How to Troubleshoot 5.4 Triton Engine Misfire Problems?

AUG 12, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

5.4 Triton Engine Overview and Misfire Issues

The 5.4 Triton engine, developed by Ford Motor Company, has been a staple in their lineup of V8 engines since its introduction in the late 1990s. This engine has been widely used in various Ford vehicles, including the popular F-150 pickup truck, Expedition SUV, and E-Series vans. Known for its robust design and reliable performance, the 5.4 Triton engine has earned a reputation for durability and power.

However, like any complex mechanical system, the 5.4 Triton engine is not without its issues. One of the most common problems reported by owners is engine misfires. A misfire occurs when one or more cylinders in the engine fail to ignite the fuel-air mixture properly, leading to a loss of power, rough running, and potential damage if left unaddressed.

Misfire issues in the 5.4 Triton engine can stem from various sources, making diagnosis and troubleshooting a critical skill for mechanics and vehicle owners alike. Common causes of misfires in this engine include faulty spark plugs, worn ignition coils, clogged fuel injectors, vacuum leaks, and issues with the engine's computer or sensors.

One of the most notorious misfire-related problems specific to the 5.4 Triton engine is the tendency for spark plugs to break during removal. This issue, particularly prevalent in models produced between 2004 and 2008, can lead to costly repairs and exacerbate existing misfire problems if not handled correctly.

Another significant contributor to misfires in the 5.4 Triton engine is carbon buildup on the valves and in the combustion chambers. This accumulation can interfere with proper fuel atomization and combustion, leading to irregular firing patterns and reduced engine efficiency.

Identifying and addressing misfire issues in the 5.4 Triton engine requires a systematic approach. Modern diagnostic tools, such as OBD-II scanners, can provide valuable information by reading error codes stored in the engine's computer. However, these codes often serve as starting points rather than definitive diagnoses, necessitating further investigation and testing.

Understanding the specific symptoms associated with 5.4 Triton engine misfires is crucial for effective troubleshooting. These may include a noticeable loss of power, especially under acceleration, rough idling, increased fuel consumption, and in some cases, visible exhaust smoke. The engine may also produce a distinct shaking or vibration, particularly when idling.

However, like any complex mechanical system, the 5.4 Triton engine is not without its issues. One of the most common problems reported by owners is engine misfires. A misfire occurs when one or more cylinders in the engine fail to ignite the fuel-air mixture properly, leading to a loss of power, rough running, and potential damage if left unaddressed.

Misfire issues in the 5.4 Triton engine can stem from various sources, making diagnosis and troubleshooting a critical skill for mechanics and vehicle owners alike. Common causes of misfires in this engine include faulty spark plugs, worn ignition coils, clogged fuel injectors, vacuum leaks, and issues with the engine's computer or sensors.

One of the most notorious misfire-related problems specific to the 5.4 Triton engine is the tendency for spark plugs to break during removal. This issue, particularly prevalent in models produced between 2004 and 2008, can lead to costly repairs and exacerbate existing misfire problems if not handled correctly.

Another significant contributor to misfires in the 5.4 Triton engine is carbon buildup on the valves and in the combustion chambers. This accumulation can interfere with proper fuel atomization and combustion, leading to irregular firing patterns and reduced engine efficiency.

Identifying and addressing misfire issues in the 5.4 Triton engine requires a systematic approach. Modern diagnostic tools, such as OBD-II scanners, can provide valuable information by reading error codes stored in the engine's computer. However, these codes often serve as starting points rather than definitive diagnoses, necessitating further investigation and testing.

Understanding the specific symptoms associated with 5.4 Triton engine misfires is crucial for effective troubleshooting. These may include a noticeable loss of power, especially under acceleration, rough idling, increased fuel consumption, and in some cases, visible exhaust smoke. The engine may also produce a distinct shaking or vibration, particularly when idling.

Market Impact of Engine Reliability

Engine reliability plays a crucial role in shaping market dynamics within the automotive industry. The impact of engine issues, such as misfires in the 5.4 Triton engine, extends far beyond individual vehicle performance, affecting brand reputation, consumer trust, and overall market share.

