How to Monitor 5.4 Triton Engine Performance Metrics?

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton Engine Overview

The Triton Inference Server, developed by NVIDIA, is a powerful open-source software designed to deploy and scale AI models in production environments. At the core of Triton's architecture lies the Triton Engine, which plays a crucial role in managing and optimizing model inference across various hardware platforms.

The Triton Engine is responsible for handling the execution of AI models, supporting a wide range of frameworks such as TensorRT, TensorFlow, PyTorch, and ONNX Runtime. It provides a unified interface for model deployment, allowing developers to seamlessly integrate different types of models into their applications without worrying about the underlying hardware complexities.

One of the key features of the Triton Engine is its ability to dynamically allocate resources and optimize performance based on the incoming workload. This adaptive approach ensures efficient utilization of available hardware, whether it's GPUs, CPUs, or specialized accelerators. The engine employs sophisticated scheduling algorithms to balance the load across multiple devices, maximizing throughput and minimizing latency.

The Triton Engine also incorporates advanced caching mechanisms to improve inference speed. By storing frequently accessed model weights and intermediate results in memory, it reduces the need for repeated computations and data transfers, leading to significant performance gains, especially for high-throughput scenarios.

Another notable aspect of the Triton Engine is its support for concurrent model execution. This feature allows multiple models to run simultaneously on the same hardware, enabling complex AI pipelines and ensemble models. The engine intelligently manages resource allocation and synchronization between different models, ensuring optimal performance and resource utilization.

The Triton Engine's architecture is designed with scalability in mind. It can seamlessly handle distributed inference across multiple nodes in a cluster, enabling horizontal scaling to meet increasing demand. This distributed capability is particularly valuable for large-scale deployments where a single machine's resources may not be sufficient to handle the inference workload.

Security and isolation are also key considerations in the Triton Engine's design. It implements robust mechanisms to ensure that different models and clients are isolated from each other, preventing unauthorized access and potential interference between workloads. This makes it suitable for multi-tenant environments where multiple users or applications share the same inference infrastructure.

In summary, the Triton Engine serves as the backbone of the Triton Inference Server, providing a flexible, efficient, and scalable platform for AI model deployment. Its advanced features and optimizations make it an ideal choice for organizations looking to streamline their AI inference workflows and maximize the performance of their deployed models.

The Triton Engine is responsible for handling the execution of AI models, supporting a wide range of frameworks such as TensorRT, TensorFlow, PyTorch, and ONNX Runtime. It provides a unified interface for model deployment, allowing developers to seamlessly integrate different types of models into their applications without worrying about the underlying hardware complexities.

One of the key features of the Triton Engine is its ability to dynamically allocate resources and optimize performance based on the incoming workload. This adaptive approach ensures efficient utilization of available hardware, whether it's GPUs, CPUs, or specialized accelerators. The engine employs sophisticated scheduling algorithms to balance the load across multiple devices, maximizing throughput and minimizing latency.

The Triton Engine also incorporates advanced caching mechanisms to improve inference speed. By storing frequently accessed model weights and intermediate results in memory, it reduces the need for repeated computations and data transfers, leading to significant performance gains, especially for high-throughput scenarios.

Another notable aspect of the Triton Engine is its support for concurrent model execution. This feature allows multiple models to run simultaneously on the same hardware, enabling complex AI pipelines and ensemble models. The engine intelligently manages resource allocation and synchronization between different models, ensuring optimal performance and resource utilization.

The Triton Engine's architecture is designed with scalability in mind. It can seamlessly handle distributed inference across multiple nodes in a cluster, enabling horizontal scaling to meet increasing demand. This distributed capability is particularly valuable for large-scale deployments where a single machine's resources may not be sufficient to handle the inference workload.

Security and isolation are also key considerations in the Triton Engine's design. It implements robust mechanisms to ensure that different models and clients are isolated from each other, preventing unauthorized access and potential interference between workloads. This makes it suitable for multi-tenant environments where multiple users or applications share the same inference infrastructure.

In summary, the Triton Engine serves as the backbone of the Triton Inference Server, providing a flexible, efficient, and scalable platform for AI model deployment. Its advanced features and optimizations make it an ideal choice for organizations looking to streamline their AI inference workflows and maximize the performance of their deployed models.

