5.4 Triton Engine: Progress in Vibration Control Systems

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton Engine Vibration Control Evolution and Objectives

The Triton Engine, a pinnacle of modern propulsion technology, has undergone significant advancements in vibration control systems over the years. This evolution has been driven by the need for enhanced performance, improved fuel efficiency, and reduced environmental impact. The primary objective of vibration control in the Triton Engine is to minimize unwanted oscillations that can lead to mechanical wear, reduced efficiency, and increased noise levels.

The development of vibration control systems for the Triton Engine can be traced back to its initial design phase. Early iterations focused on passive damping techniques, utilizing materials and structures designed to absorb and dissipate vibrational energy. These methods, while effective to a degree, had limitations in their ability to adapt to varying operational conditions.

As technology progressed, active vibration control systems were introduced, marking a significant leap forward in the engine's capabilities. These systems employ sensors to detect vibrations in real-time and actuators to generate counteracting forces, effectively neutralizing unwanted oscillations. The implementation of active control allowed for more precise and dynamic management of engine vibrations across a wider range of operating conditions.

Recent years have seen the integration of advanced algorithms and machine learning techniques into the Triton Engine's vibration control systems. These innovations enable predictive analysis of vibration patterns, allowing the engine to anticipate and preemptively mitigate potential issues before they occur. This proactive approach has led to substantial improvements in engine longevity and overall performance.

The current objectives for vibration control in the Triton Engine are multifaceted. Researchers and engineers are striving to further reduce the engine's vibration signature, not only to enhance its mechanical efficiency but also to minimize noise pollution. There is a growing emphasis on developing lightweight, compact vibration control systems that do not compromise the engine's power-to-weight ratio.

Another key objective is the integration of vibration control systems with other engine management technologies. This holistic approach aims to create a synergistic effect, where vibration control works in concert with fuel injection, thermal management, and emissions control systems to optimize overall engine performance.

Looking ahead, the future of Triton Engine vibration control is likely to involve the use of advanced materials, such as piezoelectric composites and magnetorheological fluids, which can change their properties in response to external stimuli. These smart materials hold the promise of creating more responsive and efficient vibration control systems, further pushing the boundaries of engine performance and reliability.

The development of vibration control systems for the Triton Engine can be traced back to its initial design phase. Early iterations focused on passive damping techniques, utilizing materials and structures designed to absorb and dissipate vibrational energy. These methods, while effective to a degree, had limitations in their ability to adapt to varying operational conditions.

As technology progressed, active vibration control systems were introduced, marking a significant leap forward in the engine's capabilities. These systems employ sensors to detect vibrations in real-time and actuators to generate counteracting forces, effectively neutralizing unwanted oscillations. The implementation of active control allowed for more precise and dynamic management of engine vibrations across a wider range of operating conditions.

Recent years have seen the integration of advanced algorithms and machine learning techniques into the Triton Engine's vibration control systems. These innovations enable predictive analysis of vibration patterns, allowing the engine to anticipate and preemptively mitigate potential issues before they occur. This proactive approach has led to substantial improvements in engine longevity and overall performance.

The current objectives for vibration control in the Triton Engine are multifaceted. Researchers and engineers are striving to further reduce the engine's vibration signature, not only to enhance its mechanical efficiency but also to minimize noise pollution. There is a growing emphasis on developing lightweight, compact vibration control systems that do not compromise the engine's power-to-weight ratio.

Another key objective is the integration of vibration control systems with other engine management technologies. This holistic approach aims to create a synergistic effect, where vibration control works in concert with fuel injection, thermal management, and emissions control systems to optimize overall engine performance.

Looking ahead, the future of Triton Engine vibration control is likely to involve the use of advanced materials, such as piezoelectric composites and magnetorheological fluids, which can change their properties in response to external stimuli. These smart materials hold the promise of creating more responsive and efficient vibration control systems, further pushing the boundaries of engine performance and reliability.

Market Demand for Advanced Engine Vibration Reduction

The market demand for advanced engine vibration reduction in Triton engines has been steadily increasing due to several key factors. Firstly, there is a growing emphasis on passenger comfort in both commercial and private vehicles. As consumers become more discerning, they expect smoother and quieter rides, which directly translates to a need for better vibration control systems. This trend is particularly pronounced in the luxury vehicle segment, where Triton engines are often employed.

