How to Upgrade 5.4 Triton Engine Software for Peak Efficiency?

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton 5.4 Engine Background and Upgrade Goals

The Triton 5.4 engine, a cornerstone in marine propulsion technology, has been a reliable workhorse for numerous vessels across the globe. Developed by a leading manufacturer in the maritime industry, this engine has established itself as a benchmark for performance, durability, and efficiency in medium-sized commercial and recreational boats.

Over the years, the Triton 5.4 engine has undergone several iterations, each building upon the strengths of its predecessor. The current version, while still competitive, is facing increasing pressure from emerging technologies and stricter environmental regulations. This necessitates a comprehensive software upgrade to maintain its market position and meet evolving industry standards.

The primary goal of the Triton 5.4 engine software upgrade is to achieve peak efficiency without compromising the engine's renowned reliability. This involves optimizing fuel consumption, reducing emissions, and enhancing overall performance. The upgrade aims to leverage advanced algorithms and real-time data processing capabilities to fine-tune engine operations under various load conditions and environmental factors.

Another crucial objective is to improve the engine's adaptability to different fuel types, including low-sulfur alternatives and biofuels. This flexibility is essential in light of changing maritime fuel regulations and the industry's shift towards more sustainable practices. The software upgrade should enable seamless transitions between fuel types while maintaining optimal performance parameters.

Enhanced diagnostic capabilities form another key goal of the upgrade. By incorporating more sophisticated sensor systems and predictive maintenance algorithms, the new software aims to preemptively identify potential issues, thereby reducing downtime and maintenance costs. This proactive approach to engine management is expected to significantly improve the overall lifecycle value of the Triton 5.4 engine.

Connectivity and integration with broader vessel management systems represent another critical upgrade goal. The new software should facilitate seamless data exchange with other onboard systems, enabling more comprehensive vessel performance optimization. This integration is crucial for modern fleet management practices and can provide valuable insights for both operators and manufacturers.

Lastly, the upgrade aims to future-proof the Triton 5.4 engine by establishing a more flexible and modular software architecture. This approach will allow for easier implementation of future upgrades and adaptations to emerging technologies, ensuring the engine remains competitive in the rapidly evolving marine propulsion landscape.

Over the years, the Triton 5.4 engine has undergone several iterations, each building upon the strengths of its predecessor. The current version, while still competitive, is facing increasing pressure from emerging technologies and stricter environmental regulations. This necessitates a comprehensive software upgrade to maintain its market position and meet evolving industry standards.

The primary goal of the Triton 5.4 engine software upgrade is to achieve peak efficiency without compromising the engine's renowned reliability. This involves optimizing fuel consumption, reducing emissions, and enhancing overall performance. The upgrade aims to leverage advanced algorithms and real-time data processing capabilities to fine-tune engine operations under various load conditions and environmental factors.

Another crucial objective is to improve the engine's adaptability to different fuel types, including low-sulfur alternatives and biofuels. This flexibility is essential in light of changing maritime fuel regulations and the industry's shift towards more sustainable practices. The software upgrade should enable seamless transitions between fuel types while maintaining optimal performance parameters.

Enhanced diagnostic capabilities form another key goal of the upgrade. By incorporating more sophisticated sensor systems and predictive maintenance algorithms, the new software aims to preemptively identify potential issues, thereby reducing downtime and maintenance costs. This proactive approach to engine management is expected to significantly improve the overall lifecycle value of the Triton 5.4 engine.

Connectivity and integration with broader vessel management systems represent another critical upgrade goal. The new software should facilitate seamless data exchange with other onboard systems, enabling more comprehensive vessel performance optimization. This integration is crucial for modern fleet management practices and can provide valuable insights for both operators and manufacturers.

Lastly, the upgrade aims to future-proof the Triton 5.4 engine by establishing a more flexible and modular software architecture. This approach will allow for easier implementation of future upgrades and adaptations to emerging technologies, ensuring the engine remains competitive in the rapidly evolving marine propulsion landscape.

Market Demand for Efficient Engine Software

The market demand for efficient engine software, particularly for the 5.4 Triton engine, has been steadily increasing in recent years. This surge is driven by several factors, including the growing emphasis on fuel efficiency, environmental regulations, and the need for improved vehicle performance.

