5.4 Triton Engine: Developments in ECU Technologies

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ECU Evolution for Triton Engine

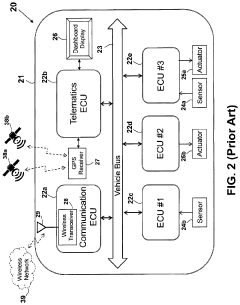

The evolution of Electronic Control Units (ECUs) for the Triton Engine represents a significant advancement in automotive technology. Over the years, ECUs have transformed from simple electronic modules to sophisticated, multi-functional control systems that optimize engine performance, fuel efficiency, and emissions.

In the early stages of Triton Engine development, ECUs were primarily focused on basic engine management functions such as fuel injection timing and ignition control. These first-generation ECUs relied on rudimentary sensors and had limited processing capabilities, resulting in relatively simple control algorithms.

As technology progressed, the second generation of ECUs for the Triton Engine incorporated more advanced sensors and increased computational power. This allowed for more precise control over engine parameters, leading to improved fuel economy and reduced emissions. Additionally, these ECUs began to integrate basic diagnostic capabilities, enabling easier maintenance and troubleshooting.

The third generation of Triton Engine ECUs marked a significant leap forward in functionality. These units introduced adaptive learning algorithms, which could adjust engine parameters based on driving conditions and vehicle usage patterns. This generation also saw the integration of more sophisticated communication protocols, allowing for better interaction with other vehicle systems.

Recent developments in ECU technology for the Triton Engine have focused on enhancing connectivity and expanding the scope of control. Modern ECUs now incorporate advanced networking capabilities, enabling over-the-air updates and real-time data exchange with cloud-based systems. This connectivity has paved the way for predictive maintenance and personalized driving experiences.

Furthermore, the latest ECUs for the Triton Engine have embraced artificial intelligence and machine learning technologies. These innovations enable more complex decision-making processes, allowing the ECU to optimize engine performance in real-time based on a wide array of factors, including driver behavior, environmental conditions, and even traffic patterns.

The integration of cybersecurity features has also become a crucial aspect of ECU evolution. As vehicles become more connected, protecting against potential cyber threats has become paramount. Modern Triton Engine ECUs now incorporate robust security measures to safeguard against unauthorized access and potential malicious attacks.

Looking ahead, the future of ECU technology for the Triton Engine is likely to focus on further integration with advanced driver assistance systems (ADAS) and autonomous driving capabilities. This will require even more powerful processors, enhanced sensor fusion techniques, and more sophisticated software algorithms to manage the increasing complexity of vehicle control systems.

In the early stages of Triton Engine development, ECUs were primarily focused on basic engine management functions such as fuel injection timing and ignition control. These first-generation ECUs relied on rudimentary sensors and had limited processing capabilities, resulting in relatively simple control algorithms.

As technology progressed, the second generation of ECUs for the Triton Engine incorporated more advanced sensors and increased computational power. This allowed for more precise control over engine parameters, leading to improved fuel economy and reduced emissions. Additionally, these ECUs began to integrate basic diagnostic capabilities, enabling easier maintenance and troubleshooting.

The third generation of Triton Engine ECUs marked a significant leap forward in functionality. These units introduced adaptive learning algorithms, which could adjust engine parameters based on driving conditions and vehicle usage patterns. This generation also saw the integration of more sophisticated communication protocols, allowing for better interaction with other vehicle systems.

Recent developments in ECU technology for the Triton Engine have focused on enhancing connectivity and expanding the scope of control. Modern ECUs now incorporate advanced networking capabilities, enabling over-the-air updates and real-time data exchange with cloud-based systems. This connectivity has paved the way for predictive maintenance and personalized driving experiences.

Furthermore, the latest ECUs for the Triton Engine have embraced artificial intelligence and machine learning technologies. These innovations enable more complex decision-making processes, allowing the ECU to optimize engine performance in real-time based on a wide array of factors, including driver behavior, environmental conditions, and even traffic patterns.

The integration of cybersecurity features has also become a crucial aspect of ECU evolution. As vehicles become more connected, protecting against potential cyber threats has become paramount. Modern Triton Engine ECUs now incorporate robust security measures to safeguard against unauthorized access and potential malicious attacks.

Looking ahead, the future of ECU technology for the Triton Engine is likely to focus on further integration with advanced driver assistance systems (ADAS) and autonomous driving capabilities. This will require even more powerful processors, enhanced sensor fusion techniques, and more sophisticated software algorithms to manage the increasing complexity of vehicle control systems.

