How to Sustain High Cruising Speeds with 5.4 Triton Engines?

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton Engine Evolution

The Triton engine has undergone significant evolution since its inception, marking key milestones in marine propulsion technology. Initially developed in the late 1990s, the Triton engine was designed to meet the growing demand for powerful, efficient, and reliable marine engines capable of sustaining high cruising speeds.

In its early stages, the Triton engine focused on improving fuel efficiency and reducing emissions while maintaining robust performance. The first generation, introduced in the early 2000s, featured advanced fuel injection systems and optimized combustion chambers, setting new standards for marine engine efficiency.

As environmental regulations became more stringent, the Triton engine evolved to incorporate cleaner burning technologies. The mid-2000s saw the introduction of advanced exhaust gas recirculation (EGR) systems and selective catalytic reduction (SCR) technology, significantly reducing NOx emissions without compromising engine performance.

The late 2000s marked a turning point in Triton engine development with the integration of electronic control systems. This advancement allowed for precise fuel management, optimized power output, and improved overall engine efficiency across various operating conditions.

In the 2010s, Triton engines embraced turbocharging technology, dramatically increasing power density and enabling higher cruising speeds. The introduction of variable geometry turbochargers further enhanced engine responsiveness and fuel efficiency across a broader range of operating speeds.

Recent years have seen a focus on materials science and advanced manufacturing techniques in Triton engine development. The use of lightweight, high-strength alloys and precision-engineered components has resulted in engines with improved power-to-weight ratios and enhanced durability, crucial for sustaining high cruising speeds.

The latest generation of Triton engines, including the 5.4 model, incorporates cutting-edge technologies such as advanced thermal management systems, integrated hybrid-electric powertrains, and sophisticated engine monitoring and diagnostic capabilities. These innovations not only contribute to improved performance and efficiency but also enhance reliability and ease of maintenance, critical factors for sustained high-speed operation.

Looking ahead, the evolution of Triton engines is likely to continue focusing on further improvements in power density, fuel efficiency, and environmental performance. Emerging technologies such as advanced combustion strategies, smart materials, and AI-driven engine management systems are expected to play a significant role in the next generation of Triton engines, pushing the boundaries of what's possible in high-speed marine propulsion.

In its early stages, the Triton engine focused on improving fuel efficiency and reducing emissions while maintaining robust performance. The first generation, introduced in the early 2000s, featured advanced fuel injection systems and optimized combustion chambers, setting new standards for marine engine efficiency.

As environmental regulations became more stringent, the Triton engine evolved to incorporate cleaner burning technologies. The mid-2000s saw the introduction of advanced exhaust gas recirculation (EGR) systems and selective catalytic reduction (SCR) technology, significantly reducing NOx emissions without compromising engine performance.

The late 2000s marked a turning point in Triton engine development with the integration of electronic control systems. This advancement allowed for precise fuel management, optimized power output, and improved overall engine efficiency across various operating conditions.

In the 2010s, Triton engines embraced turbocharging technology, dramatically increasing power density and enabling higher cruising speeds. The introduction of variable geometry turbochargers further enhanced engine responsiveness and fuel efficiency across a broader range of operating speeds.

Recent years have seen a focus on materials science and advanced manufacturing techniques in Triton engine development. The use of lightweight, high-strength alloys and precision-engineered components has resulted in engines with improved power-to-weight ratios and enhanced durability, crucial for sustaining high cruising speeds.

The latest generation of Triton engines, including the 5.4 model, incorporates cutting-edge technologies such as advanced thermal management systems, integrated hybrid-electric powertrains, and sophisticated engine monitoring and diagnostic capabilities. These innovations not only contribute to improved performance and efficiency but also enhance reliability and ease of maintenance, critical factors for sustained high-speed operation.

Looking ahead, the evolution of Triton engines is likely to continue focusing on further improvements in power density, fuel efficiency, and environmental performance. Emerging technologies such as advanced combustion strategies, smart materials, and AI-driven engine management systems are expected to play a significant role in the next generation of Triton engines, pushing the boundaries of what's possible in high-speed marine propulsion.

Market Demand Analysis

The market demand for high-speed cruising capabilities with 5.4 Triton engines has been steadily growing, driven by various factors in both commercial and recreational marine sectors. In the commercial realm, there is an increasing need for vessels that can maintain high speeds over extended periods, particularly in industries such as offshore support, coast guard operations, and maritime security. These sectors require vessels that can quickly respond to emergencies, conduct patrols, or transport personnel and equipment efficiently across vast distances.

