5.4 Triton Engine: Enhancing Fuel Injector Precision

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton Engine Fuel Injection Evolution and Objectives

The Triton Engine, a pinnacle of modern automotive engineering, has undergone significant evolution in its fuel injection system. This technological progression has been driven by the ever-increasing demands for improved engine performance, fuel efficiency, and reduced emissions. The journey of fuel injection in the Triton Engine reflects the broader trends in the automotive industry, moving from early mechanical systems to sophisticated electronic control units.

Initially, the Triton Engine utilized a basic fuel injection system, which, while an improvement over carburetors, lacked the precision required for optimal engine performance. As environmental regulations tightened and consumer expectations for fuel economy rose, the need for more advanced fuel injection technologies became apparent. This led to the development of multi-point fuel injection systems, which significantly enhanced fuel distribution and atomization.

The evolution continued with the introduction of direct injection technology in the Triton Engine. This marked a major leap forward, allowing for precise control over fuel delivery timing and quantity. Direct injection enabled higher compression ratios, improved fuel efficiency, and reduced emissions. However, as the potential of this technology became evident, so did the challenges in achieving even greater precision.

Current objectives for enhancing fuel injector precision in the Triton Engine are multifaceted. Primarily, there is a focus on developing injectors capable of delivering fuel with nanometer-level accuracy. This level of precision is crucial for optimizing the air-fuel mixture in real-time, adapting to varying engine loads and environmental conditions. Additionally, there are efforts to increase the speed of injector response, allowing for multiple injection events within a single combustion cycle.

Another key objective is the integration of advanced materials and manufacturing techniques to improve injector durability and resistance to high-pressure environments. This is particularly important as injection pressures continue to increase in pursuit of better fuel atomization. Researchers are also exploring ways to minimize injector deposits, which can significantly impact fuel spray patterns and engine efficiency over time.

The ultimate goal of these advancements is to create a fuel injection system for the Triton Engine that can dynamically adjust to provide the optimal air-fuel mixture under all operating conditions. This would result in maximized power output, minimized fuel consumption, and reduced emissions across the entire operating range of the engine. Achieving these objectives will position the Triton Engine at the forefront of internal combustion engine technology, meeting and exceeding future regulatory requirements and consumer expectations.

Initially, the Triton Engine utilized a basic fuel injection system, which, while an improvement over carburetors, lacked the precision required for optimal engine performance. As environmental regulations tightened and consumer expectations for fuel economy rose, the need for more advanced fuel injection technologies became apparent. This led to the development of multi-point fuel injection systems, which significantly enhanced fuel distribution and atomization.

The evolution continued with the introduction of direct injection technology in the Triton Engine. This marked a major leap forward, allowing for precise control over fuel delivery timing and quantity. Direct injection enabled higher compression ratios, improved fuel efficiency, and reduced emissions. However, as the potential of this technology became evident, so did the challenges in achieving even greater precision.

Current objectives for enhancing fuel injector precision in the Triton Engine are multifaceted. Primarily, there is a focus on developing injectors capable of delivering fuel with nanometer-level accuracy. This level of precision is crucial for optimizing the air-fuel mixture in real-time, adapting to varying engine loads and environmental conditions. Additionally, there are efforts to increase the speed of injector response, allowing for multiple injection events within a single combustion cycle.

Another key objective is the integration of advanced materials and manufacturing techniques to improve injector durability and resistance to high-pressure environments. This is particularly important as injection pressures continue to increase in pursuit of better fuel atomization. Researchers are also exploring ways to minimize injector deposits, which can significantly impact fuel spray patterns and engine efficiency over time.

The ultimate goal of these advancements is to create a fuel injection system for the Triton Engine that can dynamically adjust to provide the optimal air-fuel mixture under all operating conditions. This would result in maximized power output, minimized fuel consumption, and reduced emissions across the entire operating range of the engine. Achieving these objectives will position the Triton Engine at the forefront of internal combustion engine technology, meeting and exceeding future regulatory requirements and consumer expectations.

Market Demand for High-Precision Fuel Injection Systems

The market demand for high-precision fuel injection systems in the automotive industry has been steadily increasing, driven by stringent emission regulations, the pursuit of improved fuel efficiency, and the growing trend towards engine downsizing. As automotive manufacturers strive to meet these challenges, the Triton Engine's fuel injector precision enhancement project aligns perfectly with current market needs.

