5.4 Triton Engine: Improvements in Crankshaft Dynamics

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton Engine Crankshaft Evolution and Objectives

The Triton Engine, a cornerstone in marine propulsion technology, has undergone significant evolution in its crankshaft dynamics over the years. This progression has been driven by the continuous pursuit of enhanced performance, efficiency, and reliability in marine applications. The crankshaft, being a critical component in the engine's power transmission system, has been a focal point for technological advancements.

Initially, the Triton Engine's crankshaft design was based on conventional marine engine principles, prioritizing robustness and durability to withstand the harsh marine environment. As the demand for higher power output and improved fuel efficiency grew, engineers began to explore innovative approaches to crankshaft design and dynamics.

One of the key areas of development has been the optimization of crankshaft geometry. This involved refining the balance between journal diameter, web thickness, and counterweight design to minimize vibration and improve overall engine balance. The evolution of computer-aided design and simulation tools has played a crucial role in this process, allowing for more precise analysis of stress distribution and dynamic behavior under various operating conditions.

Material science advancements have also contributed significantly to the Triton Engine's crankshaft evolution. The transition from traditional forged steel to high-strength alloys and, in some cases, composite materials has enabled the creation of lighter yet stronger crankshafts. This weight reduction has led to improved engine responsiveness and reduced inertial losses.

Another area of focus has been the enhancement of lubrication systems. The development of more efficient oil delivery methods and the integration of advanced bearing materials have resulted in reduced friction and wear, thereby extending the crankshaft's operational life and improving overall engine efficiency.

The primary objectives of the ongoing research on crankshaft dynamics improvements for the Triton Engine are multifaceted. Firstly, there is a strong emphasis on further reducing vibration and noise levels, which is crucial for both passenger comfort and environmental considerations. Secondly, researchers aim to enhance the crankshaft's ability to handle higher power densities, supporting the trend towards more compact and powerful marine engines.

Additionally, there is a growing focus on improving the crankshaft's resistance to fatigue and thermal stress, particularly in light of the increasing use of alternative fuels and more demanding operational profiles. The integration of smart materials and sensors for real-time monitoring of crankshaft health and performance is also being explored as a means to enhance predictive maintenance capabilities.

Initially, the Triton Engine's crankshaft design was based on conventional marine engine principles, prioritizing robustness and durability to withstand the harsh marine environment. As the demand for higher power output and improved fuel efficiency grew, engineers began to explore innovative approaches to crankshaft design and dynamics.

One of the key areas of development has been the optimization of crankshaft geometry. This involved refining the balance between journal diameter, web thickness, and counterweight design to minimize vibration and improve overall engine balance. The evolution of computer-aided design and simulation tools has played a crucial role in this process, allowing for more precise analysis of stress distribution and dynamic behavior under various operating conditions.

Material science advancements have also contributed significantly to the Triton Engine's crankshaft evolution. The transition from traditional forged steel to high-strength alloys and, in some cases, composite materials has enabled the creation of lighter yet stronger crankshafts. This weight reduction has led to improved engine responsiveness and reduced inertial losses.

Another area of focus has been the enhancement of lubrication systems. The development of more efficient oil delivery methods and the integration of advanced bearing materials have resulted in reduced friction and wear, thereby extending the crankshaft's operational life and improving overall engine efficiency.

The primary objectives of the ongoing research on crankshaft dynamics improvements for the Triton Engine are multifaceted. Firstly, there is a strong emphasis on further reducing vibration and noise levels, which is crucial for both passenger comfort and environmental considerations. Secondly, researchers aim to enhance the crankshaft's ability to handle higher power densities, supporting the trend towards more compact and powerful marine engines.

Additionally, there is a growing focus on improving the crankshaft's resistance to fatigue and thermal stress, particularly in light of the increasing use of alternative fuels and more demanding operational profiles. The integration of smart materials and sensors for real-time monitoring of crankshaft health and performance is also being explored as a means to enhance predictive maintenance capabilities.

