How to Incorporate Carbon Tetrachloride into Safety Training Programs?

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CCl4 Safety Background

Carbon tetrachloride (CCl4) is a colorless, volatile liquid with a sweet odor that has been widely used in various industrial applications. Historically, it was employed as a solvent, cleaning agent, and fire extinguishing agent. However, its use has been significantly restricted due to its severe health and environmental hazards.

The compound was first synthesized in the mid-19th century and gained popularity in the early 20th century for its effectiveness as a degreasing agent and dry-cleaning solvent. Its non-flammable properties also made it attractive for use in fire extinguishers. However, as research progressed, the dangers associated with CCl4 exposure became increasingly apparent.

Acute exposure to carbon tetrachloride can cause severe liver and kidney damage, central nervous system depression, and in extreme cases, death. Chronic exposure has been linked to liver cirrhosis, kidney damage, and an increased risk of cancer. The compound is also a potent ozone-depleting substance, contributing to the depletion of the Earth's protective ozone layer.

Due to these risks, the use of carbon tetrachloride has been phased out in many applications. The Montreal Protocol, an international treaty designed to protect the ozone layer, banned the production of CCl4 for dispersive uses in developed countries by 1996. However, it is still produced in limited quantities for use as a feedstock in the production of other chemicals.

In the context of safety training programs, understanding the history and properties of carbon tetrachloride is crucial. While its use has diminished, it may still be encountered in legacy systems, contaminated sites, or in specific industrial processes. Safety professionals must be aware of its characteristics, potential exposure routes, and the severe health effects it can cause.

Training programs should emphasize the importance of proper handling, storage, and disposal of CCl4. This includes the use of appropriate personal protective equipment (PPE), such as chemical-resistant gloves, goggles, and respiratory protection. Proper ventilation and containment measures are also critical to prevent exposure.

Furthermore, safety training should cover emergency response procedures in case of CCl4 spills or accidental releases. This includes evacuation protocols, spill containment methods, and decontamination procedures. Given its volatile nature, training should also address the risks of vapor inhalation and the importance of air monitoring in potentially contaminated areas.

The compound was first synthesized in the mid-19th century and gained popularity in the early 20th century for its effectiveness as a degreasing agent and dry-cleaning solvent. Its non-flammable properties also made it attractive for use in fire extinguishers. However, as research progressed, the dangers associated with CCl4 exposure became increasingly apparent.

Acute exposure to carbon tetrachloride can cause severe liver and kidney damage, central nervous system depression, and in extreme cases, death. Chronic exposure has been linked to liver cirrhosis, kidney damage, and an increased risk of cancer. The compound is also a potent ozone-depleting substance, contributing to the depletion of the Earth's protective ozone layer.

Due to these risks, the use of carbon tetrachloride has been phased out in many applications. The Montreal Protocol, an international treaty designed to protect the ozone layer, banned the production of CCl4 for dispersive uses in developed countries by 1996. However, it is still produced in limited quantities for use as a feedstock in the production of other chemicals.

In the context of safety training programs, understanding the history and properties of carbon tetrachloride is crucial. While its use has diminished, it may still be encountered in legacy systems, contaminated sites, or in specific industrial processes. Safety professionals must be aware of its characteristics, potential exposure routes, and the severe health effects it can cause.

Training programs should emphasize the importance of proper handling, storage, and disposal of CCl4. This includes the use of appropriate personal protective equipment (PPE), such as chemical-resistant gloves, goggles, and respiratory protection. Proper ventilation and containment measures are also critical to prevent exposure.

Furthermore, safety training should cover emergency response procedures in case of CCl4 spills or accidental releases. This includes evacuation protocols, spill containment methods, and decontamination procedures. Given its volatile nature, training should also address the risks of vapor inhalation and the importance of air monitoring in potentially contaminated areas.

Regulatory Requirements

Carbon tetrachloride is a highly regulated substance due to its potential health and environmental hazards. Incorporating it into safety training programs requires a thorough understanding of the regulatory landscape. The Occupational Safety and Health Administration (OSHA) has established strict guidelines for the handling, storage, and use of carbon tetrachloride in workplace settings. These regulations are outlined in the Code of Federal Regulations (CFR), specifically in 29 CFR 1910.1000, which sets permissible exposure limits (PELs) for various hazardous substances, including carbon tetrachloride.

