Advances in Research on Carbon Tetrachloride Combustion Byproducts

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CCl4 Combustion Research Background and Objectives

Carbon tetrachloride (CCl4) combustion has been a subject of significant research interest due to its environmental and health implications. The study of CCl4 combustion byproducts has evolved over several decades, driven by the need to understand and mitigate the harmful effects of these compounds on the environment and human health.

Initially, research in this field focused on identifying the primary byproducts of CCl4 combustion, which include phosgene, hydrogen chloride, and chlorine gas. As analytical techniques improved, scientists were able to detect and quantify trace amounts of other chlorinated compounds, such as hexachlorobenzene and polychlorinated dibenzo-p-dioxins and dibenzofurans (PCDD/Fs).

The environmental concerns surrounding CCl4 and its combustion byproducts gained prominence in the 1970s and 1980s, coinciding with increased awareness of ozone depletion and persistent organic pollutants. This led to the phasing out of CCl4 production under the Montreal Protocol, which came into effect in 1989.

Despite the reduction in CCl4 production, research on its combustion byproducts has continued due to the persistence of CCl4 in the environment and its ongoing use in certain industrial processes. The primary objectives of current research include:

1. Developing more efficient and complete combustion processes to minimize the formation of harmful byproducts.

2. Improving detection and quantification methods for trace levels of combustion byproducts in various environmental matrices.

3. Understanding the atmospheric chemistry and environmental fate of CCl4 combustion byproducts.

4. Assessing the long-term environmental and health impacts of historical CCl4 use and combustion.

5. Exploring remediation techniques for sites contaminated with CCl4 and its combustion byproducts.

Recent technological advancements, such as high-resolution mass spectrometry and advanced computational modeling, have enabled researchers to identify previously unknown combustion byproducts and predict their formation mechanisms. This has led to a more comprehensive understanding of the complex chemical reactions that occur during CCl4 combustion.

The ultimate goal of ongoing research is to develop strategies for the safe disposal of existing CCl4 stockpiles and to minimize the environmental impact of its combustion. This includes optimizing incineration conditions, developing novel catalysts for complete decomposition, and exploring alternative destruction technologies that produce fewer harmful byproducts.

Initially, research in this field focused on identifying the primary byproducts of CCl4 combustion, which include phosgene, hydrogen chloride, and chlorine gas. As analytical techniques improved, scientists were able to detect and quantify trace amounts of other chlorinated compounds, such as hexachlorobenzene and polychlorinated dibenzo-p-dioxins and dibenzofurans (PCDD/Fs).

The environmental concerns surrounding CCl4 and its combustion byproducts gained prominence in the 1970s and 1980s, coinciding with increased awareness of ozone depletion and persistent organic pollutants. This led to the phasing out of CCl4 production under the Montreal Protocol, which came into effect in 1989.

Despite the reduction in CCl4 production, research on its combustion byproducts has continued due to the persistence of CCl4 in the environment and its ongoing use in certain industrial processes. The primary objectives of current research include:

1. Developing more efficient and complete combustion processes to minimize the formation of harmful byproducts.

2. Improving detection and quantification methods for trace levels of combustion byproducts in various environmental matrices.

3. Understanding the atmospheric chemistry and environmental fate of CCl4 combustion byproducts.

4. Assessing the long-term environmental and health impacts of historical CCl4 use and combustion.

5. Exploring remediation techniques for sites contaminated with CCl4 and its combustion byproducts.

Recent technological advancements, such as high-resolution mass spectrometry and advanced computational modeling, have enabled researchers to identify previously unknown combustion byproducts and predict their formation mechanisms. This has led to a more comprehensive understanding of the complex chemical reactions that occur during CCl4 combustion.

The ultimate goal of ongoing research is to develop strategies for the safe disposal of existing CCl4 stockpiles and to minimize the environmental impact of its combustion. This includes optimizing incineration conditions, developing novel catalysts for complete decomposition, and exploring alternative destruction technologies that produce fewer harmful byproducts.

Market Demand for CCl4 Byproduct Management

The market demand for Carbon Tetrachloride (CCl4) byproduct management has been steadily increasing due to growing environmental concerns and stricter regulations on hazardous waste disposal. As industries continue to use CCl4 in various applications, the need for effective management of its combustion byproducts has become paramount.