Reliability concerns can significantly influence consumer purchasing decisions. When faced with persistent engine problems, particularly misfires, potential buyers may hesitate to invest in vehicles equipped with the affected engine. This hesitation can lead to decreased sales and market share for manufacturers associated with problematic engines. In the case of the 5.4 Triton engine, Ford has faced challenges in maintaining consumer confidence due to reported misfire issues.

The financial implications of engine reliability problems are substantial. Manufacturers may incur significant costs related to warranty claims, recalls, and repairs. These expenses can erode profit margins and divert resources from research and development efforts. Additionally, the need for extensive troubleshooting and repairs can strain dealership networks and service centers, potentially leading to customer dissatisfaction and negative word-of-mouth.

Market perception of a brand's overall quality and reliability is heavily influenced by engine performance. Persistent misfire issues in the 5.4 Triton engine have the potential to tarnish Ford's reputation for producing dependable vehicles. This negative perception can extend beyond the affected model, impacting sales across the entire product line and potentially causing long-term damage to brand equity.

Competitors may capitalize on reliability concerns to gain market share. As consumers become aware of engine issues, they may explore alternative options from rival manufacturers. This shift in consumer preference can lead to a redistribution of market share within the automotive industry, potentially altering the competitive landscape.

Engine reliability also affects the resale value of vehicles. Models known for persistent misfire problems, such as those equipped with the 5.4 Triton engine, may experience accelerated depreciation. This can impact the overall ownership experience and influence future purchasing decisions, as consumers consider the long-term value proposition of their vehicle investments.

The market impact of engine reliability extends to the aftermarket sector as well. Increased demand for replacement parts, diagnostic tools, and specialized repair services can create opportunities for aftermarket suppliers and independent repair shops. However, this also highlights the ongoing challenges faced by vehicle owners and the potential for increased maintenance costs over the vehicle's lifetime.

Reliability concerns can significantly influence consumer purchasing decisions. When faced with persistent engine problems, particularly misfires, potential buyers may hesitate to invest in vehicles equipped with the affected engine. This hesitation can lead to decreased sales and market share for manufacturers associated with problematic engines. In the case of the 5.4 Triton engine, Ford has faced challenges in maintaining consumer confidence due to reported misfire issues.

The financial implications of engine reliability problems are substantial. Manufacturers may incur significant costs related to warranty claims, recalls, and repairs. These expenses can erode profit margins and divert resources from research and development efforts. Additionally, the need for extensive troubleshooting and repairs can strain dealership networks and service centers, potentially leading to customer dissatisfaction and negative word-of-mouth.

Market perception of a brand's overall quality and reliability is heavily influenced by engine performance. Persistent misfire issues in the 5.4 Triton engine have the potential to tarnish Ford's reputation for producing dependable vehicles. This negative perception can extend beyond the affected model, impacting sales across the entire product line and potentially causing long-term damage to brand equity.

Competitors may capitalize on reliability concerns to gain market share. As consumers become aware of engine issues, they may explore alternative options from rival manufacturers. This shift in consumer preference can lead to a redistribution of market share within the automotive industry, potentially altering the competitive landscape.

Engine reliability also affects the resale value of vehicles. Models known for persistent misfire problems, such as those equipped with the 5.4 Triton engine, may experience accelerated depreciation. This can impact the overall ownership experience and influence future purchasing decisions, as consumers consider the long-term value proposition of their vehicle investments.

The market impact of engine reliability extends to the aftermarket sector as well. Increased demand for replacement parts, diagnostic tools, and specialized repair services can create opportunities for aftermarket suppliers and independent repair shops. However, this also highlights the ongoing challenges faced by vehicle owners and the potential for increased maintenance costs over the vehicle's lifetime.

Current Diagnostic Methods and Limitations

The current diagnostic methods for troubleshooting 5.4 Triton engine misfire problems primarily rely on a combination of on-board diagnostics (OBD) systems and manual inspection techniques. OBD systems utilize various sensors throughout the engine to monitor performance and detect anomalies. When a misfire is detected, the system typically triggers a check engine light and stores a corresponding diagnostic trouble code (DTC).

