How to Diagnose 5.4 Triton Engine Electrical Failures?

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton Engine Diagnostics Overview

The 5.4 Triton engine, a prominent power plant in Ford's lineup, has been widely used in various vehicles, including the F-150, Expedition, and E-Series. As with any complex mechanical system, electrical failures can occur, presenting challenges for technicians and vehicle owners alike. Diagnosing these issues requires a systematic approach and a deep understanding of the engine's electrical components and systems.

The Triton engine's electrical system is comprised of several key components, including the battery, alternator, starter motor, ignition system, and various sensors and control modules. Each of these elements plays a crucial role in the engine's operation, and a failure in any one of them can lead to performance issues or complete engine shutdown.

Common electrical failures in the 5.4 Triton engine include battery drainage, alternator malfunction, starter motor issues, faulty ignition coils, and sensor failures. These problems can manifest in various ways, such as difficulty starting the engine, intermittent stalling, or warning lights on the dashboard.

To effectively diagnose electrical failures in the 5.4 Triton engine, technicians typically employ a multi-step process. This begins with a visual inspection of the engine bay, looking for obvious signs of wear, damage, or loose connections. Next, a battery and charging system test is performed to ensure that the electrical foundation of the vehicle is sound.

If basic tests do not reveal the issue, more advanced diagnostic tools come into play. On-board diagnostics (OBD) scanners are used to retrieve error codes stored in the engine control module (ECM). These codes can provide valuable clues about the nature and location of the electrical problem.

For more elusive issues, technicians may need to use specialized equipment such as multimeters, oscilloscopes, and current clamps to test individual components and circuits. This allows for precise measurements of voltage, current, and resistance, helping to pinpoint the exact source of the electrical failure.

It's important to note that electrical issues can sometimes be intermittent or caused by multiple factors, making diagnosis challenging. In such cases, a methodical process of elimination and thorough documentation of symptoms and test results is crucial for successful troubleshooting.

As automotive technology continues to advance, the complexity of electrical systems in engines like the 5.4 Triton has increased. This has led to the development of more sophisticated diagnostic tools and techniques, requiring technicians to continually update their skills and knowledge to effectively diagnose and repair these systems.

The Triton engine's electrical system is comprised of several key components, including the battery, alternator, starter motor, ignition system, and various sensors and control modules. Each of these elements plays a crucial role in the engine's operation, and a failure in any one of them can lead to performance issues or complete engine shutdown.

Common electrical failures in the 5.4 Triton engine include battery drainage, alternator malfunction, starter motor issues, faulty ignition coils, and sensor failures. These problems can manifest in various ways, such as difficulty starting the engine, intermittent stalling, or warning lights on the dashboard.

To effectively diagnose electrical failures in the 5.4 Triton engine, technicians typically employ a multi-step process. This begins with a visual inspection of the engine bay, looking for obvious signs of wear, damage, or loose connections. Next, a battery and charging system test is performed to ensure that the electrical foundation of the vehicle is sound.

If basic tests do not reveal the issue, more advanced diagnostic tools come into play. On-board diagnostics (OBD) scanners are used to retrieve error codes stored in the engine control module (ECM). These codes can provide valuable clues about the nature and location of the electrical problem.

For more elusive issues, technicians may need to use specialized equipment such as multimeters, oscilloscopes, and current clamps to test individual components and circuits. This allows for precise measurements of voltage, current, and resistance, helping to pinpoint the exact source of the electrical failure.

It's important to note that electrical issues can sometimes be intermittent or caused by multiple factors, making diagnosis challenging. In such cases, a methodical process of elimination and thorough documentation of symptoms and test results is crucial for successful troubleshooting.

As automotive technology continues to advance, the complexity of electrical systems in engines like the 5.4 Triton has increased. This has led to the development of more sophisticated diagnostic tools and techniques, requiring technicians to continually update their skills and knowledge to effectively diagnose and repair these systems.

