5.4 Triton Engine: Evolution of Lubrication Systems

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton Engine Lubrication Evolution and Objectives

The evolution of lubrication systems in Triton engines represents a significant journey in automotive engineering, reflecting the industry's ongoing pursuit of efficiency, performance, and sustainability. From its inception, the Triton engine has undergone numerous iterations, each marking a milestone in lubrication technology. The primary objective of this evolution has been to enhance engine performance while simultaneously reducing friction, wear, and energy losses.

In the early stages of Triton engine development, conventional oil-based lubrication systems were employed. These systems relied on a network of oil passages and pumps to distribute lubricant throughout the engine. However, as engine designs became more complex and performance demands increased, the limitations of these traditional systems became apparent. This realization sparked a series of innovations aimed at optimizing lubrication efficiency.

One of the key advancements in Triton engine lubrication was the introduction of precision oil delivery systems. These systems utilized advanced sensors and electronic controls to deliver the exact amount of oil needed to specific engine components at precisely the right time. This targeted approach not only improved overall engine efficiency but also contributed to reduced oil consumption and emissions.

Another significant development was the integration of synthetic lubricants specifically formulated for Triton engines. These advanced lubricants offered superior thermal stability, reduced viscosity, and enhanced protection against wear and corrosion. The adoption of these high-performance lubricants played a crucial role in extending engine life and maintaining optimal performance under extreme operating conditions.

The evolution of Triton engine lubrication systems also saw the implementation of innovative oil filtration technologies. Advanced filtration systems were designed to remove even the smallest contaminants from the oil, ensuring cleaner lubrication and reduced engine wear. This focus on oil purity contributed significantly to the overall reliability and longevity of Triton engines.

Recent developments in Triton engine lubrication have focused on sustainability and environmental considerations. Engineers have been working on bio-based lubricants and recycling systems that minimize the environmental impact of engine operation. These efforts align with the broader industry trend towards more eco-friendly automotive technologies.

Looking ahead, the objectives for future Triton engine lubrication systems are centered around further enhancing efficiency, reducing friction losses, and exploring novel lubrication technologies. Research is ongoing into nano-engineered lubricants, self-healing surfaces, and intelligent lubrication systems that can adapt to varying engine conditions in real-time. These advancements aim to push the boundaries of engine performance while meeting increasingly stringent environmental regulations.

In the early stages of Triton engine development, conventional oil-based lubrication systems were employed. These systems relied on a network of oil passages and pumps to distribute lubricant throughout the engine. However, as engine designs became more complex and performance demands increased, the limitations of these traditional systems became apparent. This realization sparked a series of innovations aimed at optimizing lubrication efficiency.

One of the key advancements in Triton engine lubrication was the introduction of precision oil delivery systems. These systems utilized advanced sensors and electronic controls to deliver the exact amount of oil needed to specific engine components at precisely the right time. This targeted approach not only improved overall engine efficiency but also contributed to reduced oil consumption and emissions.

Another significant development was the integration of synthetic lubricants specifically formulated for Triton engines. These advanced lubricants offered superior thermal stability, reduced viscosity, and enhanced protection against wear and corrosion. The adoption of these high-performance lubricants played a crucial role in extending engine life and maintaining optimal performance under extreme operating conditions.

The evolution of Triton engine lubrication systems also saw the implementation of innovative oil filtration technologies. Advanced filtration systems were designed to remove even the smallest contaminants from the oil, ensuring cleaner lubrication and reduced engine wear. This focus on oil purity contributed significantly to the overall reliability and longevity of Triton engines.

Recent developments in Triton engine lubrication have focused on sustainability and environmental considerations. Engineers have been working on bio-based lubricants and recycling systems that minimize the environmental impact of engine operation. These efforts align with the broader industry trend towards more eco-friendly automotive technologies.

Looking ahead, the objectives for future Triton engine lubrication systems are centered around further enhancing efficiency, reducing friction losses, and exploring novel lubrication technologies. Research is ongoing into nano-engineered lubricants, self-healing surfaces, and intelligent lubrication systems that can adapt to varying engine conditions in real-time. These advancements aim to push the boundaries of engine performance while meeting increasingly stringent environmental regulations.

Market Demand for Advanced Engine Lubrication

The market demand for advanced engine lubrication systems in Triton engines has been steadily increasing due to the growing emphasis on engine efficiency, longevity, and environmental sustainability. As automotive manufacturers strive to meet stringent emissions regulations and consumer expectations for fuel economy, the role of sophisticated lubrication systems has become paramount.

In recent years, there has been a significant shift towards more efficient and environmentally friendly engines, driving the need for advanced lubrication solutions. The Triton engine, known for its robust performance and reliability, has been at the forefront of this trend. Market research indicates that consumers are increasingly aware of the importance of proper engine lubrication in maintaining vehicle performance and reducing long-term maintenance costs.