One of the most common diagnostic tools is the OBD-II scanner, which can read these DTCs and provide valuable information about the nature and location of the misfire. However, while these codes can point technicians in the right direction, they often lack the specificity needed to pinpoint the exact cause of the misfire.

Manual inspection methods include visual checks of spark plugs, fuel injectors, and ignition coils for signs of wear or damage. Compression tests and cylinder leak-down tests are also frequently employed to assess the mechanical integrity of the engine. These tests can help identify issues such as worn piston rings, damaged valves, or blown head gaskets that may contribute to misfires.

Despite these diagnostic methods, several limitations persist in accurately identifying and resolving 5.4 Triton engine misfire problems. One significant challenge is the intermittent nature of some misfires, which may not be present during diagnostic testing. This can lead to misdiagnosis or incomplete repairs, resulting in recurring issues for vehicle owners.

Another limitation is the complexity of modern engine systems, which can make it difficult to isolate the root cause of a misfire. Multiple factors, such as fuel delivery issues, ignition system problems, or mechanical failures, can contribute to misfires, and these factors may interact in ways that are not easily discernible through current diagnostic methods.

The reliance on generic OBD codes also presents a limitation, as these codes may not always provide sufficient detail to differentiate between similar issues. For example, a misfire code may not distinguish between a faulty spark plug and a worn ignition coil, necessitating additional testing and potentially leading to unnecessary parts replacement.

Furthermore, the 5.4 Triton engine's design presents unique challenges, such as the potential for spark plug ejection or breakage during removal. This can complicate diagnostic procedures and increase the risk of damage during inspection, limiting the effectiveness of certain manual diagnostic techniques.

Lastly, the current diagnostic methods often require significant expertise and experience to interpret results accurately. This dependency on skilled technicians can lead to inconsistencies in diagnosis and repair quality across different service providers, potentially resulting in prolonged troubleshooting processes and increased costs for vehicle owners.

One of the most common diagnostic tools is the OBD-II scanner, which can read these DTCs and provide valuable information about the nature and location of the misfire. However, while these codes can point technicians in the right direction, they often lack the specificity needed to pinpoint the exact cause of the misfire.

Manual inspection methods include visual checks of spark plugs, fuel injectors, and ignition coils for signs of wear or damage. Compression tests and cylinder leak-down tests are also frequently employed to assess the mechanical integrity of the engine. These tests can help identify issues such as worn piston rings, damaged valves, or blown head gaskets that may contribute to misfires.

Despite these diagnostic methods, several limitations persist in accurately identifying and resolving 5.4 Triton engine misfire problems. One significant challenge is the intermittent nature of some misfires, which may not be present during diagnostic testing. This can lead to misdiagnosis or incomplete repairs, resulting in recurring issues for vehicle owners.

Another limitation is the complexity of modern engine systems, which can make it difficult to isolate the root cause of a misfire. Multiple factors, such as fuel delivery issues, ignition system problems, or mechanical failures, can contribute to misfires, and these factors may interact in ways that are not easily discernible through current diagnostic methods.

The reliance on generic OBD codes also presents a limitation, as these codes may not always provide sufficient detail to differentiate between similar issues. For example, a misfire code may not distinguish between a faulty spark plug and a worn ignition coil, necessitating additional testing and potentially leading to unnecessary parts replacement.

Furthermore, the 5.4 Triton engine's design presents unique challenges, such as the potential for spark plug ejection or breakage during removal. This can complicate diagnostic procedures and increase the risk of damage during inspection, limiting the effectiveness of certain manual diagnostic techniques.

Lastly, the current diagnostic methods often require significant expertise and experience to interpret results accurately. This dependency on skilled technicians can lead to inconsistencies in diagnosis and repair quality across different service providers, potentially resulting in prolonged troubleshooting processes and increased costs for vehicle owners.

