How to Select High-Performance Filters for 5.4 Triton Engines?

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

5.4 Triton Engine Filter Technology Background

The 5.4 Triton engine, developed by Ford Motor Company, has been a cornerstone of their truck and SUV lineup since its introduction in the late 1990s. This V8 engine, known for its robust performance and reliability, has undergone several iterations and improvements over the years. As with any high-performance engine, the filtration system plays a crucial role in maintaining its efficiency and longevity.

The evolution of filter technology for the 5.4 Triton engine has been driven by the increasing demands for better fuel economy, reduced emissions, and enhanced engine protection. Early versions of the engine utilized standard paper-based air and oil filters, which were adequate for the time but had limitations in terms of filtration efficiency and service life.

As environmental regulations became more stringent and consumer expectations for engine performance and durability increased, filter manufacturers began developing more advanced solutions. This led to the introduction of synthetic filter media, which offered superior particle capture efficiency and extended service intervals.

The air filtration system for the 5.4 Triton engine has seen significant advancements. Modern air filters for this engine often incorporate multi-layer designs, combining different types of filter media to capture a wide range of particle sizes. Some high-performance options now feature oiled cotton gauze elements, which provide excellent airflow characteristics while maintaining high filtration efficiency.

Oil filtration technology has also progressed substantially. Early oil filters for the 5.4 Triton were primarily designed to capture larger particles. However, as engine tolerances became tighter and oil formulations more complex, the need for finer filtration became apparent. This led to the development of filters capable of removing particles as small as 10 microns or less, significantly reducing engine wear.

Fuel filtration has become increasingly important, especially with the introduction of high-pressure fuel injection systems in later versions of the 5.4 Triton. Modern fuel filters for this engine are designed to remove not only particulate contaminants but also water, which can cause corrosion and microbial growth in the fuel system.

The trend towards extended service intervals has also influenced filter design for the 5.4 Triton. Manufacturers have focused on developing filters with higher dirt-holding capacity and improved flow characteristics, allowing for longer periods between replacements without compromising engine protection.

As the automotive industry moves towards more environmentally friendly practices, filter technology for engines like the 5.4 Triton is also adapting. There is a growing emphasis on recyclable materials and designs that minimize waste. Some manufacturers are exploring biodegradable filter media and housing materials to reduce the environmental impact of filter disposal.

The evolution of filter technology for the 5.4 Triton engine has been driven by the increasing demands for better fuel economy, reduced emissions, and enhanced engine protection. Early versions of the engine utilized standard paper-based air and oil filters, which were adequate for the time but had limitations in terms of filtration efficiency and service life.

As environmental regulations became more stringent and consumer expectations for engine performance and durability increased, filter manufacturers began developing more advanced solutions. This led to the introduction of synthetic filter media, which offered superior particle capture efficiency and extended service intervals.

The air filtration system for the 5.4 Triton engine has seen significant advancements. Modern air filters for this engine often incorporate multi-layer designs, combining different types of filter media to capture a wide range of particle sizes. Some high-performance options now feature oiled cotton gauze elements, which provide excellent airflow characteristics while maintaining high filtration efficiency.

Oil filtration technology has also progressed substantially. Early oil filters for the 5.4 Triton were primarily designed to capture larger particles. However, as engine tolerances became tighter and oil formulations more complex, the need for finer filtration became apparent. This led to the development of filters capable of removing particles as small as 10 microns or less, significantly reducing engine wear.

Fuel filtration has become increasingly important, especially with the introduction of high-pressure fuel injection systems in later versions of the 5.4 Triton. Modern fuel filters for this engine are designed to remove not only particulate contaminants but also water, which can cause corrosion and microbial growth in the fuel system.

The trend towards extended service intervals has also influenced filter design for the 5.4 Triton. Manufacturers have focused on developing filters with higher dirt-holding capacity and improved flow characteristics, allowing for longer periods between replacements without compromising engine protection.