Market Demand for Enhanced Engine Performance

The market demand for enhanced engine performance, particularly in relation to crankshaft dynamics improvements for the Triton Engine, is driven by several key factors in the automotive and marine industries. As consumers and businesses increasingly prioritize fuel efficiency, power output, and environmental sustainability, there is a growing need for advanced engine technologies that can deliver superior performance while meeting stringent regulatory requirements.

In the automotive sector, the demand for improved crankshaft dynamics stems from the pursuit of better fuel economy and reduced emissions. With governments worldwide implementing stricter fuel efficiency standards, automakers are under pressure to develop engines that can extract maximum power from each drop of fuel. Enhanced crankshaft dynamics can contribute significantly to this goal by reducing internal friction, improving power transmission, and optimizing overall engine efficiency.

The marine industry, where the Triton Engine finds extensive application, is experiencing a similar trend. Ship operators are seeking ways to reduce fuel consumption and operational costs while complying with international maritime emission regulations. Improved crankshaft dynamics can lead to more efficient propulsion systems, resulting in lower fuel consumption and reduced environmental impact for various vessel types, from small pleasure crafts to large commercial ships.

Furthermore, the growing popularity of high-performance vehicles and racing applications creates a niche market for advanced engine technologies. Enthusiasts and professional racing teams are constantly looking for ways to extract more power and improve engine reliability, making enhanced crankshaft dynamics a valuable area of research and development.

The industrial sector also contributes to the market demand for improved engine performance. Stationary engines used in power generation, construction equipment, and agricultural machinery can benefit from advancements in crankshaft dynamics, leading to increased productivity and reduced operational costs.

Market analysts project that the global market for advanced engine components, including those related to crankshaft dynamics, will continue to grow at a steady rate over the next five years. This growth is attributed to the increasing adoption of turbocharged engines, the rise of electric and hybrid powertrains, and the ongoing quest for more efficient internal combustion engines.

As environmental concerns continue to shape consumer preferences and regulatory landscapes, the demand for technologies that can improve engine performance while reducing environmental impact is expected to remain strong. This trend underscores the importance of ongoing research and development in crankshaft dynamics for engines like the Triton, positioning companies that can deliver innovative solutions at the forefront of the market.

In the automotive sector, the demand for improved crankshaft dynamics stems from the pursuit of better fuel economy and reduced emissions. With governments worldwide implementing stricter fuel efficiency standards, automakers are under pressure to develop engines that can extract maximum power from each drop of fuel. Enhanced crankshaft dynamics can contribute significantly to this goal by reducing internal friction, improving power transmission, and optimizing overall engine efficiency.

The marine industry, where the Triton Engine finds extensive application, is experiencing a similar trend. Ship operators are seeking ways to reduce fuel consumption and operational costs while complying with international maritime emission regulations. Improved crankshaft dynamics can lead to more efficient propulsion systems, resulting in lower fuel consumption and reduced environmental impact for various vessel types, from small pleasure crafts to large commercial ships.

Furthermore, the growing popularity of high-performance vehicles and racing applications creates a niche market for advanced engine technologies. Enthusiasts and professional racing teams are constantly looking for ways to extract more power and improve engine reliability, making enhanced crankshaft dynamics a valuable area of research and development.

The industrial sector also contributes to the market demand for improved engine performance. Stationary engines used in power generation, construction equipment, and agricultural machinery can benefit from advancements in crankshaft dynamics, leading to increased productivity and reduced operational costs.

Market analysts project that the global market for advanced engine components, including those related to crankshaft dynamics, will continue to grow at a steady rate over the next five years. This growth is attributed to the increasing adoption of turbocharged engines, the rise of electric and hybrid powertrains, and the ongoing quest for more efficient internal combustion engines.

As environmental concerns continue to shape consumer preferences and regulatory landscapes, the demand for technologies that can improve engine performance while reducing environmental impact is expected to remain strong. This trend underscores the importance of ongoing research and development in crankshaft dynamics for engines like the Triton, positioning companies that can deliver innovative solutions at the forefront of the market.