Existing Troubleshooting Procedures for 5.4 Triton

01 Misfire detection systems

Advanced systems for detecting misfires in 5.4 Triton engines, utilizing various sensors and algorithms to monitor engine performance and identify irregularities in combustion. These systems can analyze crankshaft speed fluctuations, exhaust gas composition, and other parameters to accurately detect and diagnose misfires.- Misfire detection systems: Advanced systems for detecting misfires in engines, including the 5.4 Triton, utilize various sensors and algorithms to monitor engine performance. These systems analyze crankshaft rotation, cylinder pressure, and exhaust gas composition to identify and diagnose misfires accurately. Real-time monitoring allows for quick detection and response to potential engine issues.

- Engine control unit (ECU) diagnostics: ECU diagnostics play a crucial role in identifying and addressing misfires in the 5.4 Triton engine. Advanced diagnostic algorithms analyze sensor data to detect irregularities in combustion, fuel injection, and ignition timing. These systems can pinpoint specific cylinders experiencing misfires and provide detailed error codes for efficient troubleshooting and repair.

- Fuel system optimization: Optimizing the fuel system is crucial for preventing misfires in the 5.4 Triton engine. This includes improving fuel injector performance, ensuring proper fuel pressure, and maintaining clean fuel filters. Advanced fuel management systems can adjust fuel delivery based on engine load and operating conditions, reducing the likelihood of misfires caused by fuel-related issues.

- Ignition system enhancements: Enhancing the ignition system can significantly reduce misfires in the 5.4 Triton engine. This involves improving spark plug design, optimizing ignition timing, and implementing advanced coil-on-plug technology. These enhancements ensure consistent and powerful spark generation, reducing the chances of incomplete combustion and misfires.

- Cylinder pressure monitoring: Implementing cylinder pressure monitoring systems can help detect and prevent misfires in the 5.4 Triton engine. These systems use pressure sensors to measure combustion pressure in each cylinder, allowing for real-time analysis of engine performance. By detecting anomalies in cylinder pressure, the system can identify misfires early and adjust engine parameters to prevent further issues.

02 Engine control unit (ECU) diagnostics

Sophisticated ECU diagnostic techniques specifically designed for the 5.4 Triton engine, capable of analyzing sensor data, fuel injection patterns, and ignition timing to identify potential causes of misfires. These diagnostics can help pinpoint issues related to fuel delivery, spark plugs, or other components that may contribute to engine misfires.Expand Specific Solutions03 Fuel system optimization

Methods for optimizing the fuel system in 5.4 Triton engines to prevent misfires, including improvements in fuel injector design, fuel pressure regulation, and fuel quality monitoring. These optimizations can help ensure consistent fuel delivery and proper atomization, reducing the likelihood of misfires caused by fuel-related issues.Expand Specific Solutions04 Ignition system enhancements

Advancements in ignition system components and control strategies for the 5.4 Triton engine, focusing on improving spark plug performance, coil pack reliability, and ignition timing accuracy. These enhancements can help maintain consistent combustion and reduce the occurrence of misfires due to ignition-related problems.Expand Specific Solutions05 Cylinder pressure monitoring

Innovative techniques for monitoring cylinder pressure in 5.4 Triton engines to detect and analyze misfires. These methods can provide real-time data on combustion quality, allowing for early detection of misfires and potential engine damage. Advanced sensors and signal processing algorithms are used to accurately measure and interpret cylinder pressure variations.Expand Specific Solutions

Key Players in Automotive Diagnostic Industry

The automotive engine misfire troubleshooting market is in a mature stage, with established players like GM, Toyota, Ford, and Hyundai dominating the field. The market size is substantial, driven by the global automotive industry's continuous growth and increasing vehicle complexity. Technologically, the sector is advanced, with companies like Bosch, Continental, and Denso leading in diagnostic tools and engine management systems. Emerging players such as BYD and Great Wall Motor are also making strides in this area, particularly in electric vehicle diagnostics. The integration of AI and IoT in engine diagnostics is pushing the technological frontier, with companies like Cummins and Caterpillar at the forefront of these innovations.