As the automotive industry moves towards more environmentally friendly practices, filter technology for engines like the 5.4 Triton is also adapting. There is a growing emphasis on recyclable materials and designs that minimize waste. Some manufacturers are exploring biodegradable filter media and housing materials to reduce the environmental impact of filter disposal.

Market Analysis for High-Performance Engine Filters

The market for high-performance engine filters, particularly those designed for 5.4 Triton engines, has shown significant growth in recent years. This surge is primarily driven by the increasing demand for enhanced engine performance and longevity among vehicle owners. The global automotive filter market, which includes high-performance filters, is expected to reach a substantial value in the coming years, with a notable portion attributed to aftermarket sales for specific engine types like the 5.4 Triton.

Consumer trends indicate a growing awareness of the importance of high-quality filtration systems in maintaining engine health and optimizing performance. This awareness has led to a shift in consumer behavior, with more vehicle owners opting for premium, high-performance filters over standard options. The market for 5.4 Triton engine filters, in particular, has seen a steady increase in demand, reflecting the enduring popularity of vehicles equipped with this engine.

The aftermarket segment for high-performance filters has been particularly robust, with many owners of 5.4 Triton-equipped vehicles seeking upgrades to enhance their engine's performance and efficiency. This trend is supported by the growing DIY culture among car enthusiasts, who are increasingly interested in personally maintaining and upgrading their vehicles.

Geographically, North America dominates the market for high-performance filters for 5.4 Triton engines, given the prevalence of Ford vehicles equipped with this engine in the region. However, other markets, particularly in Europe and Asia-Pacific, are showing increasing interest in high-performance filtration solutions, driven by a growing automotive enthusiast culture and increased awareness of engine maintenance benefits.

The competitive landscape of the high-performance filter market for 5.4 Triton engines is characterized by a mix of established automotive parts manufacturers and specialized filtration companies. These players are continuously innovating to improve filter efficiency, durability, and compatibility with specific engine types. The market has also seen the entry of new players offering niche products tailored for performance enthusiasts.

Looking ahead, the market for high-performance filters for 5.4 Triton engines is expected to continue its growth trajectory. Factors such as increasing vehicle longevity, growing environmental concerns leading to stricter emission standards, and the rising popularity of performance upgrades among vehicle owners are likely to drive this growth. Additionally, advancements in filter technology, including the development of more efficient and durable materials, are expected to further expand the market opportunities in this segment.

Consumer trends indicate a growing awareness of the importance of high-quality filtration systems in maintaining engine health and optimizing performance. This awareness has led to a shift in consumer behavior, with more vehicle owners opting for premium, high-performance filters over standard options. The market for 5.4 Triton engine filters, in particular, has seen a steady increase in demand, reflecting the enduring popularity of vehicles equipped with this engine.

The aftermarket segment for high-performance filters has been particularly robust, with many owners of 5.4 Triton-equipped vehicles seeking upgrades to enhance their engine's performance and efficiency. This trend is supported by the growing DIY culture among car enthusiasts, who are increasingly interested in personally maintaining and upgrading their vehicles.

Geographically, North America dominates the market for high-performance filters for 5.4 Triton engines, given the prevalence of Ford vehicles equipped with this engine in the region. However, other markets, particularly in Europe and Asia-Pacific, are showing increasing interest in high-performance filtration solutions, driven by a growing automotive enthusiast culture and increased awareness of engine maintenance benefits.

The competitive landscape of the high-performance filter market for 5.4 Triton engines is characterized by a mix of established automotive parts manufacturers and specialized filtration companies. These players are continuously innovating to improve filter efficiency, durability, and compatibility with specific engine types. The market has also seen the entry of new players offering niche products tailored for performance enthusiasts.

Looking ahead, the market for high-performance filters for 5.4 Triton engines is expected to continue its growth trajectory. Factors such as increasing vehicle longevity, growing environmental concerns leading to stricter emission standards, and the rising popularity of performance upgrades among vehicle owners are likely to drive this growth. Additionally, advancements in filter technology, including the development of more efficient and durable materials, are expected to further expand the market opportunities in this segment.