Current Crankshaft Dynamics Challenges

The current challenges in crankshaft dynamics for the Triton Engine primarily revolve around balancing performance, efficiency, and durability. One of the key issues is vibration control, as the crankshaft's rotational motion generates significant vibrations that can lead to increased wear, reduced engine life, and compromised performance. These vibrations are particularly problematic at higher engine speeds, where the forces acting on the crankshaft are magnified.

Another major challenge is the optimization of crankshaft weight and stiffness. Engineers must strike a delicate balance between reducing the crankshaft's mass to improve engine responsiveness and maintaining sufficient stiffness to withstand the high loads and stresses encountered during operation. This balance becomes increasingly difficult to achieve as engine power outputs continue to rise, placing greater demands on the crankshaft's structural integrity.

Friction reduction remains a persistent challenge in crankshaft dynamics. The interface between the crankshaft journals and bearings is a significant source of energy loss due to friction, impacting both engine efficiency and fuel consumption. Developing advanced materials and surface treatments to minimize friction while maintaining durability is an ongoing area of research and development.

The complexity of modern engine designs, including the trend towards downsizing and turbocharging, has introduced new challenges in crankshaft dynamics. These compact, high-output engines often subject the crankshaft to more severe loading conditions, requiring innovative solutions to manage stress concentrations and fatigue life.

Thermal management is another critical challenge, particularly in high-performance applications. The crankshaft must maintain dimensional stability and material properties across a wide range of operating temperatures. Uneven thermal expansion can lead to misalignment, increased wear, and potential failure.

Additionally, the push for improved fuel efficiency and reduced emissions has placed greater emphasis on optimizing the entire rotating assembly, including the crankshaft. This involves refining the crankshaft's geometry to minimize pumping losses and improve overall engine breathing, which in turn affects the dynamic behavior of the crankshaft.

Lastly, manufacturing challenges persist in producing crankshafts that meet increasingly stringent tolerances and performance requirements. Advanced manufacturing techniques, such as precision forging and machining, are continually being developed to address these challenges and produce crankshafts with improved dynamic characteristics.

Another major challenge is the optimization of crankshaft weight and stiffness. Engineers must strike a delicate balance between reducing the crankshaft's mass to improve engine responsiveness and maintaining sufficient stiffness to withstand the high loads and stresses encountered during operation. This balance becomes increasingly difficult to achieve as engine power outputs continue to rise, placing greater demands on the crankshaft's structural integrity.

Friction reduction remains a persistent challenge in crankshaft dynamics. The interface between the crankshaft journals and bearings is a significant source of energy loss due to friction, impacting both engine efficiency and fuel consumption. Developing advanced materials and surface treatments to minimize friction while maintaining durability is an ongoing area of research and development.

The complexity of modern engine designs, including the trend towards downsizing and turbocharging, has introduced new challenges in crankshaft dynamics. These compact, high-output engines often subject the crankshaft to more severe loading conditions, requiring innovative solutions to manage stress concentrations and fatigue life.

Thermal management is another critical challenge, particularly in high-performance applications. The crankshaft must maintain dimensional stability and material properties across a wide range of operating temperatures. Uneven thermal expansion can lead to misalignment, increased wear, and potential failure.

Additionally, the push for improved fuel efficiency and reduced emissions has placed greater emphasis on optimizing the entire rotating assembly, including the crankshaft. This involves refining the crankshaft's geometry to minimize pumping losses and improve overall engine breathing, which in turn affects the dynamic behavior of the crankshaft.

Lastly, manufacturing challenges persist in producing crankshafts that meet increasingly stringent tolerances and performance requirements. Advanced manufacturing techniques, such as precision forging and machining, are continually being developed to address these challenges and produce crankshafts with improved dynamic characteristics.

Existing Crankshaft Dynamics Solutions

01 Crankshaft design and optimization

Focuses on improving crankshaft design for Triton engines to enhance performance and reduce vibrations. This includes optimizing the crankshaft's geometry, material selection, and manufacturing processes to achieve better balance and durability.- Crankshaft balancing and vibration reduction: Various methods and systems are employed to balance the crankshaft and reduce vibrations in Triton engines. These include counterweights, harmonic balancers, and advanced design techniques to minimize dynamic forces and improve overall engine performance.