Under OSHA regulations, employers must ensure that employee exposure to carbon tetrachloride does not exceed 10 parts per million (ppm) as an 8-hour time-weighted average (TWA). Additionally, the short-term exposure limit (STEL) is set at 25 ppm for any 15-minute period. These limits are crucial components of any safety training program involving carbon tetrachloride.

The Environmental Protection Agency (EPA) also plays a significant role in regulating carbon tetrachloride. Under the Toxic Substances Control Act (TSCA), the EPA has imposed restrictions on the manufacture, processing, and distribution of carbon tetrachloride. The Clean Air Act further classifies carbon tetrachloride as a hazardous air pollutant, subject to stringent emission controls.

Safety training programs must also address the requirements set forth by the Department of Transportation (DOT) for the transportation of carbon tetrachloride. The substance is classified as a hazardous material under DOT regulations, requiring specific packaging, labeling, and documentation for transport.

State and local regulations may impose additional requirements for the use and handling of carbon tetrachloride. These can vary significantly by jurisdiction and may include more stringent exposure limits, reporting requirements, or restrictions on use. Safety training programs should incorporate a comprehensive review of applicable state and local regulations to ensure full compliance.

International regulations, such as those established by the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) program, must be considered for organizations operating globally. REACH imposes strict controls on the use of carbon tetrachloride and requires extensive documentation and risk assessment procedures.

To effectively incorporate carbon tetrachloride into safety training programs, organizations must develop a comprehensive understanding of these regulatory requirements. This includes regular monitoring of regulatory updates, as environmental and safety regulations are subject to change. Training programs should be designed to ensure that all employees who may come into contact with carbon tetrachloride are fully aware of the applicable regulations and understand their responsibilities in maintaining compliance.

Under OSHA regulations, employers must ensure that employee exposure to carbon tetrachloride does not exceed 10 parts per million (ppm) as an 8-hour time-weighted average (TWA). Additionally, the short-term exposure limit (STEL) is set at 25 ppm for any 15-minute period. These limits are crucial components of any safety training program involving carbon tetrachloride.

The Environmental Protection Agency (EPA) also plays a significant role in regulating carbon tetrachloride. Under the Toxic Substances Control Act (TSCA), the EPA has imposed restrictions on the manufacture, processing, and distribution of carbon tetrachloride. The Clean Air Act further classifies carbon tetrachloride as a hazardous air pollutant, subject to stringent emission controls.

Safety training programs must also address the requirements set forth by the Department of Transportation (DOT) for the transportation of carbon tetrachloride. The substance is classified as a hazardous material under DOT regulations, requiring specific packaging, labeling, and documentation for transport.

State and local regulations may impose additional requirements for the use and handling of carbon tetrachloride. These can vary significantly by jurisdiction and may include more stringent exposure limits, reporting requirements, or restrictions on use. Safety training programs should incorporate a comprehensive review of applicable state and local regulations to ensure full compliance.

International regulations, such as those established by the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) program, must be considered for organizations operating globally. REACH imposes strict controls on the use of carbon tetrachloride and requires extensive documentation and risk assessment procedures.

To effectively incorporate carbon tetrachloride into safety training programs, organizations must develop a comprehensive understanding of these regulatory requirements. This includes regular monitoring of regulatory updates, as environmental and safety regulations are subject to change. Training programs should be designed to ensure that all employees who may come into contact with carbon tetrachloride are fully aware of the applicable regulations and understand their responsibilities in maintaining compliance.

Hazard Identification

Carbon tetrachloride (CCl4) is a highly toxic chemical compound that poses significant risks to human health and the environment. Proper hazard identification is crucial when incorporating this substance into safety training programs. The primary hazards associated with carbon tetrachloride include its potential for liver and kidney damage, central nervous system depression, and its classification as a probable human carcinogen.

Inhalation of carbon tetrachloride vapors presents the most immediate danger in workplace settings. Even short-term exposure to high concentrations can lead to dizziness, nausea, and loss of consciousness. Prolonged or repeated exposure may result in severe liver and kidney damage. Skin contact with the liquid form can cause irritation and dermatitis, while eye contact may lead to corneal injury.

The flammability of carbon tetrachloride is relatively low, but it can decompose at high temperatures to produce toxic and corrosive fumes, including phosgene and hydrogen chloride. This decomposition risk is particularly relevant in fire scenarios or when the compound is exposed to hot surfaces or open flames.

Environmental hazards must also be considered in hazard identification. Carbon tetrachloride is known to deplete the ozone layer and contribute to global warming. Its persistence in the environment and potential for bioaccumulation in aquatic organisms further underscore its ecological impact.