Market Demand Analysis

The market demand for monitoring 5.4 Triton Engine performance metrics has been steadily increasing, driven by the growing adoption of high-performance computing systems in various industries. As organizations increasingly rely on powerful computing solutions for data-intensive applications, the need for efficient and accurate performance monitoring tools has become paramount.

In the automotive sector, where the 5.4 Triton Engine is widely used, there is a significant demand for real-time performance monitoring to optimize fuel efficiency, reduce emissions, and enhance overall engine longevity. Fleet management companies and logistics providers are particularly interested in solutions that can provide comprehensive insights into engine performance, enabling them to make data-driven decisions for maintenance scheduling and operational efficiency.

The aerospace industry has also shown a keen interest in advanced monitoring systems for the 5.4 Triton Engine, as it is utilized in certain aircraft models. The ability to track performance metrics in real-time is crucial for ensuring flight safety and minimizing downtime for maintenance.

In the marine sector, where the 5.4 Triton Engine powers various vessels, there is a growing demand for monitoring solutions that can withstand harsh maritime conditions while providing accurate performance data. This information is vital for optimizing fuel consumption, reducing environmental impact, and complying with increasingly stringent maritime regulations.

The energy sector, particularly in oil and gas exploration, has expressed interest in robust monitoring systems for the 5.4 Triton Engine used in power generation and drilling operations. The ability to monitor performance metrics in remote and challenging environments is highly valued in this industry.

Market research indicates that the global engine performance monitoring market is expected to grow significantly in the coming years. This growth is attributed to the increasing focus on operational efficiency, regulatory compliance, and the adoption of predictive maintenance strategies across industries.

Key market drivers include the rising demand for fuel-efficient engines, the need for reduced maintenance costs, and the push for more environmentally friendly operations. Additionally, the integration of Internet of Things (IoT) technologies and advanced analytics in engine monitoring systems is creating new opportunities for innovative solutions.

However, challenges such as the complexity of integrating monitoring systems with existing infrastructure and concerns about data security and privacy need to be addressed to fully capitalize on the market potential. Despite these challenges, the overall market outlook for 5.4 Triton Engine performance monitoring solutions remains positive, with substantial growth opportunities across multiple sectors.

In the automotive sector, where the 5.4 Triton Engine is widely used, there is a significant demand for real-time performance monitoring to optimize fuel efficiency, reduce emissions, and enhance overall engine longevity. Fleet management companies and logistics providers are particularly interested in solutions that can provide comprehensive insights into engine performance, enabling them to make data-driven decisions for maintenance scheduling and operational efficiency.

The aerospace industry has also shown a keen interest in advanced monitoring systems for the 5.4 Triton Engine, as it is utilized in certain aircraft models. The ability to track performance metrics in real-time is crucial for ensuring flight safety and minimizing downtime for maintenance.

In the marine sector, where the 5.4 Triton Engine powers various vessels, there is a growing demand for monitoring solutions that can withstand harsh maritime conditions while providing accurate performance data. This information is vital for optimizing fuel consumption, reducing environmental impact, and complying with increasingly stringent maritime regulations.

The energy sector, particularly in oil and gas exploration, has expressed interest in robust monitoring systems for the 5.4 Triton Engine used in power generation and drilling operations. The ability to monitor performance metrics in remote and challenging environments is highly valued in this industry.

Market research indicates that the global engine performance monitoring market is expected to grow significantly in the coming years. This growth is attributed to the increasing focus on operational efficiency, regulatory compliance, and the adoption of predictive maintenance strategies across industries.

Key market drivers include the rising demand for fuel-efficient engines, the need for reduced maintenance costs, and the push for more environmentally friendly operations. Additionally, the integration of Internet of Things (IoT) technologies and advanced analytics in engine monitoring systems is creating new opportunities for innovative solutions.

However, challenges such as the complexity of integrating monitoring systems with existing infrastructure and concerns about data security and privacy need to be addressed to fully capitalize on the market potential. Despite these challenges, the overall market outlook for 5.4 Triton Engine performance monitoring solutions remains positive, with substantial growth opportunities across multiple sectors.