- Crankshaft position sensing and control: Advanced sensing technologies are used to accurately determine crankshaft position and rotation speed. This information is crucial for engine management systems to optimize fuel injection timing, ignition timing, and other critical engine functions.

- Crankshaft design optimization: Innovative design approaches are implemented to optimize crankshaft geometry, material selection, and manufacturing processes. These improvements aim to enhance durability, reduce weight, and improve overall engine efficiency.

- Lubrication and cooling systems for crankshaft: Specialized lubrication and cooling systems are developed to manage heat and reduce friction in the crankshaft assembly. These systems play a crucial role in maintaining optimal operating conditions and extending engine life.

- Crankshaft dynamics analysis and simulation: Advanced computational methods and simulation tools are utilized to analyze and predict crankshaft dynamics under various operating conditions. These analyses help in identifying potential issues and optimizing engine design for improved performance and reliability.

02 Vibration analysis and reduction

Involves studying and mitigating crankshaft vibrations in Triton engines. This encompasses advanced modeling techniques, sensor systems for real-time monitoring, and implementation of damping mechanisms to minimize harmful oscillations and improve engine smoothness.Expand Specific Solutions03 Lubrication system enhancements

Addresses improvements in crankshaft lubrication for Triton engines. This includes developing advanced oil delivery systems, optimizing oil flow paths, and implementing new lubricant formulations to reduce friction and wear on crankshaft bearings.Expand Specific Solutions04 Crankshaft balancing techniques

Explores methods for achieving better crankshaft balance in Triton engines. This involves innovative counterweight designs, mass distribution optimization, and advanced balancing procedures to minimize engine vibrations and improve overall performance.Expand Specific Solutions05 Crankshaft monitoring and diagnostics

Focuses on developing systems for real-time monitoring and diagnostics of crankshaft dynamics in Triton engines. This includes implementing sensors, data analysis algorithms, and predictive maintenance strategies to detect potential issues and optimize engine performance.Expand Specific Solutions

Key Players in Engine Component Manufacturing

The research on crankshaft dynamics improvements for the Triton Engine is at a mature stage, with significant market potential in the automotive industry. Major players like Nissan, GM, Toyota, and Ford are actively involved, indicating a competitive landscape. The market size is substantial, driven by the demand for enhanced engine performance and efficiency. Technological advancements from established manufacturers and emerging companies like Guangxi Yuchai Machinery and SAIC GM Wuling Automobile are pushing the boundaries of crankshaft dynamics, leading to improved engine designs and performance across various vehicle segments.

GM Global Technology Operations LLC

Technical Solution: GM has focused on improving crankshaft dynamics through the implementation of an advanced active engine mount system. This system uses electromagnetic actuators to counteract engine vibrations in real-time, significantly reducing the transmission of vibrations to the vehicle body[2]. For the Triton Engine specifically, GM has developed a lightweight, high-strength crankshaft using a proprietary alloy, which offers improved stiffness and reduced inertia[4]. They have also implemented a variable oil pump system that adjusts oil pressure based on engine load and speed, optimizing lubrication and reducing parasitic losses in the crankshaft bearings[6].

Strengths: Real-time vibration control, lightweight design, and optimized lubrication. Weaknesses: Increased complexity in control systems and potential for higher maintenance costs.

Toyota Motor Corp.

Technical Solution: Toyota has developed an innovative approach to improve crankshaft dynamics in their Triton Engine. They have implemented a dual-mass flywheel system with a pendulum-type absorber, which significantly reduces torsional vibrations[1]. This system works by counteracting the engine's inherent vibrations, resulting in smoother operation and reduced stress on engine components. Additionally, Toyota has optimized the crankshaft's counterweight design using advanced computer simulations, allowing for better balance and reduced overall engine weight[3]. The company has also introduced a new bearing material with improved friction characteristics, enhancing the crankshaft's rotational efficiency and durability[5].