The primary drivers for this market demand are the environmental and health risks associated with CCl4 byproducts. These compounds, including phosgene, hydrogen chloride, and chlorine, are known to be highly toxic and can have severe impacts on human health and ecosystems. Consequently, there is a pressing need for advanced treatment technologies and disposal methods to mitigate these risks.

Regulatory pressures have also played a significant role in shaping the market demand. Many countries have implemented stringent regulations on the handling and disposal of CCl4 and its byproducts. For instance, the United States Environmental Protection Agency (EPA) has classified CCl4 as a hazardous air pollutant, requiring industries to implement rigorous control measures and treatment processes.

The industrial sector, particularly chemical manufacturing and pharmaceutical industries, represents a substantial portion of the market demand for CCl4 byproduct management. These industries often use CCl4 as a solvent or in the production of various chemicals, generating significant amounts of byproducts that require proper handling and disposal.

Another key factor driving market demand is the growing awareness of the long-term environmental impacts of CCl4 byproducts. As research continues to uncover the persistence and bioaccumulation potential of these compounds in the environment, there is an increasing push for more sustainable and environmentally friendly management solutions.

The market for CCl4 byproduct management technologies is expected to grow as industries seek innovative solutions to comply with regulations and reduce their environmental footprint. This has led to increased investment in research and development of advanced treatment technologies, such as catalytic oxidation, thermal destruction, and chemical neutralization methods.

Furthermore, the circular economy concept has gained traction in recent years, driving demand for technologies that can recover and recycle CCl4 or convert its byproducts into useful materials. This approach not only addresses environmental concerns but also offers potential economic benefits to industries.

As global efforts to combat climate change intensify, there is also a growing market demand for technologies that can reduce the greenhouse gas emissions associated with CCl4 combustion and its byproducts. This has spurred interest in developing more energy-efficient treatment processes and exploring alternative, less harmful substitutes for CCl4 in various applications.

The primary drivers for this market demand are the environmental and health risks associated with CCl4 byproducts. These compounds, including phosgene, hydrogen chloride, and chlorine, are known to be highly toxic and can have severe impacts on human health and ecosystems. Consequently, there is a pressing need for advanced treatment technologies and disposal methods to mitigate these risks.

Regulatory pressures have also played a significant role in shaping the market demand. Many countries have implemented stringent regulations on the handling and disposal of CCl4 and its byproducts. For instance, the United States Environmental Protection Agency (EPA) has classified CCl4 as a hazardous air pollutant, requiring industries to implement rigorous control measures and treatment processes.

The industrial sector, particularly chemical manufacturing and pharmaceutical industries, represents a substantial portion of the market demand for CCl4 byproduct management. These industries often use CCl4 as a solvent or in the production of various chemicals, generating significant amounts of byproducts that require proper handling and disposal.

Another key factor driving market demand is the growing awareness of the long-term environmental impacts of CCl4 byproducts. As research continues to uncover the persistence and bioaccumulation potential of these compounds in the environment, there is an increasing push for more sustainable and environmentally friendly management solutions.

The market for CCl4 byproduct management technologies is expected to grow as industries seek innovative solutions to comply with regulations and reduce their environmental footprint. This has led to increased investment in research and development of advanced treatment technologies, such as catalytic oxidation, thermal destruction, and chemical neutralization methods.

Furthermore, the circular economy concept has gained traction in recent years, driving demand for technologies that can recover and recycle CCl4 or convert its byproducts into useful materials. This approach not only addresses environmental concerns but also offers potential economic benefits to industries.

As global efforts to combat climate change intensify, there is also a growing market demand for technologies that can reduce the greenhouse gas emissions associated with CCl4 combustion and its byproducts. This has spurred interest in developing more energy-efficient treatment processes and exploring alternative, less harmful substitutes for CCl4 in various applications.

Current Challenges in CCl4 Combustion Analysis

The analysis of carbon tetrachloride (CCl4) combustion byproducts presents several significant challenges that researchers and environmental scientists are currently grappling with. One of the primary difficulties lies in the complex nature of the combustion process itself, which produces a wide array of byproducts, many of which are highly toxic and persistent in the environment.

A major challenge is the accurate detection and quantification of these byproducts. The combustion of CCl4 can generate various chlorinated compounds, including phosgene, hydrogen chloride, and chlorine gas, as well as other potentially harmful substances. The diverse range of byproducts, some of which may be present in trace amounts, requires highly sensitive and specific analytical techniques.