Current Monitoring Challenges

Monitoring the performance metrics of the 5.4 Triton Engine presents several significant challenges in the current technological landscape. One of the primary difficulties lies in the complexity of the engine's architecture, which integrates multiple components and systems that require simultaneous monitoring. This complexity necessitates a comprehensive approach to data collection and analysis, often stretching the capabilities of existing monitoring tools.

The high-speed operation of the Triton Engine poses another substantial challenge. Traditional monitoring methods may struggle to capture real-time data with sufficient accuracy and frequency, potentially missing critical performance fluctuations or anomalies. This high-speed environment demands advanced sensors and data processing techniques capable of handling large volumes of information in millisecond intervals.

Data integrity and reliability present ongoing concerns in the monitoring process. Environmental factors such as extreme temperatures, vibrations, and electromagnetic interference can affect sensor readings, leading to potential inaccuracies in performance metrics. Ensuring the consistency and trustworthiness of collected data remains a persistent challenge, requiring robust calibration and validation procedures.

The integration of legacy systems with modern monitoring technologies introduces compatibility issues. Many existing Triton Engine installations may rely on older monitoring equipment that lacks the sophistication to interface seamlessly with newer, more advanced monitoring solutions. This disparity can result in data silos and incomplete performance pictures, hindering comprehensive analysis and decision-making.

Scalability and resource management pose significant hurdles in monitoring efforts. As the number of monitored parameters increases to provide a more detailed performance profile, the demands on computational resources and data storage grow exponentially. Balancing the need for comprehensive monitoring with available infrastructure and cost considerations remains a delicate challenge for many organizations.

Cybersecurity concerns add another layer of complexity to the monitoring landscape. As monitoring systems become more interconnected and reliant on network communications, they become potential targets for cyber attacks. Protecting sensitive performance data and ensuring the integrity of monitoring systems against unauthorized access or manipulation requires ongoing vigilance and sophisticated security measures.

Lastly, the interpretation and actionable insights derived from collected performance metrics present a significant challenge. The sheer volume of data generated by comprehensive monitoring can be overwhelming, making it difficult to identify meaningful patterns or anomalies. Developing advanced analytics capabilities, including machine learning algorithms, to process and interpret this data effectively remains an ongoing challenge in the field of Triton Engine performance monitoring.

The high-speed operation of the Triton Engine poses another substantial challenge. Traditional monitoring methods may struggle to capture real-time data with sufficient accuracy and frequency, potentially missing critical performance fluctuations or anomalies. This high-speed environment demands advanced sensors and data processing techniques capable of handling large volumes of information in millisecond intervals.

Data integrity and reliability present ongoing concerns in the monitoring process. Environmental factors such as extreme temperatures, vibrations, and electromagnetic interference can affect sensor readings, leading to potential inaccuracies in performance metrics. Ensuring the consistency and trustworthiness of collected data remains a persistent challenge, requiring robust calibration and validation procedures.

The integration of legacy systems with modern monitoring technologies introduces compatibility issues. Many existing Triton Engine installations may rely on older monitoring equipment that lacks the sophistication to interface seamlessly with newer, more advanced monitoring solutions. This disparity can result in data silos and incomplete performance pictures, hindering comprehensive analysis and decision-making.

Scalability and resource management pose significant hurdles in monitoring efforts. As the number of monitored parameters increases to provide a more detailed performance profile, the demands on computational resources and data storage grow exponentially. Balancing the need for comprehensive monitoring with available infrastructure and cost considerations remains a delicate challenge for many organizations.

Cybersecurity concerns add another layer of complexity to the monitoring landscape. As monitoring systems become more interconnected and reliant on network communications, they become potential targets for cyber attacks. Protecting sensitive performance data and ensuring the integrity of monitoring systems against unauthorized access or manipulation requires ongoing vigilance and sophisticated security measures.

Lastly, the interpretation and actionable insights derived from collected performance metrics present a significant challenge. The sheer volume of data generated by comprehensive monitoring can be overwhelming, making it difficult to identify meaningful patterns or anomalies. Developing advanced analytics capabilities, including machine learning algorithms, to process and interpret this data effectively remains an ongoing challenge in the field of Triton Engine performance monitoring.