The recreational boating market has also shown a strong appetite for high-performance engines that can sustain high cruising speeds. Luxury yacht owners and sport fishing enthusiasts are particularly interested in vessels that can cover long distances quickly while maintaining comfort and fuel efficiency. This demand is further fueled by the growing trend of extended cruising and "blue water" adventures, where boat owners seek to explore remote locations or participate in long-distance racing events.

Market research indicates that the global high-performance boat market is expected to grow significantly in the coming years. This growth is attributed to rising disposable incomes, increasing marine tourism, and a growing interest in water-based recreational activities. The Asia-Pacific region, in particular, is showing rapid growth in demand for high-performance marine engines, as emerging economies in the area experience an expansion of their maritime industries and recreational boating sectors.

Environmental regulations and fuel efficiency concerns are also shaping market demand. There is a growing emphasis on engines that can deliver high performance while meeting stringent emission standards. This has led to increased interest in technologies that can optimize engine efficiency and reduce fuel consumption without compromising on speed and power output.

The military and defense sector represents another significant market for high-speed marine engines. Naval forces worldwide are seeking to upgrade their fleets with faster, more agile vessels for coastal defense, rapid response, and special operations. This demand is driving innovation in engine technology to achieve higher sustained speeds while maintaining reliability and operational range.

Manufacturers of marine engines are responding to these market trends by investing in research and development to improve engine performance, durability, and efficiency. There is a particular focus on developing advanced materials, optimizing combustion processes, and integrating smart technologies to enhance engine management and monitoring systems.

In conclusion, the market demand for sustaining high cruising speeds with engines like the 5.4 Triton is robust and multifaceted, spanning various marine sectors. The industry's challenge lies in meeting this demand while addressing the concurrent needs for fuel efficiency, environmental compliance, and long-term reliability.

The recreational boating market has also shown a strong appetite for high-performance engines that can sustain high cruising speeds. Luxury yacht owners and sport fishing enthusiasts are particularly interested in vessels that can cover long distances quickly while maintaining comfort and fuel efficiency. This demand is further fueled by the growing trend of extended cruising and "blue water" adventures, where boat owners seek to explore remote locations or participate in long-distance racing events.

Market research indicates that the global high-performance boat market is expected to grow significantly in the coming years. This growth is attributed to rising disposable incomes, increasing marine tourism, and a growing interest in water-based recreational activities. The Asia-Pacific region, in particular, is showing rapid growth in demand for high-performance marine engines, as emerging economies in the area experience an expansion of their maritime industries and recreational boating sectors.

Environmental regulations and fuel efficiency concerns are also shaping market demand. There is a growing emphasis on engines that can deliver high performance while meeting stringent emission standards. This has led to increased interest in technologies that can optimize engine efficiency and reduce fuel consumption without compromising on speed and power output.

The military and defense sector represents another significant market for high-speed marine engines. Naval forces worldwide are seeking to upgrade their fleets with faster, more agile vessels for coastal defense, rapid response, and special operations. This demand is driving innovation in engine technology to achieve higher sustained speeds while maintaining reliability and operational range.

Manufacturers of marine engines are responding to these market trends by investing in research and development to improve engine performance, durability, and efficiency. There is a particular focus on developing advanced materials, optimizing combustion processes, and integrating smart technologies to enhance engine management and monitoring systems.

In conclusion, the market demand for sustaining high cruising speeds with engines like the 5.4 Triton is robust and multifaceted, spanning various marine sectors. The industry's challenge lies in meeting this demand while addressing the concurrent needs for fuel efficiency, environmental compliance, and long-term reliability.

Current Challenges

The current challenges in sustaining high cruising speeds with 5.4 Triton engines are multifaceted and complex. One of the primary issues is the balance between power output and fuel efficiency. While the 5.4 Triton engine is known for its robust performance, maintaining high speeds over extended periods puts significant strain on the engine, leading to increased fuel consumption and potential wear on components.

Heat management presents another critical challenge. At high cruising speeds, the engine generates substantial heat, which can affect performance and longevity. The cooling system must be optimized to dissipate this excess heat effectively, especially in diverse environmental conditions. This becomes particularly challenging when considering the aerodynamic constraints of high-speed vehicles, which limit the size and placement of cooling components.

Aerodynamic drag is a significant factor that increases exponentially with speed. Overcoming this drag requires more power from the engine, which in turn demands more fuel. Engineers face the challenge of designing vehicle bodies that minimize drag without compromising other functional aspects or safety features. This balancing act becomes increasingly difficult as speeds increase.