Strengths: Reduced vibrations, improved engine smoothness, and increased durability. Weaknesses: Potentially higher manufacturing costs and increased complexity in engine design.

Innovative Crankshaft Materials and Designs

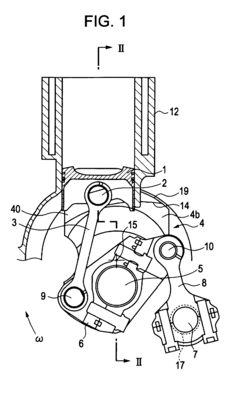

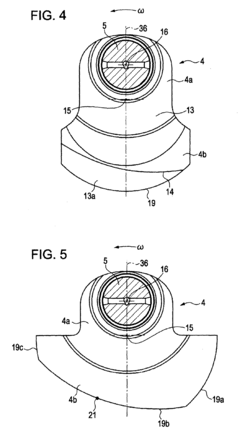

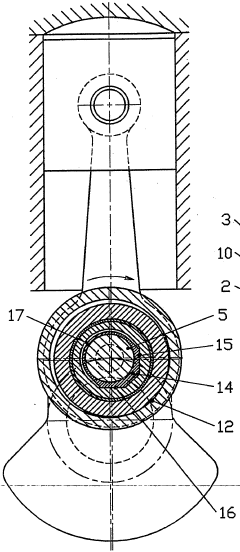

Crankshaft mechanism

PatentInactiveEP1830051B1

Innovation

- The proposed crankshaft mechanism incorporates a counterweight with a center of gravity positioned forward in the direction of rotation, featuring a larger volume and thinner sections at the forward side, strategically located to cancel out inertial forces and prevent interference between the counterweight and piston pin boss, allowing for increased piston stroke without increasing the engine's overall height.

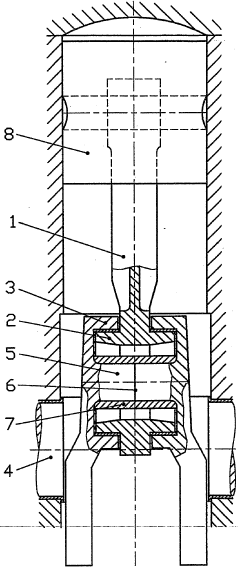

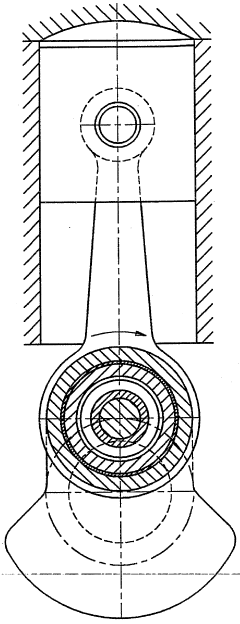

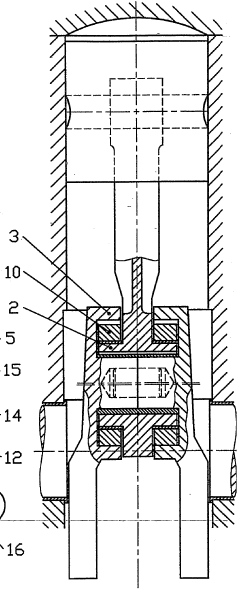

Crankshaft drive, particularly for reciprocating combustion engines

PatentWO2005045211A2

Innovation

- The design shifts the point of force application outward by transmitting driving force from bearing journals on the connecting rods to bearing eyes on the crankshaft, utilizing hollow pins and additional bearing parts to increase the lever effect without compromising speed, and incorporates asymmetrical and toothed components for enhanced power transmission and force absorption.