Market Demand Analysis

The market demand for advanced ECU (Engine Control Unit) technologies in Triton engines has been experiencing significant growth, driven by several key factors. The automotive industry's shift towards more efficient, environmentally friendly, and technologically advanced vehicles has created a strong demand for sophisticated ECU systems. These systems are crucial in optimizing engine performance, reducing emissions, and enhancing overall vehicle efficiency.

In recent years, there has been a notable increase in consumer preference for vehicles with improved fuel economy and reduced environmental impact. This trend has directly influenced the demand for ECUs capable of precise engine management, leading to better fuel efficiency and lower emissions. The market for Triton engine ECUs has expanded as automakers strive to meet stringent regulatory standards while satisfying consumer expectations for performance and sustainability.

The integration of advanced features such as adaptive cruise control, lane-keeping assistance, and autonomous driving capabilities has further boosted the demand for more complex ECU systems. These technologies require sophisticated ECUs that can process vast amounts of data in real-time, making them essential components in modern vehicle architectures. As a result, the market for Triton engine ECUs has seen a shift towards more powerful, multi-core processors and increased memory capacity to handle these advanced functionalities.

The rise of connected vehicles and the Internet of Things (IoT) has also contributed to the growing demand for advanced ECU technologies. Consumers increasingly expect their vehicles to be seamlessly integrated with their digital lives, requiring ECUs that can support connectivity features, over-the-air updates, and advanced infotainment systems. This trend has opened up new market opportunities for ECU manufacturers and suppliers in the Triton engine segment.

Furthermore, the push towards electrification and hybrid powertrains has created a new dimension of demand for ECU technologies. As Triton engines evolve to incorporate hybrid systems, the complexity of engine management increases, necessitating more sophisticated ECU solutions. This transition has led to a growing market for ECUs capable of managing both traditional internal combustion engines and electric powertrains efficiently.

The aftermarket sector has also shown significant potential for ECU technologies in Triton engines. Performance enthusiasts and tuning shops are increasingly seeking programmable ECUs that allow for customization of engine parameters, creating a niche but lucrative market segment. This trend has driven innovation in user-friendly interfaces and software tools for ECU tuning and calibration.

In conclusion, the market demand for ECU technologies in Triton engines is robust and multifaceted, driven by regulatory pressures, consumer preferences, technological advancements, and the evolving landscape of the automotive industry. As vehicles continue to become more complex and connected, the importance of advanced ECU systems is expected to grow, presenting significant opportunities for innovation and market expansion in the coming years.

In recent years, there has been a notable increase in consumer preference for vehicles with improved fuel economy and reduced environmental impact. This trend has directly influenced the demand for ECUs capable of precise engine management, leading to better fuel efficiency and lower emissions. The market for Triton engine ECUs has expanded as automakers strive to meet stringent regulatory standards while satisfying consumer expectations for performance and sustainability.

The integration of advanced features such as adaptive cruise control, lane-keeping assistance, and autonomous driving capabilities has further boosted the demand for more complex ECU systems. These technologies require sophisticated ECUs that can process vast amounts of data in real-time, making them essential components in modern vehicle architectures. As a result, the market for Triton engine ECUs has seen a shift towards more powerful, multi-core processors and increased memory capacity to handle these advanced functionalities.

The rise of connected vehicles and the Internet of Things (IoT) has also contributed to the growing demand for advanced ECU technologies. Consumers increasingly expect their vehicles to be seamlessly integrated with their digital lives, requiring ECUs that can support connectivity features, over-the-air updates, and advanced infotainment systems. This trend has opened up new market opportunities for ECU manufacturers and suppliers in the Triton engine segment.

Furthermore, the push towards electrification and hybrid powertrains has created a new dimension of demand for ECU technologies. As Triton engines evolve to incorporate hybrid systems, the complexity of engine management increases, necessitating more sophisticated ECU solutions. This transition has led to a growing market for ECUs capable of managing both traditional internal combustion engines and electric powertrains efficiently.

The aftermarket sector has also shown significant potential for ECU technologies in Triton engines. Performance enthusiasts and tuning shops are increasingly seeking programmable ECUs that allow for customization of engine parameters, creating a niche but lucrative market segment. This trend has driven innovation in user-friendly interfaces and software tools for ECU tuning and calibration.

In conclusion, the market demand for ECU technologies in Triton engines is robust and multifaceted, driven by regulatory pressures, consumer preferences, technological advancements, and the evolving landscape of the automotive industry. As vehicles continue to become more complex and connected, the importance of advanced ECU systems is expected to grow, presenting significant opportunities for innovation and market expansion in the coming years.