GM Global Technology Operations LLC

Technical Solution: GM's approach to troubleshooting 5.4 Triton engine misfire problems involves a comprehensive diagnostic system. They utilize advanced onboard diagnostics (OBD-II) to pinpoint specific cylinder misfires[1]. The system employs misfire detection algorithms that analyze crankshaft acceleration data to identify irregularities in combustion[3]. GM has also developed a proprietary software tool that can interpret complex misfire patterns, distinguishing between mechanical issues and fuel delivery problems[5]. This tool integrates with the vehicle's ECU to provide real-time data analysis and suggested repair procedures.

Strengths: Highly accurate misfire detection, integration with vehicle systems for comprehensive diagnostics. Weaknesses: May require specialized GM tools for full functionality, potentially costly for independent repair shops.

Ford Global Technologies LLC

Technical Solution: Ford's approach to 5.4 Triton engine misfire troubleshooting incorporates a multi-faceted diagnostic strategy. They employ an advanced misfire detection system that utilizes crankshaft position sensor data to identify individual cylinder misfires with high precision[2]. Ford has also developed a proprietary Powertrain Control Module (PCM) calibration that can differentiate between various causes of misfires, such as ignition system failures, fuel injector issues, or mechanical problems[4]. Additionally, Ford's diagnostic system includes a machine learning algorithm that learns from historical misfire data to improve detection accuracy over time[6].

Strengths: High-precision misfire detection, adaptive learning capabilities for improved diagnostics. Weaknesses: May require frequent software updates to maintain effectiveness, potentially complex for DIY repairs.

Advanced Sensor Technologies for Misfire Detection

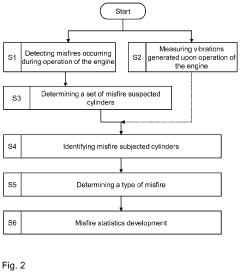

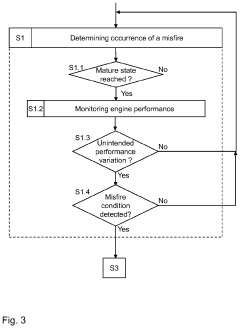

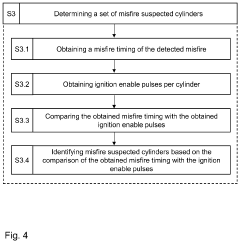

Method and control unit for identifying misfire subjected cylinders of an internal combustion engine

PatentActiveUS20230340921A1

Innovation

- A method involving a control unit that measures vibrations generated by the engine using vibration sensors to identify cylinders experiencing misfire, allowing for the classification of misfire types such as no combustion, incomplete combustion, continuous, intermittent, or single misfire events.

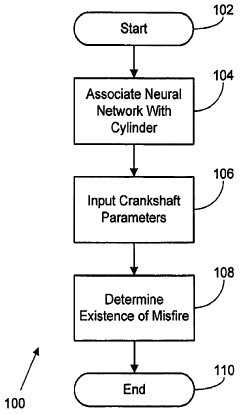

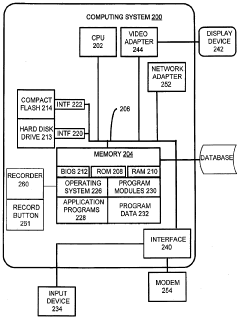

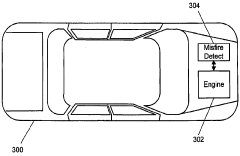

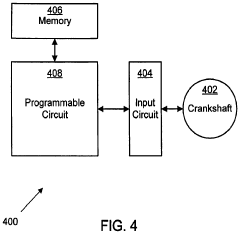

Neural network-based engine misfire detection systems and methods

PatentWO2008154055A2

Innovation

- The use of neural networks, specifically time-lagged recurrent neural networks, is implemented to detect misfire events in engines by associating each neural network with a cylinder and inputting crankshaft parameters such as rotational speed, acceleration, and angular position, allowing for improved compensation for torsional oscillations and enhanced accuracy.