Existing Monitoring Solutions

01 Performance monitoring and metrics collection

Systems and methods for monitoring and collecting performance metrics of the Triton Engine. This includes real-time data gathering, analysis of engine parameters, and reporting of key performance indicators to assess engine efficiency and reliability.- Performance monitoring and metrics collection: Systems and methods for monitoring and collecting performance metrics of the Triton Engine. This includes real-time data gathering, analysis of engine parameters, and reporting of key performance indicators to assess engine efficiency and reliability.

- Optimization of engine performance: Techniques for optimizing Triton Engine performance through data-driven approaches. This involves analyzing collected metrics, identifying areas for improvement, and implementing adjustments to enhance overall engine efficiency and output.

- Predictive maintenance and fault detection: Advanced algorithms and systems for predicting maintenance needs and detecting potential faults in the Triton Engine. By analyzing performance metrics and historical data, these methods aim to prevent failures and optimize maintenance schedules.

- Integration with broader system performance: Approaches for integrating Triton Engine performance metrics with broader system performance indicators. This enables a holistic view of system efficiency and helps in identifying interdependencies between the engine and other components.

- Machine learning for performance analysis: Application of machine learning techniques to analyze Triton Engine performance metrics. These methods can identify patterns, predict future performance, and provide insights for continuous improvement of engine efficiency and reliability.

02 Optimization of engine performance

Techniques for optimizing Triton Engine performance through data-driven approaches. This involves analyzing collected metrics, identifying areas for improvement, and implementing adjustments to enhance overall engine efficiency and output.Expand Specific Solutions03 Predictive maintenance and diagnostics

Advanced systems for predicting maintenance needs and diagnosing potential issues in the Triton Engine. These solutions use performance metrics and machine learning algorithms to forecast maintenance requirements and detect anomalies before they lead to failures.Expand Specific Solutions04 Integration with broader system performance

Methods for integrating Triton Engine performance metrics with overall system performance data. This allows for a comprehensive view of how engine performance impacts and interacts with other components of the larger system or application.Expand Specific Solutions05 Visualization and reporting of performance metrics

Tools and techniques for visualizing and reporting Triton Engine performance metrics. This includes creating dashboards, generating automated reports, and providing intuitive interfaces for stakeholders to understand and act upon performance data.Expand Specific Solutions

Key Industry Players

The monitoring of 5.4 Triton Engine Performance Metrics is at a mature stage in the industry, with a well-established market and significant competition among key players. The market size is substantial, driven by the widespread use of these engines in various applications. Companies like Caterpillar, Rolls-Royce, and Scania CV AB have developed advanced monitoring systems, leveraging their extensive experience in engine manufacturing. The technology's maturity is evident in the sophisticated performance tracking tools offered by firms such as Honeywell International Technologies and Robert Bosch GmbH, which integrate real-time data analytics and predictive maintenance capabilities. This competitive landscape has led to continuous innovation in monitoring solutions, enhancing engine efficiency and reliability across multiple sectors.

Caterpillar, Inc.

Technical Solution: Caterpillar has developed an advanced monitoring system for the 5.4 Triton engine that utilizes real-time data analytics and machine learning algorithms. The system employs a network of sensors strategically placed throughout the engine to collect performance metrics such as fuel consumption, exhaust temperature, oil pressure, and vibration levels. This data is then processed through Caterpillar's proprietary software, which uses predictive modeling to identify potential issues before they become critical. The system also incorporates edge computing capabilities, allowing for rapid on-site analysis and decision-making[1]. Additionally, Caterpillar has integrated their monitoring solution with cloud-based platforms, enabling remote monitoring and fleet-wide performance optimization[3].

Strengths: Comprehensive data collection, predictive maintenance capabilities, and integration with existing Caterpillar fleet management systems. Weaknesses: May require significant initial investment and potential complexity in implementation for non-Caterpillar engines.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has engineered a sophisticated monitoring solution for the 5.4 Triton engine, leveraging their expertise in aerospace engine monitoring. Their approach combines advanced sensor technology with AI-driven analytics to provide real-time performance insights. The system utilizes high-fidelity sensors to capture a wide range of engine parameters, including combustion efficiency, thermal performance, and mechanical stress. This data is processed through Rolls-Royce's proprietary IntelligentEngine platform, which employs machine learning algorithms to analyze performance trends and detect anomalies[2]. The solution also incorporates digital twin technology, creating a virtual replica of each engine to simulate performance under various conditions and optimize maintenance schedules[4].