When identifying hazards for safety training purposes, it is essential to consider the specific workplace applications of carbon tetrachloride. In industrial settings, it may be used as a solvent, cleaning agent, or in the production of refrigerants. Each application presents unique exposure risks that must be addressed in training programs.

The physical properties of carbon tetrachloride, such as its high volatility and ability to penetrate many common protective materials, should be emphasized in hazard identification. This information is critical for selecting appropriate personal protective equipment (PPE) and engineering controls to mitigate exposure risks.

Hazard communication systems, including proper labeling and safety data sheets (SDS), play a vital role in hazard identification. Training programs should ensure that all personnel can interpret these resources correctly to understand the full spectrum of risks associated with carbon tetrachloride.

Lastly, the potential for synergistic effects when carbon tetrachloride is combined with other chemicals or substances in the workplace must be addressed. These interactions can amplify toxicity or create new hazards that may not be immediately apparent when considering the compound in isolation.

Inhalation of carbon tetrachloride vapors presents the most immediate danger in workplace settings. Even short-term exposure to high concentrations can lead to dizziness, nausea, and loss of consciousness. Prolonged or repeated exposure may result in severe liver and kidney damage. Skin contact with the liquid form can cause irritation and dermatitis, while eye contact may lead to corneal injury.

The flammability of carbon tetrachloride is relatively low, but it can decompose at high temperatures to produce toxic and corrosive fumes, including phosgene and hydrogen chloride. This decomposition risk is particularly relevant in fire scenarios or when the compound is exposed to hot surfaces or open flames.

Environmental hazards must also be considered in hazard identification. Carbon tetrachloride is known to deplete the ozone layer and contribute to global warming. Its persistence in the environment and potential for bioaccumulation in aquatic organisms further underscore its ecological impact.

When identifying hazards for safety training purposes, it is essential to consider the specific workplace applications of carbon tetrachloride. In industrial settings, it may be used as a solvent, cleaning agent, or in the production of refrigerants. Each application presents unique exposure risks that must be addressed in training programs.

The physical properties of carbon tetrachloride, such as its high volatility and ability to penetrate many common protective materials, should be emphasized in hazard identification. This information is critical for selecting appropriate personal protective equipment (PPE) and engineering controls to mitigate exposure risks.

Hazard communication systems, including proper labeling and safety data sheets (SDS), play a vital role in hazard identification. Training programs should ensure that all personnel can interpret these resources correctly to understand the full spectrum of risks associated with carbon tetrachloride.

Lastly, the potential for synergistic effects when carbon tetrachloride is combined with other chemicals or substances in the workplace must be addressed. These interactions can amplify toxicity or create new hazards that may not be immediately apparent when considering the compound in isolation.

Current Training Methods

01 Production and purification of carbon tetrachloride

Various methods for producing and purifying carbon tetrachloride are described. These include chemical synthesis processes, distillation techniques, and purification methods to obtain high-quality carbon tetrachloride for industrial and laboratory use.- Production and purification of carbon tetrachloride: Various methods for producing and purifying carbon tetrachloride are described. These include chemical synthesis processes, distillation techniques, and purification methods to obtain high-quality carbon tetrachloride for industrial and laboratory use.

- Applications of carbon tetrachloride in chemical processes: Carbon tetrachloride is utilized in various chemical processes, including as a solvent, reagent, or intermediate in the production of other chemicals. Its applications span across different industries, such as pharmaceuticals, agrochemicals, and materials science.

- Environmental and safety considerations: Due to its environmental impact and health hazards, research focuses on developing alternatives to carbon tetrachloride and methods for its safe handling, storage, and disposal. This includes studies on its atmospheric effects and strategies for reducing its use in industrial processes.

- Detection and analysis methods for carbon tetrachloride: Various analytical techniques and methods have been developed for detecting and quantifying carbon tetrachloride in different matrices, including air, water, and soil. These methods are crucial for environmental monitoring and quality control in industrial settings.

- Historical uses and developments: The historical applications of carbon tetrachloride, including its use as a fire extinguishing agent, cleaning solvent, and refrigerant, are documented. The evolution of its usage and the subsequent restrictions due to environmental concerns are also discussed.