The automotive industry has witnessed a surge in demand for engines that can deliver higher power output while consuming less fuel. This has led to the development of more compact and high-pressure engines, which in turn require more advanced lubrication systems to manage increased thermal and mechanical stresses. The Triton engine's evolution in lubrication technology has been driven by these market demands, with a focus on reducing friction, improving heat dissipation, and extending oil change intervals.

Environmental concerns have also played a crucial role in shaping the market demand for advanced lubrication systems. With governments worldwide implementing stricter emissions standards, engine manufacturers are under pressure to develop technologies that reduce harmful exhaust emissions. Advanced lubrication systems contribute to this goal by minimizing engine wear, reducing oil consumption, and improving overall engine efficiency.

The commercial vehicle sector, where Triton engines are widely used, has shown a particularly strong demand for advanced lubrication systems. Fleet operators are increasingly focused on total cost of ownership, seeking engines that offer extended service intervals and improved fuel efficiency. This has led to a growing market for lubrication systems that can withstand harsh operating conditions while maintaining optimal engine performance over longer periods.

Moreover, the rise of predictive maintenance and IoT-enabled engines has created a new dimension in the demand for advanced lubrication systems. Customers now expect lubrication systems that can provide real-time data on oil quality, viscosity, and contamination levels, allowing for more precise maintenance scheduling and reducing downtime.

As the automotive industry continues to evolve towards electrification, there is also an emerging market for specialized lubrication systems designed for hybrid powertrains. These systems must be capable of handling the unique challenges posed by engines that frequently switch between combustion and electric power, creating new opportunities for innovation in Triton engine lubrication technology.

In recent years, there has been a significant shift towards more efficient and environmentally friendly engines, driving the need for advanced lubrication solutions. The Triton engine, known for its robust performance and reliability, has been at the forefront of this trend. Market research indicates that consumers are increasingly aware of the importance of proper engine lubrication in maintaining vehicle performance and reducing long-term maintenance costs.

The automotive industry has witnessed a surge in demand for engines that can deliver higher power output while consuming less fuel. This has led to the development of more compact and high-pressure engines, which in turn require more advanced lubrication systems to manage increased thermal and mechanical stresses. The Triton engine's evolution in lubrication technology has been driven by these market demands, with a focus on reducing friction, improving heat dissipation, and extending oil change intervals.

Environmental concerns have also played a crucial role in shaping the market demand for advanced lubrication systems. With governments worldwide implementing stricter emissions standards, engine manufacturers are under pressure to develop technologies that reduce harmful exhaust emissions. Advanced lubrication systems contribute to this goal by minimizing engine wear, reducing oil consumption, and improving overall engine efficiency.

The commercial vehicle sector, where Triton engines are widely used, has shown a particularly strong demand for advanced lubrication systems. Fleet operators are increasingly focused on total cost of ownership, seeking engines that offer extended service intervals and improved fuel efficiency. This has led to a growing market for lubrication systems that can withstand harsh operating conditions while maintaining optimal engine performance over longer periods.

Moreover, the rise of predictive maintenance and IoT-enabled engines has created a new dimension in the demand for advanced lubrication systems. Customers now expect lubrication systems that can provide real-time data on oil quality, viscosity, and contamination levels, allowing for more precise maintenance scheduling and reducing downtime.

As the automotive industry continues to evolve towards electrification, there is also an emerging market for specialized lubrication systems designed for hybrid powertrains. These systems must be capable of handling the unique challenges posed by engines that frequently switch between combustion and electric power, creating new opportunities for innovation in Triton engine lubrication technology.

Current Challenges in Triton Engine Lubrication

The Triton Engine, known for its advanced design and performance, faces several critical challenges in its lubrication system. One of the primary issues is the increasing demand for higher efficiency and reduced fuel consumption, which puts additional stress on the lubrication system. As engine designs become more compact and power-dense, the lubrication system must adapt to smaller spaces while maintaining optimal performance.

Heat management presents another significant challenge. Modern Triton Engines generate more heat due to higher combustion pressures and temperatures. The lubrication system must not only protect engine components from wear but also play a crucial role in heat dissipation. This dual function requires advanced oil formulations and more efficient oil circulation systems.

The push for extended oil change intervals poses a unique challenge for Triton Engine lubrication. Longer-lasting oils must maintain their protective properties under extreme conditions for extended periods, necessitating innovations in oil chemistry and filtration technologies. This requirement is further complicated by the need to comply with increasingly stringent environmental regulations, which limit the use of certain additives traditionally used to enhance oil performance.

Friction reduction remains a constant challenge in Triton Engine lubrication. As manufacturers strive to improve fuel efficiency, minimizing friction losses becomes paramount. This necessitates the development of advanced surface treatments, low-friction coatings, and novel lubricant formulations that can maintain a protective film even under boundary lubrication conditions.

