How to Align Timing Chains in 5.4 Triton Engines Accurately?

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton Engine Timing Chain Overview

The 5.4 Triton engine, developed by Ford Motor Company, is a V8 engine that has been widely used in various Ford vehicles, including the F-150 pickup truck, Expedition SUV, and E-Series vans. One of the critical components of this engine is its timing chain system, which plays a crucial role in ensuring proper engine operation and performance.

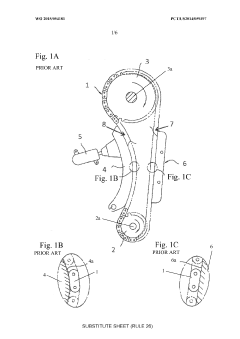

The timing chain in the 5.4 Triton engine is responsible for synchronizing the rotation of the crankshaft with the camshafts, controlling the precise timing of valve opening and closing in relation to piston movement. This synchronization is essential for optimal engine performance, fuel efficiency, and emissions control. The Triton engine typically employs a dual overhead cam (DOHC) design, which means it has two separate timing chains - one for each cylinder bank.

The timing chain system in the 5.4 Triton engine consists of several key components, including the timing chains themselves, tensioners, guides, and sprockets. The chains are made of high-strength materials to withstand the high-speed rotation and tension they experience during engine operation. Tensioners are used to maintain proper chain tension, while guides help keep the chains aligned and prevent excessive vibration or slapping against other engine components.

One of the notable features of the 5.4 Triton engine's timing chain system is its variable valve timing (VVT) technology. This advanced system allows for dynamic adjustment of valve timing based on engine speed and load, resulting in improved performance and efficiency across a wide range of operating conditions. The VVT system adds complexity to the timing chain setup, as it requires additional components and precise control mechanisms.

Over the years, the 5.4 Triton engine's timing chain system has undergone several revisions and improvements. Early versions of the engine were known to experience timing chain-related issues, including premature wear, stretching, and potential failure. These problems could lead to poor engine performance, increased fuel consumption, and in severe cases, engine damage. Ford has addressed many of these concerns in later iterations of the engine, implementing design changes and using more durable materials.

Accurate alignment of the timing chains in the 5.4 Triton engine is critical for several reasons. Proper alignment ensures that the valves open and close at the correct times in relation to piston movement, preventing potential interference between valves and pistons. It also maintains optimal engine timing for combustion efficiency, power output, and emissions control. Additionally, correct timing chain alignment helps minimize wear on the chain and related components, potentially extending the lifespan of the engine.

The timing chain in the 5.4 Triton engine is responsible for synchronizing the rotation of the crankshaft with the camshafts, controlling the precise timing of valve opening and closing in relation to piston movement. This synchronization is essential for optimal engine performance, fuel efficiency, and emissions control. The Triton engine typically employs a dual overhead cam (DOHC) design, which means it has two separate timing chains - one for each cylinder bank.

The timing chain system in the 5.4 Triton engine consists of several key components, including the timing chains themselves, tensioners, guides, and sprockets. The chains are made of high-strength materials to withstand the high-speed rotation and tension they experience during engine operation. Tensioners are used to maintain proper chain tension, while guides help keep the chains aligned and prevent excessive vibration or slapping against other engine components.

One of the notable features of the 5.4 Triton engine's timing chain system is its variable valve timing (VVT) technology. This advanced system allows for dynamic adjustment of valve timing based on engine speed and load, resulting in improved performance and efficiency across a wide range of operating conditions. The VVT system adds complexity to the timing chain setup, as it requires additional components and precise control mechanisms.

Over the years, the 5.4 Triton engine's timing chain system has undergone several revisions and improvements. Early versions of the engine were known to experience timing chain-related issues, including premature wear, stretching, and potential failure. These problems could lead to poor engine performance, increased fuel consumption, and in severe cases, engine damage. Ford has addressed many of these concerns in later iterations of the engine, implementing design changes and using more durable materials.