Environmental concerns and government regulations worldwide have pushed automakers to develop cleaner, more efficient engines. High-precision fuel injection systems play a crucial role in achieving these goals by optimizing fuel delivery and combustion processes. The European Union's Euro 7 standards and similar regulations in other regions have set ambitious targets for reducing vehicle emissions, creating a strong demand for advanced fuel injection technologies.

Fuel efficiency has become a key selling point for consumers, especially in regions with high fuel prices or environmental consciousness. Precise fuel injection contributes significantly to improved fuel economy by ensuring optimal fuel-air mixture and reducing waste. As consumers increasingly prioritize fuel-efficient vehicles, the demand for engines with high-precision injection systems continues to grow.

The trend towards engine downsizing has further amplified the need for precise fuel injection. Smaller engines require more accurate fuel delivery to maintain performance while reducing fuel consumption and emissions. This trend is particularly evident in the passenger car segment, where manufacturers are replacing larger naturally aspirated engines with smaller turbocharged units equipped with advanced fuel injection systems.

In the commercial vehicle sector, the demand for high-precision fuel injection systems is equally strong. Fleet operators are constantly seeking ways to reduce operating costs, with fuel efficiency being a primary concern. Advanced fuel injection technologies offer significant potential for improving the fuel economy of trucks and buses, leading to increased interest from manufacturers and fleet owners alike.

The aftermarket segment also presents opportunities for high-precision fuel injection systems. As vehicle owners become more aware of the benefits of these technologies, there is a growing market for retrofitting older vehicles with advanced fuel injection systems to improve performance and efficiency.

Emerging markets, particularly in Asia and South America, are experiencing rapid growth in vehicle production and sales. As these markets mature and adopt stricter emission standards, the demand for high-precision fuel injection systems is expected to surge, creating new opportunities for manufacturers and suppliers in the automotive industry.

Environmental concerns and government regulations worldwide have pushed automakers to develop cleaner, more efficient engines. High-precision fuel injection systems play a crucial role in achieving these goals by optimizing fuel delivery and combustion processes. The European Union's Euro 7 standards and similar regulations in other regions have set ambitious targets for reducing vehicle emissions, creating a strong demand for advanced fuel injection technologies.

Fuel efficiency has become a key selling point for consumers, especially in regions with high fuel prices or environmental consciousness. Precise fuel injection contributes significantly to improved fuel economy by ensuring optimal fuel-air mixture and reducing waste. As consumers increasingly prioritize fuel-efficient vehicles, the demand for engines with high-precision injection systems continues to grow.

The trend towards engine downsizing has further amplified the need for precise fuel injection. Smaller engines require more accurate fuel delivery to maintain performance while reducing fuel consumption and emissions. This trend is particularly evident in the passenger car segment, where manufacturers are replacing larger naturally aspirated engines with smaller turbocharged units equipped with advanced fuel injection systems.

In the commercial vehicle sector, the demand for high-precision fuel injection systems is equally strong. Fleet operators are constantly seeking ways to reduce operating costs, with fuel efficiency being a primary concern. Advanced fuel injection technologies offer significant potential for improving the fuel economy of trucks and buses, leading to increased interest from manufacturers and fleet owners alike.

The aftermarket segment also presents opportunities for high-precision fuel injection systems. As vehicle owners become more aware of the benefits of these technologies, there is a growing market for retrofitting older vehicles with advanced fuel injection systems to improve performance and efficiency.

Emerging markets, particularly in Asia and South America, are experiencing rapid growth in vehicle production and sales. As these markets mature and adopt stricter emission standards, the demand for high-precision fuel injection systems is expected to surge, creating new opportunities for manufacturers and suppliers in the automotive industry.

Current Challenges in Triton Engine Fuel Injector Precision

The Triton Engine, renowned for its advanced design and performance capabilities, faces significant challenges in achieving optimal fuel injector precision. One of the primary issues is the complexity of managing fuel injection timing and quantity across a wide range of operating conditions. As engine speeds and loads fluctuate, maintaining consistent and accurate fuel delivery becomes increasingly difficult, leading to potential inefficiencies and increased emissions.