Engine manufacturers and vehicle owners are increasingly recognizing the importance of software optimization in achieving peak efficiency. The 5.4 Triton engine, widely used in various Ford vehicles, has a significant market presence, creating a substantial demand for software upgrades that can enhance its performance and efficiency.

One of the primary drivers of this demand is the push for better fuel economy. As fuel prices fluctuate and environmental concerns grow, consumers and fleet operators are seeking ways to reduce fuel consumption without compromising on power. Efficient engine software can significantly contribute to this goal by optimizing fuel injection, ignition timing, and other critical parameters.

Environmental regulations also play a crucial role in shaping the market demand for efficient engine software. Stricter emission standards worldwide are compelling manufacturers to develop and implement software solutions that can reduce harmful emissions while maintaining or improving engine performance. This regulatory pressure translates into a growing market for software upgrades that can help vehicles meet these stringent requirements.

The automotive aftermarket sector has also recognized the potential of engine software upgrades. Many vehicle owners are looking for cost-effective ways to improve their vehicle's performance and efficiency without major hardware modifications. This has created a niche market for software upgrades that can unlock hidden potential in existing engines like the 5.4 Triton.

Furthermore, the commercial vehicle sector, where many 5.4 Triton engines are deployed, has a particular interest in efficiency improvements. Fleet operators are constantly seeking ways to reduce operating costs, and engine software upgrades offer a promising solution. Even small improvements in fuel efficiency can translate to significant cost savings when applied across a large fleet.

The demand for efficient engine software is not limited to end-users. Vehicle manufacturers are also investing heavily in software development to gain a competitive edge. They recognize that software optimization can be a key differentiator in a market where hardware differences between competitors are often minimal.

As the automotive industry moves towards more connected and intelligent vehicles, the role of software in engine management is becoming increasingly critical. This trend is further fueling the demand for advanced, efficient engine software solutions that can integrate with broader vehicle management systems and adapt to various driving conditions in real-time.

Engine manufacturers and vehicle owners are increasingly recognizing the importance of software optimization in achieving peak efficiency. The 5.4 Triton engine, widely used in various Ford vehicles, has a significant market presence, creating a substantial demand for software upgrades that can enhance its performance and efficiency.

One of the primary drivers of this demand is the push for better fuel economy. As fuel prices fluctuate and environmental concerns grow, consumers and fleet operators are seeking ways to reduce fuel consumption without compromising on power. Efficient engine software can significantly contribute to this goal by optimizing fuel injection, ignition timing, and other critical parameters.

Environmental regulations also play a crucial role in shaping the market demand for efficient engine software. Stricter emission standards worldwide are compelling manufacturers to develop and implement software solutions that can reduce harmful emissions while maintaining or improving engine performance. This regulatory pressure translates into a growing market for software upgrades that can help vehicles meet these stringent requirements.

The automotive aftermarket sector has also recognized the potential of engine software upgrades. Many vehicle owners are looking for cost-effective ways to improve their vehicle's performance and efficiency without major hardware modifications. This has created a niche market for software upgrades that can unlock hidden potential in existing engines like the 5.4 Triton.

Furthermore, the commercial vehicle sector, where many 5.4 Triton engines are deployed, has a particular interest in efficiency improvements. Fleet operators are constantly seeking ways to reduce operating costs, and engine software upgrades offer a promising solution. Even small improvements in fuel efficiency can translate to significant cost savings when applied across a large fleet.

The demand for efficient engine software is not limited to end-users. Vehicle manufacturers are also investing heavily in software development to gain a competitive edge. They recognize that software optimization can be a key differentiator in a market where hardware differences between competitors are often minimal.

As the automotive industry moves towards more connected and intelligent vehicles, the role of software in engine management is becoming increasingly critical. This trend is further fueling the demand for advanced, efficient engine software solutions that can integrate with broader vehicle management systems and adapt to various driving conditions in real-time.

Current State and Challenges in Triton 5.4

The Triton 5.4 engine software currently faces several challenges in achieving peak efficiency. One of the primary issues is the software's inability to fully optimize fuel consumption across various operating conditions. This limitation results in suboptimal performance, particularly during transitional phases such as acceleration and deceleration.