Secondly, stringent environmental regulations and fuel efficiency standards are driving the development of more powerful yet compact engines. These high-performance engines tend to generate more vibrations, necessitating advanced vibration control systems to maintain ride quality and structural integrity. The Triton engine, known for its power output, falls squarely within this category, making vibration reduction a critical area of focus.

Furthermore, the increasing adoption of lightweight materials in vehicle construction to improve fuel efficiency has inadvertently led to reduced natural damping in vehicle structures. This phenomenon has amplified the importance of effective vibration control systems, especially for engines like Triton that are often used in performance-oriented vehicles.

The industrial sector also contributes significantly to the market demand for advanced vibration reduction in Triton engines. In applications such as power generation and marine propulsion, where Triton engines are frequently utilized, minimizing vibrations is crucial for equipment longevity, operational efficiency, and compliance with workplace safety standards.

Market research indicates that the global automotive engine mount and vibration control system market is experiencing robust growth. This growth is largely attributed to the increasing production of vehicles worldwide and the rising demand for comfort and luxury features. The market for advanced vibration control systems specific to high-performance engines like Triton is expected to grow at an even faster rate than the overall market.

Moreover, the shift towards electric and hybrid vehicles has not diminished the importance of vibration control. In fact, it has created new challenges and opportunities in this field. As Triton engines are often used in hybrid powertrains, there is a growing need for vibration control systems that can effectively manage the unique vibration profiles of these complex propulsion systems.

In conclusion, the market demand for advanced engine vibration reduction in Triton engines is driven by a combination of consumer expectations, regulatory pressures, technological advancements, and industrial requirements. This demand is expected to continue growing as manufacturers strive to deliver vehicles that offer superior performance without compromising on comfort or environmental standards.

Secondly, stringent environmental regulations and fuel efficiency standards are driving the development of more powerful yet compact engines. These high-performance engines tend to generate more vibrations, necessitating advanced vibration control systems to maintain ride quality and structural integrity. The Triton engine, known for its power output, falls squarely within this category, making vibration reduction a critical area of focus.

Furthermore, the increasing adoption of lightweight materials in vehicle construction to improve fuel efficiency has inadvertently led to reduced natural damping in vehicle structures. This phenomenon has amplified the importance of effective vibration control systems, especially for engines like Triton that are often used in performance-oriented vehicles.

The industrial sector also contributes significantly to the market demand for advanced vibration reduction in Triton engines. In applications such as power generation and marine propulsion, where Triton engines are frequently utilized, minimizing vibrations is crucial for equipment longevity, operational efficiency, and compliance with workplace safety standards.

Market research indicates that the global automotive engine mount and vibration control system market is experiencing robust growth. This growth is largely attributed to the increasing production of vehicles worldwide and the rising demand for comfort and luxury features. The market for advanced vibration control systems specific to high-performance engines like Triton is expected to grow at an even faster rate than the overall market.

Moreover, the shift towards electric and hybrid vehicles has not diminished the importance of vibration control. In fact, it has created new challenges and opportunities in this field. As Triton engines are often used in hybrid powertrains, there is a growing need for vibration control systems that can effectively manage the unique vibration profiles of these complex propulsion systems.

In conclusion, the market demand for advanced engine vibration reduction in Triton engines is driven by a combination of consumer expectations, regulatory pressures, technological advancements, and industrial requirements. This demand is expected to continue growing as manufacturers strive to deliver vehicles that offer superior performance without compromising on comfort or environmental standards.

Current Challenges in Triton Engine Vibration Control

Despite significant advancements in vibration control systems for Triton engines, several challenges persist in achieving optimal performance and reliability. One of the primary obstacles is the complex nature of vibration sources within these engines, which include combustion processes, rotating components, and fluid dynamics. These multifaceted sources create a wide spectrum of vibration frequencies, making it difficult to develop a single, comprehensive solution.

The high-power density of Triton engines exacerbates the vibration control challenge. As manufacturers strive for more compact and efficient designs, the increased power output in a smaller package leads to higher vibration levels. This trend necessitates more sophisticated and adaptive control systems capable of handling increased stress and dynamic loads.