Current Challenges in 5.4 Triton Engine Filtration

The 5.4 Triton engine, a popular powerplant in Ford vehicles, faces several challenges in its filtration system that impact performance and longevity. One of the primary issues is the accumulation of carbon deposits in the intake valves and combustion chambers. This buildup can lead to reduced engine efficiency, decreased fuel economy, and potential misfires. The engine's design, which incorporates direct fuel injection, exacerbates this problem as fuel no longer washes over the intake valves, leaving them more susceptible to carbon accumulation.

Another significant challenge is the engine's sensitivity to oil contamination. The 5.4 Triton utilizes a high-pressure oil system to actuate its variable cam timing mechanism. Any degradation in oil quality or presence of contaminants can lead to timing chain wear, tensioner failures, and ultimately, engine damage. This necessitates a robust oil filtration system capable of maintaining oil purity under demanding conditions.

The engine's air filtration system also faces challenges, particularly in dusty or polluted environments. Inadequate air filtration can result in accelerated wear of internal engine components, reduced performance, and increased emissions. The stock air filter may struggle to balance between high flow rates necessary for optimal performance and effective particulate capture.

Fuel filtration presents another area of concern for the 5.4 Triton. The engine's fuel injectors are precision components that require clean, contaminant-free fuel to operate efficiently. Any impurities in the fuel can lead to injector clogging, inconsistent spray patterns, and reduced engine performance. The challenge lies in designing a fuel filtration system that can effectively remove contaminants without restricting fuel flow, especially under high-demand situations.

The coolant system in the 5.4 Triton engine is also prone to filtration-related issues. Over time, coolant can become contaminated with rust, scale, and other debris, which can lead to radiator clogging and reduced cooling efficiency. This challenge is compounded by the engine's tendency to run at higher temperatures, making effective coolant filtration crucial for maintaining optimal operating conditions and preventing overheating.

Lastly, the crankcase ventilation system, which helps manage blow-by gases, faces filtration challenges. Ineffective filtration of these gases can lead to oil contamination and increased engine wear. The system must effectively separate oil mist from the gases while maintaining proper crankcase pressure, a delicate balance that requires careful design consideration.

Another significant challenge is the engine's sensitivity to oil contamination. The 5.4 Triton utilizes a high-pressure oil system to actuate its variable cam timing mechanism. Any degradation in oil quality or presence of contaminants can lead to timing chain wear, tensioner failures, and ultimately, engine damage. This necessitates a robust oil filtration system capable of maintaining oil purity under demanding conditions.

The engine's air filtration system also faces challenges, particularly in dusty or polluted environments. Inadequate air filtration can result in accelerated wear of internal engine components, reduced performance, and increased emissions. The stock air filter may struggle to balance between high flow rates necessary for optimal performance and effective particulate capture.

Fuel filtration presents another area of concern for the 5.4 Triton. The engine's fuel injectors are precision components that require clean, contaminant-free fuel to operate efficiently. Any impurities in the fuel can lead to injector clogging, inconsistent spray patterns, and reduced engine performance. The challenge lies in designing a fuel filtration system that can effectively remove contaminants without restricting fuel flow, especially under high-demand situations.

The coolant system in the 5.4 Triton engine is also prone to filtration-related issues. Over time, coolant can become contaminated with rust, scale, and other debris, which can lead to radiator clogging and reduced cooling efficiency. This challenge is compounded by the engine's tendency to run at higher temperatures, making effective coolant filtration crucial for maintaining optimal operating conditions and preventing overheating.

Lastly, the crankcase ventilation system, which helps manage blow-by gases, faces filtration challenges. Ineffective filtration of these gases can lead to oil contamination and increased engine wear. The system must effectively separate oil mist from the gases while maintaining proper crankcase pressure, a delicate balance that requires careful design consideration.