Another critical challenge lies in the miniaturization of fuel injector components. As manufacturers strive for more compact engine designs, the physical constraints on injector size become more pronounced. This reduction in size makes it harder to maintain the necessary precision in fuel atomization and spray patterns, which are crucial for efficient combustion.

The durability of fuel injectors under high-pressure conditions presents an ongoing challenge. The Triton Engine's high-performance nature subjects injectors to extreme pressures and temperatures, potentially leading to wear and degradation over time. This wear can result in changes to the injector's spray pattern and flow rate, compromising the engine's overall performance and efficiency.

Fuel quality variations pose another significant hurdle. The Triton Engine must maintain precision across a range of fuel compositions and qualities, which can vary significantly depending on geographical location and fuel source. Adapting to these variations while maintaining optimal performance is a complex task that requires sophisticated control systems and injector designs.

Environmental regulations and emission standards continue to become more stringent, placing additional pressure on fuel injector technology. Meeting these standards while maintaining or improving engine performance necessitates ever-increasing precision in fuel delivery and atomization. This challenge is compounded by the need to reduce particulate emissions and NOx formation, which are directly influenced by injection characteristics.

The integration of advanced materials in fuel injector construction presents both opportunities and challenges. While new materials can offer improved durability and performance, they often come with increased manufacturing complexity and cost. Balancing these factors while achieving the required precision is a significant engineering challenge.

Lastly, the development of control algorithms and software for managing fuel injection faces ongoing challenges. As engine management systems become more complex, the task of optimizing fuel injection across all operating conditions becomes increasingly demanding. This requires sophisticated modeling, real-time adjustments, and predictive capabilities that push the boundaries of current technology.

Another critical challenge lies in the miniaturization of fuel injector components. As manufacturers strive for more compact engine designs, the physical constraints on injector size become more pronounced. This reduction in size makes it harder to maintain the necessary precision in fuel atomization and spray patterns, which are crucial for efficient combustion.

The durability of fuel injectors under high-pressure conditions presents an ongoing challenge. The Triton Engine's high-performance nature subjects injectors to extreme pressures and temperatures, potentially leading to wear and degradation over time. This wear can result in changes to the injector's spray pattern and flow rate, compromising the engine's overall performance and efficiency.

Fuel quality variations pose another significant hurdle. The Triton Engine must maintain precision across a range of fuel compositions and qualities, which can vary significantly depending on geographical location and fuel source. Adapting to these variations while maintaining optimal performance is a complex task that requires sophisticated control systems and injector designs.

Environmental regulations and emission standards continue to become more stringent, placing additional pressure on fuel injector technology. Meeting these standards while maintaining or improving engine performance necessitates ever-increasing precision in fuel delivery and atomization. This challenge is compounded by the need to reduce particulate emissions and NOx formation, which are directly influenced by injection characteristics.

The integration of advanced materials in fuel injector construction presents both opportunities and challenges. While new materials can offer improved durability and performance, they often come with increased manufacturing complexity and cost. Balancing these factors while achieving the required precision is a significant engineering challenge.

Lastly, the development of control algorithms and software for managing fuel injection faces ongoing challenges. As engine management systems become more complex, the task of optimizing fuel injection across all operating conditions becomes increasingly demanding. This requires sophisticated modeling, real-time adjustments, and predictive capabilities that push the boundaries of current technology.

Existing Solutions for Enhancing Fuel Injector Precision

01 Precision fuel injection control

Advanced control systems for fuel injectors in Triton engines to enhance precision and efficiency. These systems utilize electronic controls, sensors, and algorithms to optimize fuel delivery timing and quantity based on engine conditions and performance requirements.- Precision fuel injection control: Advanced control systems for fuel injectors in Triton engines to enhance precision and efficiency. This includes electronic control units, sensors, and algorithms to optimize fuel delivery timing and quantity based on engine conditions.

- High-pressure fuel injection systems: Development of high-pressure fuel injection systems for Triton engines to improve atomization and combustion efficiency. These systems utilize advanced pump designs and reinforced components to handle increased fuel pressures.

- Multi-stage injection technology: Implementation of multi-stage injection techniques in Triton engine fuel injectors to optimize combustion processes. This involves precise control of multiple injection events per combustion cycle to reduce emissions and improve performance.

