5.4 Triton Engine: Enhancing Valve Mechanisms for Longevity

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton Engine Valve Evolution

The evolution of valve mechanisms in the Triton Engine represents a critical aspect of its overall development and performance enhancement. Initially, the engine utilized simple poppet valves, which were adequate for basic operations but faced challenges in terms of durability and efficiency at higher operating temperatures and pressures.

As engine technology advanced, the focus shifted towards improving valve materials and designs. The introduction of sodium-filled valves marked a significant milestone, allowing for better heat dissipation and reduced thermal stress. This innovation particularly benefited the exhaust valves, which are exposed to the highest temperatures within the engine.

The next phase of evolution saw the implementation of variable valve timing (VVT) systems. This technology allowed for dynamic adjustment of valve opening and closing times, optimizing engine performance across different operating conditions. The Triton Engine's VVT system initially used hydraulic actuators, later transitioning to more precise electric solenoid actuators for finer control.

Valve coating technologies also played a crucial role in enhancing longevity. The application of diamond-like carbon (DLC) coatings to valve stems significantly reduced friction and wear, extending the lifespan of these critical components. Additionally, the use of titanium for valve construction in high-performance variants of the Triton Engine provided a balance of strength and light weight, contributing to improved engine responsiveness.

Recent developments have focused on valve lift control systems, allowing for variable valve lift in addition to timing adjustments. This technology, often referred to as variable valve lift and timing (VVLT), provides even greater flexibility in engine operation, further improving fuel efficiency and power output across a broader range of engine speeds.

The integration of advanced sensors and control systems has enabled real-time monitoring of valve performance. This data-driven approach allows for predictive maintenance and early detection of potential valve issues, significantly enhancing the overall reliability and longevity of the Triton Engine's valve system.

Looking towards the future, research is being conducted on electromagnetic valve actuators, which could potentially eliminate the need for traditional camshafts altogether. This technology promises even more precise control over valve operation, potentially leading to further improvements in engine efficiency and performance. However, challenges remain in terms of cost-effectiveness and reliability for mass production applications.

As engine technology advanced, the focus shifted towards improving valve materials and designs. The introduction of sodium-filled valves marked a significant milestone, allowing for better heat dissipation and reduced thermal stress. This innovation particularly benefited the exhaust valves, which are exposed to the highest temperatures within the engine.

The next phase of evolution saw the implementation of variable valve timing (VVT) systems. This technology allowed for dynamic adjustment of valve opening and closing times, optimizing engine performance across different operating conditions. The Triton Engine's VVT system initially used hydraulic actuators, later transitioning to more precise electric solenoid actuators for finer control.

Valve coating technologies also played a crucial role in enhancing longevity. The application of diamond-like carbon (DLC) coatings to valve stems significantly reduced friction and wear, extending the lifespan of these critical components. Additionally, the use of titanium for valve construction in high-performance variants of the Triton Engine provided a balance of strength and light weight, contributing to improved engine responsiveness.

Recent developments have focused on valve lift control systems, allowing for variable valve lift in addition to timing adjustments. This technology, often referred to as variable valve lift and timing (VVLT), provides even greater flexibility in engine operation, further improving fuel efficiency and power output across a broader range of engine speeds.

The integration of advanced sensors and control systems has enabled real-time monitoring of valve performance. This data-driven approach allows for predictive maintenance and early detection of potential valve issues, significantly enhancing the overall reliability and longevity of the Triton Engine's valve system.

Looking towards the future, research is being conducted on electromagnetic valve actuators, which could potentially eliminate the need for traditional camshafts altogether. This technology promises even more precise control over valve operation, potentially leading to further improvements in engine efficiency and performance. However, challenges remain in terms of cost-effectiveness and reliability for mass production applications.

Market Demand Analysis

The market demand for enhanced valve mechanisms in Triton Engines is driven by several key factors in the automotive and marine industries. As engines continue to evolve, there is a growing need for more durable and efficient components, particularly in high-performance and heavy-duty applications. The longevity of valve mechanisms directly impacts engine reliability, maintenance costs, and overall performance, making it a critical area of focus for manufacturers and end-users alike.

In the automotive sector, the push for increased fuel efficiency and reduced emissions has led to the development of engines that operate under higher pressures and temperatures. This trend has intensified the wear and tear on valve mechanisms, creating a substantial market for solutions that can withstand these harsh conditions. Fleet operators and individual vehicle owners are increasingly seeking engines with extended service intervals and reduced maintenance requirements, further driving the demand for long-lasting valve mechanisms.

The marine industry presents another significant market for enhanced valve mechanisms. Commercial shipping companies and naval operations require engines that can operate reliably for extended periods at sea. The corrosive marine environment adds an extra layer of challenge to valve longevity, making improvements in this area particularly valuable. As global trade continues to expand, the demand for more efficient and durable marine engines is expected to grow, creating opportunities for advanced valve technologies.