The integration of new materials in engine construction, such as lightweight alloys and composites, presents additional challenges for lubrication systems. These materials may have different thermal expansion properties and surface characteristics, requiring lubricants that are compatible and effective across a diverse range of materials and operating conditions.

Lastly, the trend towards electrification and hybrid powertrains introduces new complexities to Triton Engine lubrication. In hybrid systems, engines may experience frequent start-stop cycles and varying load conditions, which can lead to increased wear and oil degradation. The lubrication system must be designed to provide adequate protection during these transitional phases while also accommodating the unique requirements of electric components in hybrid powertrains.

Addressing these challenges requires a multidisciplinary approach, combining advancements in materials science, tribology, fluid dynamics, and chemical engineering. The future of Triton Engine lubrication lies in developing intelligent systems that can adapt to varying operating conditions, potentially incorporating real-time monitoring and active oil management technologies to optimize performance and longevity.

Heat management presents another significant challenge. Modern Triton Engines generate more heat due to higher combustion pressures and temperatures. The lubrication system must not only protect engine components from wear but also play a crucial role in heat dissipation. This dual function requires advanced oil formulations and more efficient oil circulation systems.

The push for extended oil change intervals poses a unique challenge for Triton Engine lubrication. Longer-lasting oils must maintain their protective properties under extreme conditions for extended periods, necessitating innovations in oil chemistry and filtration technologies. This requirement is further complicated by the need to comply with increasingly stringent environmental regulations, which limit the use of certain additives traditionally used to enhance oil performance.

Friction reduction remains a constant challenge in Triton Engine lubrication. As manufacturers strive to improve fuel efficiency, minimizing friction losses becomes paramount. This necessitates the development of advanced surface treatments, low-friction coatings, and novel lubricant formulations that can maintain a protective film even under boundary lubrication conditions.

The integration of new materials in engine construction, such as lightweight alloys and composites, presents additional challenges for lubrication systems. These materials may have different thermal expansion properties and surface characteristics, requiring lubricants that are compatible and effective across a diverse range of materials and operating conditions.

Lastly, the trend towards electrification and hybrid powertrains introduces new complexities to Triton Engine lubrication. In hybrid systems, engines may experience frequent start-stop cycles and varying load conditions, which can lead to increased wear and oil degradation. The lubrication system must be designed to provide adequate protection during these transitional phases while also accommodating the unique requirements of electric components in hybrid powertrains.

Addressing these challenges requires a multidisciplinary approach, combining advancements in materials science, tribology, fluid dynamics, and chemical engineering. The future of Triton Engine lubrication lies in developing intelligent systems that can adapt to varying operating conditions, potentially incorporating real-time monitoring and active oil management technologies to optimize performance and longevity.