- Injector nozzle design improvements: Advancements in fuel injector nozzle designs for Triton engines to enhance spray patterns and fuel atomization. This includes optimized orifice geometries, coating technologies, and materials to improve durability and reduce deposit formation.

- Adaptive injection strategies: Development of adaptive fuel injection strategies for Triton engines to optimize performance across various operating conditions. This involves real-time adjustments to injection parameters based on factors such as load, speed, and environmental conditions.

02 High-pressure fuel injection technology

Implementation of high-pressure fuel injection systems in Triton engines to improve fuel atomization and combustion efficiency. These systems operate at elevated pressures to achieve finer fuel droplets and more precise fuel distribution within the combustion chamber.Expand Specific Solutions03 Multi-stage injection strategies

Development of multi-stage injection techniques for Triton engine fuel injectors to optimize combustion processes. These strategies involve multiple injection events per combustion cycle, allowing for improved fuel economy, reduced emissions, and enhanced engine performance across various operating conditions.Expand Specific Solutions04 Injector nozzle design optimization

Advancements in fuel injector nozzle designs for Triton engines to improve spray patterns and fuel distribution. These optimizations focus on nozzle geometry, hole size, and arrangement to enhance fuel atomization and mixing with air in the combustion chamber.Expand Specific Solutions05 Adaptive injection control systems

Implementation of adaptive control systems for fuel injectors in Triton engines to maintain precision over time. These systems use real-time feedback and learning algorithms to adjust injection parameters, compensating for wear, environmental factors, and variations in fuel quality.Expand Specific Solutions

Key Players in Precision Fuel Injection Industry

The research on enhancing fuel injector precision in the Triton Engine is in a competitive and evolving landscape. The market is in a growth phase, driven by increasing demand for fuel-efficient and low-emission engines. Major players like DENSO, Robert Bosch, and Continental Automotive are leading the technological advancements, with significant investments in R&D. Emerging companies from Asia, such as Weichai Power and Geely, are also making strides in this field. The technology is approaching maturity, with established manufacturers refining existing solutions while new entrants focus on innovative approaches to improve precision and efficiency.

DENSO Corp.

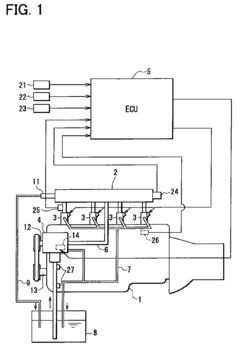

Technical Solution: DENSO has developed advanced fuel injector technology for the Triton Engine, focusing on precision and efficiency. Their system utilizes high-pressure direct injection with piezoelectric actuators, allowing for multiple injections per combustion cycle[1]. This technology enables finer atomization of fuel particles, resulting in more complete combustion and reduced emissions. DENSO's injectors incorporate advanced electronic control units (ECUs) that can adjust injection timing and duration with microsecond precision[2]. The company has also implemented a closed-loop feedback system that continuously monitors and adjusts fuel delivery based on real-time engine performance data[3].

Strengths: High precision control, improved fuel efficiency, and reduced emissions. Weaknesses: Higher cost compared to conventional injectors, and potential reliability issues with complex electronic components.

Robert Bosch GmbH

Technical Solution: Bosch has made significant strides in enhancing fuel injector precision for the Triton Engine through their innovative HDEV5 high-pressure injector system. This technology utilizes a unique servo-hydraulic valve control concept, allowing for extremely fast and precise injection events[4]. The HDEV5 system can achieve injection pressures of up to 2,500 bar, enabling superior fuel atomization and mixture formation[5]. Bosch has also integrated advanced solenoid technology with their injectors, providing rapid response times and the ability to perform multiple injections within a single combustion cycle. Their system incorporates adaptive learning algorithms that continuously optimize injection parameters based on engine operating conditions and fuel quality[6].

Strengths: Extremely high injection pressures, adaptive optimization, and compatibility with various fuel types. Weaknesses: Complexity may lead to higher maintenance requirements, and initial implementation costs can be substantial.

Core Innovations in Fuel Injector Design

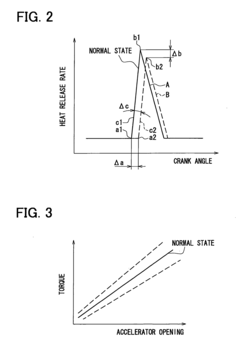

Fuel injection system

PatentInactiveEP1593824A2

Innovation

- A fuel injection system that employs a controller with standard state estimation and correction means, using a cylinder internal pressure sensor to adjust injection start timing, amount, and supply pressure to maintain a standard combustion state, even when fuel viscosity or performance changes, by detecting differences in cylinder internal pressure and heat release rates.