In the power generation sector, stationary engines used in backup power systems and remote locations also benefit from enhanced valve mechanisms. The need for uninterrupted power supply in critical applications such as hospitals, data centers, and industrial facilities underscores the importance of engine reliability and longevity. This market segment values solutions that can reduce downtime and maintenance costs, making improved valve mechanisms an attractive proposition.

The aftermarket for engine components represents another substantial opportunity for enhanced valve mechanisms. As older engines reach the end of their service life, owners often look for upgrades that can extend the operational lifespan of their equipment. This creates a steady demand for advanced valve solutions that can be retrofitted to existing engines, offering improved performance and durability.

Market analysis indicates that the global demand for high-performance engine components, including valve mechanisms, is projected to grow steadily over the next decade. This growth is fueled by the expansion of transportation networks in developing economies, the ongoing modernization of fleets in developed countries, and the increasing focus on sustainability and efficiency across all industries that rely on internal combustion engines.

In the automotive sector, the push for increased fuel efficiency and reduced emissions has led to the development of engines that operate under higher pressures and temperatures. This trend has intensified the wear and tear on valve mechanisms, creating a substantial market for solutions that can withstand these harsh conditions. Fleet operators and individual vehicle owners are increasingly seeking engines with extended service intervals and reduced maintenance requirements, further driving the demand for long-lasting valve mechanisms.

The marine industry presents another significant market for enhanced valve mechanisms. Commercial shipping companies and naval operations require engines that can operate reliably for extended periods at sea. The corrosive marine environment adds an extra layer of challenge to valve longevity, making improvements in this area particularly valuable. As global trade continues to expand, the demand for more efficient and durable marine engines is expected to grow, creating opportunities for advanced valve technologies.

In the power generation sector, stationary engines used in backup power systems and remote locations also benefit from enhanced valve mechanisms. The need for uninterrupted power supply in critical applications such as hospitals, data centers, and industrial facilities underscores the importance of engine reliability and longevity. This market segment values solutions that can reduce downtime and maintenance costs, making improved valve mechanisms an attractive proposition.

The aftermarket for engine components represents another substantial opportunity for enhanced valve mechanisms. As older engines reach the end of their service life, owners often look for upgrades that can extend the operational lifespan of their equipment. This creates a steady demand for advanced valve solutions that can be retrofitted to existing engines, offering improved performance and durability.

Market analysis indicates that the global demand for high-performance engine components, including valve mechanisms, is projected to grow steadily over the next decade. This growth is fueled by the expansion of transportation networks in developing economies, the ongoing modernization of fleets in developed countries, and the increasing focus on sustainability and efficiency across all industries that rely on internal combustion engines.

Current Valve Challenges

The current valve challenges in the Triton Engine primarily revolve around longevity and performance under extreme conditions. One of the most significant issues is valve wear, particularly in high-temperature environments. The constant opening and closing of valves, combined with exposure to combustion gases, leads to accelerated degradation of valve surfaces and seats. This wear not only reduces engine efficiency but also increases the risk of valve failure, potentially causing catastrophic engine damage.

Another challenge is thermal management. The valves in the Triton Engine are subjected to rapid temperature fluctuations, which can cause thermal fatigue and distortion. This thermal stress can lead to valve warping, affecting the seal between the valve and seat, and resulting in compression loss or exhaust gas leakage. The need for materials that can withstand these thermal cycles while maintaining structural integrity is paramount.

Valve stem sealing presents an ongoing challenge. As the engine operates, the valve stems move through guide bushings, and maintaining an effective seal to prevent oil leakage into the combustion chamber or exhaust gases escaping into the crankcase is crucial. Current sealing technologies struggle to maintain their effectiveness over extended periods, particularly in high-mileage engines.

The demand for increased engine performance and fuel efficiency has led to higher combustion pressures and temperatures. This trend exacerbates the stress on valve components, pushing current materials and designs to their limits. Valve float, where the valve fails to follow the cam profile at high engine speeds, becomes more pronounced, potentially leading to valve-to-piston contact and engine failure.

Deposit formation on valve surfaces is another persistent issue. Carbon deposits from fuel combustion can accumulate on valve faces and seats, affecting valve sealing and heat transfer. These deposits can lead to hot spots, accelerating valve deterioration and potentially causing pre-ignition or knocking.

Lastly, the challenge of reducing valve train mass while maintaining durability remains significant. Lighter valves allow for higher engine speeds and improved efficiency, but this must be balanced against the need for structural integrity and longevity. Current lightweight materials often struggle to match the durability of traditional valve materials in long-term use scenarios.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, innovative design techniques, and cutting-edge manufacturing processes. The development of new valve mechanisms for the Triton Engine must focus on enhancing heat resistance, reducing friction, improving sealing capabilities, and optimizing valve geometry to ensure longevity without compromising performance.