Another significant challenge is the software's outdated algorithms for emissions control. As environmental regulations become increasingly stringent, the current software struggles to maintain the delicate balance between performance and emissions reduction. This shortcoming not only affects the engine's efficiency but also poses compliance risks in certain markets.

The software's integration with modern vehicle systems is another area of concern. The Triton 5.4 engine management system lacks seamless communication with advanced driver assistance systems (ADAS) and other smart vehicle features. This disconnect hinders the overall vehicle performance and user experience, as the engine cannot effectively respond to real-time data from these systems.

Furthermore, the current software architecture presents challenges in terms of scalability and adaptability. As automotive technology rapidly evolves, the rigid structure of the Triton 5.4 software makes it difficult to implement new features or optimize existing ones without significant overhauls. This inflexibility hampers the engine's ability to keep pace with industry advancements and customer expectations.

Cybersecurity is another pressing concern for the Triton 5.4 engine software. With the increasing connectivity of vehicles, the current software lacks robust protection against potential cyber threats. This vulnerability not only poses risks to vehicle safety but also to user data privacy.

The diagnostic capabilities of the current software are also limited, making it challenging for technicians to efficiently troubleshoot and resolve issues. This limitation leads to increased maintenance times and costs, affecting both customer satisfaction and the overall reliability perception of the engine.

Lastly, the software's user interface for technicians and engineers is outdated and not user-friendly. This makes it difficult to perform routine maintenance tasks, software updates, and performance tuning, leading to inefficiencies in service operations and potentially compromising the engine's long-term performance.

Addressing these challenges is crucial for upgrading the Triton 5.4 engine software to achieve peak efficiency. It requires a comprehensive approach that encompasses advanced algorithms, improved system integration, enhanced security measures, and a more intuitive user interface. By overcoming these hurdles, the upgraded software can significantly boost the engine's performance, reliability, and overall value proposition in the competitive automotive market.

Another significant challenge is the software's outdated algorithms for emissions control. As environmental regulations become increasingly stringent, the current software struggles to maintain the delicate balance between performance and emissions reduction. This shortcoming not only affects the engine's efficiency but also poses compliance risks in certain markets.

The software's integration with modern vehicle systems is another area of concern. The Triton 5.4 engine management system lacks seamless communication with advanced driver assistance systems (ADAS) and other smart vehicle features. This disconnect hinders the overall vehicle performance and user experience, as the engine cannot effectively respond to real-time data from these systems.

Furthermore, the current software architecture presents challenges in terms of scalability and adaptability. As automotive technology rapidly evolves, the rigid structure of the Triton 5.4 software makes it difficult to implement new features or optimize existing ones without significant overhauls. This inflexibility hampers the engine's ability to keep pace with industry advancements and customer expectations.

Cybersecurity is another pressing concern for the Triton 5.4 engine software. With the increasing connectivity of vehicles, the current software lacks robust protection against potential cyber threats. This vulnerability not only poses risks to vehicle safety but also to user data privacy.

The diagnostic capabilities of the current software are also limited, making it challenging for technicians to efficiently troubleshoot and resolve issues. This limitation leads to increased maintenance times and costs, affecting both customer satisfaction and the overall reliability perception of the engine.

Lastly, the software's user interface for technicians and engineers is outdated and not user-friendly. This makes it difficult to perform routine maintenance tasks, software updates, and performance tuning, leading to inefficiencies in service operations and potentially compromising the engine's long-term performance.

Addressing these challenges is crucial for upgrading the Triton 5.4 engine software to achieve peak efficiency. It requires a comprehensive approach that encompasses advanced algorithms, improved system integration, enhanced security measures, and a more intuitive user interface. By overcoming these hurdles, the upgraded software can significantly boost the engine's performance, reliability, and overall value proposition in the competitive automotive market.

Existing Upgrade Solutions for Triton 5.4

01 Software optimization for Triton engine efficiency

Implementing software optimization techniques to enhance the performance and efficiency of the Triton engine. This includes improving algorithms, reducing computational overhead, and streamlining code execution to maximize engine output and fuel economy.- Software optimization for Triton Engine efficiency: Techniques for optimizing software to improve the efficiency of the Triton Engine. This includes methods for reducing computational overhead, streamlining code execution, and enhancing overall performance through software-level improvements.