Furthermore, the reactivity and instability of certain combustion byproducts pose significant obstacles to their analysis. Some compounds may degrade rapidly or react with other substances in the sampling environment, making it difficult to obtain accurate measurements. This instability necessitates the development of specialized sampling and preservation methods to ensure the integrity of the samples during collection, transport, and analysis.

Another challenge lies in the potential for secondary reactions occurring in the post-combustion environment. These reactions can lead to the formation of additional compounds not directly produced during the initial combustion process, further complicating the analysis and interpretation of results. Researchers must consider these potential transformations when designing experimental setups and analytical protocols.

The variability in combustion conditions also presents a significant hurdle. Factors such as temperature, pressure, oxygen availability, and the presence of catalysts or inhibitors can greatly influence the types and quantities of byproducts formed. This variability makes it challenging to develop standardized methods for byproduct analysis and to compare results across different studies or experimental conditions.

Moreover, the potential for synergistic effects between CCl4 combustion byproducts and other pollutants in real-world scenarios adds another layer of complexity to the analysis. Understanding these interactions and their implications for environmental and health impacts requires interdisciplinary approaches and advanced modeling techniques.

Lastly, the development of comprehensive risk assessment models for CCl4 combustion byproducts remains a significant challenge. These models must integrate data on byproduct formation, environmental fate, and toxicological effects to provide meaningful insights for regulatory decision-making and environmental management strategies.

A major challenge is the accurate detection and quantification of these byproducts. The combustion of CCl4 can generate various chlorinated compounds, including phosgene, hydrogen chloride, and chlorine gas, as well as other potentially harmful substances. The diverse range of byproducts, some of which may be present in trace amounts, requires highly sensitive and specific analytical techniques.

Furthermore, the reactivity and instability of certain combustion byproducts pose significant obstacles to their analysis. Some compounds may degrade rapidly or react with other substances in the sampling environment, making it difficult to obtain accurate measurements. This instability necessitates the development of specialized sampling and preservation methods to ensure the integrity of the samples during collection, transport, and analysis.

Another challenge lies in the potential for secondary reactions occurring in the post-combustion environment. These reactions can lead to the formation of additional compounds not directly produced during the initial combustion process, further complicating the analysis and interpretation of results. Researchers must consider these potential transformations when designing experimental setups and analytical protocols.

The variability in combustion conditions also presents a significant hurdle. Factors such as temperature, pressure, oxygen availability, and the presence of catalysts or inhibitors can greatly influence the types and quantities of byproducts formed. This variability makes it challenging to develop standardized methods for byproduct analysis and to compare results across different studies or experimental conditions.

Moreover, the potential for synergistic effects between CCl4 combustion byproducts and other pollutants in real-world scenarios adds another layer of complexity to the analysis. Understanding these interactions and their implications for environmental and health impacts requires interdisciplinary approaches and advanced modeling techniques.

Lastly, the development of comprehensive risk assessment models for CCl4 combustion byproducts remains a significant challenge. These models must integrate data on byproduct formation, environmental fate, and toxicological effects to provide meaningful insights for regulatory decision-making and environmental management strategies.

Existing CCl4 Combustion Byproduct Detection Methods

01 Formation of chlorine gas and phosgene

When carbon tetrachloride undergoes combustion, it can produce toxic byproducts such as chlorine gas and phosgene. These substances are highly hazardous and can pose significant health and environmental risks. The formation of these byproducts is a major concern in industrial processes involving carbon tetrachloride combustion.- Formation of chlorine gas and phosgene: When carbon tetrachloride undergoes combustion, it can produce chlorine gas and phosgene as byproducts. These toxic gases are formed due to the breakdown of the carbon-chlorine bonds in the molecule under high temperatures. The formation of these byproducts poses significant health and environmental risks.

- Production of carbon dioxide and hydrogen chloride: The combustion of carbon tetrachloride typically results in the formation of carbon dioxide and hydrogen chloride. Carbon dioxide is a common product of carbon-based compound combustion, while hydrogen chloride is formed from the chlorine atoms present in the molecule. These byproducts contribute to air pollution and can have acidifying effects on the environment.

- Generation of chlorinated organic compounds: Incomplete combustion of carbon tetrachloride can lead to the formation of various chlorinated organic compounds. These may include chloroform, dichloromethane, and other partially chlorinated hydrocarbons. The presence of these compounds in combustion byproducts can have significant environmental and health implications.

- Formation of metal chlorides in presence of metals: When carbon tetrachloride combustion occurs in the presence of metals or metal-containing compounds, it can result in the formation of metal chlorides. These metal chlorides are produced through reactions between the chlorine released during combustion and the metal surfaces or particles present in the combustion environment.