Market Demand for Engine Diagnostics

The market demand for engine diagnostics, particularly for the 5.4 Triton engine, has been steadily growing due to the increasing complexity of modern vehicle systems and the need for efficient, accurate troubleshooting. As vehicles become more technologically advanced, the demand for sophisticated diagnostic tools and techniques has surged among automotive repair shops, dealerships, and individual mechanics.

The 5.4 Triton engine, widely used in Ford vehicles, has a significant presence in the market, creating a substantial need for specialized diagnostic solutions. Electrical failures in these engines can be particularly challenging to diagnose, driving the demand for advanced diagnostic equipment and expertise. This demand is further fueled by the aging fleet of vehicles equipped with the 5.4 Triton engine, as older vehicles tend to require more frequent repairs and maintenance.

The automotive diagnostics market has been expanding globally, with a particular focus on electrical system diagnostics. Industry reports indicate that the automotive diagnostic scan tools market is expected to grow significantly in the coming years, driven by the increasing electronic content in vehicles and the need for quick, accurate fault detection.

For the 5.4 Triton engine specifically, there is a growing market for both professional-grade diagnostic tools and consumer-level solutions. Professional mechanics and repair shops seek comprehensive diagnostic systems that can quickly identify electrical issues, while do-it-yourself enthusiasts look for more affordable, user-friendly options to troubleshoot their vehicles at home.

The demand for engine diagnostics is also influenced by regulatory pressures and environmental concerns. Stricter emissions standards require more precise engine management, leading to an increased need for accurate diagnostic tools to ensure compliance and optimal performance. This trend is particularly relevant for the 5.4 Triton engine, which has been subject to various emissions-related recalls and updates over the years.

Moreover, the rise of connected vehicle technologies and telematics has created new opportunities in the engine diagnostics market. Remote diagnostics capabilities are becoming increasingly popular, allowing for real-time monitoring and early detection of potential electrical failures in the 5.4 Triton engine and other powertrains.

As the automotive industry continues to evolve towards electrification, there is also a growing demand for diagnostic tools that can handle both traditional internal combustion engines like the 5.4 Triton and newer hybrid or electric powertrains. This trend is driving innovation in diagnostic technologies and creating new market segments within the automotive repair and maintenance industry.

The 5.4 Triton engine, widely used in Ford vehicles, has a significant presence in the market, creating a substantial need for specialized diagnostic solutions. Electrical failures in these engines can be particularly challenging to diagnose, driving the demand for advanced diagnostic equipment and expertise. This demand is further fueled by the aging fleet of vehicles equipped with the 5.4 Triton engine, as older vehicles tend to require more frequent repairs and maintenance.

The automotive diagnostics market has been expanding globally, with a particular focus on electrical system diagnostics. Industry reports indicate that the automotive diagnostic scan tools market is expected to grow significantly in the coming years, driven by the increasing electronic content in vehicles and the need for quick, accurate fault detection.

For the 5.4 Triton engine specifically, there is a growing market for both professional-grade diagnostic tools and consumer-level solutions. Professional mechanics and repair shops seek comprehensive diagnostic systems that can quickly identify electrical issues, while do-it-yourself enthusiasts look for more affordable, user-friendly options to troubleshoot their vehicles at home.

The demand for engine diagnostics is also influenced by regulatory pressures and environmental concerns. Stricter emissions standards require more precise engine management, leading to an increased need for accurate diagnostic tools to ensure compliance and optimal performance. This trend is particularly relevant for the 5.4 Triton engine, which has been subject to various emissions-related recalls and updates over the years.

Moreover, the rise of connected vehicle technologies and telematics has created new opportunities in the engine diagnostics market. Remote diagnostics capabilities are becoming increasingly popular, allowing for real-time monitoring and early detection of potential electrical failures in the 5.4 Triton engine and other powertrains.

As the automotive industry continues to evolve towards electrification, there is also a growing demand for diagnostic tools that can handle both traditional internal combustion engines like the 5.4 Triton and newer hybrid or electric powertrains. This trend is driving innovation in diagnostic technologies and creating new market segments within the automotive repair and maintenance industry.