Another challenge is thermal management. The valves in the Triton Engine are subjected to rapid temperature fluctuations, which can cause thermal fatigue and distortion. This thermal stress can lead to valve warping, affecting the seal between the valve and seat, and resulting in compression loss or exhaust gas leakage. The need for materials that can withstand these thermal cycles while maintaining structural integrity is paramount.

Valve stem sealing presents an ongoing challenge. As the engine operates, the valve stems move through guide bushings, and maintaining an effective seal to prevent oil leakage into the combustion chamber or exhaust gases escaping into the crankcase is crucial. Current sealing technologies struggle to maintain their effectiveness over extended periods, particularly in high-mileage engines.

The demand for increased engine performance and fuel efficiency has led to higher combustion pressures and temperatures. This trend exacerbates the stress on valve components, pushing current materials and designs to their limits. Valve float, where the valve fails to follow the cam profile at high engine speeds, becomes more pronounced, potentially leading to valve-to-piston contact and engine failure.

Deposit formation on valve surfaces is another persistent issue. Carbon deposits from fuel combustion can accumulate on valve faces and seats, affecting valve sealing and heat transfer. These deposits can lead to hot spots, accelerating valve deterioration and potentially causing pre-ignition or knocking.

Lastly, the challenge of reducing valve train mass while maintaining durability remains significant. Lighter valves allow for higher engine speeds and improved efficiency, but this must be balanced against the need for structural integrity and longevity. Current lightweight materials often struggle to match the durability of traditional valve materials in long-term use scenarios.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, innovative design techniques, and cutting-edge manufacturing processes. The development of new valve mechanisms for the Triton Engine must focus on enhancing heat resistance, reducing friction, improving sealing capabilities, and optimizing valve geometry to ensure longevity without compromising performance.

Existing Longevity Solutions

01 Advanced valve mechanism designs

Innovative valve mechanism designs are implemented to enhance the longevity of Triton Engine valves. These designs focus on reducing wear and tear, improving valve sealing, and optimizing valve timing. Advanced materials and coatings are used to increase durability and resistance to high temperatures and pressures.- Advanced valve mechanism designs: Innovative valve mechanism designs are implemented to enhance the longevity of Triton Engine valves. These designs focus on reducing wear and tear, improving valve sealing, and optimizing valve timing. Advanced materials and coatings are used to increase durability and resistance to high temperatures and pressures.

- Lubrication systems for valve mechanisms: Specialized lubrication systems are developed to ensure proper lubrication of valve components, reducing friction and wear. These systems may include oil jets, integrated oil channels, or advanced lubricant formulations specifically designed for high-performance engine valve mechanisms.

- Thermal management solutions: Effective thermal management solutions are implemented to control valve temperatures and prevent thermal fatigue. These may include advanced cooling systems, heat-resistant materials, and thermal barrier coatings to protect valve components from extreme heat and extend their operational life.

- Valve actuation and control systems: Advanced valve actuation and control systems are developed to optimize valve operation and reduce stress on valve components. These may include variable valve timing, electronic valve control, or hydraulic valve actuation systems that improve engine performance while extending valve mechanism longevity.

- Maintenance and monitoring technologies: Innovative maintenance and monitoring technologies are implemented to detect and prevent valve mechanism issues before they lead to failure. These may include advanced sensors, predictive maintenance algorithms, and real-time monitoring systems that help extend the operational life of Triton Engine valve mechanisms.

02 Lubrication systems for valve mechanisms

Specialized lubrication systems are developed to ensure proper lubrication of valve components, reducing friction and wear. These systems may include oil spray nozzles, improved oil channels, and advanced oil filtration methods to maintain clean and effective lubrication throughout the valve mechanism's lifecycle.Expand Specific Solutions03 Thermal management solutions

Effective thermal management solutions are implemented to control and dissipate heat in the valve mechanism area. This includes advanced cooling systems, heat-resistant materials, and thermal barriers to protect valve components from excessive heat exposure, thereby extending their operational life.Expand Specific Solutions04 Valve actuation and control systems

Advanced valve actuation and control systems are developed to optimize valve operation and reduce stress on valve components. These may include variable valve timing, electronic valve control, and hydraulic or pneumatic actuation systems that provide precise control and reduce mechanical wear.Expand Specific Solutions05 Maintenance and monitoring technologies

Innovative maintenance and monitoring technologies are integrated into Triton Engine valve mechanisms to detect early signs of wear or potential failures. These may include sensors, diagnostic systems, and predictive maintenance algorithms that allow for timely interventions and replacements, ultimately extending the overall longevity of the valve system.Expand Specific Solutions