Existing Triton Engine Lubrication Solutions

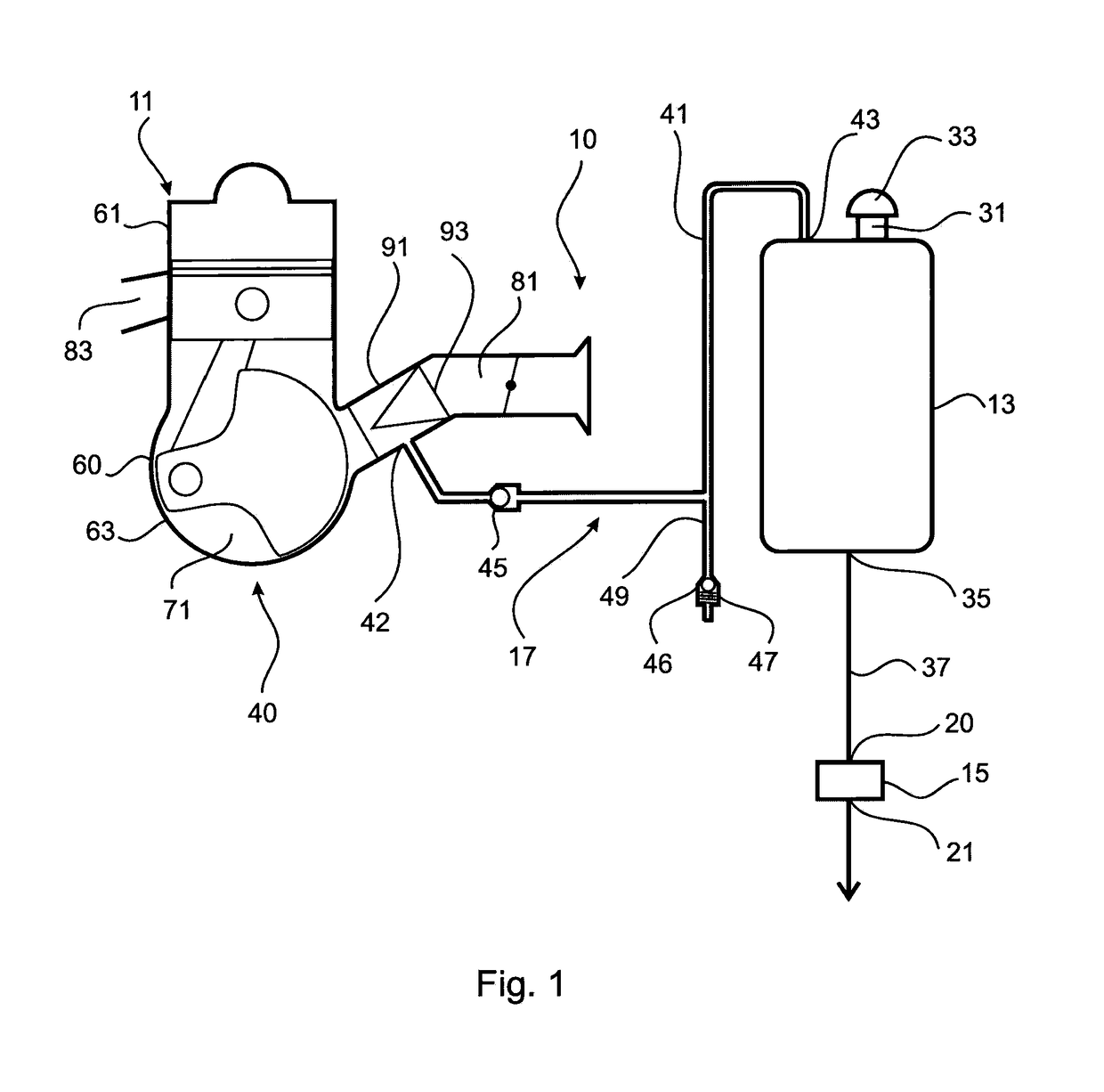

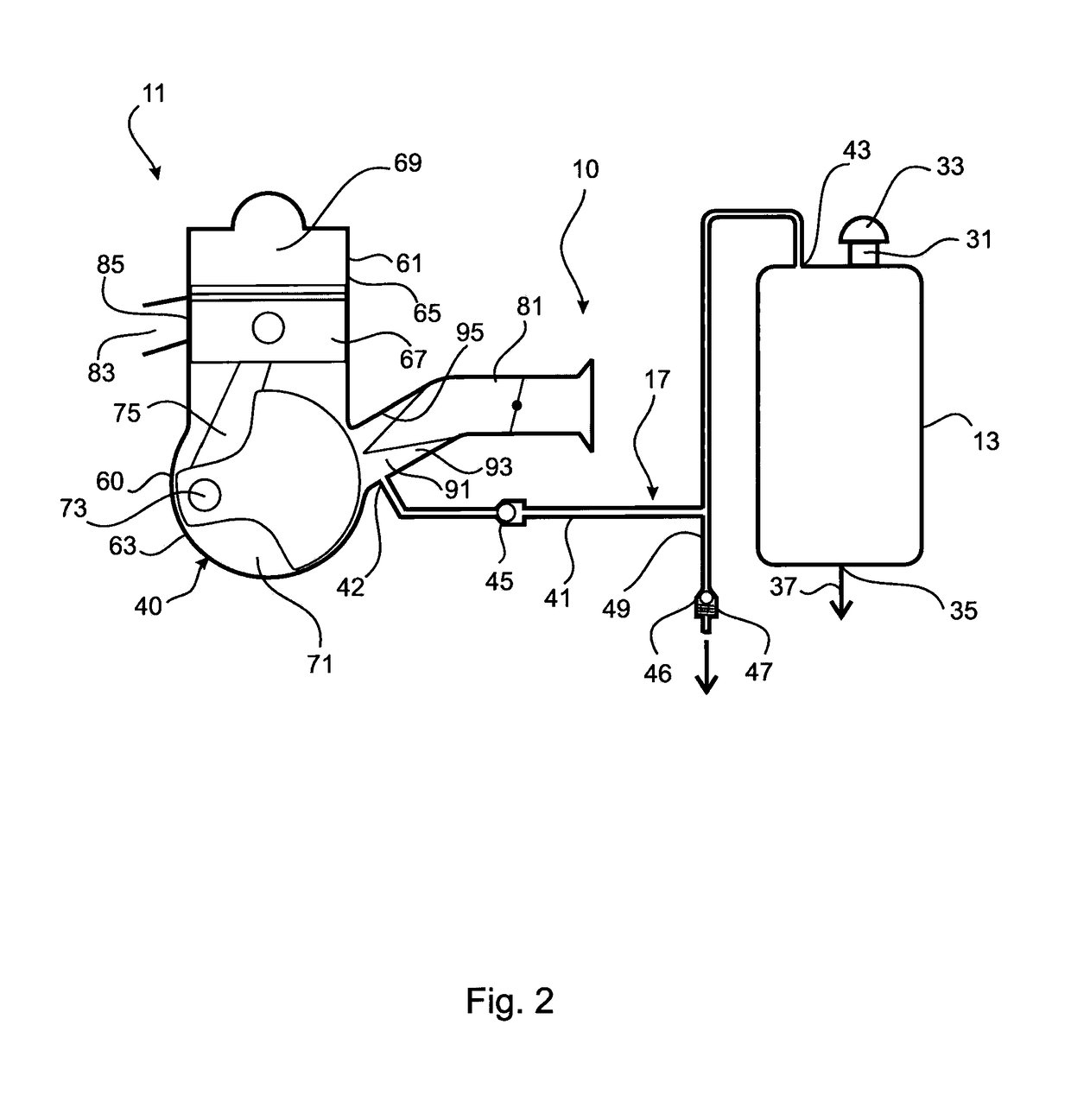

01 Oil circulation and distribution systems

Triton engine lubrication systems often incorporate advanced oil circulation and distribution mechanisms. These systems ensure efficient oil flow throughout the engine, providing proper lubrication to critical components. Features may include strategically placed oil passages, pumps, and filters to maintain optimal oil pressure and cleanliness.- Oil circulation and distribution systems: Triton engine lubrication systems often incorporate advanced oil circulation and distribution mechanisms. These systems ensure efficient oil flow throughout the engine, providing proper lubrication to critical components. They may include specialized pumps, channels, and passages designed to optimize oil delivery and maintain consistent engine performance.

- Filtration and contamination control: Effective filtration and contamination control are crucial aspects of Triton engine lubrication systems. These systems often feature advanced filtration technologies to remove impurities and debris from the oil, prolonging engine life and maintaining optimal performance. Some designs may incorporate bypass filtration or multi-stage filtration processes to ensure thorough cleaning of the lubricant.

- Temperature management and cooling: Triton engine lubrication systems often integrate temperature management features to maintain optimal oil viscosity and prevent overheating. These may include oil coolers, thermostats, or heat exchangers that work in conjunction with the engine's cooling system. Such features help extend oil life and ensure consistent lubrication performance across various operating conditions.