5.4 Triton Electrical System Challenges

The 5.4 Triton engine, a popular powerplant in Ford vehicles, has faced numerous electrical system challenges over the years. These issues have significantly impacted the engine's performance and reliability, leading to frequent complaints from vehicle owners and increased warranty claims for manufacturers.

One of the primary challenges lies in the complex nature of the Triton's electrical system. The engine utilizes a sophisticated network of sensors, control modules, and wiring harnesses to manage various functions, including fuel injection, ignition timing, and emissions control. This intricate design, while offering advanced capabilities, also introduces multiple potential points of failure.

Corrosion and water intrusion have been persistent problems for the Triton's electrical components. The engine compartment's exposure to harsh environmental conditions, such as moisture, salt, and temperature fluctuations, can lead to degradation of connectors, wiring insulation, and sensor contacts. This degradation often results in intermittent electrical faults that are difficult to diagnose and repair.

Another significant challenge is the sensitivity of the engine's control modules to voltage fluctuations. The Powertrain Control Module (PCM) and other electronic control units are susceptible to damage from power surges or insufficient voltage supply. This vulnerability can lead to erratic engine behavior, misfires, or complete system shutdowns.

The Triton engine's coil-on-plug ignition system has been a source of frequent electrical failures. These individual coils, mounted directly on each spark plug, are prone to heat-related degradation and insulation breakdown. When a coil fails, it can cause misfires, reduced engine performance, and increased fuel consumption.

Wiring harness issues have also plagued the 5.4 Triton. Over time, the constant heat cycles and engine vibration can cause wires to chafe, leading to short circuits or open circuits. These wiring problems are often challenging to locate and repair, as they may occur in hard-to-reach areas of the engine compartment.

The engine's fuel injectors and their associated electrical connections have been another area of concern. Electrical resistance in the injector circuits can cause inconsistent fuel delivery, leading to poor engine performance and increased emissions. Diagnosing these issues often requires specialized equipment and expertise.

Lastly, the integration of the engine's electrical system with the vehicle's broader network has introduced additional complexities. Communication errors between the engine control modules and other vehicle systems can trigger fault codes and affect drivability. These integration challenges often require comprehensive diagnostic approaches that consider the entire vehicle electrical architecture.

One of the primary challenges lies in the complex nature of the Triton's electrical system. The engine utilizes a sophisticated network of sensors, control modules, and wiring harnesses to manage various functions, including fuel injection, ignition timing, and emissions control. This intricate design, while offering advanced capabilities, also introduces multiple potential points of failure.

Corrosion and water intrusion have been persistent problems for the Triton's electrical components. The engine compartment's exposure to harsh environmental conditions, such as moisture, salt, and temperature fluctuations, can lead to degradation of connectors, wiring insulation, and sensor contacts. This degradation often results in intermittent electrical faults that are difficult to diagnose and repair.

Another significant challenge is the sensitivity of the engine's control modules to voltage fluctuations. The Powertrain Control Module (PCM) and other electronic control units are susceptible to damage from power surges or insufficient voltage supply. This vulnerability can lead to erratic engine behavior, misfires, or complete system shutdowns.

The Triton engine's coil-on-plug ignition system has been a source of frequent electrical failures. These individual coils, mounted directly on each spark plug, are prone to heat-related degradation and insulation breakdown. When a coil fails, it can cause misfires, reduced engine performance, and increased fuel consumption.

Wiring harness issues have also plagued the 5.4 Triton. Over time, the constant heat cycles and engine vibration can cause wires to chafe, leading to short circuits or open circuits. These wiring problems are often challenging to locate and repair, as they may occur in hard-to-reach areas of the engine compartment.

The engine's fuel injectors and their associated electrical connections have been another area of concern. Electrical resistance in the injector circuits can cause inconsistent fuel delivery, leading to poor engine performance and increased emissions. Diagnosing these issues often requires specialized equipment and expertise.