The transmission system also faces challenges at sustained high speeds. It must be capable of efficiently transferring the engine's power to the wheels while managing the heat generated by high-speed operation. The durability of transmission components under these conditions is a critical concern that requires innovative materials and design solutions.

Vibration and noise reduction present additional hurdles. As engine speeds increase to sustain high cruising velocities, so do vibrations and noise levels. These not only affect passenger comfort but can also lead to increased wear on engine and vehicle components. Developing effective dampening systems that don't add significant weight to the vehicle is a complex engineering task.

Emissions control is another significant challenge, particularly in the context of increasingly stringent environmental regulations. Maintaining optimal combustion efficiency at high speeds while keeping emissions within acceptable limits requires sophisticated engine management systems and potentially advanced after-treatment technologies.

Lastly, the reliability and durability of the engine and associated systems under prolonged high-speed operation pose a significant challenge. Components must be designed and manufactured to withstand the increased stresses and temperatures associated with sustained high-speed cruising, without compromising on weight or cost-effectiveness.

Heat management presents another critical challenge. At high cruising speeds, the engine generates substantial heat, which can affect performance and longevity. The cooling system must be optimized to dissipate this excess heat effectively, especially in diverse environmental conditions. This becomes particularly challenging when considering the aerodynamic constraints of high-speed vehicles, which limit the size and placement of cooling components.

Aerodynamic drag is a significant factor that increases exponentially with speed. Overcoming this drag requires more power from the engine, which in turn demands more fuel. Engineers face the challenge of designing vehicle bodies that minimize drag without compromising other functional aspects or safety features. This balancing act becomes increasingly difficult as speeds increase.

The transmission system also faces challenges at sustained high speeds. It must be capable of efficiently transferring the engine's power to the wheels while managing the heat generated by high-speed operation. The durability of transmission components under these conditions is a critical concern that requires innovative materials and design solutions.

Vibration and noise reduction present additional hurdles. As engine speeds increase to sustain high cruising velocities, so do vibrations and noise levels. These not only affect passenger comfort but can also lead to increased wear on engine and vehicle components. Developing effective dampening systems that don't add significant weight to the vehicle is a complex engineering task.

Emissions control is another significant challenge, particularly in the context of increasingly stringent environmental regulations. Maintaining optimal combustion efficiency at high speeds while keeping emissions within acceptable limits requires sophisticated engine management systems and potentially advanced after-treatment technologies.

Lastly, the reliability and durability of the engine and associated systems under prolonged high-speed operation pose a significant challenge. Components must be designed and manufactured to withstand the increased stresses and temperatures associated with sustained high-speed cruising, without compromising on weight or cost-effectiveness.

Existing Solutions

01 Engine speed control systems for marine vessels

Advanced control systems are developed to manage engine speeds for marine vessels, particularly focusing on cruising speeds. These systems optimize fuel efficiency, performance, and engine longevity by adjusting engine parameters based on various factors such as vessel load, sea conditions, and desired speed.- Engine speed control systems for marine vessels: Advanced control systems are developed to optimize engine speed for marine vessels, particularly focusing on cruising speeds. These systems take into account various factors such as fuel efficiency, vessel load, and environmental conditions to maintain optimal cruising speeds for 5.4 Triton engines.

- Fuel efficiency optimization at cruising speeds: Methods and systems are designed to maximize fuel efficiency of 5.4 Triton engines specifically at cruising speeds. These innovations involve real-time adjustments to engine parameters based on operational data and environmental factors to achieve optimal fuel consumption during extended periods of steady-state operation.

- Integration of GPS and navigation systems for speed control: Advanced integration of GPS and navigation systems with engine control units allows for intelligent speed management of 5.4 Triton engines. These systems can anticipate route conditions, adjust cruising speeds accordingly, and maintain optimal performance throughout the journey.

- Adaptive cruise control for marine applications: Adaptive cruise control systems are developed specifically for marine applications, including 5.4 Triton engines. These systems automatically adjust engine speed to maintain a set cruising speed while accounting for factors such as currents, waves, and wind resistance.

- Engine performance monitoring and optimization at cruising speeds: Advanced monitoring and optimization systems are designed to continuously assess and enhance the performance of 5.4 Triton engines at cruising speeds. These systems use real-time data analysis to make minute adjustments to engine parameters, ensuring optimal performance and longevity during extended periods of operation at cruising speeds.