Current ECU Challenges

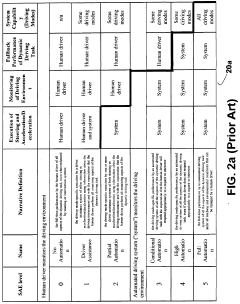

The current challenges facing Electronic Control Unit (ECU) technologies for Triton engines are multifaceted and complex, reflecting the rapidly evolving automotive landscape. One of the primary challenges is the increasing demand for computational power to handle more sophisticated engine control algorithms and advanced driver assistance systems (ADAS). As Triton engines become more efficient and environmentally friendly, ECUs must process and analyze larger volumes of data in real-time, pushing the limits of current hardware capabilities.

Another significant challenge is the integration of multiple functionalities into a single ECU. Modern vehicles require ECUs to manage not only engine performance but also emissions control, transmission operations, and various other subsystems. This consolidation of functions puts pressure on ECU designers to create more versatile and robust systems without significantly increasing costs or complexity.

The need for enhanced cybersecurity measures presents a growing concern for ECU technologies. As vehicles become more connected and reliant on software, the risk of cyber attacks targeting ECUs increases. Developing secure communication protocols and implementing robust encryption methods without compromising system performance is a critical challenge that ECU manufacturers must address.

Electromagnetic compatibility (EMC) and environmental resilience pose additional hurdles for ECU development. With the increasing number of electronic components in vehicles, ECUs must be designed to operate reliably in environments with high levels of electromagnetic interference. Furthermore, they must withstand extreme temperatures, vibrations, and other harsh conditions typical in automotive applications.

The transition towards electrification and hybrid powertrains introduces new challenges for ECU technologies in Triton engines. ECUs must now be capable of managing complex power distribution systems, regenerative braking, and the interplay between electric motors and internal combustion engines in hybrid setups. This requires a significant expansion of ECU capabilities and the development of new control strategies.

Lastly, the automotive industry's push for standardization and interoperability presents both a challenge and an opportunity for ECU technologies. Developing ECUs that comply with emerging standards such as AUTOSAR (AUTomotive Open System ARchitecture) while maintaining proprietary advantages is a delicate balance that manufacturers must strike. This standardization effort aims to reduce development costs and improve software reusability but also requires significant investment in new development processes and tools.

Another significant challenge is the integration of multiple functionalities into a single ECU. Modern vehicles require ECUs to manage not only engine performance but also emissions control, transmission operations, and various other subsystems. This consolidation of functions puts pressure on ECU designers to create more versatile and robust systems without significantly increasing costs or complexity.

The need for enhanced cybersecurity measures presents a growing concern for ECU technologies. As vehicles become more connected and reliant on software, the risk of cyber attacks targeting ECUs increases. Developing secure communication protocols and implementing robust encryption methods without compromising system performance is a critical challenge that ECU manufacturers must address.

Electromagnetic compatibility (EMC) and environmental resilience pose additional hurdles for ECU development. With the increasing number of electronic components in vehicles, ECUs must be designed to operate reliably in environments with high levels of electromagnetic interference. Furthermore, they must withstand extreme temperatures, vibrations, and other harsh conditions typical in automotive applications.

The transition towards electrification and hybrid powertrains introduces new challenges for ECU technologies in Triton engines. ECUs must now be capable of managing complex power distribution systems, regenerative braking, and the interplay between electric motors and internal combustion engines in hybrid setups. This requires a significant expansion of ECU capabilities and the development of new control strategies.

Lastly, the automotive industry's push for standardization and interoperability presents both a challenge and an opportunity for ECU technologies. Developing ECUs that comply with emerging standards such as AUTOSAR (AUTomotive Open System ARchitecture) while maintaining proprietary advantages is a delicate balance that manufacturers must strike. This standardization effort aims to reduce development costs and improve software reusability but also requires significant investment in new development processes and tools.

Existing ECU Solutions

01 Engine Control Unit (ECU) for Triton Engine

The Triton Engine ECU is a specialized electronic control unit designed to manage and optimize the performance of Triton engines. It controls various engine parameters such as fuel injection, ignition timing, and air-fuel ratio to ensure efficient operation and compliance with emission standards.- Engine Control Unit (ECU) Design for Triton Engines: Specialized ECU designs for Triton engines, focusing on optimizing performance, fuel efficiency, and emissions control. These ECUs are tailored to the specific requirements of Triton engine configurations, incorporating advanced algorithms and sensors for precise engine management.