Existing High-Performance Filter Solutions

01 Air filter design for improved engine performance

Specialized air filter designs can enhance the performance of 5.4 Triton engines by improving airflow and filtration efficiency. These filters may incorporate advanced materials or unique shapes to maximize air intake while effectively trapping contaminants, leading to better engine breathing and increased power output.- Air filter design for improved engine performance: Specialized air filter designs can enhance the performance of 5.4 Triton engines by improving airflow and filtration efficiency. These filters may incorporate advanced materials or unique shapes to maximize air intake while effectively trapping contaminants, resulting in better engine breathing and increased power output.

- Oil filtration systems for engine protection: Enhanced oil filtration systems can significantly improve the performance and longevity of 5.4 Triton engines. These systems may include high-efficiency oil filters or bypass filtration setups that remove smaller particles, reducing engine wear and maintaining optimal oil quality for better engine performance.

- Fuel filter innovations for improved combustion: Advanced fuel filtration technologies can enhance the performance of 5.4 Triton engines by ensuring cleaner fuel delivery. These innovations may include multi-stage filtration systems or filters with water separation capabilities, resulting in more efficient combustion and improved engine power.

- Exhaust filtration for emissions control and performance: Exhaust filtration systems, such as high-flow catalytic converters or particulate filters, can improve both emissions control and engine performance in 5.4 Triton engines. These systems may reduce back pressure while effectively filtering exhaust gases, leading to improved engine efficiency and power output.

- Electronic filtering and engine management systems: Advanced electronic filtering and engine management systems can optimize the performance of 5.4 Triton engines. These may include sophisticated sensors and control units that monitor and adjust various engine parameters in real-time, ensuring optimal fuel mixture, ignition timing, and overall engine efficiency.

02 Oil filtration systems for engine protection

Enhanced oil filtration systems can significantly improve the performance and longevity of 5.4 Triton engines. These systems may include high-efficiency oil filters, bypass filtration, or advanced filter media to remove harmful particles and contaminants from the engine oil, reducing wear and maintaining optimal engine performance.Expand Specific Solutions03 Fuel filter innovations for improved combustion

Advanced fuel filtration technologies can enhance the performance of 5.4 Triton engines by ensuring cleaner fuel delivery to the combustion chamber. These innovations may include multi-stage filtration, water separation systems, or high-capacity filters that remove impurities and prevent fuel system damage, resulting in improved engine efficiency and power output.Expand Specific Solutions04 Exhaust filtration for emissions control and performance

Exhaust filtration systems designed specifically for 5.4 Triton engines can help balance emissions control with performance optimization. These systems may incorporate catalytic converters, particulate filters, or advanced exhaust gas recirculation (EGR) filters to reduce harmful emissions while maintaining or improving engine performance through optimized back pressure management.Expand Specific Solutions05 Electronic filtering and engine management systems

Advanced electronic filtering and engine management systems can significantly enhance the performance of 5.4 Triton engines. These systems may include sophisticated sensors, adaptive algorithms, and real-time monitoring capabilities to optimize fuel injection, ignition timing, and overall engine operation based on various input parameters, resulting in improved power, efficiency, and reliability.Expand Specific Solutions

Key Players in Automotive Filtration Industry

The market for high-performance filters for 5.4 Triton engines is in a mature stage, with established players and steady demand. The global automotive filter market size is estimated to be around $20 billion, with moderate growth expected. Technologically, filters are well-developed but continue to evolve for improved efficiency and environmental performance. Key players like Cummins Filtration, Donaldson, and MANN+HUMMEL lead in innovation, while companies such as Weichai Power and Pingyuan Filter are emerging as strong competitors, particularly in Asian markets. The industry is characterized by ongoing R&D efforts to meet stricter emission standards and enhance engine performance across various applications.