Environmental Impact of Improved Engine Efficiency

Improvements in crankshaft dynamics for the Triton Engine have significant implications for environmental sustainability. Enhanced engine efficiency directly correlates with reduced fuel consumption and lower emissions, contributing to a smaller carbon footprint. The optimized crankshaft design leads to smoother power delivery and reduced vibrations, which not only improves engine performance but also extends the engine's lifespan. This longevity reduces the need for frequent replacements, thereby minimizing waste and conserving resources in the long term.

The refined crankshaft dynamics also contribute to more efficient combustion processes. This results in more complete fuel burning, reducing the release of unburned hydrocarbons and particulate matter into the atmosphere. The improved efficiency translates to better fuel economy, which is crucial in an era of increasing environmental consciousness and stringent emission regulations. By consuming less fuel per unit of power output, the enhanced Triton Engine helps conserve fossil fuel resources and reduces the overall environmental impact of vehicle operation.

Moreover, the advancements in crankshaft dynamics can lead to a reduction in noise pollution. The smoother operation of the engine components results in decreased mechanical noise, contributing to a more pleasant urban environment and potentially reducing stress on local ecosystems sensitive to noise disturbances. This aspect of environmental impact is often overlooked but is increasingly important in densely populated areas.

The improved engine efficiency also has cascading effects on the vehicle's overall environmental performance. With better fuel economy, vehicles equipped with the enhanced Triton Engine can travel longer distances on the same amount of fuel, potentially reducing the frequency of refueling stops. This not only saves time for the users but also decreases the energy consumption associated with fuel transportation and distribution.

Furthermore, the advancements in crankshaft dynamics may pave the way for more effective integration of hybrid technologies. The improved efficiency and smoother operation can complement electric powertrains, potentially leading to even greater reductions in emissions and fuel consumption in hybrid vehicles. This synergy between traditional combustion engines and electric systems represents a crucial step towards more sustainable transportation solutions.

In conclusion, the environmental impact of improved engine efficiency through enhanced crankshaft dynamics in the Triton Engine is multifaceted and significant. It encompasses reduced emissions, improved fuel economy, extended engine lifespan, decreased noise pollution, and potential synergies with hybrid technologies. These improvements collectively contribute to a more sustainable and environmentally friendly transportation sector, aligning with global efforts to mitigate climate change and reduce the ecological footprint of automotive technologies.

The refined crankshaft dynamics also contribute to more efficient combustion processes. This results in more complete fuel burning, reducing the release of unburned hydrocarbons and particulate matter into the atmosphere. The improved efficiency translates to better fuel economy, which is crucial in an era of increasing environmental consciousness and stringent emission regulations. By consuming less fuel per unit of power output, the enhanced Triton Engine helps conserve fossil fuel resources and reduces the overall environmental impact of vehicle operation.

Moreover, the advancements in crankshaft dynamics can lead to a reduction in noise pollution. The smoother operation of the engine components results in decreased mechanical noise, contributing to a more pleasant urban environment and potentially reducing stress on local ecosystems sensitive to noise disturbances. This aspect of environmental impact is often overlooked but is increasingly important in densely populated areas.

The improved engine efficiency also has cascading effects on the vehicle's overall environmental performance. With better fuel economy, vehicles equipped with the enhanced Triton Engine can travel longer distances on the same amount of fuel, potentially reducing the frequency of refueling stops. This not only saves time for the users but also decreases the energy consumption associated with fuel transportation and distribution.

Furthermore, the advancements in crankshaft dynamics may pave the way for more effective integration of hybrid technologies. The improved efficiency and smoother operation can complement electric powertrains, potentially leading to even greater reductions in emissions and fuel consumption in hybrid vehicles. This synergy between traditional combustion engines and electric systems represents a crucial step towards more sustainable transportation solutions.

In conclusion, the environmental impact of improved engine efficiency through enhanced crankshaft dynamics in the Triton Engine is multifaceted and significant. It encompasses reduced emissions, improved fuel economy, extended engine lifespan, decreased noise pollution, and potential synergies with hybrid technologies. These improvements collectively contribute to a more sustainable and environmentally friendly transportation sector, aligning with global efforts to mitigate climate change and reduce the ecological footprint of automotive technologies.