Lastly, the integration of the engine's electrical system with the vehicle's broader network has introduced additional complexities. Communication errors between the engine control modules and other vehicle systems can trigger fault codes and affect drivability. These integration challenges often require comprehensive diagnostic approaches that consider the entire vehicle electrical architecture.

Current Diagnostic Methods for Triton Engines

01 Electrical system diagnostics and fault detection

Advanced diagnostic systems and methods for detecting electrical failures in 5.4 Triton engines. These systems utilize sensors and computerized analysis to identify issues in the engine's electrical components, allowing for early detection and prevention of potential failures.- Electrical system diagnostics and fault detection: Advanced diagnostic systems for detecting and analyzing electrical failures in 5.4 Triton engines. These systems use sensors and computerized algorithms to identify issues in the engine's electrical components, helping to prevent failures and improve overall performance.

- Improved wiring harness design: Enhanced wiring harness designs for 5.4 Triton engines to reduce the risk of electrical failures. These designs incorporate better insulation, more robust connectors, and optimized routing to minimize wear and exposure to heat and vibration.

- Engine control module (ECM) enhancements: Advancements in ECM technology for 5.4 Triton engines, including improved software algorithms and hardware components. These enhancements help to better manage electrical systems, monitor performance, and prevent failures through early detection and intervention.

- Electrical component protection and cooling: Innovative solutions for protecting and cooling electrical components in 5.4 Triton engines. These include improved heat dissipation methods, protective coatings, and strategic placement of components to reduce exposure to extreme temperatures and environmental factors.

- Alternator and battery system improvements: Enhancements to the alternator and battery systems in 5.4 Triton engines to ensure consistent power supply and reduce the risk of electrical failures. These improvements include more efficient alternators, advanced battery management systems, and better integration with the engine's electrical network.

02 Improved wiring harness design

Enhanced wiring harness designs for 5.4 Triton engines to reduce the risk of electrical failures. These designs incorporate better insulation, more robust connectors, and optimized routing to minimize wear and exposure to heat and vibration.Expand Specific Solutions03 Engine control module (ECM) enhancements

Advancements in ECM technology for 5.4 Triton engines, including improved software algorithms and hardware components. These enhancements aim to better manage electrical systems, monitor performance, and prevent failures through adaptive control strategies.Expand Specific Solutions04 Electrical component protection and cooling

Innovative methods for protecting and cooling electrical components in 5.4 Triton engines. These solutions include advanced heat dissipation techniques, protective coatings, and improved component placement to reduce the risk of heat-related electrical failures.Expand Specific Solutions05 Ignition system improvements

Enhancements to the ignition system of 5.4 Triton engines, focusing on more reliable spark plug designs, coil-on-plug technology, and advanced ignition control modules. These improvements aim to reduce the likelihood of misfires and other ignition-related electrical failures.Expand Specific Solutions

Key Players in Automotive Diagnostics

The market for diagnosing 5.4 Triton engine electrical failures is in a mature stage, with a significant global presence due to the widespread use of these engines in Ford vehicles. The market size is substantial, driven by the large number of vehicles equipped with this engine type and the ongoing need for maintenance and repairs. Technologically, the field is well-developed, with established diagnostic procedures and tools available. Companies like Continental Automotive GmbH, Weichai Power, and United Automotive Electronic Systems Co., Ltd. are key players in providing diagnostic solutions and components for these engines, leveraging their expertise in automotive electronics and powertrain systems to address electrical failure issues effectively.

China FAW Co., Ltd.

Technical Solution: China FAW Co., Ltd. has developed a robust diagnostic system for engine electrical failures, applicable to various engine types including those similar to the 5.4 Triton. Their approach combines traditional diagnostic methods with emerging technologies in the field of artificial intelligence and big data analytics. The system employs a network of advanced sensors throughout the engine, monitoring key electrical parameters such as voltage fluctuations, current draw, and electromagnetic emissions[12]. This data is processed by an onboard AI system that uses machine learning algorithms to identify patterns indicative of potential electrical failures. FAW's system also incorporates a unique "historical learning" feature that builds a database of electrical behavior specific to each vehicle, allowing for highly personalized diagnostics[13]. Additionally, they have implemented a cloud-based platform that enables remote diagnostics and over-the-air updates to the diagnostic software, ensuring the system remains up-to-date with the latest fault recognition patterns[14].