Environmental Regulations Impact on Engine Design

Environmental regulations have significantly impacted engine design, particularly in the context of troubleshooting 5.4 Triton engine misfire problems. These regulations, aimed at reducing emissions and improving fuel efficiency, have led to substantial changes in engine technology and diagnostic approaches.

The introduction of stricter emission standards, such as the Environmental Protection Agency's (EPA) Tier 3 standards in the United States, has necessitated the development of more sophisticated engine management systems. These systems are designed to optimize fuel combustion and minimize harmful emissions, which in turn has increased the complexity of diagnosing misfire issues in engines like the 5.4 Triton.

One of the key impacts of environmental regulations on engine design has been the widespread adoption of electronic fuel injection systems. These systems allow for precise control of fuel delivery, which is crucial for meeting emission standards. However, they also introduce new potential points of failure that can contribute to misfires, such as faulty fuel injectors or compromised fuel pressure regulators.

The implementation of exhaust gas recirculation (EGR) systems, mandated by emissions regulations, has also affected engine performance and misfire diagnosis. While EGR systems effectively reduce nitrogen oxide emissions, they can lead to carbon buildup in the intake system, potentially causing misfires if not properly maintained.

Catalytic converters, another critical component for emissions control, have become more advanced to meet stringent regulations. However, their presence can mask certain misfire symptoms, making diagnosis more challenging. Technicians must now consider the catalytic converter's condition when troubleshooting misfire problems in the 5.4 Triton engine.

The push for improved fuel economy has led to the development of variable valve timing (VVT) systems. While these systems enhance efficiency, they introduce additional complexity to the engine design. Malfunctions in VVT components can result in misfires, requiring technicians to have a deeper understanding of these systems when diagnosing issues.

Environmental regulations have also driven the adoption of more durable materials and coatings to ensure long-term emissions compliance. This has resulted in changes to cylinder head designs, piston materials, and valve train components in engines like the 5.4 Triton. While these improvements generally enhance engine longevity, they can also alter the characteristics of misfire symptoms, necessitating updated diagnostic approaches.

The integration of on-board diagnostic (OBD) systems, mandated by environmental regulations, has revolutionized the way misfires are detected and diagnosed. These systems continuously monitor engine performance and can quickly identify misfires, but they also require technicians to be proficient in interpreting diagnostic trouble codes and using advanced scanning tools.

The introduction of stricter emission standards, such as the Environmental Protection Agency's (EPA) Tier 3 standards in the United States, has necessitated the development of more sophisticated engine management systems. These systems are designed to optimize fuel combustion and minimize harmful emissions, which in turn has increased the complexity of diagnosing misfire issues in engines like the 5.4 Triton.

One of the key impacts of environmental regulations on engine design has been the widespread adoption of electronic fuel injection systems. These systems allow for precise control of fuel delivery, which is crucial for meeting emission standards. However, they also introduce new potential points of failure that can contribute to misfires, such as faulty fuel injectors or compromised fuel pressure regulators.

The implementation of exhaust gas recirculation (EGR) systems, mandated by emissions regulations, has also affected engine performance and misfire diagnosis. While EGR systems effectively reduce nitrogen oxide emissions, they can lead to carbon buildup in the intake system, potentially causing misfires if not properly maintained.

Catalytic converters, another critical component for emissions control, have become more advanced to meet stringent regulations. However, their presence can mask certain misfire symptoms, making diagnosis more challenging. Technicians must now consider the catalytic converter's condition when troubleshooting misfire problems in the 5.4 Triton engine.

The push for improved fuel economy has led to the development of variable valve timing (VVT) systems. While these systems enhance efficiency, they introduce additional complexity to the engine design. Malfunctions in VVT components can result in misfires, requiring technicians to have a deeper understanding of these systems when diagnosing issues.

Environmental regulations have also driven the adoption of more durable materials and coatings to ensure long-term emissions compliance. This has resulted in changes to cylinder head designs, piston materials, and valve train components in engines like the 5.4 Triton. While these improvements generally enhance engine longevity, they can also alter the characteristics of misfire symptoms, necessitating updated diagnostic approaches.