Triton Engine Integration Considerations

The integration of improved crankshaft dynamics into the Triton Engine requires careful consideration of several factors to ensure optimal performance and compatibility. Firstly, the engine's overall design and architecture must be evaluated to determine the feasibility of incorporating new crankshaft technologies. This includes assessing the available space within the engine block, the existing bearing configurations, and the potential impact on other engine components.

Material selection plays a crucial role in crankshaft integration. Advanced materials, such as high-strength alloys or composite materials, may offer improved strength-to-weight ratios and enhanced vibration damping properties. However, their compatibility with existing engine components and manufacturing processes must be thoroughly examined to avoid potential issues during production and operation.

The lubrication system is another critical aspect to consider when integrating improved crankshaft dynamics. Enhanced oil flow patterns and optimized oil passages may be necessary to accommodate the new crankshaft design and ensure proper lubrication of all bearing surfaces. This may require modifications to the oil pump, oil galleries, and related components to maintain optimal oil pressure and distribution throughout the engine.

Balancing considerations are paramount when integrating a new crankshaft design. The improved dynamics may alter the engine's overall balance characteristics, necessitating adjustments to counterweights or the implementation of additional balancing measures. This ensures smooth operation across the entire RPM range and minimizes unwanted vibrations that could affect engine performance and longevity.

The integration process must also account for the engine's power output and torque characteristics. Changes in crankshaft dynamics can influence the engine's power delivery and efficiency. Therefore, careful tuning of the engine management system, including adjustments to ignition timing, fuel injection parameters, and valve timing, may be required to fully capitalize on the benefits of the improved crankshaft design.

Durability and reliability testing are essential components of the integration process. Extensive bench testing, followed by real-world trials, should be conducted to validate the performance improvements and ensure that the new crankshaft design meets or exceeds the engine's longevity requirements. This testing phase may reveal the need for additional modifications or refinements to other engine components to fully realize the benefits of the improved crankshaft dynamics.

Finally, manufacturing and assembly processes must be evaluated and potentially modified to accommodate the new crankshaft design. This may involve updating tooling, revising assembly procedures, and implementing new quality control measures to ensure consistent production of the integrated Triton Engine with improved crankshaft dynamics.

Material selection plays a crucial role in crankshaft integration. Advanced materials, such as high-strength alloys or composite materials, may offer improved strength-to-weight ratios and enhanced vibration damping properties. However, their compatibility with existing engine components and manufacturing processes must be thoroughly examined to avoid potential issues during production and operation.

The lubrication system is another critical aspect to consider when integrating improved crankshaft dynamics. Enhanced oil flow patterns and optimized oil passages may be necessary to accommodate the new crankshaft design and ensure proper lubrication of all bearing surfaces. This may require modifications to the oil pump, oil galleries, and related components to maintain optimal oil pressure and distribution throughout the engine.

Balancing considerations are paramount when integrating a new crankshaft design. The improved dynamics may alter the engine's overall balance characteristics, necessitating adjustments to counterweights or the implementation of additional balancing measures. This ensures smooth operation across the entire RPM range and minimizes unwanted vibrations that could affect engine performance and longevity.

The integration process must also account for the engine's power output and torque characteristics. Changes in crankshaft dynamics can influence the engine's power delivery and efficiency. Therefore, careful tuning of the engine management system, including adjustments to ignition timing, fuel injection parameters, and valve timing, may be required to fully capitalize on the benefits of the improved crankshaft design.

Durability and reliability testing are essential components of the integration process. Extensive bench testing, followed by real-world trials, should be conducted to validate the performance improvements and ensure that the new crankshaft design meets or exceeds the engine's longevity requirements. This testing phase may reveal the need for additional modifications or refinements to other engine components to fully realize the benefits of the improved crankshaft dynamics.

Finally, manufacturing and assembly processes must be evaluated and potentially modified to accommodate the new crankshaft design. This may involve updating tooling, revising assembly procedures, and implementing new quality control measures to ensure consistent production of the integrated Triton Engine with improved crankshaft dynamics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!