Strengths: High-precision sensor technology, advanced AI analytics, and integration with digital twin simulations. Weaknesses: Potentially high cost and may be overly complex for simpler engine applications.

Core Monitoring Innovations

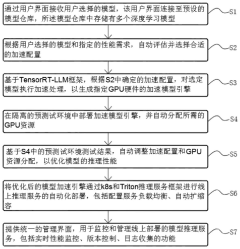

Automatic deployment method based on TensorRT-LLM model reasoning acceleration service

PatentActiveCN117992078A

Innovation

- Adopt an automated deployment method based on TensorRT-LLM model inference acceleration service, receive model selection through the user interface, automatically evaluate acceleration configuration, generate an acceleration model engine suitable for GPU hardware, and combine containerization technology and inference service framework to achieve rapid deployment of models and efficient operation, providing a unified management interface for real-time monitoring and management.

Regulatory Compliance

Monitoring the performance metrics of the 5.4 Triton Engine requires adherence to various regulatory standards and compliance requirements. These regulations are designed to ensure the engine's operation meets safety, environmental, and performance standards set by governing bodies.

The Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) are two primary regulatory agencies that oversee engine emissions and performance in the United States. These agencies establish strict guidelines for engine manufacturers to follow, including specific performance metrics that must be monitored and reported.

For the 5.4 Triton Engine, compliance with EPA Tier 3 and CARB LEV III standards is crucial. These standards set limits on emissions of pollutants such as nitrogen oxides (NOx), particulate matter (PM), and carbon monoxide (CO). To meet these requirements, engine performance metrics must be continuously monitored and optimized.

The On-Board Diagnostics (OBD) system plays a vital role in regulatory compliance for the 5.4 Triton Engine. OBD systems are mandated by law to monitor various engine components and systems, including the fuel system, ignition system, and emissions control devices. Any malfunctions or performance issues detected by the OBD system must be reported through the use of diagnostic trouble codes (DTCs).

Fuel efficiency standards, such as the Corporate Average Fuel Economy (CAFE) regulations, also impact the monitoring of the 5.4 Triton Engine's performance metrics. These standards require manufacturers to achieve specific fuel economy targets across their vehicle fleets, necessitating close monitoring of engine efficiency and fuel consumption.

In addition to emissions and fuel efficiency, noise regulations must be considered when monitoring the 5.4 Triton Engine's performance. The National Highway Traffic Safety Administration (NHTSA) sets standards for vehicle noise emissions, which include limits on engine noise levels. This requires monitoring of engine sound output and vibration characteristics.

Compliance with these regulatory standards necessitates the implementation of advanced monitoring systems and data collection methods. Real-time monitoring of engine performance metrics, such as exhaust gas temperature, fuel pressure, and air-fuel ratio, is essential for ensuring ongoing compliance and identifying potential issues before they lead to regulatory violations.

Regular reporting and documentation of engine performance metrics are also critical components of regulatory compliance. Manufacturers must maintain detailed records of engine performance data and be prepared to submit this information to regulatory agencies upon request. This includes data from both laboratory testing and real-world operation.

The Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) are two primary regulatory agencies that oversee engine emissions and performance in the United States. These agencies establish strict guidelines for engine manufacturers to follow, including specific performance metrics that must be monitored and reported.

For the 5.4 Triton Engine, compliance with EPA Tier 3 and CARB LEV III standards is crucial. These standards set limits on emissions of pollutants such as nitrogen oxides (NOx), particulate matter (PM), and carbon monoxide (CO). To meet these requirements, engine performance metrics must be continuously monitored and optimized.

The On-Board Diagnostics (OBD) system plays a vital role in regulatory compliance for the 5.4 Triton Engine. OBD systems are mandated by law to monitor various engine components and systems, including the fuel system, ignition system, and emissions control devices. Any malfunctions or performance issues detected by the OBD system must be reported through the use of diagnostic trouble codes (DTCs).

Fuel efficiency standards, such as the Corporate Average Fuel Economy (CAFE) regulations, also impact the monitoring of the 5.4 Triton Engine's performance metrics. These standards require manufacturers to achieve specific fuel economy targets across their vehicle fleets, necessitating close monitoring of engine efficiency and fuel consumption.