MAHLE International GmbH

Technical Solution: MAHLE has developed a comprehensive filtration solution for 5.4 Triton engines, focusing on optimizing engine performance and longevity. Their air filter design incorporates a pleated media with a large surface area and uniform pleat spacing, maximizing dust-holding capacity while minimizing airflow restriction[7]. For oil filtration, MAHLE utilizes a synthetic-blend media with a gradient density structure, allowing for both high dirt-holding capacity and fine particle capture[8]. They have also introduced an innovative fuel filter design with integrated water separation and heating elements, ensuring reliable operation in cold climates and with varying fuel qualities[9].

Strengths: Balanced performance across air, oil, and fuel filtration; innovative features like integrated heating elements. Weaknesses: Potential complexity in filter replacement due to advanced features, and possibly higher cost compared to standard filters.

Cummins Filtration IP, Inc.

Technical Solution: Cummins Filtration has engineered a range of high-performance filters tailored for 5.4 Triton engines, emphasizing durability and efficiency. Their air filtration system incorporates a dual-stage design with a pre-cleaner and main filter, utilizing advanced media technology that combines synthetic and natural fibers for optimal dust-holding capacity and engine protection[4]. For fuel filtration, Cummins has developed a multi-layer filter media with water-separating capabilities, ensuring fuel quality and protecting injection systems[5]. Additionally, their NanoNet® technology in oil filters provides superior contaminant removal, with up to 99.9% efficiency for particles as small as 4 microns[6].

Strengths: Excellent contaminant removal, robust design for harsh conditions, and integrated water separation in fuel filters. Weaknesses: May be more expensive than generic alternatives, and could require specific tools or training for replacement.

Innovative Filtration Technologies for 5.4 Triton

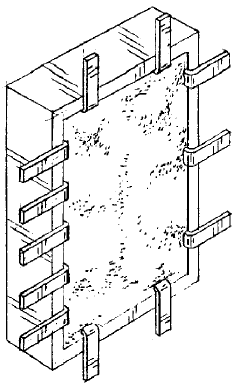

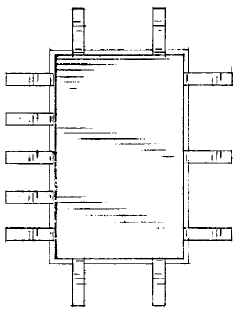

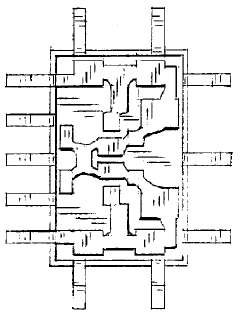

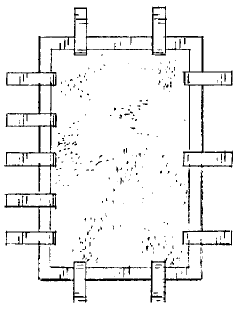

High performance RF/microwave filters for surface mount technology with a shielding metal bracket

PatentInactiveUS5999067A

Innovation

- The solution involves mounting internal filter components into a folded metal bracket that nests within a plastic housing, allowing for automated assembly and soldering, followed by filling the interior with a void-filling material like epoxy, which solidifies to affix and structurally support the components, and utilizing the circuit board's ground plane as the ground connection, eliminating the need for a separate lid and enhancing shielding.

Environmental Impact of Advanced Engine Filters

The environmental impact of advanced engine filters for 5.4 Triton engines is a crucial consideration in the pursuit of high-performance filtration solutions. These filters play a significant role in reducing harmful emissions and improving overall engine efficiency, thereby contributing to a more sustainable automotive industry.

Advanced engine filters are designed to capture a higher percentage of particulate matter and other pollutants compared to traditional filters. This enhanced filtration capability leads to a substantial reduction in the release of harmful substances into the atmosphere. By effectively trapping fine particles, these filters help mitigate air pollution and its associated health risks, particularly in urban areas where vehicle emissions are a major concern.

