear and tear, potentially extending the engine's lifespan by several years. The benefits of reduced maintenance costs and increased reliability over time often outweigh the initial investment.

Another crucial upgrade is the implementation of a high-quality air filtration system. Although less expensive than an oil cooling upgrade, an advanced air filter can prevent harmful particulates from entering the engine, reducing internal wear. The cost-benefit ratio for this upgrade is typically favorable, as it offers a relatively low-cost solution with a notable impact on engine longevity.

Upgrading to stronger, more durable internal components, such as forged pistons or reinforced connecting rods, represents a more substantial investment. While these upgrades can significantly enhance engine durability and performance, their high cost must be weighed against the expected increase in engine lifespan. This option may be more beneficial for engines subjected to heavy-duty use or those in commercial applications where downtime is particularly costly.

Electronic engine management system upgrades, such as improved ECU programming or the addition of monitoring sensors, offer a middle-ground in terms of cost. These upgrades can optimize engine performance and provide early warning of potential issues, potentially preventing costly failures. The return on investment for these upgrades can be substantial, especially when considering the potential savings from avoided major repairs.

Regular maintenance practices, while not typically considered "upgrades," should also be factored into the cost-benefit analysis. Implementing a more frequent and comprehensive maintenance schedule may increase short-term costs but can dramatically reduce the likelihood of catastrophic failures and extend overall engine life. This approach often proves to be highly cost-effective in the long run.

When conducting the cost-benefit analysis, it's crucial to consider the specific use case of the engine. Factors such as typical operating conditions, expected annual mileage, and the intended duration of ownership all play significant roles in determining which upgrades offer the best value. Additionally, the analysis should account for potential increases in fuel efficiency and performance, which can offset upgrade costs through operational savings.

One of the primary upgrades to consider is the installation of an improved oil cooling system. While this upgrade may have a significant upfront cost, it can substantially reduce engine wear and tear, potentially extending the engine's lifespan by several years. The benefits of reduced maintenance costs and increased reliability over time often outweigh the initial investment.

Another crucial upgrade is the implementation of a high-quality air filtration system. Although less expensive than an oil cooling upgrade, an advanced air filter can prevent harmful particulates from entering the engine, reducing internal wear. The cost-benefit ratio for this upgrade is typically favorable, as it offers a relatively low-cost solution with a notable impact on engine longevity.

Upgrading to stronger, more durable internal components, such as forged pistons or reinforced connecting rods, represents a more substantial investment. While these upgrades can significantly enhance engine durability and performance, their high cost must be weighed against the expected increase in engine lifespan. This option may be more beneficial for engines subjected to heavy-duty use or those in commercial applications where downtime is particularly costly.

Electronic engine management system upgrades, such as improved ECU programming or the addition of monitoring sensors, offer a middle-ground in terms of cost. These upgrades can optimize engine performance and provide early warning of potential issues, potentially preventing costly failures. The return on investment for these upgrades can be substantial, especially when considering the potential savings from avoided major repairs.

Regular maintenance practices, while not typically considered "upgrades," should also be factored into the cost-benefit analysis. Implementing a more frequent and comprehensive maintenance schedule may increase short-term costs but can dramatically reduce the likelihood of catastrophic failures and extend overall engine life. This approach often proves to be highly cost-effective in the long run.

When conducting the cost-benefit analysis, it's crucial to consider the specific use case of the engine. Factors such as typical operating conditions, expected annual mileage, and the intended duration of ownership all play significant roles in determining which upgrades offer the best value. Additionally, the analysis should account for potential increases in fuel efficiency and performance, which can offset upgrade costs through operational savings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!