Strengths: Personalized diagnostics through historical learning, AI-driven fault detection, and cloud-based remote diagnostics capabilities. Weaknesses: May require significant data collection period for optimal performance and potential challenges in adapting the system to non-FAW vehicles.

Continental Automotive France SAS

Technical Solution: Continental Automotive France SAS has developed a comprehensive diagnostic system for engine electrical failures, applicable to engines like the 5.4 Triton. Their approach focuses on a holistic view of the engine's electrical system, utilizing advanced sensor technology and data analytics. The system employs a network of smart sensors that monitor various electrical parameters, including voltage, current, and electromagnetic interference patterns[7]. These sensors feed data into a central processing unit that uses artificial intelligence algorithms to analyze the electrical system's behavior in real-time. Continental's system also incorporates thermal imaging technology to detect hotspots that may indicate impending electrical failures[8]. Additionally, they have developed a unique "electrical signature" analysis technique that can identify subtle changes in the engine's electrical patterns, potentially indicating developing issues before they become critical failures[9].

Strengths: Comprehensive monitoring with advanced sensor technology, AI-driven analysis, and innovative electrical signature detection. Weaknesses: Potentially high implementation cost and may require specialized training for technicians to fully utilize all features.

Advanced Electrical Failure Detection Techniques

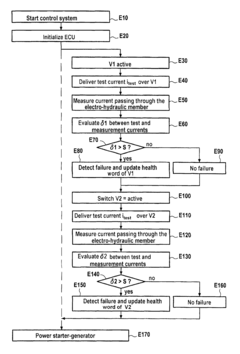

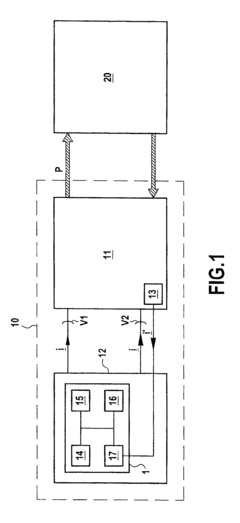

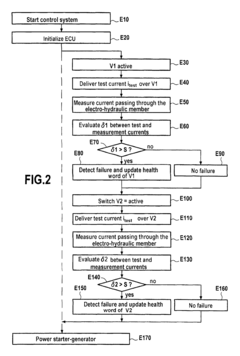

Method and a device for detecting an electrical failure affecting an electric control system of a hydraulic actuator of variable geometries of an aeroengine

PatentActiveUS9116518B2

Innovation

- Implementing a self-testing method that delivers a predetermined test electric current through both control paths before the engine starter-generator is powered, evaluating the difference between the test current and the current transformed into hydraulic power, and detecting failures if the difference exceeds a predefined threshold, ensuring both paths are tested before they are used in operation.

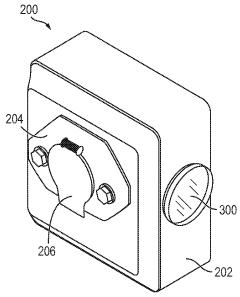

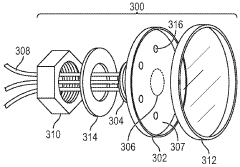

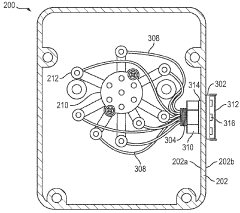

Electrical power monitoring system

PatentActiveUS20180265001A1

Innovation

- An electrical power monitoring system that continuously monitors voltage at conductive terminals in a junction box, using light sources to visually indicate power presence, simplifying fault detection and eliminating the need for spare cables.

Regulatory Standards for Engine Diagnostics

Regulatory standards for engine diagnostics play a crucial role in ensuring the safety, reliability, and environmental compliance of automotive engines, including the 5.4 Triton engine. These standards are established by various regulatory bodies and industry organizations to provide a framework for consistent and effective diagnostic procedures.