The use of high-performance filters in 5.4 Triton engines also contributes to improved fuel efficiency. By maintaining cleaner air intake and fuel systems, these filters help optimize engine performance, resulting in better fuel combustion and reduced fuel consumption. This, in turn, leads to lower carbon dioxide emissions per mile driven, aligning with global efforts to combat climate change and reduce greenhouse gas emissions from the transportation sector.

Furthermore, advanced engine filters often have extended service life compared to conventional filters. This longevity reduces the frequency of filter replacements, thereby decreasing the amount of waste generated from discarded filters. Many of these high-performance filters are also designed with recyclable materials, further minimizing their environmental footprint throughout their lifecycle.

The manufacturing processes of advanced engine filters have also evolved to become more environmentally friendly. Many filter manufacturers now employ sustainable production methods, utilizing recycled materials and implementing energy-efficient manufacturing techniques. This shift towards greener production practices helps reduce the overall environmental impact associated with filter manufacturing.

It is worth noting that the environmental benefits of advanced engine filters extend beyond direct emissions reduction. By protecting engine components from contaminants, these filters help prolong engine life and maintain optimal performance over time. This increased durability reduces the need for premature engine replacements or major repairs, which in turn conserves resources and energy that would otherwise be expended in manufacturing new engine parts or entire vehicles.

In conclusion, the selection of high-performance filters for 5.4 Triton engines has far-reaching environmental implications. From reducing harmful emissions and improving fuel efficiency to promoting sustainable manufacturing practices and extending engine life, these advanced filters play a crucial role in minimizing the ecological footprint of automotive transportation. As environmental concerns continue to shape the automotive industry, the importance of such innovative filtration solutions in achieving sustainability goals cannot be overstated.

Advanced engine filters are designed to capture a higher percentage of particulate matter and other pollutants compared to traditional filters. This enhanced filtration capability leads to a substantial reduction in the release of harmful substances into the atmosphere. By effectively trapping fine particles, these filters help mitigate air pollution and its associated health risks, particularly in urban areas where vehicle emissions are a major concern.

The use of high-performance filters in 5.4 Triton engines also contributes to improved fuel efficiency. By maintaining cleaner air intake and fuel systems, these filters help optimize engine performance, resulting in better fuel combustion and reduced fuel consumption. This, in turn, leads to lower carbon dioxide emissions per mile driven, aligning with global efforts to combat climate change and reduce greenhouse gas emissions from the transportation sector.

Furthermore, advanced engine filters often have extended service life compared to conventional filters. This longevity reduces the frequency of filter replacements, thereby decreasing the amount of waste generated from discarded filters. Many of these high-performance filters are also designed with recyclable materials, further minimizing their environmental footprint throughout their lifecycle.

The manufacturing processes of advanced engine filters have also evolved to become more environmentally friendly. Many filter manufacturers now employ sustainable production methods, utilizing recycled materials and implementing energy-efficient manufacturing techniques. This shift towards greener production practices helps reduce the overall environmental impact associated with filter manufacturing.

It is worth noting that the environmental benefits of advanced engine filters extend beyond direct emissions reduction. By protecting engine components from contaminants, these filters help prolong engine life and maintain optimal performance over time. This increased durability reduces the need for premature engine replacements or major repairs, which in turn conserves resources and energy that would otherwise be expended in manufacturing new engine parts or entire vehicles.

In conclusion, the selection of high-performance filters for 5.4 Triton engines has far-reaching environmental implications. From reducing harmful emissions and improving fuel efficiency to promoting sustainable manufacturing practices and extending engine life, these advanced filters play a crucial role in minimizing the ecological footprint of automotive transportation. As environmental concerns continue to shape the automotive industry, the importance of such innovative filtration solutions in achieving sustainability goals cannot be overstated.

Cost-Benefit Analysis of High-Performance Filters

When considering high-performance filters for 5.4 Triton engines, a comprehensive cost-benefit analysis is crucial to make informed decisions. This analysis involves evaluating the initial investment, long-term savings, and overall performance improvements associated with these filters.