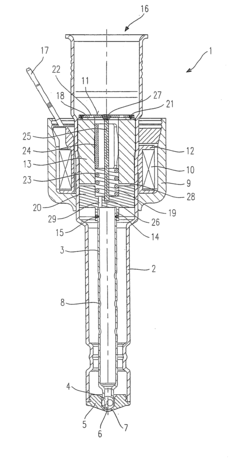

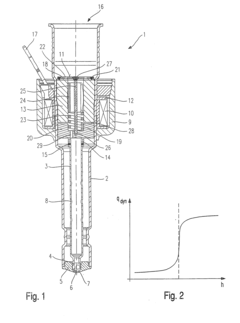

Fuel injection valve

PatentInactiveUS20040011899A1

Innovation

- A fuel injector design incorporating an elastic membrane at the inflow-side end face of the inner pole, which is lifted by a plunger to release an orifice, enabling a stepped lift-throttle function and precise fuel flow control, integrated with a compact and cost-effective structure.

Environmental Impact of Improved Fuel Injection Systems

The enhancement of fuel injector precision in the Triton Engine has significant implications for environmental sustainability. Improved fuel injection systems contribute to more efficient combustion processes, resulting in reduced emissions and better fuel economy. This advancement aligns with global efforts to mitigate climate change and improve air quality in urban areas.

One of the primary environmental benefits of enhanced fuel injector precision is the reduction of carbon dioxide (CO2) emissions. By optimizing fuel delivery and combustion, engines can achieve more complete fuel burning, leading to lower CO2 output per unit of energy produced. This improvement directly contributes to decreasing the carbon footprint of vehicles equipped with the Triton Engine, supporting efforts to meet increasingly stringent emissions standards worldwide.

Moreover, precise fuel injection helps minimize the production of other harmful pollutants, such as nitrogen oxides (NOx) and particulate matter (PM). These pollutants are major contributors to smog formation and respiratory health issues in densely populated areas. By reducing their emission, improved fuel injection systems in the Triton Engine can play a crucial role in enhancing air quality and public health in urban environments.

The environmental impact extends beyond emissions reduction. Enhanced fuel injector precision also leads to improved fuel efficiency, which translates to lower overall fuel consumption. This reduction in fuel demand has far-reaching consequences, including decreased pressure on fossil fuel resources and reduced environmental impacts associated with oil extraction, refining, and transportation.

Furthermore, the advancement in fuel injection technology can potentially extend engine life and reduce the frequency of maintenance requirements. This longevity contributes to sustainability by reducing the need for replacement parts and minimizing waste generation associated with engine repairs and replacements.

The improved fuel injection systems also have indirect environmental benefits. As engines become more efficient and cleaner, it may accelerate the adoption of cleaner technologies in various industries beyond automotive, such as marine and industrial applications. This ripple effect could lead to broader environmental improvements across multiple sectors.

However, it is important to consider the potential environmental trade-offs. The production of more precise fuel injectors may require more resource-intensive manufacturing processes or rare materials. A comprehensive life cycle assessment would be necessary to fully understand the net environmental impact, considering both the benefits during operation and any additional environmental costs during production and disposal.

One of the primary environmental benefits of enhanced fuel injector precision is the reduction of carbon dioxide (CO2) emissions. By optimizing fuel delivery and combustion, engines can achieve more complete fuel burning, leading to lower CO2 output per unit of energy produced. This improvement directly contributes to decreasing the carbon footprint of vehicles equipped with the Triton Engine, supporting efforts to meet increasingly stringent emissions standards worldwide.

Moreover, precise fuel injection helps minimize the production of other harmful pollutants, such as nitrogen oxides (NOx) and particulate matter (PM). These pollutants are major contributors to smog formation and respiratory health issues in densely populated areas. By reducing their emission, improved fuel injection systems in the Triton Engine can play a crucial role in enhancing air quality and public health in urban environments.