- Production of particulate matter and soot: The combustion of carbon tetrachloride can generate particulate matter and soot, especially under conditions of incomplete combustion. These fine particles can contain a mixture of carbon, chlorine-containing compounds, and other byproducts. The release of particulate matter and soot contributes to air pollution and can have adverse effects on respiratory health.

02 Carbon dioxide and carbon monoxide production

The combustion of carbon tetrachloride typically results in the formation of carbon dioxide and carbon monoxide. These gases are common combustion byproducts and contribute to air pollution and greenhouse gas emissions. The ratio of CO2 to CO produced can vary depending on the combustion conditions and available oxygen.Expand Specific Solutions03 Hydrogen chloride formation

Hydrogen chloride is another significant byproduct of carbon tetrachloride combustion. This corrosive gas can form when the chlorine atoms in carbon tetrachloride react with hydrogen present in the combustion environment. The presence of hydrogen chloride can lead to acid rain and other environmental issues.Expand Specific Solutions04 Particulate matter and soot generation

The incomplete combustion of carbon tetrachloride can result in the formation of particulate matter and soot. These fine particles can have adverse effects on air quality and human health. The amount and composition of particulate matter produced depend on factors such as combustion temperature and oxygen availability.Expand Specific Solutions05 Catalytic decomposition and byproduct reduction

Various catalytic methods have been developed to reduce the formation of harmful byproducts during carbon tetrachloride combustion. These techniques aim to promote more complete combustion or facilitate the breakdown of toxic compounds into less harmful substances. Catalysts can help minimize the production of chlorinated organic compounds and other hazardous byproducts.Expand Specific Solutions

Key Players in CCl4 Research and Industry

The research on carbon tetrachloride combustion byproducts is in a mature stage, with significant contributions from both academic institutions and industry players. The market for this technology is relatively stable, driven by environmental regulations and industrial applications. Companies like Occidental Chemical Corp., Shandong Dongyue Fluo-Silicon Materials Co., Ltd., and China Petroleum & Chemical Corp. are key players in this field, leveraging their expertise in chemical manufacturing and processing. Academic institutions such as Changzhou University and Nanjing Tech University contribute to advancing the research. The technology's maturity is evident in the involvement of established firms like DuPont de Nemours, Inc. and Praxair Technology, Inc., which have extensive experience in chemical engineering and industrial gas applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced catalytic oxidation processes for the treatment of carbon tetrachloride combustion byproducts. Their approach involves using noble metal catalysts supported on high-surface-area materials to promote the complete oxidation of chlorinated organic compounds at lower temperatures[1]. The company has also implemented thermal oxidation systems with specialized scrubbers to capture and neutralize acidic byproducts like hydrogen chloride[2]. Additionally, Sinopec has invested in research on plasma-assisted combustion techniques that can potentially reduce the formation of harmful byproducts during carbon tetrachloride incineration[3].

Strengths: Extensive experience in petrochemical processes, large-scale implementation capabilities, and strong R&D resources. Weaknesses: High capital costs for advanced treatment systems and potential regulatory challenges in different markets.

Praxair Technology, Inc.

Technical Solution: Praxair Technology has developed innovative oxy-fuel combustion systems specifically designed for the destruction of carbon tetrachloride and other chlorinated compounds. Their technology utilizes pure oxygen instead of air to achieve higher combustion temperatures and more complete oxidation of organic molecules[4]. The company has also implemented advanced flue gas treatment systems that incorporate dry scrubbing and activated carbon adsorption to remove residual chlorinated byproducts and dioxins[5]. Praxair's research efforts have focused on optimizing combustion conditions to minimize the formation of problematic byproducts while maximizing destruction efficiency[6].

Strengths: Expertise in industrial gas applications, well-established global presence, and strong focus on environmental technologies. Weaknesses: Reliance on oxygen supply infrastructure and potential high operational costs.

Innovative Approaches in CCl4 Byproduct Analysis

Method for reusing heavy end by-products in the manufacture of polychlorinated alkanes

PatentInactiveEP1663920A2

Innovation

- Recovering heavy end by-products through distillation, subjecting them to exhaustive high-temperature chlorination to produce carbon tetrachloride, and recycling it back into the process to produce additional polychlorinated alkanes, thereby maximizing the utilization of starting materials and reducing waste.