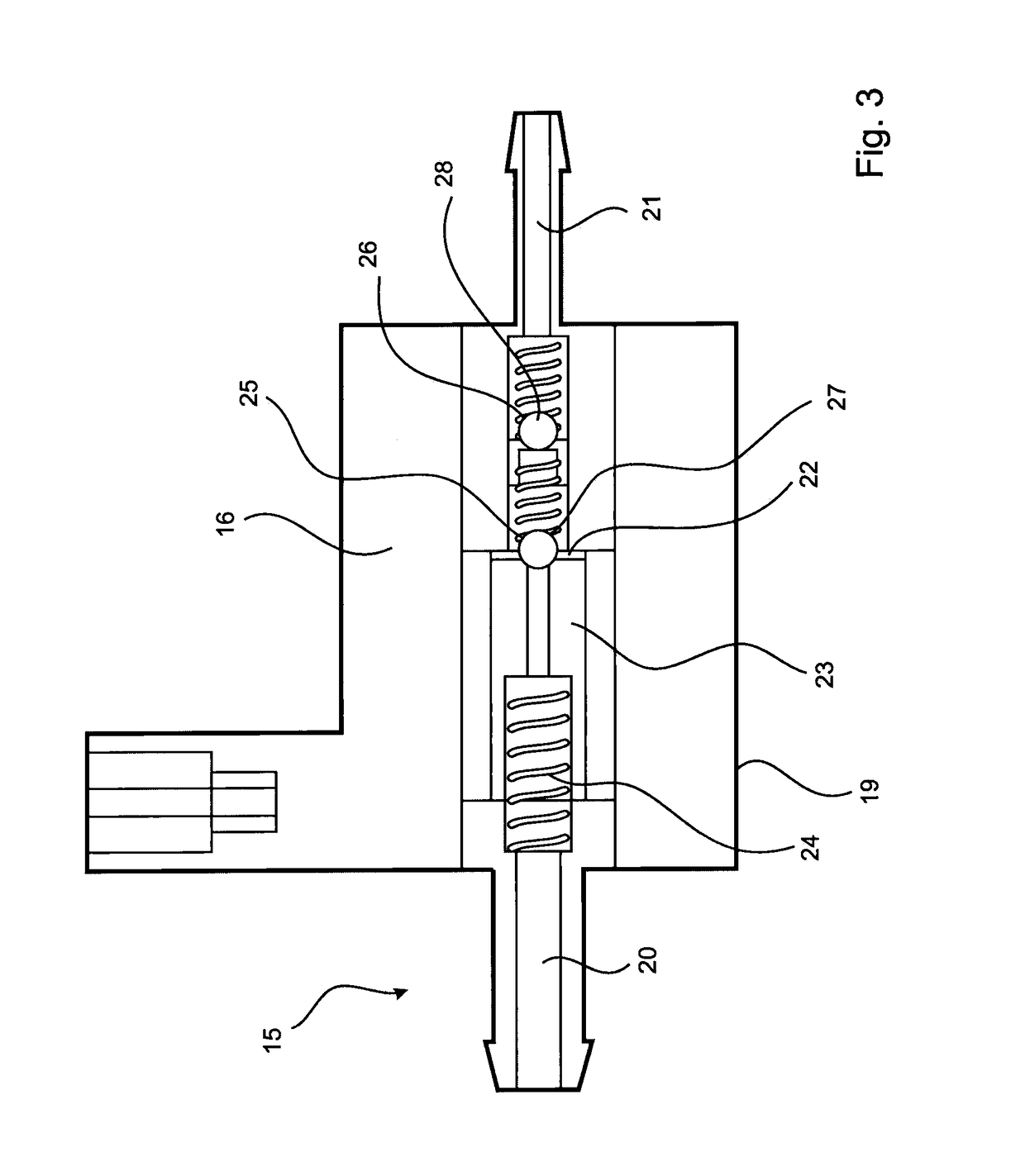

- Pressure regulation and monitoring: Pressure regulation and monitoring are essential components of Triton engine lubrication systems. These systems may incorporate pressure relief valves, sensors, and electronic control units to maintain optimal oil pressure throughout the engine. Advanced monitoring capabilities can alert operators to potential issues and help prevent damage caused by inadequate lubrication.

- Specialized lubrication for high-performance applications: Triton engine lubrication systems designed for high-performance or heavy-duty applications may incorporate specialized features. These can include dry sump systems, piston cooling jets, or variable oil pump designs. Such advanced systems aim to provide superior lubrication under extreme conditions, enhancing engine durability and performance in demanding environments.

02 Crankcase ventilation and oil separation

Many Triton engine lubrication systems include sophisticated crankcase ventilation and oil separation technologies. These systems help manage oil mist and vapors within the engine, reducing emissions and improving overall engine efficiency. They may incorporate baffles, separators, and specialized valves to control oil circulation and prevent contamination.Expand Specific Solutions03 Cooling and heat management

Triton engine lubrication systems often integrate cooling and heat management features. These may include oil coolers, temperature sensors, and thermostatic valves to maintain optimal oil temperature. Proper heat management ensures consistent lubrication performance and helps extend engine life by preventing oil degradation due to excessive heat.Expand Specific Solutions04 Lubrication monitoring and control systems

Advanced monitoring and control systems are frequently incorporated into Triton engine lubrication systems. These may include pressure sensors, flow meters, and electronic control units that continuously monitor oil conditions and adjust lubrication parameters. Such systems can provide real-time diagnostics and optimize lubrication based on engine operating conditions.Expand Specific Solutions05 Specialized lubricants and additives

Triton engine lubrication systems may utilize specialized lubricants and additives designed for high-performance applications. These formulations can include friction modifiers, anti-wear agents, and detergents to enhance engine protection and efficiency. The use of tailored lubricants can contribute to improved fuel economy and reduced emissions in Triton engines.Expand Specific Solutions

Key Players in Engine Lubrication Technology

The evolution of lubrication systems in Triton engines represents a competitive landscape in a mature industry with steady growth. The market size is substantial, driven by the automotive and industrial sectors' demand for efficient engine technologies. Technologically, the field is advancing, with companies like United Technologies Corp., Honda Motor Co., and Toyota Motor Corp. leading innovation. These firms, along with others such as Hyundai Motor Co. and Volvo Lastvagnar AB, are investing in research and development to improve lubrication efficiency, reduce friction, and enhance engine performance. The technology's maturity varies, with established players refining existing systems while newer entrants like Hans Jensen Lubricators A/S introduce specialized solutions for niche applications.

Honda Motor Co., Ltd.

Technical Solution: Honda has made significant strides in the evolution of lubrication systems for their engines, including those in the Triton family. They have developed a variable cylinder management (VCM) system that deactivates cylinders under light load conditions, reducing oil consumption and improving fuel efficiency[4]. Honda has also implemented a high-efficiency oil pump with variable flow control, optimizing oil pressure based on engine operating conditions. Their latest engines feature a low-viscosity oil formulation specifically designed to reduce internal friction[5]. Furthermore, Honda has introduced a unique piston design with a molybdenum coating on the piston skirts, minimizing friction between the piston and cylinder wall[6].