Key Industry Players

The research on enhancing valve mechanisms for longevity in Triton Engine is in a competitive and evolving stage. The market is experiencing growth due to increasing demand for efficient and durable engine components. Major players like Ford, GM, Toyota, and Caterpillar are investing heavily in R&D to improve valve technology. Specialized companies such as Jacobs Vehicle Systems and FEV Motorentechnik are focusing on innovative valve actuation solutions. The technology is maturing, with companies like Bosch and AVL List contributing advanced engineering expertise. Emerging players from China, including Japhl Powertrain Systems and Hebei MeiBang, are also entering the market, intensifying competition and driving further innovation in valve longevity solutions.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced valve mechanism for the Triton Engine that focuses on longevity and performance. Their system incorporates a variable valve timing (VVT) technology with dual independent camshaft phasing[1]. This allows for precise control of valve opening and closing times, optimizing engine performance across various operating conditions. Ford's valve mechanism also features a low-friction roller finger follower design, which significantly reduces wear on valve components[2]. Additionally, they have implemented a hydraulic lash adjuster system that automatically maintains proper valve clearance, eliminating the need for manual adjustments and ensuring consistent performance over time[3]. The valve stems are coated with a diamond-like carbon (DLC) material, which provides excellent wear resistance and reduces friction, further enhancing longevity[4].

Strengths: Improved fuel efficiency, reduced emissions, and extended engine life due to reduced wear. The system's adaptability to various operating conditions enhances overall engine performance. Weaknesses: Increased complexity may lead to higher manufacturing costs and potential maintenance challenges in the long term.

GM Global Technology Operations LLC

Technical Solution: GM has developed a cutting-edge valve mechanism for enhancing longevity in their engine designs, including applications for the Triton Engine. Their system incorporates a Dynamic Skip Fire (DSF) technology, which allows for individual cylinder deactivation[1]. This reduces wear on valve components by selectively operating only the necessary cylinders based on power demand. GM's valve mechanism also features a patented two-step roller finger follower design, which provides two distinct valve lift profiles[2]. This allows for optimized valve operation at both low and high engine speeds, reducing overall stress on the valve train. Additionally, GM has implemented an advanced hydraulic lash adjuster with a high-pressure oil feed, ensuring consistent valve clearance and reducing wear over time[3]. The valve seats are made from a proprietary sintered metal alloy that offers superior heat resistance and durability[4].

Strengths: Significantly reduced wear on valve components, improved fuel efficiency, and adaptability to various driving conditions. The system's ability to deactivate cylinders reduces overall engine wear. Weaknesses: The complex nature of the DSF system may increase initial production costs and potentially require specialized maintenance.

Core Valve Innovations

Valve structure

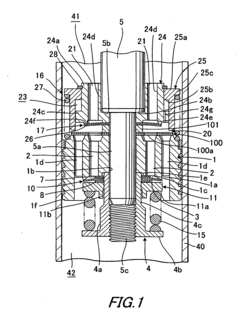

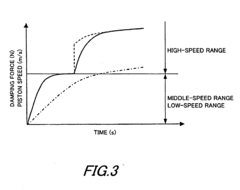

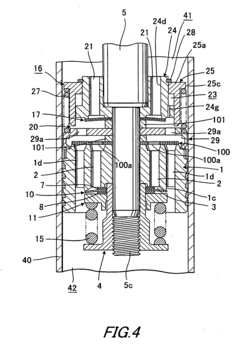

PatentInactiveEP1898119B1

Innovation

- A valve structure for a damper that includes a piston with a first and second chamber, a leaf valve, and parallel flow channels, where an open/close valve closes the first flow channel when pressure exceeds a certain level, and a relief valve in the second flow channel opens at higher pressures, allowing increased damping force at high piston speeds.