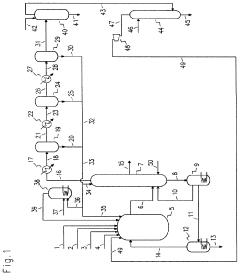

Chlorinolysis process for producing carbon tetrachloride

PatentActiveUS20210130266A1

Innovation

- A process involving a chlorination zone with chlorine, a C1 chlorinated compound, and a carbon/second chlorine source to produce a reaction mixture that favors the formation of carbon tetrachloride over perchloroethylene, using waste products as the carbon/second chlorine source to enhance efficiency and reduce impurity formation.

Environmental Impact of CCl4 Combustion Byproducts

The combustion of carbon tetrachloride (CCl4) produces several byproducts that can have significant environmental impacts. These byproducts primarily include phosgene, hydrogen chloride, and chlorine gas, all of which pose serious risks to both human health and the environment.

Phosgene, a highly toxic gas, is one of the most concerning byproducts of CCl4 combustion. When released into the atmosphere, it can cause severe respiratory issues and, in high concentrations, can be lethal. Phosgene also contributes to the formation of photochemical smog, exacerbating air pollution in urban areas.

Hydrogen chloride, another byproduct, is a strong acid that can cause acid rain when it combines with atmospheric moisture. This acid rain can have detrimental effects on ecosystems, including the acidification of soil and water bodies, damaging vegetation, and harming aquatic life. Additionally, hydrogen chloride can corrode infrastructure and buildings, leading to economic losses.

Chlorine gas, also produced during CCl4 combustion, is a powerful oxidizing agent that can react with organic matter in the environment. This reactivity can lead to the formation of harmful chlorinated organic compounds, which may persist in the environment and bioaccumulate in food chains, potentially causing long-term ecological damage.

The release of these combustion byproducts can also contribute to the depletion of the ozone layer. CCl4 itself is an ozone-depleting substance, and its combustion byproducts can further exacerbate this problem, leading to increased UV radiation reaching the Earth's surface and associated health risks for humans and ecosystems.

In aquatic environments, the deposition of CCl4 combustion byproducts can lead to the acidification of water bodies, altering pH levels and potentially disrupting the delicate balance of aquatic ecosystems. This can result in the loss of sensitive species and changes in biodiversity.

The environmental impact of CCl4 combustion byproducts extends to soil quality as well. Acidic deposition can lead to the leaching of essential nutrients from the soil, reducing its fertility and affecting plant growth. This, in turn, can have cascading effects on terrestrial ecosystems and agricultural productivity.

Given the wide-ranging and severe environmental impacts of CCl4 combustion byproducts, there is a pressing need for continued research into mitigation strategies and alternative technologies. This includes developing more efficient combustion processes, implementing advanced emission control systems, and exploring safer alternatives to CCl4 in industrial applications.

Phosgene, a highly toxic gas, is one of the most concerning byproducts of CCl4 combustion. When released into the atmosphere, it can cause severe respiratory issues and, in high concentrations, can be lethal. Phosgene also contributes to the formation of photochemical smog, exacerbating air pollution in urban areas.

Hydrogen chloride, another byproduct, is a strong acid that can cause acid rain when it combines with atmospheric moisture. This acid rain can have detrimental effects on ecosystems, including the acidification of soil and water bodies, damaging vegetation, and harming aquatic life. Additionally, hydrogen chloride can corrode infrastructure and buildings, leading to economic losses.

Chlorine gas, also produced during CCl4 combustion, is a powerful oxidizing agent that can react with organic matter in the environment. This reactivity can lead to the formation of harmful chlorinated organic compounds, which may persist in the environment and bioaccumulate in food chains, potentially causing long-term ecological damage.

The release of these combustion byproducts can also contribute to the depletion of the ozone layer. CCl4 itself is an ozone-depleting substance, and its combustion byproducts can further exacerbate this problem, leading to increased UV radiation reaching the Earth's surface and associated health risks for humans and ecosystems.

In aquatic environments, the deposition of CCl4 combustion byproducts can lead to the acidification of water bodies, altering pH levels and potentially disrupting the delicate balance of aquatic ecosystems. This can result in the loss of sensitive species and changes in biodiversity.

The environmental impact of CCl4 combustion byproducts extends to soil quality as well. Acidic deposition can lead to the leaching of essential nutrients from the soil, reducing its fertility and affecting plant growth. This, in turn, can have cascading effects on terrestrial ecosystems and agricultural productivity.