- Fuel Injection Control Systems: Advanced fuel injection control systems integrated into Triton Engine ECUs, enabling precise fuel delivery and combustion timing. These systems utilize real-time data from various engine sensors to optimize fuel-air mixture and improve overall engine efficiency.

- Emissions Reduction Technologies: Implementation of emissions reduction technologies within Triton Engine ECUs, including exhaust gas recirculation (EGR) control, selective catalytic reduction (SCR), and particulate filter management. These features help Triton engines meet stringent environmental regulations while maintaining performance.

- Diagnostic and Monitoring Systems: Integration of advanced diagnostic and monitoring systems in Triton Engine ECUs, allowing for real-time performance analysis, fault detection, and predictive maintenance. These systems enhance engine reliability and facilitate efficient troubleshooting and servicing.

- ECU Communication and Integration: Development of communication protocols and integration capabilities for Triton Engine ECUs, enabling seamless interaction with other vehicle systems and external diagnostic tools. This includes support for CAN bus networks, OBD-II compatibility, and remote monitoring features.

02 Fuel Management System Integration

The ECU incorporates advanced fuel management systems to optimize fuel consumption and engine performance. This includes precise control of fuel injection timing and quantity, as well as adaptive learning algorithms to adjust for varying operating conditions and fuel quality.Expand Specific Solutions03 Emission Control and Environmental Compliance

Triton Engine ECUs are designed with sophisticated emission control strategies to meet stringent environmental regulations. This includes real-time monitoring of exhaust gases, adjustment of engine parameters to reduce emissions, and integration with after-treatment systems.Expand Specific Solutions04 Diagnostic and Monitoring Capabilities

Advanced diagnostic features are integrated into the ECU, allowing for real-time monitoring of engine performance, early detection of potential issues, and storage of fault codes for maintenance purposes. This enhances reliability and facilitates easier troubleshooting and maintenance.Expand Specific Solutions05 Integration with Vehicle Systems

The Triton Engine ECU is designed to interface seamlessly with other vehicle systems such as transmission control units, stability control systems, and onboard diagnostics. This integration allows for improved overall vehicle performance, efficiency, and safety.Expand Specific Solutions

Key ECU Manufacturers

The development of ECU technologies for Triton engines is in a mature phase, with significant market growth driven by increasing demand for advanced engine control systems. The global market size for automotive ECUs is substantial, expected to reach billions of dollars in the coming years. Major players like Bosch, Continental, Denso, and Toyota are at the forefront, leveraging their extensive R&D capabilities to enhance ECU performance, efficiency, and integration with other vehicle systems. Emerging companies such as BRP and Astemo are also making strides, focusing on specialized ECU solutions for specific engine types and applications.

Toyota Motor Corp.

Technical Solution: Toyota has developed a state-of-the-art ECU system for Triton engines, emphasizing reliability and environmental performance. Their solution utilizes a high-speed, low-power microcontroller specifically optimized for automotive applications[1]. The ECU incorporates advanced machine learning algorithms that continuously adapt engine parameters based on driving patterns and environmental conditions[2]. Toyota's system features integrated hybrid powertrain management capabilities, optimizing the interaction between combustion engine and electric motor in hybrid configurations[3]. The ECU supports advanced emissions control strategies, including real-time monitoring and adjustment of exhaust aftertreatment systems[4]. Additionally, Toyota has implemented a robust cybersecurity framework to protect the ECU from potential cyber threats[5].

Strengths: Extensive experience in hybrid powertrain systems, strong focus on reliability and environmental performance. Weaknesses: Potential challenges in rapidly adapting to market changes, may face competition from more specialized ECU manufacturers.

DENSO Corp.

Technical Solution: DENSO has developed a cutting-edge ECU system for Triton engines, emphasizing fuel efficiency and emissions reduction. Their solution utilizes a high-speed, low-power microprocessor specifically designed for automotive applications[1]. The ECU incorporates advanced combustion control algorithms that optimize fuel injection timing and quantity in real-time[2]. DENSO's system also features integrated thermal management, ensuring optimal engine temperature for improved efficiency and longevity[3]. The ECU supports advanced diagnostics and prognostics, enabling predictive maintenance and reducing downtime[4]. Additionally, DENSO has implemented a modular software architecture, allowing for easier updates and customization to meet specific engine requirements[5].