The Environmental Protection Agency (EPA) in the United States sets forth stringent regulations for on-board diagnostic (OBD) systems. These regulations require modern vehicles, including those equipped with the 5.4 Triton engine, to have sophisticated diagnostic capabilities that can detect and report electrical failures and other malfunctions. The OBD-II standard, which became mandatory for all vehicles sold in the US from 1996 onwards, specifies a standardized diagnostic connector and communication protocol.

In addition to EPA regulations, the California Air Resources Board (CARB) has implemented even more stringent OBD requirements. These standards often serve as a benchmark for other states and countries. CARB regulations mandate enhanced monitoring of emission-related components and systems, including those that could lead to electrical failures in engines like the 5.4 Triton.

The Society of Automotive Engineers (SAE) has developed numerous standards and recommended practices for engine diagnostics. SAE J1979 defines the diagnostic test modes and parameter IDs used in OBD-II systems, which are essential for diagnosing electrical failures in the 5.4 Triton engine. SAE J2012 standardizes the diagnostic trouble codes (DTCs) used to identify specific faults, ensuring consistency across different vehicle makes and models.

International standards also influence engine diagnostic practices. The ISO 15031 series of standards provides guidelines for communication between vehicle OBD systems and external test equipment. These standards ensure that diagnostic tools can effectively interface with the 5.4 Triton engine's electronic control unit (ECU) to retrieve fault codes and live data streams.

Regulatory bodies also mandate specific performance criteria for diagnostic systems. For instance, the Federal Motor Vehicle Safety Standards (FMVSS) in the US include requirements for the malfunction indicator light (MIL) activation and the storage of freeze frame data when certain faults are detected. These standards ensure that electrical failures in the 5.4 Triton engine are promptly identified and reported to the vehicle operator.

As automotive technology advances, regulatory standards continue to evolve. Recent updates have focused on cybersecurity aspects of vehicle diagnostics, recognizing the increasing connectivity of modern vehicles. The UN Regulation No. 155 on Cyber Security and Cyber Security Management System sets new requirements for safeguarding diagnostic systems against unauthorized access and potential cyber threats.

The Environmental Protection Agency (EPA) in the United States sets forth stringent regulations for on-board diagnostic (OBD) systems. These regulations require modern vehicles, including those equipped with the 5.4 Triton engine, to have sophisticated diagnostic capabilities that can detect and report electrical failures and other malfunctions. The OBD-II standard, which became mandatory for all vehicles sold in the US from 1996 onwards, specifies a standardized diagnostic connector and communication protocol.

In addition to EPA regulations, the California Air Resources Board (CARB) has implemented even more stringent OBD requirements. These standards often serve as a benchmark for other states and countries. CARB regulations mandate enhanced monitoring of emission-related components and systems, including those that could lead to electrical failures in engines like the 5.4 Triton.

The Society of Automotive Engineers (SAE) has developed numerous standards and recommended practices for engine diagnostics. SAE J1979 defines the diagnostic test modes and parameter IDs used in OBD-II systems, which are essential for diagnosing electrical failures in the 5.4 Triton engine. SAE J2012 standardizes the diagnostic trouble codes (DTCs) used to identify specific faults, ensuring consistency across different vehicle makes and models.

International standards also influence engine diagnostic practices. The ISO 15031 series of standards provides guidelines for communication between vehicle OBD systems and external test equipment. These standards ensure that diagnostic tools can effectively interface with the 5.4 Triton engine's electronic control unit (ECU) to retrieve fault codes and live data streams.

Regulatory bodies also mandate specific performance criteria for diagnostic systems. For instance, the Federal Motor Vehicle Safety Standards (FMVSS) in the US include requirements for the malfunction indicator light (MIL) activation and the storage of freeze frame data when certain faults are detected. These standards ensure that electrical failures in the 5.4 Triton engine are promptly identified and reported to the vehicle operator.