Given the wide-ranging and severe environmental impacts of CCl4 combustion byproducts, there is a pressing need for continued research into mitigation strategies and alternative technologies. This includes developing more efficient combustion processes, implementing advanced emission control systems, and exploring safer alternatives to CCl4 in industrial applications.

Regulatory Framework for CCl4 Handling and Disposal

The regulatory framework for carbon tetrachloride (CCl4) handling and disposal has evolved significantly in response to the growing understanding of its environmental and health impacts. At the international level, the Montreal Protocol on Substances that Deplete the Ozone Layer, adopted in 1987, has been instrumental in phasing out the production and consumption of CCl4. This treaty has been universally ratified and has led to a dramatic reduction in CCl4 emissions globally.

In the United States, the Environmental Protection Agency (EPA) regulates CCl4 under various statutes. The Toxic Substances Control Act (TSCA) lists CCl4 as a priority chemical, subjecting it to risk evaluations and potential restrictions. The Clean Air Act classifies CCl4 as a hazardous air pollutant, requiring strict emission controls in industrial processes. Additionally, the Resource Conservation and Recovery Act (RCRA) governs the disposal of CCl4 as a hazardous waste.

The Occupational Safety and Health Administration (OSHA) has established permissible exposure limits for CCl4 in the workplace, mandating engineering controls and personal protective equipment to minimize worker exposure. These regulations are crucial in industries where CCl4 is still used or produced as a byproduct.

European Union regulations on CCl4 are equally stringent. The REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation requires manufacturers and importers to register CCl4 and provide safety data. The CLP (Classification, Labeling and Packaging) regulation ensures that the hazards of CCl4 are clearly communicated to workers and consumers.

Disposal of CCl4 and its combustion byproducts is strictly regulated. Incineration is the preferred method for destroying CCl4, but it must be conducted under controlled conditions to prevent the formation of even more toxic compounds. Specialized hazardous waste facilities are required for this process, with stringent monitoring and reporting requirements.

Recent advances in research on CCl4 combustion byproducts have led to updates in regulatory frameworks. There is an increased focus on monitoring and controlling the formation of persistent organic pollutants (POPs) during CCl4 incineration. Regulatory bodies are now requiring more sophisticated air pollution control devices and continuous emission monitoring systems for facilities handling CCl4.

The global trend is towards even stricter regulations on CCl4. Many countries are implementing total bans on its production and use, with exceptions only for essential laboratory and analytical applications. There is also a growing emphasis on finding and remediating CCl4-contaminated sites, with regulatory frameworks being developed to guide these cleanup efforts.

In the United States, the Environmental Protection Agency (EPA) regulates CCl4 under various statutes. The Toxic Substances Control Act (TSCA) lists CCl4 as a priority chemical, subjecting it to risk evaluations and potential restrictions. The Clean Air Act classifies CCl4 as a hazardous air pollutant, requiring strict emission controls in industrial processes. Additionally, the Resource Conservation and Recovery Act (RCRA) governs the disposal of CCl4 as a hazardous waste.

The Occupational Safety and Health Administration (OSHA) has established permissible exposure limits for CCl4 in the workplace, mandating engineering controls and personal protective equipment to minimize worker exposure. These regulations are crucial in industries where CCl4 is still used or produced as a byproduct.

European Union regulations on CCl4 are equally stringent. The REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation requires manufacturers and importers to register CCl4 and provide safety data. The CLP (Classification, Labeling and Packaging) regulation ensures that the hazards of CCl4 are clearly communicated to workers and consumers.

Disposal of CCl4 and its combustion byproducts is strictly regulated. Incineration is the preferred method for destroying CCl4, but it must be conducted under controlled conditions to prevent the formation of even more toxic compounds. Specialized hazardous waste facilities are required for this process, with stringent monitoring and reporting requirements.

Recent advances in research on CCl4 combustion byproducts have led to updates in regulatory frameworks. There is an increased focus on monitoring and controlling the formation of persistent organic pollutants (POPs) during CCl4 incineration. Regulatory bodies are now requiring more sophisticated air pollution control devices and continuous emission monitoring systems for facilities handling CCl4.

The global trend is towards even stricter regulations on CCl4. Many countries are implementing total bans on its production and use, with exceptions only for essential laboratory and analytical applications. There is also a growing emphasis on finding and remediating CCl4-contaminated sites, with regulatory frameworks being developed to guide these cleanup efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!