Accurate alignment of the timing chains in the 5.4 Triton engine is critical for several reasons. Proper alignment ensures that the valves open and close at the correct times in relation to piston movement, preventing potential interference between valves and pistons. It also maintains optimal engine timing for combustion efficiency, power output, and emissions control. Additionally, correct timing chain alignment helps minimize wear on the chain and related components, potentially extending the lifespan of the engine.

Market Demand for Precision Engine Timing

The market demand for precision engine timing, particularly in the context of 5.4 Triton engines, has been steadily growing due to the increasing complexity and performance requirements of modern automotive engines. This demand is driven by several key factors in the automotive industry and consumer preferences.

Firstly, there is a growing emphasis on fuel efficiency and emissions reduction across the automotive sector. Precise timing chain alignment in engines like the 5.4 Triton is crucial for optimal combustion efficiency, directly impacting fuel consumption and exhaust emissions. As environmental regulations become more stringent worldwide, manufacturers are under pressure to deliver engines that meet these standards, creating a significant market for precision timing solutions.

The performance automotive segment also contributes to this demand. Enthusiasts and high-performance vehicle owners seek ways to maximize engine output and reliability. Accurate timing chain alignment is essential for achieving peak performance, as even slight misalignments can lead to power loss, increased wear, and potential engine damage. This niche market drives innovation in timing chain alignment techniques and tools.

Moreover, the aftermarket and repair sector represents a substantial portion of the demand. As 5.4 Triton engines age, the need for timing chain replacements and alignments increases. Professional mechanics and DIY enthusiasts alike seek reliable methods and tools for accurate timing chain alignment, creating a sustained market for specialized equipment and training.

The commercial vehicle sector, where many 5.4 Triton engines are utilized, also contributes significantly to this demand. Fleet operators prioritize engine longevity and minimal downtime, making precise timing chain alignment a critical maintenance task. This sector's need for efficient and accurate alignment methods drives the development of advanced diagnostic tools and alignment techniques.

Additionally, the push towards predictive maintenance in the automotive industry is influencing the market for precision engine timing. Advanced sensors and diagnostic systems that can detect early signs of timing chain misalignment are becoming increasingly popular, creating new market opportunities for technology providers in this space.

The global nature of the automotive supply chain also plays a role in shaping this market. As engine components are sourced and assembled worldwide, there's a growing need for standardized, precise alignment methods that can be consistently applied across different manufacturing and service locations, further driving the demand for advanced alignment technologies and training.

Firstly, there is a growing emphasis on fuel efficiency and emissions reduction across the automotive sector. Precise timing chain alignment in engines like the 5.4 Triton is crucial for optimal combustion efficiency, directly impacting fuel consumption and exhaust emissions. As environmental regulations become more stringent worldwide, manufacturers are under pressure to deliver engines that meet these standards, creating a significant market for precision timing solutions.

The performance automotive segment also contributes to this demand. Enthusiasts and high-performance vehicle owners seek ways to maximize engine output and reliability. Accurate timing chain alignment is essential for achieving peak performance, as even slight misalignments can lead to power loss, increased wear, and potential engine damage. This niche market drives innovation in timing chain alignment techniques and tools.

Moreover, the aftermarket and repair sector represents a substantial portion of the demand. As 5.4 Triton engines age, the need for timing chain replacements and alignments increases. Professional mechanics and DIY enthusiasts alike seek reliable methods and tools for accurate timing chain alignment, creating a sustained market for specialized equipment and training.

The commercial vehicle sector, where many 5.4 Triton engines are utilized, also contributes significantly to this demand. Fleet operators prioritize engine longevity and minimal downtime, making precise timing chain alignment a critical maintenance task. This sector's need for efficient and accurate alignment methods drives the development of advanced diagnostic tools and alignment techniques.

Additionally, the push towards predictive maintenance in the automotive industry is influencing the market for precision engine timing. Advanced sensors and diagnostic systems that can detect early signs of timing chain misalignment are becoming increasingly popular, creating new market opportunities for technology providers in this space.