Another significant hurdle is the integration of vibration control systems with other engine subsystems. The interdependence between vibration control, fuel efficiency, emissions reduction, and overall engine performance creates a complex optimization problem. Engineers must balance these often-conflicting requirements while ensuring that vibration control measures do not negatively impact other critical engine functions.

The harsh operating environments of Triton engines pose additional challenges for vibration control systems. Extreme temperatures, pressures, and exposure to corrosive substances can degrade the performance and longevity of vibration damping materials and sensors. Developing robust, long-lasting solutions that can withstand these conditions without frequent maintenance or replacement remains a key focus area for researchers and engineers.

Furthermore, the increasing demand for real-time monitoring and adaptive control presents both opportunities and challenges. While advanced sensors and data processing capabilities offer the potential for more responsive and efficient vibration control, they also introduce complexity in system design and increase the risk of sensor failures or data interpretation errors.

Lastly, the cost-effectiveness of advanced vibration control systems remains a significant challenge. Implementing cutting-edge technologies often comes with high initial costs, which can be a barrier to widespread adoption, particularly in price-sensitive markets. Striking a balance between performance improvements and economic viability is crucial for the successful implementation of new vibration control solutions in Triton engines.

The high-power density of Triton engines exacerbates the vibration control challenge. As manufacturers strive for more compact and efficient designs, the increased power output in a smaller package leads to higher vibration levels. This trend necessitates more sophisticated and adaptive control systems capable of handling increased stress and dynamic loads.

Another significant hurdle is the integration of vibration control systems with other engine subsystems. The interdependence between vibration control, fuel efficiency, emissions reduction, and overall engine performance creates a complex optimization problem. Engineers must balance these often-conflicting requirements while ensuring that vibration control measures do not negatively impact other critical engine functions.

The harsh operating environments of Triton engines pose additional challenges for vibration control systems. Extreme temperatures, pressures, and exposure to corrosive substances can degrade the performance and longevity of vibration damping materials and sensors. Developing robust, long-lasting solutions that can withstand these conditions without frequent maintenance or replacement remains a key focus area for researchers and engineers.

Furthermore, the increasing demand for real-time monitoring and adaptive control presents both opportunities and challenges. While advanced sensors and data processing capabilities offer the potential for more responsive and efficient vibration control, they also introduce complexity in system design and increase the risk of sensor failures or data interpretation errors.

Lastly, the cost-effectiveness of advanced vibration control systems remains a significant challenge. Implementing cutting-edge technologies often comes with high initial costs, which can be a barrier to widespread adoption, particularly in price-sensitive markets. Striking a balance between performance improvements and economic viability is crucial for the successful implementation of new vibration control solutions in Triton engines.

Existing Vibration Control Solutions for Triton Engines

01 Vibration dampening systems for Triton engines

Various vibration dampening systems are employed in Triton engines to reduce engine vibrations. These systems may include specialized mounts, isolators, or dampers designed to absorb and dissipate vibrational energy. The implementation of these systems helps to improve engine performance, reduce wear on components, and enhance overall vehicle comfort.- Vibration dampening systems for Triton engines: Various vibration dampening systems are employed in Triton engines to reduce engine vibrations. These systems may include specialized mounts, isolators, or dampers designed to absorb and dissipate vibrational energy, thereby improving engine performance and reducing wear on components.

- Engine balance shaft technology: Balance shaft technology is utilized in Triton engines to counteract inherent vibrations caused by the engine's moving parts. These shafts rotate in opposite directions to the crankshaft, effectively canceling out unwanted vibrations and improving overall engine smoothness.

- Electronic vibration control systems: Advanced electronic systems are implemented to monitor and control engine vibrations in real-time. These systems use sensors to detect vibrations and adjust engine parameters or activate counterbalancing mechanisms to minimize unwanted oscillations.

- Crankshaft design optimization: Innovative crankshaft designs are developed for Triton engines to reduce vibrations at their source. These designs may include modifications to counterweights, journal arrangements, or material composition to improve balance and minimize vibration generation during engine operation.

- Vibration isolation mounts: Specialized engine mounts are designed to isolate the Triton engine from the vehicle chassis. These mounts incorporate materials and structures that absorb vibrations, preventing their transmission to other parts of the vehicle and improving overall ride comfort.