Strengths: Reduced oil consumption, improved fuel efficiency, and decreased engine wear. Weaknesses: Potential increase in system complexity and higher initial manufacturing costs.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has made significant advancements in lubrication systems for their engines, including those in the Triton family. They have developed a continuously variable oil pump (CVOP) that adjusts oil pressure based on engine speed and load, reducing parasitic losses and improving fuel efficiency[7]. Hyundai has also implemented a split cooling system that separates the cylinder head and block cooling circuits, allowing for more precise temperature control and reduced friction[8]. Their latest engines feature low-friction piston rings with a special DLC (Diamond-Like Carbon) coating, minimizing friction between the piston and cylinder wall. Additionally, Hyundai has introduced an integrated thermal management system that optimizes engine oil temperature, further enhancing overall engine efficiency and longevity[9].

Strengths: Improved fuel efficiency, reduced engine wear, and enhanced thermal management. Weaknesses: Increased system complexity and potentially higher production costs.

Innovative Lubrication Technologies Analysis

Engine lubrication system

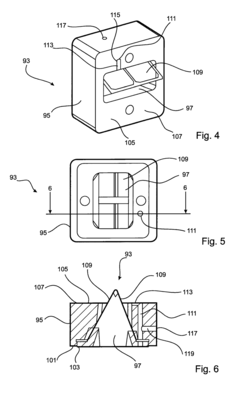

PatentActiveUS10184367B2

Innovation

- A system comprising a solenoid actuated positive displacement pump with a pressurization system that establishes a positive pressure at the pump inlet to assist in delivering lubrication oil with entrained vapour cavities, allowing for selective control of pumping strokes and improving metering accuracy, and includes a pressure release system to prevent excessive pressure buildup.

Environmental Impact of Lubrication Systems

The environmental impact of lubrication systems in Triton engines has become an increasingly important consideration in the evolution of these systems. As engine technologies have advanced, so too have the requirements for more environmentally friendly lubrication solutions. Traditional mineral-based lubricants, while effective, have raised concerns due to their non-renewable nature and potential for environmental contamination.

One of the primary environmental challenges associated with conventional lubrication systems is the risk of oil leaks and spills. These incidents can lead to soil and water pollution, causing harm to ecosystems and wildlife. In response, modern Triton engine lubrication systems have incorporated advanced sealing technologies and more robust containment designs to minimize the likelihood of leaks.

The disposal of used lubricants presents another significant environmental issue. Improper disposal can result in groundwater contamination and soil degradation. To address this, the industry has developed more efficient oil filtration and recycling processes, extending the life of lubricants and reducing the frequency of oil changes. Additionally, there has been a shift towards the use of biodegradable lubricants, which can naturally break down in the environment without causing long-term harm.

Emissions from lubricant volatilization have also been a focus of environmental concern. As engines operate at high temperatures, some lubricant components can vaporize and contribute to air pollution. In response, lubricant formulations for Triton engines have evolved to include more stable compounds with higher boiling points, reducing volatile organic compound (VOC) emissions.

The production of lubricants itself has environmental implications, from the extraction of raw materials to the manufacturing processes. The industry has made strides in developing synthetic lubricants that offer improved performance and longevity compared to conventional oils, potentially reducing the overall environmental footprint of lubricant production and use.

Energy efficiency has become a key factor in the environmental impact of lubrication systems. Advanced lubricants have been engineered to reduce friction more effectively, leading to improved fuel efficiency and reduced emissions from Triton engines. This not only contributes to lower operating costs but also aligns with global efforts to reduce greenhouse gas emissions.

As environmental regulations become more stringent, the evolution of lubrication systems in Triton engines continues to prioritize sustainability. Research and development efforts are focusing on creating lubricants from renewable sources, such as plant-based oils, which offer a more sustainable alternative to petroleum-based products. These bio-lubricants are designed to maintain the high performance standards required by modern engines while significantly reducing environmental impact throughout their lifecycle.

One of the primary environmental challenges associated with conventional lubrication systems is the risk of oil leaks and spills. These incidents can lead to soil and water pollution, causing harm to ecosystems and wildlife. In response, modern Triton engine lubrication systems have incorporated advanced sealing technologies and more robust containment designs to minimize the likelihood of leaks.

The disposal of used lubricants presents another significant environmental issue. Improper disposal can result in groundwater contamination and soil degradation. To address this, the industry has developed more efficient oil filtration and recycling processes, extending the life of lubricants and reducing the frequency of oil changes. Additionally, there has been a shift towards the use of biodegradable lubricants, which can naturally break down in the environment without causing long-term harm.

Emissions from lubricant volatilization have also been a focus of environmental concern. As engines operate at high temperatures, some lubricant components can vaporize and contribute to air pollution. In response, lubricant formulations for Triton engines have evolved to include more stable compounds with higher boiling points, reducing volatile organic compound (VOC) emissions.