The global nature of the automotive supply chain also plays a role in shaping this market. As engine components are sourced and assembled worldwide, there's a growing need for standardized, precise alignment methods that can be consistently applied across different manufacturing and service locations, further driving the demand for advanced alignment technologies and training.

Current Challenges in 5.4 Triton Timing Chain Alignment

The alignment of timing chains in 5.4 Triton engines presents several significant challenges that have persisted over the years. One of the primary issues is the complexity of the engine design itself. The 5.4 Triton engine features a dual overhead cam (DOHC) configuration with four valves per cylinder, resulting in a more intricate timing chain system compared to simpler engine designs.

The timing chain system in these engines consists of multiple chains, tensioners, and guides, which must all work in perfect harmony to maintain proper engine timing. The presence of multiple chains increases the potential points of failure and complicates the alignment process. Each chain must be precisely positioned and tensioned to ensure optimal engine performance and longevity.

Another challenge lies in the wear characteristics of the timing chain components. Over time, the chains can stretch, and the plastic guides and tensioners can wear down, leading to timing discrepancies. This wear is often uneven, making it difficult to achieve accurate alignment without replacing multiple components simultaneously.

The limited access to the timing chain system within the engine bay poses a significant obstacle for technicians. The compact design of modern engines, including the 5.4 Triton, means that reaching and manipulating the timing chains often requires extensive disassembly of surrounding components. This not only increases the time and labor required for alignment but also introduces additional risks of damaging other engine parts during the process.

Precision in timing is crucial for the 5.4 Triton engine, as even slight misalignments can lead to severe engine damage. The interference design of this engine means that if the timing is off, pistons can collide with valves, resulting in catastrophic failure. This high-stakes scenario puts immense pressure on technicians to achieve perfect alignment, leaving little room for error.

The lack of specialized tools designed specifically for the 5.4 Triton engine's timing chain alignment further complicates the process. While generic timing tools exist, they may not always provide the level of precision required for this particular engine model. This often forces technicians to improvise or adapt tools, which can lead to inconsistencies in the alignment process.

Lastly, the variability between individual engines presents a challenge. Factors such as manufacturing tolerances, previous repairs, and the engine's operational history can all affect the timing chain system's behavior. This variability means that a one-size-fits-all approach to alignment is often insufficient, requiring technicians to adapt their methods based on the specific condition of each engine they encounter.

The timing chain system in these engines consists of multiple chains, tensioners, and guides, which must all work in perfect harmony to maintain proper engine timing. The presence of multiple chains increases the potential points of failure and complicates the alignment process. Each chain must be precisely positioned and tensioned to ensure optimal engine performance and longevity.

Another challenge lies in the wear characteristics of the timing chain components. Over time, the chains can stretch, and the plastic guides and tensioners can wear down, leading to timing discrepancies. This wear is often uneven, making it difficult to achieve accurate alignment without replacing multiple components simultaneously.

The limited access to the timing chain system within the engine bay poses a significant obstacle for technicians. The compact design of modern engines, including the 5.4 Triton, means that reaching and manipulating the timing chains often requires extensive disassembly of surrounding components. This not only increases the time and labor required for alignment but also introduces additional risks of damaging other engine parts during the process.

Precision in timing is crucial for the 5.4 Triton engine, as even slight misalignments can lead to severe engine damage. The interference design of this engine means that if the timing is off, pistons can collide with valves, resulting in catastrophic failure. This high-stakes scenario puts immense pressure on technicians to achieve perfect alignment, leaving little room for error.

The lack of specialized tools designed specifically for the 5.4 Triton engine's timing chain alignment further complicates the process. While generic timing tools exist, they may not always provide the level of precision required for this particular engine model. This often forces technicians to improvise or adapt tools, which can lead to inconsistencies in the alignment process.