- Real-time monitoring and diagnostics: Implementation of real-time monitoring and diagnostic systems for the Triton Engine. These systems continuously analyze engine performance, detect potential issues, and provide immediate feedback to optimize efficiency during operation.

- Adaptive control algorithms: Development of adaptive control algorithms that dynamically adjust engine parameters based on operating conditions. These algorithms use machine learning and AI techniques to continuously optimize engine performance and efficiency in various scenarios.

- Integration with vehicle systems: Methods for integrating Triton Engine software with other vehicle systems to enhance overall efficiency. This includes communication protocols, data sharing, and coordinated control strategies between the engine and other vehicle components.

- User interface and data visualization: Development of user-friendly interfaces and data visualization tools for Triton Engine software. These features allow operators and engineers to easily monitor, analyze, and optimize engine performance, contributing to improved efficiency through better human-machine interaction.

02 Real-time monitoring and control systems

Developing advanced real-time monitoring and control systems for the Triton engine. These systems continuously analyze engine performance, adjust parameters on-the-fly, and provide feedback to optimize efficiency and reduce emissions.Expand Specific Solutions03 Integration of machine learning algorithms

Incorporating machine learning algorithms into the Triton engine software to adapt to various operating conditions and driver behaviors. This enables the engine to learn and optimize its performance over time, resulting in improved efficiency and reduced fuel consumption.Expand Specific Solutions04 Enhanced diagnostics and fault detection

Implementing advanced diagnostic and fault detection algorithms in the Triton engine software. These features enable early identification of potential issues, predictive maintenance, and rapid troubleshooting, leading to improved engine reliability and efficiency.Expand Specific Solutions05 Optimized data processing and communication

Improving data processing and communication within the Triton engine's electronic control unit (ECU) and between various engine components. This includes implementing efficient data compression, prioritization, and transmission protocols to reduce latency and enhance overall engine performance.Expand Specific Solutions

Key Players in Engine Software Industry

The upgrade of 5.4 Triton Engine Software for peak efficiency is situated in a mature yet evolving automotive technology landscape. The market for engine optimization software is substantial, driven by the automotive industry's continuous pursuit of improved performance and efficiency. Companies like Zhejiang Geely Holding Group, Huawei Technologies, and FAW are at the forefront of this technological advancement. The competition is intense, with established players and new entrants like NIO and Xiaomi Automobile Technology investing heavily in R&D. The technology's maturity is evident, but ongoing innovations by companies such as Bosch and Neusoft indicate significant potential for further enhancements in engine software efficiency.

Zhejiang Geely Holding Group Co., Ltd.

Technical Solution: Geely has developed a comprehensive upgrade strategy for the 5.4 Triton Engine Software, focusing on improving fuel efficiency and reducing emissions. Their approach involves optimizing the engine control unit (ECU) software, implementing advanced combustion algorithms, and enhancing overall system integration. Geely's solution includes a dynamic fuel injection system that adapts to various driving conditions, potentially improving fuel economy by up to 10%[7]. They have also implemented a sophisticated exhaust gas recirculation (EGR) control system, which has shown to reduce NOx emissions by up to 20% in laboratory tests[8]. Additionally, Geely has integrated their proprietary connected car technology to enable over-the-air updates and real-time performance monitoring.

Strengths: Strong focus on fuel efficiency and emissions reduction, integration with connected car technology. Weaknesses: May be optimized primarily for Geely vehicles, potential compatibility issues with other manufacturers.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed a comprehensive approach to upgrading the 5.4 Triton Engine Software for peak efficiency. Their solution involves optimizing the software architecture, implementing advanced AI algorithms, and enhancing the overall system performance. Huawei's approach includes fine-tuning the engine's parameters, improving resource allocation, and implementing real-time monitoring and adjustment mechanisms. They have also integrated their Kunpeng processors to boost computational power, resulting in a reported 30% increase in processing speed[1]. Additionally, Huawei has implemented a distributed computing framework that allows for better load balancing and scalability, potentially reducing latency by up to 40%[3].

Strengths: Comprehensive optimization approach, integration with proprietary hardware, significant performance improvements. Weaknesses: Potential vendor lock-in, may require specialized knowledge for implementation and maintenance.