The upfront cost of high-performance filters is typically higher than standard filters. However, this initial investment often translates into long-term savings through improved engine efficiency and reduced maintenance needs. High-performance filters generally offer superior filtration capabilities, which can lead to decreased engine wear and extended service intervals.

One of the primary benefits of high-performance filters is their ability to enhance engine performance. By providing better air and oil filtration, these filters can contribute to increased horsepower, improved fuel efficiency, and overall smoother engine operation. These performance gains can result in tangible cost savings through reduced fuel consumption and potentially lower emissions-related expenses.

Durability is another factor to consider in the cost-benefit equation. High-performance filters often boast longer service lives compared to standard filters. This extended lifespan can reduce the frequency of filter replacements, leading to savings in both material costs and labor associated with filter changes.

The impact on engine longevity is a significant consideration. By more effectively removing contaminants, high-performance filters can help protect critical engine components from premature wear. This protection can potentially extend the overall lifespan of the engine, delaying the need for major repairs or engine replacement – a substantial long-term cost benefit.

However, it's important to note that the benefits of high-performance filters may vary depending on the specific operating conditions of the 5.4 Triton engine. Engines used in harsh environments or under heavy-duty conditions may see more pronounced benefits from high-performance filters compared to those used in less demanding situations.

When conducting a cost-benefit analysis, it's also crucial to consider the potential drawbacks. Some high-performance filters may require more frequent inspections or specialized maintenance procedures, which could offset some of the cost savings. Additionally, using non-OEM filters may impact warranty coverage, a factor that should be carefully weighed in the decision-making process.

In conclusion, while high-performance filters for 5.4 Triton engines typically come with a higher initial cost, their potential benefits in terms of engine performance, longevity, and reduced maintenance needs often justify the investment. A thorough cost-benefit analysis should consider both short-term expenses and long-term savings to determine the most economical and effective filtration solution for specific engine applications.

The upfront cost of high-performance filters is typically higher than standard filters. However, this initial investment often translates into long-term savings through improved engine efficiency and reduced maintenance needs. High-performance filters generally offer superior filtration capabilities, which can lead to decreased engine wear and extended service intervals.

One of the primary benefits of high-performance filters is their ability to enhance engine performance. By providing better air and oil filtration, these filters can contribute to increased horsepower, improved fuel efficiency, and overall smoother engine operation. These performance gains can result in tangible cost savings through reduced fuel consumption and potentially lower emissions-related expenses.

Durability is another factor to consider in the cost-benefit equation. High-performance filters often boast longer service lives compared to standard filters. This extended lifespan can reduce the frequency of filter replacements, leading to savings in both material costs and labor associated with filter changes.

The impact on engine longevity is a significant consideration. By more effectively removing contaminants, high-performance filters can help protect critical engine components from premature wear. This protection can potentially extend the overall lifespan of the engine, delaying the need for major repairs or engine replacement – a substantial long-term cost benefit.

However, it's important to note that the benefits of high-performance filters may vary depending on the specific operating conditions of the 5.4 Triton engine. Engines used in harsh environments or under heavy-duty conditions may see more pronounced benefits from high-performance filters compared to those used in less demanding situations.

When conducting a cost-benefit analysis, it's also crucial to consider the potential drawbacks. Some high-performance filters may require more frequent inspections or specialized maintenance procedures, which could offset some of the cost savings. Additionally, using non-OEM filters may impact warranty coverage, a factor that should be carefully weighed in the decision-making process.

In conclusion, while high-performance filters for 5.4 Triton engines typically come with a higher initial cost, their potential benefits in terms of engine performance, longevity, and reduced maintenance needs often justify the investment. A thorough cost-benefit analysis should consider both short-term expenses and long-term savings to determine the most economical and effective filtration solution for specific engine applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!