Lastly, the variability between individual engines presents a challenge. Factors such as manufacturing tolerances, previous repairs, and the engine's operational history can all affect the timing chain system's behavior. This variability means that a one-size-fits-all approach to alignment is often insufficient, requiring technicians to adapt their methods based on the specific condition of each engine they encounter.

Existing Timing Chain Alignment Methods

01 Timing chain tensioning and alignment systems

Advanced systems for maintaining proper tension and alignment of timing chains, including automatic tensioners and guide mechanisms. These systems help ensure accurate timing and reduce wear on engine components, improving overall engine performance and longevity.- Timing chain tensioning and alignment systems: Advanced systems for maintaining proper tension and alignment of timing chains, including automatic tensioners and guide mechanisms. These systems help ensure accurate timing and reduce wear on engine components, improving overall engine performance and longevity.

- Optical and laser-based alignment techniques: Utilization of optical and laser-based technologies for precise alignment of timing chains. These methods provide high accuracy in measuring and adjusting chain positioning, potentially reducing installation errors and improving engine timing accuracy.

- Computer-aided design and simulation for timing chain systems: Implementation of advanced CAD and simulation software to design and optimize timing chain systems. These tools allow for virtual testing and refinement of chain alignment, reducing development time and improving accuracy before physical prototyping.

- Sensor-based monitoring and adjustment systems: Integration of sensors and electronic control systems to continuously monitor and adjust timing chain alignment. These systems can detect misalignment in real-time and make necessary adjustments, maintaining optimal engine performance and preventing potential damage.

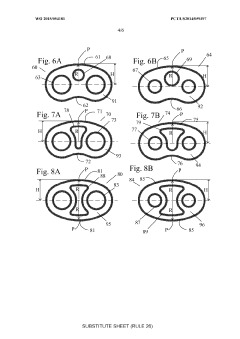

- Innovative chain and sprocket designs for improved alignment: Development of novel chain and sprocket designs that inherently improve alignment accuracy. These designs may include self-aligning features, reduced friction materials, or geometries that maintain better positioning during operation, enhancing overall timing accuracy and engine efficiency.

02 Optical measurement techniques for chain alignment

Use of optical sensors and imaging systems to precisely measure and monitor timing chain alignment. These techniques allow for real-time assessment of chain position and movement, enabling more accurate adjustments and maintenance.Expand Specific Solutions03 Computer-aided design and simulation for timing chains

Implementation of advanced CAD and simulation software to optimize timing chain design and predict alignment accuracy. These tools allow engineers to model and analyze chain behavior under various conditions, leading to improved designs and reduced prototyping costs.Expand Specific Solutions04 Sensor-based monitoring and adjustment systems

Integration of sensors and control systems to continuously monitor timing chain alignment and make automatic adjustments. These systems can detect misalignments early and compensate for wear, maintaining optimal engine timing and performance.Expand Specific Solutions05 Manufacturing processes for high-precision timing chains

Advanced manufacturing techniques and quality control processes to produce timing chains with improved dimensional accuracy and consistency. These methods include precision machining, heat treatment, and rigorous inspection procedures to ensure optimal alignment and performance.Expand Specific Solutions

Key Players in Automotive Engine Components

The timing chain alignment in 5.4 Triton engines represents a mature technology within the automotive industry, with the market for this specific application being relatively stable. The competitive landscape is characterized by established players like Ford, BorgWarner, and Litens Automotive, who have extensive experience in engine component manufacturing. While the market size for this particular application is limited, it is part of the broader automotive engine components sector. The technology's maturity is evident in the refined solutions offered by companies such as Ford Global Technologies and BorgWarner, which have developed specialized tools and techniques for accurate timing chain alignment in these engines.

BorgWarner, Inc.