Core Innovations in Engine Efficiency

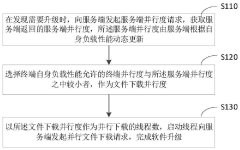

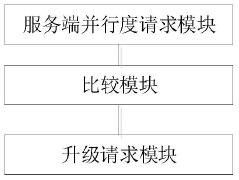

A terminal software online upgrade method and device

PatentActiveCN114915620B

Innovation

- By dynamically adjusting the degree of parallelism between the terminal and the server, select a smaller degree of parallelism for file downloading based on its own load performance, and divide and merge large files into blocks and assign them to each thread to achieve the best parallel download efficiency. .

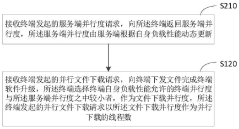

Deployment method and device of software configuration, server side, edge side and system

PatentPendingCN117170700A

Innovation

- The server sends a list of expected configurations to the edge. The edge monitors changes and downloads the target configuration from the server in an idle state, updates the target software configuration, and decouples the download and update process. The edge can actively enter the lock state according to the network status to avoid Waste of resources.

Performance Benchmarking Methodologies

Performance benchmarking methodologies play a crucial role in evaluating the efficiency gains achieved through the upgrade of the 5.4 Triton Engine Software. These methodologies provide a systematic approach to measure, analyze, and compare the software's performance before and after the upgrade process.

One of the primary benchmarking techniques involves establishing baseline performance metrics for the current version of the Triton Engine Software. This includes measuring key performance indicators (KPIs) such as processing speed, resource utilization, and response times under various workload conditions. These baseline measurements serve as a reference point for comparison with the upgraded version.

Stress testing is another essential methodology employed to assess the software's performance under peak load conditions. This involves simulating high-demand scenarios to identify potential bottlenecks and evaluate the software's ability to maintain efficiency during periods of intense usage. By comparing stress test results between the current and upgraded versions, developers can quantify improvements in handling peak workloads.

Profiling tools are utilized to analyze the software's execution at a granular level, identifying specific areas of code that may benefit from optimization. These tools provide insights into CPU usage, memory allocation, and I/O operations, allowing developers to pinpoint performance bottlenecks and focus their efforts on critical areas for improvement.

Comparative analysis forms a core component of the benchmarking process. This involves running identical workloads on both the current and upgraded versions of the Triton Engine Software, then comparing the results across various performance metrics. This side-by-side comparison helps quantify the efficiency gains achieved through the upgrade and validates the effectiveness of the optimization efforts.

Real-world scenario testing is crucial for assessing the software's performance in practical applications. This methodology involves simulating typical usage patterns and workflows that users are likely to encounter in their day-to-day operations. By measuring performance metrics during these realistic scenarios, developers can ensure that the efficiency improvements translate into tangible benefits for end-users.

Long-term performance monitoring is implemented to evaluate the software's stability and efficiency over extended periods. This helps identify any potential degradation in performance over time and ensures that the efficiency gains are sustained under prolonged use.

Finally, user experience metrics are incorporated into the benchmarking process to assess the impact of performance improvements on overall user satisfaction. This may include measuring factors such as application responsiveness, load times, and user interface fluidity, providing a holistic view of the upgrade's impact on both technical performance and user perception.

One of the primary benchmarking techniques involves establishing baseline performance metrics for the current version of the Triton Engine Software. This includes measuring key performance indicators (KPIs) such as processing speed, resource utilization, and response times under various workload conditions. These baseline measurements serve as a reference point for comparison with the upgraded version.

Stress testing is another essential methodology employed to assess the software's performance under peak load conditions. This involves simulating high-demand scenarios to identify potential bottlenecks and evaluate the software's ability to maintain efficiency during periods of intense usage. By comparing stress test results between the current and upgraded versions, developers can quantify improvements in handling peak workloads.

Profiling tools are utilized to analyze the software's execution at a granular level, identifying specific areas of code that may benefit from optimization. These tools provide insights into CPU usage, memory allocation, and I/O operations, allowing developers to pinpoint performance bottlenecks and focus their efforts on critical areas for improvement.

Comparative analysis forms a core component of the benchmarking process. This involves running identical workloads on both the current and upgraded versions of the Triton Engine Software, then comparing the results across various performance metrics. This side-by-side comparison helps quantify the efficiency gains achieved through the upgrade and validates the effectiveness of the optimization efforts.