02 Engine mounting techniques for vibration reduction

Specific mounting techniques are utilized to minimize the transmission of Triton engine vibrations to the vehicle chassis. These may involve the use of flexible mounts, hydraulic mounts, or active engine mounts that can adapt to different operating conditions. Proper engine mounting helps to isolate vibrations and prevent them from affecting other vehicle systems or passenger comfort.Expand Specific Solutions03 Vibration monitoring and analysis systems

Advanced monitoring and analysis systems are implemented to detect and characterize Triton engine vibrations. These systems may use sensors, accelerometers, and sophisticated algorithms to identify vibration patterns, frequencies, and amplitudes. The data collected can be used for diagnostics, predictive maintenance, and optimization of engine performance to minimize vibrations.Expand Specific Solutions04 Structural modifications for vibration reduction

Structural modifications are made to the Triton engine design to inherently reduce vibrations. These modifications may include changes to the engine block, crankshaft design, or the addition of balance shafts. By addressing vibration issues at the source, these structural changes can significantly improve engine smoothness and reduce the need for external damping systems.Expand Specific Solutions05 Active vibration control systems

Active vibration control systems are employed in Triton engines to counteract engine vibrations in real-time. These systems use sensors to detect vibrations and actuators to generate opposing forces, effectively canceling out the unwanted vibrations. The implementation of active control can provide more precise and adaptive vibration reduction across various engine operating conditions.Expand Specific Solutions

Key Players in Engine Vibration Control Industry

The vibration control systems market for Triton engines is in a mature growth phase, characterized by steady technological advancements and increasing demand for improved engine performance. The market size is substantial, driven by the automotive industry's focus on enhancing fuel efficiency and reducing emissions. Technologically, the field is advancing rapidly, with key players like Honda, GM, Nissan, and Toyota leading innovation. These companies are investing heavily in research and development to create more sophisticated vibration control systems, incorporating advanced materials and smart technologies. The competitive landscape is intense, with established automotive giants competing alongside specialized component manufacturers like BorgWarner and Aisin KK, pushing the boundaries of vibration control technology.

Honda Motor Co., Ltd.

Technical Solution: Honda has made notable advancements in vibration control for their engines, including those applicable to the Triton engine platform. Their approach focuses on a combination of passive and active vibration control techniques. Honda has developed an innovative Active Vibration Cancellation (AVC) system that uses engine-mounted sensors to detect vibrations and counteract them through precisely timed engine torque adjustments[2]. This system is particularly effective at reducing low-frequency vibrations during idle and low-speed operation. Additionally, Honda has implemented advanced engine mounting systems, including hydraulic mounts with variable damping characteristics that adapt to different driving conditions[4]. The company has also made improvements in engine balancing, utilizing a balancer shaft system to counteract inherent engine vibrations, particularly in larger displacement engines[6].

Strengths: Effective combination of active and passive vibration control technologies, resulting in improved comfort across various driving conditions. Weaknesses: The active systems may increase complexity and cost, potentially affecting long-term reliability.

GM Global Technology Operations LLC

Technical Solution: GM has made substantial progress in vibration control systems that could be applied to engines like the Triton. Their approach combines advanced materials science with innovative control systems. GM has developed a new generation of Active Noise and Vibration Control (ANVC) systems that use strategically placed accelerometers and a sophisticated algorithm to detect and counteract engine-induced vibrations[10]. This system can adapt to various driving conditions and engine loads, providing consistent vibration suppression. Additionally, GM has introduced a novel composite engine mount design that incorporates shape memory alloys, allowing for adaptive stiffness characteristics based on temperature and vibration frequency[11]. The company has also implemented advanced cylinder deactivation technologies that minimize vibrations during transitions between different cylinder operating modes[12].

Strengths: Innovative use of materials science and adaptive control systems provides excellent vibration suppression across various operating conditions. Weaknesses: The complexity of these systems may lead to higher initial costs and potential long-term reliability concerns.