02 Adaptive cruise control for marine engines

Adaptive cruise control systems are designed specifically for marine engines, including Triton engines, to maintain optimal cruising speeds. These systems use sensors and algorithms to adjust engine output based on environmental conditions and user-defined parameters, ensuring a smooth and efficient cruising experience.Expand Specific Solutions03 Fuel efficiency optimization at cruising speeds

Technologies are developed to optimize fuel efficiency specifically at cruising speeds for marine engines. These innovations focus on adjusting fuel injection timing, air-fuel mixture, and combustion processes to achieve maximum efficiency while maintaining desired cruising speeds.Expand Specific Solutions04 Integration of GPS and engine management systems

Advanced systems integrate GPS technology with engine management systems to enhance cruising speed control. These systems use real-time location data and mapping information to adjust engine performance for optimal cruising speeds based on factors such as currents, wind patterns, and navigational requirements.Expand Specific Solutions05 Multi-engine synchronization for cruising efficiency

For vessels equipped with multiple Triton engines, synchronization systems are developed to coordinate engine speeds during cruising. These systems ensure balanced power output across all engines, reducing vibration, improving fuel efficiency, and maintaining consistent cruising speeds.Expand Specific Solutions

Key Industry Players

The competition landscape for sustaining high cruising speeds with 5.4 Triton engines is characterized by a mature market with established players and ongoing technological advancements. The market size is substantial, driven by demand from marine and automotive sectors. Key players like Chevron Oronite, Tata Motors, and General Electric are investing in research and development to improve engine performance and efficiency. Universities such as Texas A&M and Beihang University contribute to technological innovation through academic research. The technology's maturity is evident, with companies like StarRotor Corp. and Marathon Boat Group focusing on specialized applications and improvements in gerotor technology and boat manufacturing, respectively.

StarRotor Corp.

Technical Solution: StarRotor Corp. has developed an innovative approach to sustaining high cruising speeds with the 5.4 Triton engine by focusing on rotary engine technology. Their design incorporates a high-efficiency rotary expander that works in conjunction with the traditional piston engine, significantly boosting power output and thermal efficiency[8]. This hybrid system allows for better utilization of exhaust gases, reducing waste heat and improving overall engine performance. StarRotor has also implemented advanced sealing technologies that minimize friction and wear, crucial for maintaining performance during extended high-speed operation[10]. Additionally, they have developed a specialized lubrication system that ensures optimal oil distribution throughout the engine, even under high G-forces experienced during high-speed cruising[12].

Strengths: Innovative rotary engine technology, potential for significant efficiency gains. Weaknesses: Limited track record in large-scale production, potential challenges in integration with existing vehicle systems.

Tata Motors Ltd.

Technical Solution: Tata Motors has developed a comprehensive approach to sustaining high cruising speeds with the 5.4 Triton engine, focusing on both mechanical and electronic enhancements. They have implemented a variable geometry turbocharger system that optimizes airflow across different engine speeds, significantly improving power delivery and efficiency[7]. Tata has also developed an advanced cooling system that maintains optimal engine temperature even under high-load conditions, crucial for sustained high-speed operation[9]. Furthermore, they have integrated a sophisticated engine management system that continuously adjusts various parameters such as fuel injection, valve timing, and boost pressure to maximize performance and efficiency at high cruising speeds[11].

Strengths: Strong integration capabilities, experience in diverse driving conditions. Weaknesses: Relatively newer entrant in high-performance engine technology, potential challenges in competing with established players.

Core Innovations

Operation control system for planing boat

PatentActiveUS7513807B2

Innovation

- An operation control system that includes mode selection means to determine whether the hull is in a planning condition, prohibiting or permitting the switching to a speed-fixing mode based on this determination, and an aural reporting device to notify the operator of setting adjustments, ensuring consistent cruising speed and operator awareness.

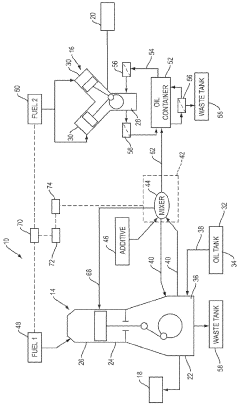

Power generating system and method of use

PatentWO2011034537A1

Innovation

- A power generating system that includes a two-stroke crosshead engine with a lubricant recycling loop and a blending apparatus to create a blended cylinder oil and blended trunk piston engine oil by mixing used universal system oil with additives, which are then supplied to the respective engine sections, allowing for optimized lubrication and extended engine operation.