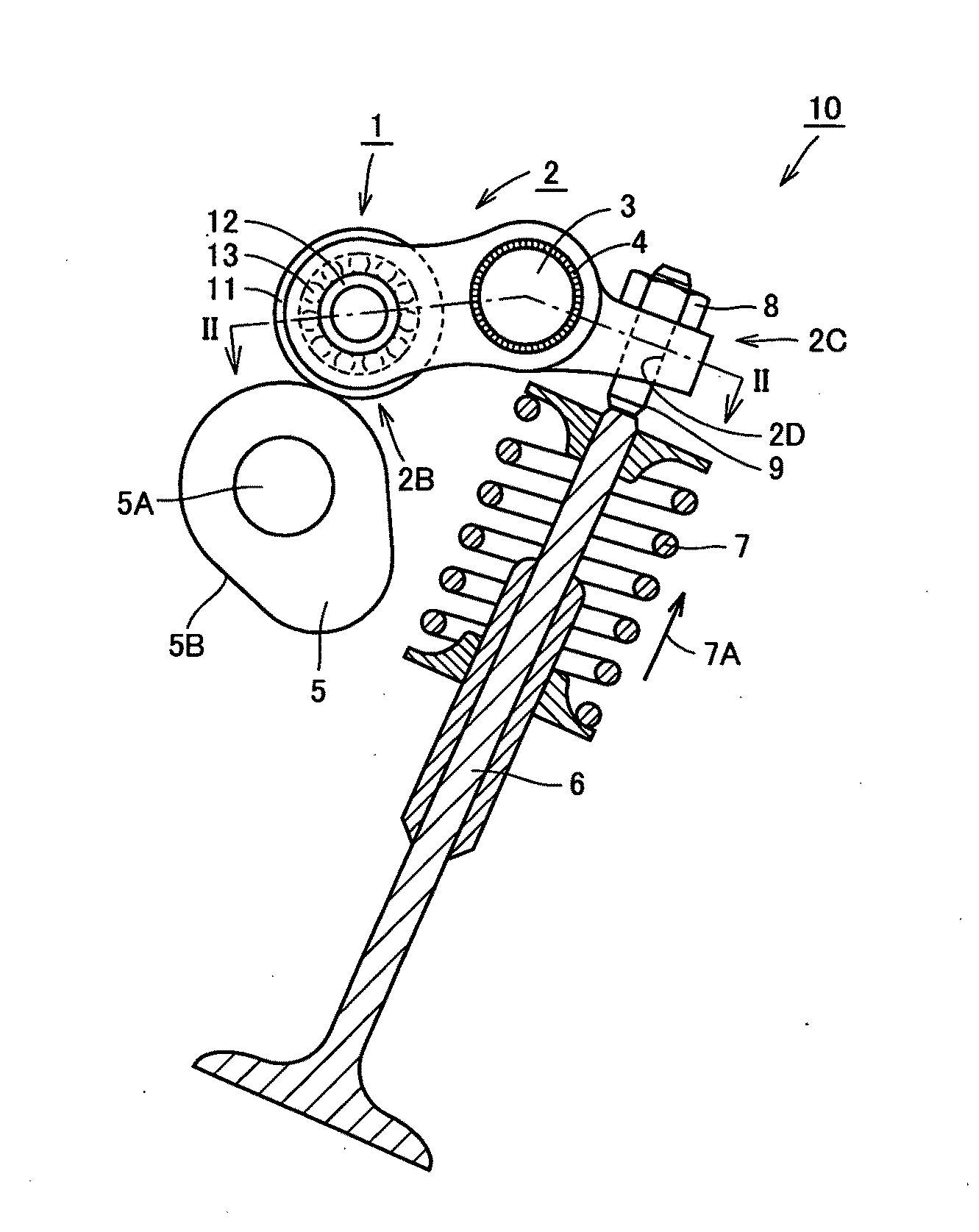

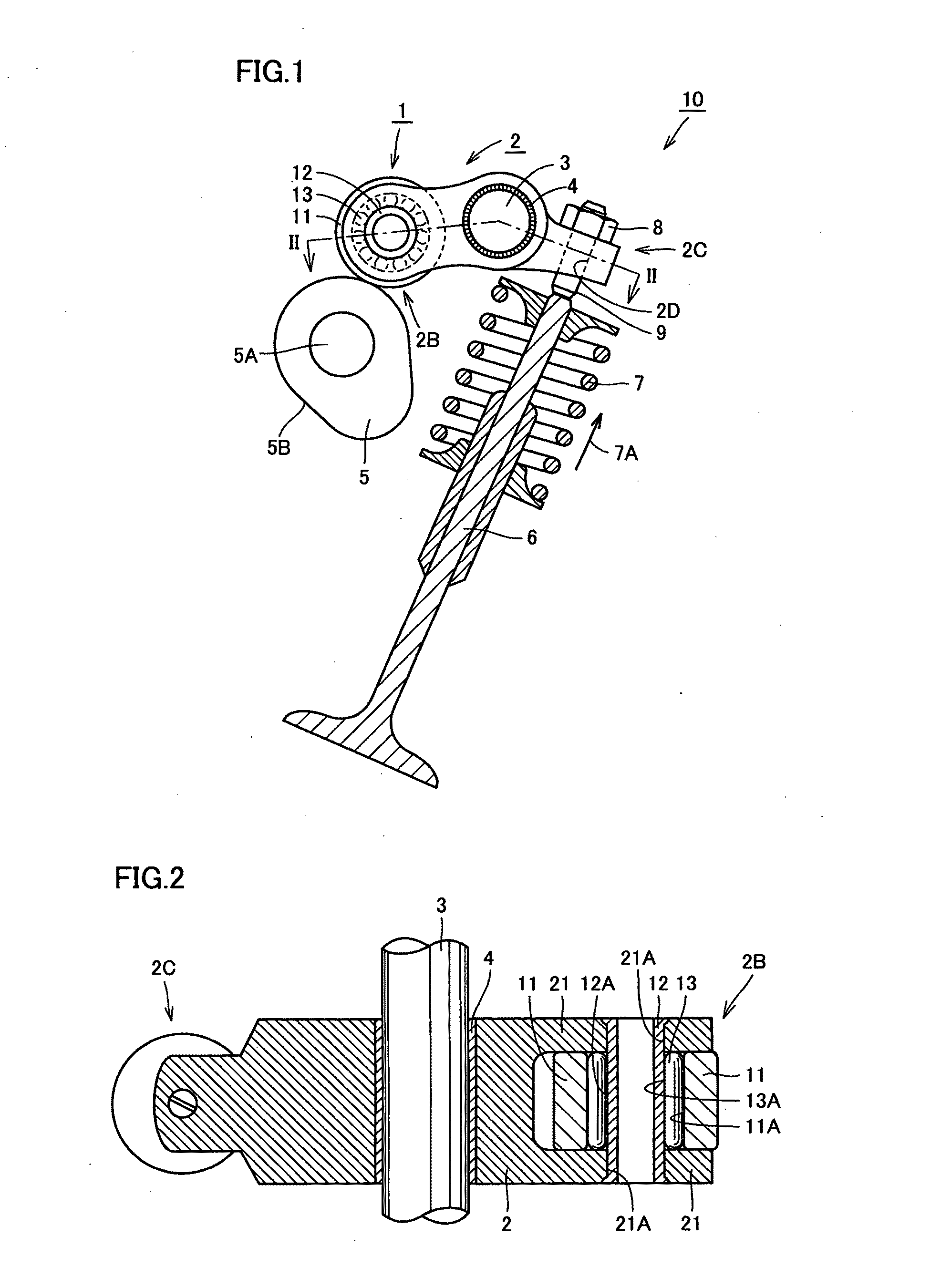

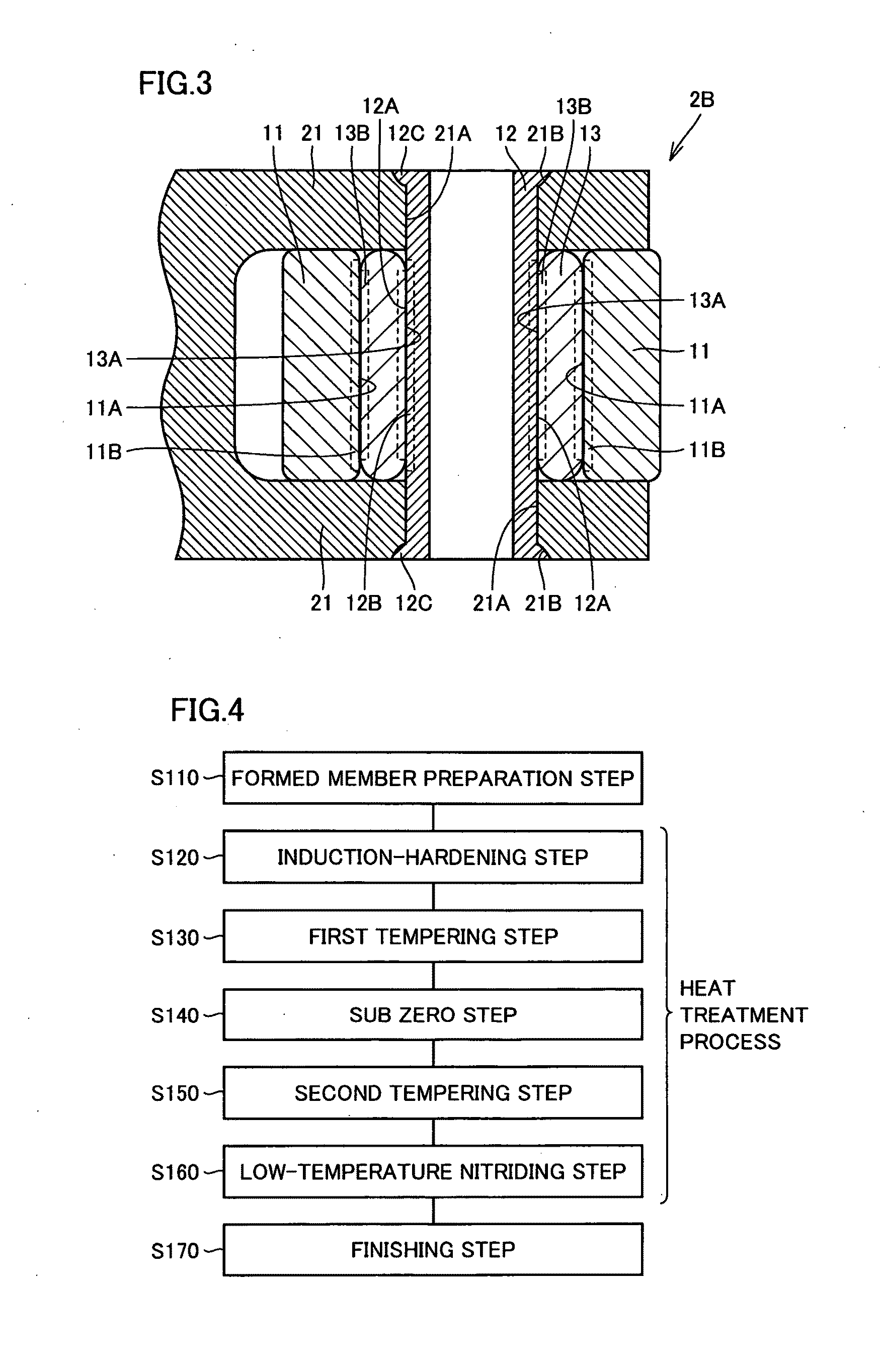

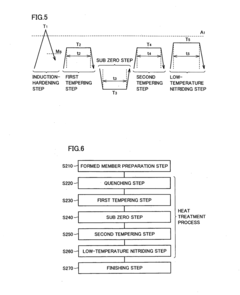

Roller follower, valve train, induction hardening apparatus, method of heat treatment of shaft member, method of manufacturing shaft, and shaft

PatentInactiveUS20100319642A1

Innovation

- A roller follower design featuring a steel member with a specific composition, including carbon and chromium, and the generation of large-sized carbides at the rolling contact surface to improve hardness and wear resistance, along with an induction hardening apparatus for quench-hardening the shaft while maintaining the end portion's workability.

Material Science Advancements

Material science advancements play a crucial role in enhancing valve mechanisms for longevity in Triton Engine. The development of innovative materials has significantly contributed to improving the durability and performance of engine valves, addressing the challenges posed by extreme operating conditions.

One of the key areas of focus in material science for valve mechanisms is the development of high-temperature resistant alloys. These advanced materials, such as nickel-based superalloys and titanium aluminides, exhibit exceptional strength and oxidation resistance at elevated temperatures. By incorporating these alloys into valve components, engineers have been able to extend the operational lifespan of valves and improve overall engine efficiency.