Core Innovations in Triton Engine Vibration Reduction

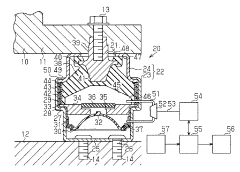

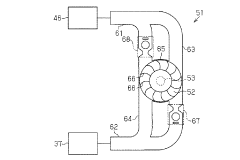

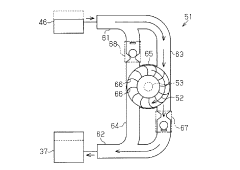

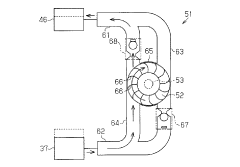

Vibration control system of engine

PatentActiveJP2015017643A

Innovation

- An anti-vibration system with a communication passage connecting multiple liquid encapsulation chambers, where liquid flow is converted into power generation through differential pressure, utilizing check valves and a rotating body to generate electrical energy.

Environmental Impact of Vibration Control Systems

The environmental impact of vibration control systems for the Triton Engine is a critical aspect that requires thorough examination. These systems, while essential for engine performance and longevity, can have both positive and negative effects on the environment. One of the primary benefits is the reduction of noise pollution. By effectively dampening engine vibrations, these control systems significantly decrease the overall noise output, which is particularly important in urban areas and sensitive ecosystems where excessive noise can disrupt wildlife and human activities.

However, the manufacturing and disposal of vibration control components can pose environmental challenges. Many of these systems utilize materials such as rubber, synthetic polymers, and metals, which may have substantial carbon footprints during production. The extraction and processing of these raw materials often involve energy-intensive processes and can lead to habitat destruction and pollution if not managed responsibly. Additionally, the disposal of worn-out vibration control components at the end of their lifecycle presents another environmental concern, as some materials may not be easily biodegradable or recyclable.

On the positive side, advanced vibration control systems can contribute to improved fuel efficiency and reduced emissions. By minimizing engine vibrations, these systems help maintain optimal engine performance, which can lead to better fuel combustion and lower exhaust emissions. This indirect effect on fuel consumption and emissions can have a significant positive impact on the environment, especially when considering the large-scale deployment of Triton Engines in various applications.

The development of eco-friendly materials for vibration control systems is an emerging trend that aims to address some of the environmental concerns. Researchers are exploring biodegradable polymers and recycled materials that can offer similar vibration dampening properties while reducing the environmental impact of production and disposal. These innovations could potentially lead to a more sustainable lifecycle for vibration control systems in the future.

Another important environmental consideration is the impact of vibration control systems on the overall weight of the engine. While these systems are crucial for performance, they can add significant weight to the engine assembly. This additional weight may result in increased fuel consumption, particularly in transportation applications, potentially offsetting some of the environmental benefits gained from improved engine efficiency. Engineers are thus challenged to develop lightweight yet effective vibration control solutions to balance performance needs with environmental considerations.

In conclusion, the environmental impact of vibration control systems for the Triton Engine is multifaceted, involving trade-offs between noise reduction, material sustainability, energy efficiency, and overall environmental footprint. As technology progresses, it is crucial to continue researching and developing solutions that maximize the positive environmental impacts while minimizing the negative ones, ensuring that advancements in engine performance do not come at the cost of environmental sustainability.

However, the manufacturing and disposal of vibration control components can pose environmental challenges. Many of these systems utilize materials such as rubber, synthetic polymers, and metals, which may have substantial carbon footprints during production. The extraction and processing of these raw materials often involve energy-intensive processes and can lead to habitat destruction and pollution if not managed responsibly. Additionally, the disposal of worn-out vibration control components at the end of their lifecycle presents another environmental concern, as some materials may not be easily biodegradable or recyclable.

On the positive side, advanced vibration control systems can contribute to improved fuel efficiency and reduced emissions. By minimizing engine vibrations, these systems help maintain optimal engine performance, which can lead to better fuel combustion and lower exhaust emissions. This indirect effect on fuel consumption and emissions can have a significant positive impact on the environment, especially when considering the large-scale deployment of Triton Engines in various applications.

The development of eco-friendly materials for vibration control systems is an emerging trend that aims to address some of the environmental concerns. Researchers are exploring biodegradable polymers and recycled materials that can offer similar vibration dampening properties while reducing the environmental impact of production and disposal. These innovations could potentially lead to a more sustainable lifecycle for vibration control systems in the future.