Technical Solution: BorgWarner has developed a sophisticated approach to timing chain alignment for engines like the 5.4 Triton. Their method focuses on precision engineering and advanced materials. BorgWarner uses a proprietary chain link design that reduces friction and improves durability, helping maintain alignment over time[10]. They've also created a variable force tensioner system that adjusts chain tension based on engine speed and load, ensuring optimal alignment under various operating conditions[12]. BorgWarner's alignment process incorporates micro-etched timing marks on sprockets and chains for precise positioning. They've developed a specialized optical alignment tool that uses high-resolution cameras to verify correct timing marks alignment during installation[14]. Additionally, BorgWarner has implemented a predictive maintenance system that uses engine data and machine learning algorithms to forecast potential timing chain issues before they lead to misalignment[16].

Strengths: Advanced chain design improves longevity and alignment stability. Variable force tensioner adapts to different engine conditions. Optical alignment tool ensures high precision. Weaknesses: May be more expensive than traditional systems. Requires advanced diagnostic equipment for maintenance.

Robert Bosch GmbH

Technical Solution: Bosch has developed an innovative approach to timing chain alignment applicable to engines like the 5.4 Triton. Their method incorporates advanced materials and design principles to create more durable and precise timing components. Bosch uses a high-strength, low-friction coating on their timing chains to reduce wear and maintain alignment accuracy over time[7]. They've also developed a smart chain tensioner system that uses oil pressure and electronic controls to dynamically adjust chain tension based on engine load and speed[9]. Bosch's alignment procedure involves using laser-etched timing marks on sprockets and a digital alignment tool that provides real-time feedback during installation[11]. Additionally, they've implemented a chain wear monitoring system that uses acoustic sensors to detect early signs of misalignment or chain stretching, allowing for preventive maintenance[13].

Strengths: Advanced materials and coatings improve longevity. Smart tensioner system adapts to various operating conditions. Digital alignment tools enhance precision. Weaknesses: Higher initial cost due to advanced technology. May require specialized training for mechanics.

Innovative Timing Chain Alignment Techniques

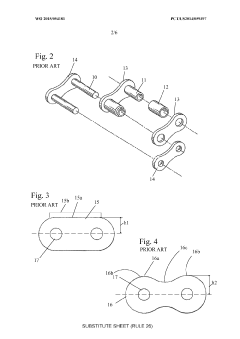

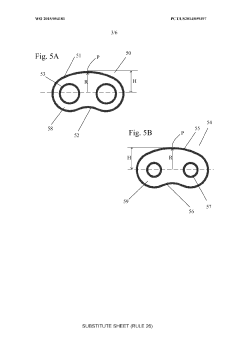

Low mass chain link and assembly for friction reduction

PatentWO2015054181A1

Innovation

- The design incorporates low mass links with optimized convex and concave edge profiles and additional holes or windows to reduce frictional contact, allowing for reduced mass and improved efficiency, with the convex edges forming arcs that optimize contact points for friction reduction and the concave edges or holes minimizing material while maintaining structural integrity.

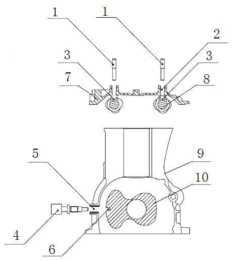

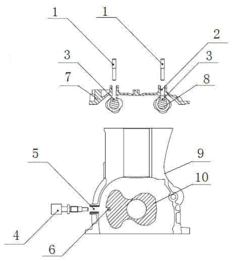

Alignment tooling for engine timing system

PatentInactiveCN201896639U

Innovation

- It adopts a combined structure of positioning pins, positioning holes, and positioning grooves. After the positioning grooves and holes of the camshaft and crankshaft are aligned, the positioning pins are inserted for positioning to ensure the fixed alignment of the camshaft and the crankshaft, so that the sprocket can be installed correctly. Align the chain.

Engine Performance Impact Analysis

The alignment of timing chains in 5.4 Triton engines has a significant impact on overall engine performance. When timing chains are properly aligned, the engine operates at peak efficiency, delivering optimal power output and fuel economy. Conversely, misaligned timing chains can lead to a host of performance issues, ranging from reduced engine power to potential engine damage.