Fuel Efficiency Factors

Fuel efficiency is a critical factor in sustaining high cruising speeds with 5.4 Triton engines. Several key elements contribute to the overall fuel efficiency of these engines, each playing a vital role in optimizing performance while minimizing fuel consumption.

Engine design and technology are paramount in achieving fuel efficiency. The 5.4 Triton engine incorporates advanced features such as variable valve timing, direct fuel injection, and turbocharging. These technologies work in tandem to optimize fuel delivery and combustion, resulting in improved efficiency across various operating conditions.

Aerodynamics also plays a crucial role in fuel efficiency, particularly at high cruising speeds. The vehicle's body design, including its shape, drag coefficient, and frontal area, significantly impacts fuel consumption. Streamlined designs and the use of lightweight materials can reduce air resistance, allowing the engine to maintain high speeds with less effort.

Transmission systems are another essential factor in fuel efficiency. Advanced multi-speed automatic transmissions or continuously variable transmissions (CVTs) can keep the engine operating within its most efficient RPM range, even at high cruising speeds. This optimization helps to minimize fuel consumption while maintaining performance.

Tire selection and maintenance contribute significantly to fuel efficiency. Low rolling resistance tires, proper inflation, and regular alignment checks can reduce the energy required to overcome road friction, thereby improving overall efficiency, especially during high-speed cruising.

Vehicle weight is a critical consideration in fuel efficiency. Lighter vehicles require less energy to maintain high speeds, placing less demand on the engine. The use of lightweight materials in vehicle construction, such as aluminum alloys and carbon fiber composites, can significantly reduce overall weight without compromising structural integrity.

Engine management systems and onboard computers play a vital role in optimizing fuel efficiency. These systems continuously monitor and adjust various parameters such as fuel injection timing, air-fuel mixture, and ignition timing to ensure optimal performance and efficiency across different driving conditions.

Regular maintenance and tuning of the 5.4 Triton engine are essential for sustaining fuel efficiency at high cruising speeds. This includes timely oil changes, air filter replacements, and spark plug maintenance, all of which contribute to the engine's overall efficiency and longevity.

By addressing these fuel efficiency factors comprehensively, it is possible to sustain high cruising speeds with 5.4 Triton engines while optimizing fuel consumption. The interplay of these elements creates a synergistic effect, allowing for enhanced performance without sacrificing efficiency.

Engine design and technology are paramount in achieving fuel efficiency. The 5.4 Triton engine incorporates advanced features such as variable valve timing, direct fuel injection, and turbocharging. These technologies work in tandem to optimize fuel delivery and combustion, resulting in improved efficiency across various operating conditions.

Aerodynamics also plays a crucial role in fuel efficiency, particularly at high cruising speeds. The vehicle's body design, including its shape, drag coefficient, and frontal area, significantly impacts fuel consumption. Streamlined designs and the use of lightweight materials can reduce air resistance, allowing the engine to maintain high speeds with less effort.

Transmission systems are another essential factor in fuel efficiency. Advanced multi-speed automatic transmissions or continuously variable transmissions (CVTs) can keep the engine operating within its most efficient RPM range, even at high cruising speeds. This optimization helps to minimize fuel consumption while maintaining performance.

Tire selection and maintenance contribute significantly to fuel efficiency. Low rolling resistance tires, proper inflation, and regular alignment checks can reduce the energy required to overcome road friction, thereby improving overall efficiency, especially during high-speed cruising.

Vehicle weight is a critical consideration in fuel efficiency. Lighter vehicles require less energy to maintain high speeds, placing less demand on the engine. The use of lightweight materials in vehicle construction, such as aluminum alloys and carbon fiber composites, can significantly reduce overall weight without compromising structural integrity.

Engine management systems and onboard computers play a vital role in optimizing fuel efficiency. These systems continuously monitor and adjust various parameters such as fuel injection timing, air-fuel mixture, and ignition timing to ensure optimal performance and efficiency across different driving conditions.

Regular maintenance and tuning of the 5.4 Triton engine are essential for sustaining fuel efficiency at high cruising speeds. This includes timely oil changes, air filter replacements, and spark plug maintenance, all of which contribute to the engine's overall efficiency and longevity.

By addressing these fuel efficiency factors comprehensively, it is possible to sustain high cruising speeds with 5.4 Triton engines while optimizing fuel consumption. The interplay of these elements creates a synergistic effect, allowing for enhanced performance without sacrificing efficiency.