The integration of on-board diagnostic (OBD) systems, mandated by environmental regulations, has revolutionized the way misfires are detected and diagnosed. These systems continuously monitor engine performance and can quickly identify misfires, but they also require technicians to be proficient in interpreting diagnostic trouble codes and using advanced scanning tools.

Cost-Benefit Analysis of Misfire Prevention

Conducting a cost-benefit analysis of misfire prevention for the 5.4 Triton engine is crucial for vehicle owners and manufacturers alike. The primary costs associated with misfire prevention include regular maintenance, diagnostic tools, and potential parts replacement. Regular maintenance, such as spark plug replacement and fuel system cleaning, can range from $100 to $300 per service. Diagnostic tools for identifying misfires may cost between $50 and $500, depending on their sophistication.

On the benefit side, preventing misfires can lead to significant savings in fuel efficiency, as misfires can reduce fuel economy by up to 20%. For a vehicle driven 15,000 miles annually, this could translate to savings of $300 to $500 per year in fuel costs. Additionally, preventing misfires extends the life of catalytic converters, which can cost upwards of $1,000 to replace if damaged due to prolonged misfiring.

The long-term benefits of misfire prevention are substantial. By maintaining optimal engine performance, vehicle owners can avoid costly repairs that may result from ignoring misfires. These repairs can include replacing damaged pistons, valves, or even entire engine rebuilds, which can cost several thousand dollars. Furthermore, preventing misfires ensures better overall vehicle reliability, reducing the likelihood of breakdowns and associated towing costs.

From an environmental perspective, misfire prevention contributes to reduced emissions. A properly functioning engine produces fewer pollutants, aligning with increasingly stringent environmental regulations. This can lead to indirect benefits such as avoiding potential fines or penalties in regions with strict emissions standards.

For manufacturers, investing in robust misfire prevention systems during the design and production phases can lead to improved brand reputation and customer satisfaction. While this may increase initial production costs, it can result in fewer warranty claims and recalls, potentially saving millions in the long run.

In conclusion, the cost-benefit analysis strongly favors investing in misfire prevention for the 5.4 Triton engine. The initial costs of maintenance and diagnostics are significantly outweighed by the long-term savings in fuel efficiency, reduced repair costs, and extended engine life. Both vehicle owners and manufacturers stand to gain from prioritizing misfire prevention strategies.

On the benefit side, preventing misfires can lead to significant savings in fuel efficiency, as misfires can reduce fuel economy by up to 20%. For a vehicle driven 15,000 miles annually, this could translate to savings of $300 to $500 per year in fuel costs. Additionally, preventing misfires extends the life of catalytic converters, which can cost upwards of $1,000 to replace if damaged due to prolonged misfiring.

The long-term benefits of misfire prevention are substantial. By maintaining optimal engine performance, vehicle owners can avoid costly repairs that may result from ignoring misfires. These repairs can include replacing damaged pistons, valves, or even entire engine rebuilds, which can cost several thousand dollars. Furthermore, preventing misfires ensures better overall vehicle reliability, reducing the likelihood of breakdowns and associated towing costs.

From an environmental perspective, misfire prevention contributes to reduced emissions. A properly functioning engine produces fewer pollutants, aligning with increasingly stringent environmental regulations. This can lead to indirect benefits such as avoiding potential fines or penalties in regions with strict emissions standards.

For manufacturers, investing in robust misfire prevention systems during the design and production phases can lead to improved brand reputation and customer satisfaction. While this may increase initial production costs, it can result in fewer warranty claims and recalls, potentially saving millions in the long run.

In conclusion, the cost-benefit analysis strongly favors investing in misfire prevention for the 5.4 Triton engine. The initial costs of maintenance and diagnostics are significantly outweighed by the long-term savings in fuel efficiency, reduced repair costs, and extended engine life. Both vehicle owners and manufacturers stand to gain from prioritizing misfire prevention strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!