Accurate timing chain alignment ensures that the camshafts and crankshaft are synchronized, allowing for precise valve timing. This synchronization is crucial for proper combustion, as it determines when the intake and exhaust valves open and close relative to the piston position. In the 5.4 Triton engine, even a slight misalignment can result in a noticeable decrease in performance.

One of the primary effects of misaligned timing chains is reduced engine power. When the valve timing is off, the engine may experience a loss of compression, leading to decreased horsepower and torque. This power loss can be particularly noticeable during acceleration or when the engine is under heavy load. Additionally, fuel efficiency may suffer as the engine struggles to maintain optimal combustion conditions.

Misalignment can also cause increased engine wear and potential damage. If the timing is significantly off, valves may contact pistons, resulting in bent valves or damaged pistons. This type of damage can be catastrophic and may require extensive engine repairs or even a complete engine replacement.

Furthermore, improper timing chain alignment can lead to rough idling, engine misfires, and poor overall drivability. These issues not only affect the driver's experience but can also trigger the engine's check engine light, potentially leading to failed emissions tests.

In terms of long-term reliability, accurate timing chain alignment is crucial. Properly aligned chains experience less wear and are less likely to stretch over time. This reduces the frequency of timing chain replacements and helps maintain consistent engine performance throughout the vehicle's lifespan.

It's worth noting that the 5.4 Triton engine's performance is particularly sensitive to timing chain alignment due to its design. The engine's overhead cam configuration and the use of multiple timing chains make precise alignment critical for maintaining the intended valve timing across all cylinders.

In conclusion, the accurate alignment of timing chains in 5.4 Triton engines is essential for maximizing engine performance, ensuring longevity, and preventing potentially costly damage. Regular maintenance and proper alignment techniques are crucial for maintaining optimal engine operation and avoiding the negative performance impacts associated with misaligned timing chains.

Accurate timing chain alignment ensures that the camshafts and crankshaft are synchronized, allowing for precise valve timing. This synchronization is crucial for proper combustion, as it determines when the intake and exhaust valves open and close relative to the piston position. In the 5.4 Triton engine, even a slight misalignment can result in a noticeable decrease in performance.

One of the primary effects of misaligned timing chains is reduced engine power. When the valve timing is off, the engine may experience a loss of compression, leading to decreased horsepower and torque. This power loss can be particularly noticeable during acceleration or when the engine is under heavy load. Additionally, fuel efficiency may suffer as the engine struggles to maintain optimal combustion conditions.

Misalignment can also cause increased engine wear and potential damage. If the timing is significantly off, valves may contact pistons, resulting in bent valves or damaged pistons. This type of damage can be catastrophic and may require extensive engine repairs or even a complete engine replacement.

Furthermore, improper timing chain alignment can lead to rough idling, engine misfires, and poor overall drivability. These issues not only affect the driver's experience but can also trigger the engine's check engine light, potentially leading to failed emissions tests.

In terms of long-term reliability, accurate timing chain alignment is crucial. Properly aligned chains experience less wear and are less likely to stretch over time. This reduces the frequency of timing chain replacements and helps maintain consistent engine performance throughout the vehicle's lifespan.

It's worth noting that the 5.4 Triton engine's performance is particularly sensitive to timing chain alignment due to its design. The engine's overhead cam configuration and the use of multiple timing chains make precise alignment critical for maintaining the intended valve timing across all cylinders.

In conclusion, the accurate alignment of timing chains in 5.4 Triton engines is essential for maximizing engine performance, ensuring longevity, and preventing potentially costly damage. Regular maintenance and proper alignment techniques are crucial for maintaining optimal engine operation and avoiding the negative performance impacts associated with misaligned timing chains.