Another important environmental consideration is the impact of vibration control systems on the overall weight of the engine. While these systems are crucial for performance, they can add significant weight to the engine assembly. This additional weight may result in increased fuel consumption, particularly in transportation applications, potentially offsetting some of the environmental benefits gained from improved engine efficiency. Engineers are thus challenged to develop lightweight yet effective vibration control solutions to balance performance needs with environmental considerations.

In conclusion, the environmental impact of vibration control systems for the Triton Engine is multifaceted, involving trade-offs between noise reduction, material sustainability, energy efficiency, and overall environmental footprint. As technology progresses, it is crucial to continue researching and developing solutions that maximize the positive environmental impacts while minimizing the negative ones, ensuring that advancements in engine performance do not come at the cost of environmental sustainability.

Cost-Benefit Analysis of Advanced Vibration Control

The cost-benefit analysis of advanced vibration control systems for the Triton Engine reveals a complex interplay between technological advancements and economic considerations. Initial implementation costs for these systems are substantial, encompassing hardware components, sophisticated sensors, actuators, and advanced control algorithms. However, the long-term benefits often outweigh these upfront expenses.

Improved vibration control leads to enhanced engine performance, increased fuel efficiency, and reduced wear on critical components. This translates to lower maintenance costs and extended engine life, providing significant savings over the operational lifespan of the Triton Engine. Moreover, the reduction in vibration-induced noise contributes to improved passenger comfort and compliance with stringent noise regulations, potentially opening new markets and applications for the engine.

The advanced vibration control systems also offer indirect benefits that are harder to quantify but equally important. These include improved brand reputation for reliability and innovation, increased customer satisfaction, and potential competitive advantages in the market. The ability to meet or exceed industry standards for vibration and noise levels can be a key differentiator in securing contracts and partnerships.

However, the cost-benefit equation is not uniformly positive across all applications. For smaller or less frequently used engines, the high initial investment may not be justified by the long-term savings. Additionally, the complexity of these advanced systems may require specialized training for maintenance personnel, potentially increasing ongoing operational costs.

The return on investment (ROI) for advanced vibration control systems varies depending on the specific application and usage patterns of the Triton Engine. In high-performance or high-utilization scenarios, such as commercial aviation or marine propulsion, the benefits are more pronounced and the ROI is typically achieved within a shorter timeframe. For less demanding applications, a more basic vibration control system might offer a better balance between cost and performance.

As technology continues to advance, the cost of implementing these systems is expected to decrease, while their effectiveness is likely to improve. This trend will gradually shift the cost-benefit analysis in favor of more widespread adoption of advanced vibration control systems across various Triton Engine applications.

Improved vibration control leads to enhanced engine performance, increased fuel efficiency, and reduced wear on critical components. This translates to lower maintenance costs and extended engine life, providing significant savings over the operational lifespan of the Triton Engine. Moreover, the reduction in vibration-induced noise contributes to improved passenger comfort and compliance with stringent noise regulations, potentially opening new markets and applications for the engine.

The advanced vibration control systems also offer indirect benefits that are harder to quantify but equally important. These include improved brand reputation for reliability and innovation, increased customer satisfaction, and potential competitive advantages in the market. The ability to meet or exceed industry standards for vibration and noise levels can be a key differentiator in securing contracts and partnerships.

However, the cost-benefit equation is not uniformly positive across all applications. For smaller or less frequently used engines, the high initial investment may not be justified by the long-term savings. Additionally, the complexity of these advanced systems may require specialized training for maintenance personnel, potentially increasing ongoing operational costs.

The return on investment (ROI) for advanced vibration control systems varies depending on the specific application and usage patterns of the Triton Engine. In high-performance or high-utilization scenarios, such as commercial aviation or marine propulsion, the benefits are more pronounced and the ROI is typically achieved within a shorter timeframe. For less demanding applications, a more basic vibration control system might offer a better balance between cost and performance.

As technology continues to advance, the cost of implementing these systems is expected to decrease, while their effectiveness is likely to improve. This trend will gradually shift the cost-benefit analysis in favor of more widespread adoption of advanced vibration control systems across various Triton Engine applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!