As automotive technology advances, regulatory standards continue to evolve. Recent updates have focused on cybersecurity aspects of vehicle diagnostics, recognizing the increasing connectivity of modern vehicles. The UN Regulation No. 155 on Cyber Security and Cyber Security Management System sets new requirements for safeguarding diagnostic systems against unauthorized access and potential cyber threats.

Environmental Impact of Engine Failures

Engine failures, particularly electrical failures in the 5.4 Triton engine, can have significant environmental impacts that extend beyond the immediate vehicle performance issues. These impacts primarily stem from increased emissions, reduced fuel efficiency, and the potential for hazardous material leakage.

When electrical failures occur in the 5.4 Triton engine, the engine's combustion process may be compromised, leading to incomplete fuel burning. This results in higher levels of harmful emissions, including carbon monoxide, nitrogen oxides, and unburned hydrocarbons. These pollutants contribute to air quality degradation, smog formation, and increased greenhouse gas emissions, exacerbating climate change concerns.

Furthermore, electrical failures can cause the engine to operate inefficiently, consuming more fuel than necessary. This increased fuel consumption not only depletes non-renewable resources but also leads to higher carbon dioxide emissions, further contributing to the vehicle's carbon footprint.

In cases where electrical failures lead to more severe engine malfunctions, there is a risk of oil or coolant leakage. These fluids can contaminate soil and water sources if not properly contained and disposed of, potentially harming local ecosystems and wildlife.

The environmental impact extends to the manufacturing and disposal of replacement parts required to address electrical failures. The production of new components consumes energy and raw materials, while the disposal of faulty parts contributes to electronic waste, which can be challenging to recycle and may release harmful substances if not properly managed.

Moreover, frequent engine failures may lead to premature vehicle retirement, increasing the demand for new vehicle production and the associated environmental costs of manufacturing. This cycle of premature replacement and increased production places additional strain on natural resources and energy supplies.

To mitigate these environmental impacts, it is crucial to develop more robust diagnostic tools and preventive maintenance strategies for the 5.4 Triton engine's electrical systems. Improved diagnostics can lead to earlier detection of potential failures, reducing the likelihood of severe malfunctions and their associated environmental consequences. Additionally, advancing engine management systems and electrical components to be more resilient and efficient can help minimize the occurrence of failures and their environmental impact over the long term.

When electrical failures occur in the 5.4 Triton engine, the engine's combustion process may be compromised, leading to incomplete fuel burning. This results in higher levels of harmful emissions, including carbon monoxide, nitrogen oxides, and unburned hydrocarbons. These pollutants contribute to air quality degradation, smog formation, and increased greenhouse gas emissions, exacerbating climate change concerns.

Furthermore, electrical failures can cause the engine to operate inefficiently, consuming more fuel than necessary. This increased fuel consumption not only depletes non-renewable resources but also leads to higher carbon dioxide emissions, further contributing to the vehicle's carbon footprint.

In cases where electrical failures lead to more severe engine malfunctions, there is a risk of oil or coolant leakage. These fluids can contaminate soil and water sources if not properly contained and disposed of, potentially harming local ecosystems and wildlife.

The environmental impact extends to the manufacturing and disposal of replacement parts required to address electrical failures. The production of new components consumes energy and raw materials, while the disposal of faulty parts contributes to electronic waste, which can be challenging to recycle and may release harmful substances if not properly managed.

Moreover, frequent engine failures may lead to premature vehicle retirement, increasing the demand for new vehicle production and the associated environmental costs of manufacturing. This cycle of premature replacement and increased production places additional strain on natural resources and energy supplies.

To mitigate these environmental impacts, it is crucial to develop more robust diagnostic tools and preventive maintenance strategies for the 5.4 Triton engine's electrical systems. Improved diagnostics can lead to earlier detection of potential failures, reducing the likelihood of severe malfunctions and their associated environmental consequences. Additionally, advancing engine management systems and electrical components to be more resilient and efficient can help minimize the occurrence of failures and their environmental impact over the long term.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!