The environmental impact extends beyond emissions reduction. Enhanced fuel injector precision also leads to improved fuel efficiency, which translates to lower overall fuel consumption. This reduction in fuel demand has far-reaching consequences, including decreased pressure on fossil fuel resources and reduced environmental impacts associated with oil extraction, refining, and transportation.

Furthermore, the advancement in fuel injection technology can potentially extend engine life and reduce the frequency of maintenance requirements. This longevity contributes to sustainability by reducing the need for replacement parts and minimizing waste generation associated with engine repairs and replacements.

The improved fuel injection systems also have indirect environmental benefits. As engines become more efficient and cleaner, it may accelerate the adoption of cleaner technologies in various industries beyond automotive, such as marine and industrial applications. This ripple effect could lead to broader environmental improvements across multiple sectors.

However, it is important to consider the potential environmental trade-offs. The production of more precise fuel injectors may require more resource-intensive manufacturing processes or rare materials. A comprehensive life cycle assessment would be necessary to fully understand the net environmental impact, considering both the benefits during operation and any additional environmental costs during production and disposal.

Cost-Benefit Analysis of Precision Fuel Injection Technologies

The cost-benefit analysis of precision fuel injection technologies for the Triton Engine reveals a complex interplay of economic factors and performance improvements. Initial implementation costs for advanced fuel injector systems are substantial, encompassing hardware upgrades, software development, and manufacturing process modifications. These upfront expenses can range from $500,000 to $2 million, depending on the scale of production and the sophistication of the chosen technology.

However, the long-term benefits of enhanced fuel injector precision are significant. Improved fuel economy is a primary advantage, with potential fuel savings of 5-10% over the engine's lifetime. For a fleet of vehicles, this translates to substantial cost reductions in fuel expenditure. Additionally, more precise fuel injection leads to reduced emissions, potentially saving manufacturers millions in regulatory compliance costs and avoiding potential fines.

The enhanced performance resulting from precision fuel injection can also command a premium in the market. Vehicles equipped with these advanced systems may see a 2-5% increase in sales price, contributing to higher profit margins. Moreover, the improved reliability and longevity of engines with precise fuel injection can lead to reduced warranty claims and enhanced brand reputation, factors that are difficult to quantify but significantly impact long-term profitability.

From an operational perspective, precision fuel injection technologies offer benefits in terms of reduced maintenance requirements and extended service intervals. This can result in lower total cost of ownership for end-users, a compelling selling point that can drive market share growth and customer loyalty.

The return on investment (ROI) for implementing precision fuel injection in the Triton Engine is estimated to occur within 3-5 years, depending on production volumes and market conditions. This timeline considers the initial capital outlay against the cumulative benefits of fuel savings, reduced emissions, and increased market value of the product.

It's important to note that the cost-benefit ratio improves over time as production scales up and technology costs decrease. Early adopters may face higher initial costs but stand to gain significant competitive advantages in a market increasingly focused on efficiency and environmental performance.

However, the long-term benefits of enhanced fuel injector precision are significant. Improved fuel economy is a primary advantage, with potential fuel savings of 5-10% over the engine's lifetime. For a fleet of vehicles, this translates to substantial cost reductions in fuel expenditure. Additionally, more precise fuel injection leads to reduced emissions, potentially saving manufacturers millions in regulatory compliance costs and avoiding potential fines.

The enhanced performance resulting from precision fuel injection can also command a premium in the market. Vehicles equipped with these advanced systems may see a 2-5% increase in sales price, contributing to higher profit margins. Moreover, the improved reliability and longevity of engines with precise fuel injection can lead to reduced warranty claims and enhanced brand reputation, factors that are difficult to quantify but significantly impact long-term profitability.

From an operational perspective, precision fuel injection technologies offer benefits in terms of reduced maintenance requirements and extended service intervals. This can result in lower total cost of ownership for end-users, a compelling selling point that can drive market share growth and customer loyalty.

The return on investment (ROI) for implementing precision fuel injection in the Triton Engine is estimated to occur within 3-5 years, depending on production volumes and market conditions. This timeline considers the initial capital outlay against the cumulative benefits of fuel savings, reduced emissions, and increased market value of the product.

It's important to note that the cost-benefit ratio improves over time as production scales up and technology costs decrease. Early adopters may face higher initial costs but stand to gain significant competitive advantages in a market increasingly focused on efficiency and environmental performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!