Coating technologies have also seen significant advancements in recent years. Thermal barrier coatings (TBCs) and wear-resistant coatings have been developed to protect valve surfaces from thermal fatigue, erosion, and corrosion. These coatings, often composed of ceramic materials or advanced metal alloys, provide an additional layer of protection, reducing wear and extending valve life.

Composite materials have emerged as a promising solution for valve applications. Carbon fiber reinforced polymers (CFRPs) and ceramic matrix composites (CMCs) offer excellent strength-to-weight ratios and thermal properties. These materials allow for the design of lighter valves with improved heat dissipation characteristics, contributing to enhanced engine performance and fuel efficiency.

Nanotechnology has opened up new possibilities in material science for valve mechanisms. Nanostructured materials and nanocomposites have demonstrated superior mechanical properties and thermal stability compared to their conventional counterparts. The incorporation of nanoparticles or nanofibers into valve materials has shown potential in improving wear resistance and reducing friction, leading to increased longevity.

Surface engineering techniques have also advanced significantly, allowing for the modification of valve surfaces at the microscopic level. Techniques such as laser surface texturing and ion implantation have been employed to create optimized surface topographies that enhance lubrication, reduce friction, and improve wear resistance.

The development of self-healing materials represents a cutting-edge approach to valve longevity. These materials have the ability to repair minor damage autonomously, potentially extending the lifespan of valve components and reducing maintenance requirements. While still in the early stages of development, self-healing materials show promise for future applications in engine valve mechanisms.

In conclusion, material science advancements have significantly contributed to enhancing valve mechanisms for longevity in Triton Engine. The continuous development of high-performance alloys, coatings, composites, and surface engineering techniques offers promising solutions for improving valve durability and overall engine performance.

One of the key areas of focus in material science for valve mechanisms is the development of high-temperature resistant alloys. These advanced materials, such as nickel-based superalloys and titanium aluminides, exhibit exceptional strength and oxidation resistance at elevated temperatures. By incorporating these alloys into valve components, engineers have been able to extend the operational lifespan of valves and improve overall engine efficiency.

Coating technologies have also seen significant advancements in recent years. Thermal barrier coatings (TBCs) and wear-resistant coatings have been developed to protect valve surfaces from thermal fatigue, erosion, and corrosion. These coatings, often composed of ceramic materials or advanced metal alloys, provide an additional layer of protection, reducing wear and extending valve life.

Composite materials have emerged as a promising solution for valve applications. Carbon fiber reinforced polymers (CFRPs) and ceramic matrix composites (CMCs) offer excellent strength-to-weight ratios and thermal properties. These materials allow for the design of lighter valves with improved heat dissipation characteristics, contributing to enhanced engine performance and fuel efficiency.