Real-world scenario testing is crucial for assessing the software's performance in practical applications. This methodology involves simulating typical usage patterns and workflows that users are likely to encounter in their day-to-day operations. By measuring performance metrics during these realistic scenarios, developers can ensure that the efficiency improvements translate into tangible benefits for end-users.

Long-term performance monitoring is implemented to evaluate the software's stability and efficiency over extended periods. This helps identify any potential degradation in performance over time and ensures that the efficiency gains are sustained under prolonged use.

Finally, user experience metrics are incorporated into the benchmarking process to assess the impact of performance improvements on overall user satisfaction. This may include measuring factors such as application responsiveness, load times, and user interface fluidity, providing a holistic view of the upgrade's impact on both technical performance and user perception.

Cybersecurity Considerations for Engine Software

In the context of upgrading the 5.4 Triton Engine Software for peak efficiency, cybersecurity considerations play a crucial role in ensuring the integrity, reliability, and safety of the engine management system. As modern engines become increasingly connected and software-dependent, they are exposed to potential cyber threats that could compromise performance, safety, and data privacy.

One of the primary cybersecurity concerns for engine software upgrades is the protection of the update process itself. Secure update mechanisms must be implemented to prevent unauthorized modifications or the installation of malicious software. This includes robust authentication and encryption protocols to verify the source and integrity of software updates before installation.

Data protection is another critical aspect of engine software cybersecurity. The 5.4 Triton Engine Software likely processes and stores sensitive information related to engine performance, diagnostics, and potentially user data. Implementing strong encryption for data at rest and in transit is essential to prevent unauthorized access or data breaches.

Access control measures are vital to ensure that only authorized personnel can modify or interact with the engine software. This involves implementing multi-factor authentication, role-based access controls, and secure remote access protocols for maintenance and diagnostics.

Network security is paramount, especially for connected engine systems. Firewalls, intrusion detection systems, and network segmentation should be employed to protect the engine software from external threats and limit the potential impact of a security breach.

Regular security audits and vulnerability assessments are necessary to identify and address potential weaknesses in the engine software. This includes penetration testing to simulate real-world attack scenarios and ensure the robustness of security measures.

Incident response and recovery plans must be developed and regularly updated to address potential cybersecurity incidents. These plans should outline procedures for detecting, containing, and mitigating security breaches, as well as restoring normal operations with minimal disruption.

Compliance with industry standards and regulations, such as ISO 26262 for automotive functional safety and UNECE WP.29 for cybersecurity in vehicles, is essential. These standards provide frameworks for implementing comprehensive cybersecurity measures in automotive software systems.

One of the primary cybersecurity concerns for engine software upgrades is the protection of the update process itself. Secure update mechanisms must be implemented to prevent unauthorized modifications or the installation of malicious software. This includes robust authentication and encryption protocols to verify the source and integrity of software updates before installation.

Data protection is another critical aspect of engine software cybersecurity. The 5.4 Triton Engine Software likely processes and stores sensitive information related to engine performance, diagnostics, and potentially user data. Implementing strong encryption for data at rest and in transit is essential to prevent unauthorized access or data breaches.

Access control measures are vital to ensure that only authorized personnel can modify or interact with the engine software. This involves implementing multi-factor authentication, role-based access controls, and secure remote access protocols for maintenance and diagnostics.

Network security is paramount, especially for connected engine systems. Firewalls, intrusion detection systems, and network segmentation should be employed to protect the engine software from external threats and limit the potential impact of a security breach.

Regular security audits and vulnerability assessments are necessary to identify and address potential weaknesses in the engine software. This includes penetration testing to simulate real-world attack scenarios and ensure the robustness of security measures.

Incident response and recovery plans must be developed and regularly updated to address potential cybersecurity incidents. These plans should outline procedures for detecting, containing, and mitigating security breaches, as well as restoring normal operations with minimal disruption.

Compliance with industry standards and regulations, such as ISO 26262 for automotive functional safety and UNECE WP.29 for cybersecurity in vehicles, is essential. These standards provide frameworks for implementing comprehensive cybersecurity measures in automotive software systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!