The production of lubricants itself has environmental implications, from the extraction of raw materials to the manufacturing processes. The industry has made strides in developing synthetic lubricants that offer improved performance and longevity compared to conventional oils, potentially reducing the overall environmental footprint of lubricant production and use.

Energy efficiency has become a key factor in the environmental impact of lubrication systems. Advanced lubricants have been engineered to reduce friction more effectively, leading to improved fuel efficiency and reduced emissions from Triton engines. This not only contributes to lower operating costs but also aligns with global efforts to reduce greenhouse gas emissions.

As environmental regulations become more stringent, the evolution of lubrication systems in Triton engines continues to prioritize sustainability. Research and development efforts are focusing on creating lubricants from renewable sources, such as plant-based oils, which offer a more sustainable alternative to petroleum-based products. These bio-lubricants are designed to maintain the high performance standards required by modern engines while significantly reducing environmental impact throughout their lifecycle.

Triton Engine Efficiency Optimization

The optimization of Triton Engine efficiency is a critical focus in the evolution of marine propulsion systems. As lubrication systems play a pivotal role in engine performance, their development has been instrumental in enhancing overall engine efficiency. The progression of lubrication technologies in Triton Engines has been marked by significant advancements in materials, design, and control systems.

Early Triton Engine models relied on conventional oil-based lubrication systems, which, while effective, had limitations in terms of heat dissipation and friction reduction. The introduction of synthetic lubricants marked a significant milestone, offering improved thermal stability and reduced viscosity variation across a wide temperature range. This advancement allowed for more consistent lubrication performance in diverse operating conditions, contributing to increased engine efficiency.

The integration of precision oil delivery systems has further enhanced lubrication effectiveness. Modern Triton Engines employ sophisticated oil galleries and spray nozzles that target critical components with precision-timed lubrication. This targeted approach ensures optimal oil distribution, reducing excess oil consumption and minimizing power losses associated with oil churning.

Advanced filtration technologies have also played a crucial role in Triton Engine efficiency optimization. The implementation of high-efficiency oil filters and centrifugal oil cleaners has significantly extended oil life and maintained lubricant quality over longer periods. This not only reduces maintenance frequency but also ensures consistent engine performance and longevity.

The development of smart lubrication systems represents a leap forward in Triton Engine efficiency. These systems utilize real-time monitoring of oil condition, temperature, and pressure to dynamically adjust lubrication parameters. By optimizing oil flow and viscosity based on engine load and environmental conditions, smart lubrication systems minimize friction losses and maximize power output.

Recent innovations in surface engineering have further contributed to efficiency gains. The application of low-friction coatings and surface texturing on engine components has reduced friction at the microscopic level. These advancements, combined with improved lubricant formulations, have resulted in measurable reductions in fuel consumption and emissions.

Looking ahead, the integration of nanotechnology in lubrication systems holds promise for future Triton Engine efficiency improvements. Nano-engineered lubricants and additives have the potential to further reduce friction, enhance heat transfer, and provide superior protection against wear and corrosion. As these technologies mature, they are expected to push the boundaries of engine efficiency and reliability.

Early Triton Engine models relied on conventional oil-based lubrication systems, which, while effective, had limitations in terms of heat dissipation and friction reduction. The introduction of synthetic lubricants marked a significant milestone, offering improved thermal stability and reduced viscosity variation across a wide temperature range. This advancement allowed for more consistent lubrication performance in diverse operating conditions, contributing to increased engine efficiency.

The integration of precision oil delivery systems has further enhanced lubrication effectiveness. Modern Triton Engines employ sophisticated oil galleries and spray nozzles that target critical components with precision-timed lubrication. This targeted approach ensures optimal oil distribution, reducing excess oil consumption and minimizing power losses associated with oil churning.

Advanced filtration technologies have also played a crucial role in Triton Engine efficiency optimization. The implementation of high-efficiency oil filters and centrifugal oil cleaners has significantly extended oil life and maintained lubricant quality over longer periods. This not only reduces maintenance frequency but also ensures consistent engine performance and longevity.

The development of smart lubrication systems represents a leap forward in Triton Engine efficiency. These systems utilize real-time monitoring of oil condition, temperature, and pressure to dynamically adjust lubrication parameters. By optimizing oil flow and viscosity based on engine load and environmental conditions, smart lubrication systems minimize friction losses and maximize power output.

Recent innovations in surface engineering have further contributed to efficiency gains. The application of low-friction coatings and surface texturing on engine components has reduced friction at the microscopic level. These advancements, combined with improved lubricant formulations, have resulted in measurable reductions in fuel consumption and emissions.

Looking ahead, the integration of nanotechnology in lubrication systems holds promise for future Triton Engine efficiency improvements. Nano-engineered lubricants and additives have the potential to further reduce friction, enhance heat transfer, and provide superior protection against wear and corrosion. As these technologies mature, they are expected to push the boundaries of engine efficiency and reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!