Strengths: Strong expertise in powertrain systems, focus on energy efficiency, and extensive experience in automotive electronics. Weaknesses: Potentially higher initial costs, may face challenges in rapidly evolving markets.

Core ECU Innovations

A Method and Apparatus for Optimal Navigation to Multiple Locations

PatentInactiveUS20210356279A1

Innovation

- A computer-based system that utilizes advanced algorithms and data processing to plan optimal navigation routes by analyzing multiple locations and tasks, determining the most efficient order and timing for visits, and providing real-time adjustments based on dynamic conditions.

Engine control unit (ECU) and method to adapt the ECU for trigger wheel irregularities

PatentActiveUS11268464B2

Innovation

- The ECU is adapted to detect and learn the actual dimensions of the trigger wheel, including tooth width and gap, during production, and stores this data in a table to set dynamic time ranges for tooth detection, preventing false errors and ensuring accurate engine position management even with irregularities.

Emissions Regulations

Emissions regulations have become increasingly stringent worldwide, driving significant advancements in Engine Control Unit (ECU) technologies for the Triton Engine. These regulations aim to reduce harmful emissions and improve air quality, necessitating sophisticated control systems to optimize engine performance while minimizing environmental impact.

The European Union's Euro 6 standards, implemented in 2014, set strict limits on nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM) emissions. Similarly, the United States Environmental Protection Agency (EPA) has established Tier 3 standards, which require substantial reductions in emissions across various vehicle categories.

To meet these stringent requirements, ECU technologies for the Triton Engine have evolved to incorporate advanced sensors and control algorithms. Real-time monitoring of exhaust gases, engine temperature, and fuel consumption allows for precise adjustments to engine parameters, ensuring optimal combustion efficiency and emissions reduction.

One key development is the integration of selective catalytic reduction (SCR) systems, which require ECUs to manage urea injection for NOx reduction. ECUs must accurately control urea dosing based on engine load, temperature, and exhaust gas composition to maintain emission compliance across various operating conditions.

Particulate filter management has also become a critical function of modern ECUs. By monitoring filter loading and initiating regeneration cycles, ECUs help maintain the effectiveness of particulate traps while minimizing fuel consumption penalties associated with regeneration processes.

Advanced on-board diagnostics (OBD) systems, mandated by emissions regulations, have led to the development of more sophisticated ECU self-monitoring capabilities. These systems continuously check for malfunctions in emissions-related components and alert drivers when issues arise, ensuring long-term compliance with emissions standards.

The implementation of start-stop systems, driven by both emissions regulations and fuel economy standards, has required ECUs to manage complex engine shutdown and restart sequences. This functionality demands precise control over fuel injection, ignition timing, and auxiliary systems to maintain emissions compliance during frequent engine restarts.

As regulations continue to evolve, ECU technologies for the Triton Engine are expected to incorporate more predictive capabilities, leveraging artificial intelligence and machine learning algorithms to anticipate driving conditions and optimize engine performance proactively. This approach will be crucial in meeting future emissions targets while maintaining or improving vehicle performance and fuel efficiency.

The European Union's Euro 6 standards, implemented in 2014, set strict limits on nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM) emissions. Similarly, the United States Environmental Protection Agency (EPA) has established Tier 3 standards, which require substantial reductions in emissions across various vehicle categories.

To meet these stringent requirements, ECU technologies for the Triton Engine have evolved to incorporate advanced sensors and control algorithms. Real-time monitoring of exhaust gases, engine temperature, and fuel consumption allows for precise adjustments to engine parameters, ensuring optimal combustion efficiency and emissions reduction.

One key development is the integration of selective catalytic reduction (SCR) systems, which require ECUs to manage urea injection for NOx reduction. ECUs must accurately control urea dosing based on engine load, temperature, and exhaust gas composition to maintain emission compliance across various operating conditions.

Particulate filter management has also become a critical function of modern ECUs. By monitoring filter loading and initiating regeneration cycles, ECUs help maintain the effectiveness of particulate traps while minimizing fuel consumption penalties associated with regeneration processes.

Advanced on-board diagnostics (OBD) systems, mandated by emissions regulations, have led to the development of more sophisticated ECU self-monitoring capabilities. These systems continuously check for malfunctions in emissions-related components and alert drivers when issues arise, ensuring long-term compliance with emissions standards.

The implementation of start-stop systems, driven by both emissions regulations and fuel economy standards, has required ECUs to manage complex engine shutdown and restart sequences. This functionality demands precise control over fuel injection, ignition timing, and auxiliary systems to maintain emissions compliance during frequent engine restarts.