Nanotechnology has opened up new possibilities in material science for valve mechanisms. Nanostructured materials and nanocomposites have demonstrated superior mechanical properties and thermal stability compared to their conventional counterparts. The incorporation of nanoparticles or nanofibers into valve materials has shown potential in improving wear resistance and reducing friction, leading to increased longevity.

Surface engineering techniques have also advanced significantly, allowing for the modification of valve surfaces at the microscopic level. Techniques such as laser surface texturing and ion implantation have been employed to create optimized surface topographies that enhance lubrication, reduce friction, and improve wear resistance.

The development of self-healing materials represents a cutting-edge approach to valve longevity. These materials have the ability to repair minor damage autonomously, potentially extending the lifespan of valve components and reducing maintenance requirements. While still in the early stages of development, self-healing materials show promise for future applications in engine valve mechanisms.

In conclusion, material science advancements have significantly contributed to enhancing valve mechanisms for longevity in Triton Engine. The continuous development of high-performance alloys, coatings, composites, and surface engineering techniques offers promising solutions for improving valve durability and overall engine performance.

Environmental Impact Assessment

The environmental impact assessment of enhancing valve mechanisms for longevity in Triton Engine reveals several key considerations. Primarily, the focus on extending valve lifespan contributes to reduced engine replacements and overall resource consumption. This improvement in durability translates to fewer manufacturing cycles, thereby decreasing the carbon footprint associated with production processes.

Moreover, the enhanced valve mechanisms potentially lead to improved engine efficiency, resulting in reduced fuel consumption and lower emissions. This aspect is particularly significant in the context of stringent environmental regulations and the global push towards cleaner transportation solutions. The reduction in fuel consumption not only conserves non-renewable resources but also minimizes the release of harmful pollutants into the atmosphere.

The longevity of valve mechanisms also addresses the issue of waste generation. By extending the operational life of engine components, there is a notable decrease in the frequency of part replacements. This reduction in waste contributes to minimizing the environmental burden associated with disposal and recycling processes of engine components.

However, it is crucial to consider the potential environmental trade-offs. The development of more durable valve mechanisms may involve the use of advanced materials or coatings, which could have their own environmental implications during production or end-of-life disposal. A comprehensive life cycle assessment would be necessary to fully understand these impacts.

Additionally, the research and development process itself should be evaluated for its environmental footprint. This includes energy consumption in laboratories, material usage in prototyping, and potential waste generation during testing phases. Implementing sustainable practices in the R&D process can further enhance the overall environmental benefits of the project.

The long-term environmental benefits of enhanced valve mechanisms extend beyond the immediate engine performance. By contributing to the overall longevity of Triton Engines, this innovation supports the principles of circular economy and sustainable product design. It aligns with global efforts to reduce the environmental impact of transportation and industrial sectors, which are significant contributors to greenhouse gas emissions and resource depletion.

In conclusion, while the primary focus of enhancing valve mechanisms is on engine performance and longevity, the environmental implications are substantial and largely positive. The potential for reduced emissions, decreased resource consumption, and minimized waste generation positions this research as a valuable contribution to sustainable engineering practices in the automotive and industrial sectors.

Moreover, the enhanced valve mechanisms potentially lead to improved engine efficiency, resulting in reduced fuel consumption and lower emissions. This aspect is particularly significant in the context of stringent environmental regulations and the global push towards cleaner transportation solutions. The reduction in fuel consumption not only conserves non-renewable resources but also minimizes the release of harmful pollutants into the atmosphere.

The longevity of valve mechanisms also addresses the issue of waste generation. By extending the operational life of engine components, there is a notable decrease in the frequency of part replacements. This reduction in waste contributes to minimizing the environmental burden associated with disposal and recycling processes of engine components.

However, it is crucial to consider the potential environmental trade-offs. The development of more durable valve mechanisms may involve the use of advanced materials or coatings, which could have their own environmental implications during production or end-of-life disposal. A comprehensive life cycle assessment would be necessary to fully understand these impacts.

Additionally, the research and development process itself should be evaluated for its environmental footprint. This includes energy consumption in laboratories, material usage in prototyping, and potential waste generation during testing phases. Implementing sustainable practices in the R&D process can further enhance the overall environmental benefits of the project.

The long-term environmental benefits of enhanced valve mechanisms extend beyond the immediate engine performance. By contributing to the overall longevity of Triton Engines, this innovation supports the principles of circular economy and sustainable product design. It aligns with global efforts to reduce the environmental impact of transportation and industrial sectors, which are significant contributors to greenhouse gas emissions and resource depletion.

In conclusion, while the primary focus of enhancing valve mechanisms is on engine performance and longevity, the environmental implications are substantial and largely positive. The potential for reduced emissions, decreased resource consumption, and minimized waste generation positions this research as a valuable contribution to sustainable engineering practices in the automotive and industrial sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!