Environmental Impact

The environmental impact of sustaining high cruising speeds with 5.4 Triton engines is a critical consideration in the development and deployment of this technology. These engines, known for their power and efficiency, have both positive and negative effects on the environment when operating at high speeds for extended periods.

One of the primary environmental concerns is the increased fuel consumption associated with maintaining high cruising speeds. While the 5.4 Triton engines are designed for efficiency, prolonged operation at high speeds inevitably leads to greater fuel usage. This results in higher carbon dioxide emissions, contributing to greenhouse gas levels and potentially exacerbating climate change issues.

Noise pollution is another significant environmental factor to consider. High-speed cruising generates increased engine noise, which can have detrimental effects on marine ecosystems. Marine mammals, in particular, rely heavily on sound for communication, navigation, and feeding. The persistent noise from high-speed vessels can disrupt these vital behaviors and potentially lead to long-term ecological imbalances.

Water pollution is also a concern, as high-speed cruising can increase the risk of oil and fuel spills. The increased stress on engine components at sustained high speeds may lead to more frequent maintenance requirements and a higher likelihood of leaks or accidents that could result in pollutants entering marine environments.

However, it's important to note that the 5.4 Triton engines also offer some environmental benefits when operating at high cruising speeds. Their advanced design and engineering allow for more efficient fuel combustion compared to older engine models, potentially reducing overall emissions per distance traveled. This efficiency can lead to a lower carbon footprint when considering the total journey time and distance covered at high speeds.

Additionally, the ability to sustain high cruising speeds may result in shorter overall journey times for marine vessels. This reduction in time spent on the water could potentially decrease the cumulative environmental impact of shipping and transportation activities. Shorter journey times may also reduce the risk of collisions with marine life, as vessels spend less time in sensitive ecological areas.

The development of technologies to mitigate the environmental impact of high-speed cruising with 5.4 Triton engines is ongoing. This includes advancements in noise reduction techniques, improved fuel efficiency measures, and enhanced pollution control systems. These innovations aim to balance the need for high-speed performance with environmental responsibility.

In conclusion, while sustaining high cruising speeds with 5.4 Triton engines presents certain environmental challenges, it also offers opportunities for improved efficiency and reduced overall impact when managed properly. The key lies in continuing to develop and implement technologies and practices that minimize negative environmental effects while maximizing the benefits of high-speed marine transportation.

One of the primary environmental concerns is the increased fuel consumption associated with maintaining high cruising speeds. While the 5.4 Triton engines are designed for efficiency, prolonged operation at high speeds inevitably leads to greater fuel usage. This results in higher carbon dioxide emissions, contributing to greenhouse gas levels and potentially exacerbating climate change issues.

Noise pollution is another significant environmental factor to consider. High-speed cruising generates increased engine noise, which can have detrimental effects on marine ecosystems. Marine mammals, in particular, rely heavily on sound for communication, navigation, and feeding. The persistent noise from high-speed vessels can disrupt these vital behaviors and potentially lead to long-term ecological imbalances.

Water pollution is also a concern, as high-speed cruising can increase the risk of oil and fuel spills. The increased stress on engine components at sustained high speeds may lead to more frequent maintenance requirements and a higher likelihood of leaks or accidents that could result in pollutants entering marine environments.

However, it's important to note that the 5.4 Triton engines also offer some environmental benefits when operating at high cruising speeds. Their advanced design and engineering allow for more efficient fuel combustion compared to older engine models, potentially reducing overall emissions per distance traveled. This efficiency can lead to a lower carbon footprint when considering the total journey time and distance covered at high speeds.

Additionally, the ability to sustain high cruising speeds may result in shorter overall journey times for marine vessels. This reduction in time spent on the water could potentially decrease the cumulative environmental impact of shipping and transportation activities. Shorter journey times may also reduce the risk of collisions with marine life, as vessels spend less time in sensitive ecological areas.

The development of technologies to mitigate the environmental impact of high-speed cruising with 5.4 Triton engines is ongoing. This includes advancements in noise reduction techniques, improved fuel efficiency measures, and enhanced pollution control systems. These innovations aim to balance the need for high-speed performance with environmental responsibility.

In conclusion, while sustaining high cruising speeds with 5.4 Triton engines presents certain environmental challenges, it also offers opportunities for improved efficiency and reduced overall impact when managed properly. The key lies in continuing to develop and implement technologies and practices that minimize negative environmental effects while maximizing the benefits of high-speed marine transportation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!