As regulations continue to evolve, ECU technologies for the Triton Engine are expected to incorporate more predictive capabilities, leveraging artificial intelligence and machine learning algorithms to anticipate driving conditions and optimize engine performance proactively. This approach will be crucial in meeting future emissions targets while maintaining or improving vehicle performance and fuel efficiency.

ECU Cybersecurity

As the automotive industry continues to evolve, cybersecurity has become a critical concern for Electronic Control Units (ECUs) in Triton engines. The increasing connectivity and complexity of modern vehicles have exposed ECUs to potential cyber threats, necessitating robust security measures. To address these challenges, several key developments in ECU cybersecurity have emerged.

One significant advancement is the implementation of secure boot processes. This ensures that only authenticated and authorized software can be executed on the ECU, preventing malicious code injection during startup. Secure boot utilizes cryptographic signatures and hardware-based root of trust to verify the integrity of firmware before allowing it to run.

Another crucial development is the adoption of secure over-the-air (OTA) update mechanisms. As ECUs require frequent software updates to enhance performance and address vulnerabilities, secure OTA updates enable manufacturers to deliver patches remotely without compromising security. These systems employ encryption, digital signatures, and secure protocols to protect the update process from tampering and unauthorized access.

Intrusion detection and prevention systems (IDPS) have also been integrated into ECU architectures. These systems continuously monitor network traffic and ECU behavior for anomalies, detecting potential cyber attacks in real-time. Advanced IDPS solutions utilize machine learning algorithms to adapt to evolving threat landscapes and improve detection accuracy over time.

Secure communication protocols have been developed to protect data exchange between ECUs and external systems. Protocols such as Automotive Ethernet with MACsec (Media Access Control Security) provide encryption and authentication for in-vehicle network communications, safeguarding against eavesdropping and man-in-the-middle attacks.

Hardware security modules (HSMs) have been incorporated into ECU designs to provide a secure environment for cryptographic operations and key storage. These dedicated hardware components offer tamper-resistant protection for sensitive data and cryptographic functions, enhancing the overall security posture of the ECU.

To address the growing complexity of ECU software, formal verification techniques have been employed to mathematically prove the correctness and security properties of critical code components. This approach helps identify and eliminate vulnerabilities that may not be detected through traditional testing methods.

Lastly, the development of secure coding practices and guidelines specific to automotive ECUs has gained traction. These practices focus on writing robust, secure code that minimizes vulnerabilities and follows industry-standard security principles. Manufacturers are increasingly adopting these guidelines to ensure consistent security implementation across their ECU development processes.

One significant advancement is the implementation of secure boot processes. This ensures that only authenticated and authorized software can be executed on the ECU, preventing malicious code injection during startup. Secure boot utilizes cryptographic signatures and hardware-based root of trust to verify the integrity of firmware before allowing it to run.

Another crucial development is the adoption of secure over-the-air (OTA) update mechanisms. As ECUs require frequent software updates to enhance performance and address vulnerabilities, secure OTA updates enable manufacturers to deliver patches remotely without compromising security. These systems employ encryption, digital signatures, and secure protocols to protect the update process from tampering and unauthorized access.

Intrusion detection and prevention systems (IDPS) have also been integrated into ECU architectures. These systems continuously monitor network traffic and ECU behavior for anomalies, detecting potential cyber attacks in real-time. Advanced IDPS solutions utilize machine learning algorithms to adapt to evolving threat landscapes and improve detection accuracy over time.

Secure communication protocols have been developed to protect data exchange between ECUs and external systems. Protocols such as Automotive Ethernet with MACsec (Media Access Control Security) provide encryption and authentication for in-vehicle network communications, safeguarding against eavesdropping and man-in-the-middle attacks.

Hardware security modules (HSMs) have been incorporated into ECU designs to provide a secure environment for cryptographic operations and key storage. These dedicated hardware components offer tamper-resistant protection for sensitive data and cryptographic functions, enhancing the overall security posture of the ECU.

To address the growing complexity of ECU software, formal verification techniques have been employed to mathematically prove the correctness and security properties of critical code components. This approach helps identify and eliminate vulnerabilities that may not be detected through traditional testing methods.

Lastly, the development of secure coding practices and guidelines specific to automotive ECUs has gained traction. These practices focus on writing robust, secure code that minimizes vulnerabilities and follows industry-standard security principles. Manufacturers are increasingly adopting these guidelines to ensure consistent security implementation across their ECU development processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!