In addition to emissions and fuel efficiency, noise regulations must be considered when monitoring the 5.4 Triton Engine's performance. The National Highway Traffic Safety Administration (NHTSA) sets standards for vehicle noise emissions, which include limits on engine noise levels. This requires monitoring of engine sound output and vibration characteristics.

Compliance with these regulatory standards necessitates the implementation of advanced monitoring systems and data collection methods. Real-time monitoring of engine performance metrics, such as exhaust gas temperature, fuel pressure, and air-fuel ratio, is essential for ensuring ongoing compliance and identifying potential issues before they lead to regulatory violations.

Regular reporting and documentation of engine performance metrics are also critical components of regulatory compliance. Manufacturers must maintain detailed records of engine performance data and be prepared to submit this information to regulatory agencies upon request. This includes data from both laboratory testing and real-world operation.

Data Security and Privacy

Monitoring the performance metrics of the 5.4 Triton Engine requires careful consideration of data security and privacy. As this engine is likely used in critical applications, protecting sensitive performance data is paramount. Implementing robust encryption protocols for data transmission and storage is essential to prevent unauthorized access or interception. This includes using industry-standard encryption algorithms and regularly updating encryption keys.

Access control mechanisms must be implemented to ensure that only authorized personnel can view and analyze the engine's performance metrics. This involves implementing multi-factor authentication, role-based access control, and detailed audit logs to track all data access and modifications. Regular security audits and penetration testing should be conducted to identify and address potential vulnerabilities in the monitoring system.

Data anonymization techniques should be employed when sharing or analyzing performance metrics, especially if the data is to be used for research or shared with third parties. This may involve removing or obfuscating identifying information while maintaining the statistical relevance of the data. Implementing data masking techniques can help protect sensitive information while still allowing for meaningful analysis.

Compliance with relevant data protection regulations, such as GDPR or CCPA, is crucial when handling engine performance data. This includes implementing data retention policies, providing mechanisms for data subjects to exercise their rights, and ensuring proper data handling procedures are in place throughout the data lifecycle.

Secure data storage solutions, such as encrypted databases or secure cloud storage, should be utilized to protect performance metrics at rest. Regular backups and disaster recovery plans should be implemented to ensure data integrity and availability in case of system failures or security incidents.

Network security measures, including firewalls, intrusion detection systems, and virtual private networks (VPNs), should be employed to protect the transmission of performance data across networks. This is particularly important if the monitoring system is connected to external networks or the internet.

Implementing a comprehensive incident response plan is essential to address potential data breaches or security incidents promptly. This plan should outline procedures for detecting, containing, and mitigating security threats, as well as notifying affected parties and regulatory bodies if required.

Access control mechanisms must be implemented to ensure that only authorized personnel can view and analyze the engine's performance metrics. This involves implementing multi-factor authentication, role-based access control, and detailed audit logs to track all data access and modifications. Regular security audits and penetration testing should be conducted to identify and address potential vulnerabilities in the monitoring system.

Data anonymization techniques should be employed when sharing or analyzing performance metrics, especially if the data is to be used for research or shared with third parties. This may involve removing or obfuscating identifying information while maintaining the statistical relevance of the data. Implementing data masking techniques can help protect sensitive information while still allowing for meaningful analysis.

Compliance with relevant data protection regulations, such as GDPR or CCPA, is crucial when handling engine performance data. This includes implementing data retention policies, providing mechanisms for data subjects to exercise their rights, and ensuring proper data handling procedures are in place throughout the data lifecycle.

Secure data storage solutions, such as encrypted databases or secure cloud storage, should be utilized to protect performance metrics at rest. Regular backups and disaster recovery plans should be implemented to ensure data integrity and availability in case of system failures or security incidents.

Network security measures, including firewalls, intrusion detection systems, and virtual private networks (VPNs), should be employed to protect the transmission of performance data across networks. This is particularly important if the monitoring system is connected to external networks or the internet.

Implementing a comprehensive incident response plan is essential to address potential data breaches or security incidents promptly. This plan should outline procedures for detecting, containing, and mitigating security threats, as well as notifying affected parties and regulatory bodies if required.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!