Maintenance and Reliability Considerations

The maintenance and reliability of timing chains in 5.4 Triton engines are critical factors for ensuring optimal engine performance and longevity. Proper alignment of timing chains is essential to prevent premature wear, reduce the risk of engine failure, and maintain fuel efficiency. Regular inspection and maintenance of the timing chain system are crucial for detecting early signs of wear or misalignment, which can lead to significant engine damage if left unaddressed.

One of the primary considerations in maintaining timing chain alignment is the use of high-quality replacement parts. OEM or equivalent-grade components should be used to ensure proper fit and function. The use of substandard parts can lead to accelerated wear and increased likelihood of timing chain failure. Additionally, the tensioners and guides associated with the timing chain system should be inspected and replaced as necessary during maintenance procedures.

The frequency of timing chain maintenance should be based on the vehicle's mileage and operating conditions. In general, it is recommended to inspect the timing chain system every 60,000 to 100,000 miles, depending on the specific engine model and usage patterns. However, more frequent inspections may be necessary for vehicles operated in harsh conditions or those with a history of timing chain issues.

Proper lubrication is another critical factor in maintaining timing chain reliability. The use of high-quality engine oil and adherence to recommended oil change intervals are essential for minimizing wear on the timing chain and related components. Contaminated or degraded oil can accelerate chain wear and contribute to premature failure.

When performing timing chain alignment, it is crucial to follow manufacturer-specified procedures and use the correct tools. This includes utilizing timing marks, alignment tools, and torque specifications as outlined in the service manual. Failure to adhere to these procedures can result in improper chain tension, misalignment, or damage to engine components.

The impact of timing chain maintenance on overall engine reliability cannot be overstated. A well-maintained timing chain system contributes to consistent valve timing, which is essential for optimal engine performance, fuel efficiency, and emissions control. Conversely, neglecting timing chain maintenance can lead to a cascade of engine problems, potentially resulting in catastrophic engine failure and costly repairs.

In conclusion, maintaining proper timing chain alignment in 5.4 Triton engines requires a comprehensive approach that includes regular inspections, the use of quality parts, adherence to maintenance schedules, and proper lubrication practices. By prioritizing these maintenance and reliability considerations, engine longevity can be maximized, and the risk of unexpected failures can be significantly reduced.

One of the primary considerations in maintaining timing chain alignment is the use of high-quality replacement parts. OEM or equivalent-grade components should be used to ensure proper fit and function. The use of substandard parts can lead to accelerated wear and increased likelihood of timing chain failure. Additionally, the tensioners and guides associated with the timing chain system should be inspected and replaced as necessary during maintenance procedures.

The frequency of timing chain maintenance should be based on the vehicle's mileage and operating conditions. In general, it is recommended to inspect the timing chain system every 60,000 to 100,000 miles, depending on the specific engine model and usage patterns. However, more frequent inspections may be necessary for vehicles operated in harsh conditions or those with a history of timing chain issues.

Proper lubrication is another critical factor in maintaining timing chain reliability. The use of high-quality engine oil and adherence to recommended oil change intervals are essential for minimizing wear on the timing chain and related components. Contaminated or degraded oil can accelerate chain wear and contribute to premature failure.

When performing timing chain alignment, it is crucial to follow manufacturer-specified procedures and use the correct tools. This includes utilizing timing marks, alignment tools, and torque specifications as outlined in the service manual. Failure to adhere to these procedures can result in improper chain tension, misalignment, or damage to engine components.

The impact of timing chain maintenance on overall engine reliability cannot be overstated. A well-maintained timing chain system contributes to consistent valve timing, which is essential for optimal engine performance, fuel efficiency, and emissions control. Conversely, neglecting timing chain maintenance can lead to a cascade of engine problems, potentially resulting in catastrophic engine failure and costly repairs.

In conclusion, maintaining proper timing chain alignment in 5.4 Triton engines requires a comprehensive approach that includes regular inspections, the use of quality parts, adherence to maintenance schedules, and proper lubrication practices. By prioritizing these maintenance and reliability considerations, engine longevity can be maximized, and the risk of unexpected failures can be significantly reduced.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!