02 Applications of carbon tetrachloride in chemical processes

Carbon tetrachloride is utilized in various chemical processes as a solvent, reagent, or intermediate. It finds applications in organic synthesis, extraction processes, and as a raw material for the production of other chlorinated compounds.Expand Specific Solutions03 Environmental and safety considerations

Due to its environmental impact and health hazards, research focuses on alternatives to carbon tetrachloride and methods for its safe handling, storage, and disposal. This includes developing eco-friendly substitutes and implementing safety measures in industrial settings.Expand Specific Solutions04 Detection and analysis of carbon tetrachloride

Techniques and apparatus for detecting and analyzing carbon tetrachloride in various matrices are developed. These include spectroscopic methods, chromatographic techniques, and specialized sensors for monitoring carbon tetrachloride levels in air, water, and soil.Expand Specific Solutions05 Historical uses and patents related to carbon tetrachloride

Early patents and historical documents describe various applications of carbon tetrachloride, including its use as a fire extinguishing agent, cleaning solvent, and in the production of refrigerants. These patents provide insight into the evolution of carbon tetrachloride's industrial applications over time.Expand Specific Solutions

Key Stakeholders

The incorporation of carbon tetrachloride into safety training programs is a critical issue in the chemical industry, currently in a mature stage of development. The market for such training is substantial, driven by stringent safety regulations and the high-risk nature of handling this chemical. Companies like Wacker Chemie AG, Occidental Chemical Corp., and Tronox LLC are at the forefront of developing comprehensive safety protocols. The technology for safe handling and training is well-established, with 3M Innovative Properties Co. and DuPont de Nemours, Inc. contributing significantly to advancements in protective equipment and safety procedures. Educational institutions such as Changzhou University and Central South University play crucial roles in research and training, ensuring a steady pipeline of skilled professionals in this field.

Occidental Chemical Corp.

Technical Solution: Occidental Chemical Corp. has implemented a robust safety training program for carbon tetrachloride handling. Their approach focuses on a combination of theoretical knowledge and practical skills. The program includes detailed modules on the chemical properties of carbon tetrachloride, its health hazards, and environmental impacts. They have developed a series of interactive e-learning courses that employees must complete before handling the substance[4]. Additionally, they conduct regular hands-on training sessions in controlled environments, simulating various scenarios such as proper storage, transportation, and spill containment[5]. The company has also integrated advanced air quality monitoring systems into their facilities, which are used as teaching tools during training to demonstrate the importance of proper ventilation and personal protective equipment[6].

Strengths: Comprehensive theoretical and practical training; Use of interactive e-learning platforms; Integration of real-world monitoring systems in training. Weaknesses: Potential for high training costs; Requires frequent updates to align with changing regulations and best practices.

3M Innovative Properties Co.

Technical Solution: 3M Innovative Properties Co. has developed an innovative approach to incorporating carbon tetrachloride into safety training programs. Their method utilizes augmented reality (AR) technology to create interactive training modules that allow employees to visualize potential hazards and practice safety procedures in a risk-free environment[7]. The company has also developed specialized personal protective equipment (PPE) with integrated sensors that can detect carbon tetrachloride exposure levels in real-time, providing immediate feedback during training exercises[8]. Their program includes a comprehensive curriculum covering the chemical properties of carbon tetrachloride, proper handling techniques, emergency response procedures, and environmental protection measures. 3M has also implemented a peer-to-peer training system, where experienced handlers mentor new employees, ensuring knowledge transfer and practical skill development[9].

Strengths: Cutting-edge AR technology for immersive training; Innovative PPE with real-time exposure monitoring; Comprehensive curriculum with peer-to-peer mentoring. Weaknesses: High initial investment in AR technology and specialized PPE; Requires regular updates to maintain technological relevance.

Best Practices Analysis

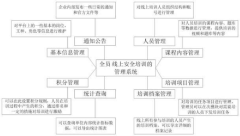

Management system for whole-staff online safety training

PatentPendingCN117853285A

Innovation

- An all-staff online safety training management system is designed, which uses cloud servers and user terminals to connect through the network. It includes a certification module, a training module, an assessment module, a storage module and a management module. Users can log in through a browser for training, and administrators can Online supervision and management, automatic storage of training files, support for video playback, fast loading and encryption, and configuration of training materials to adapt to different network environments.

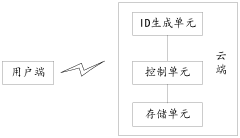

Safety production training rapid matching system and video matching method

PatentActiveCN111125432A

Innovation

- A quick matching system for safety production training is designed, which uses the communication connection between the client and the cloud, through ID generation, storage and control units, combined with machine learning methods, to monitor the user's learning time and match training videos, automatically generate certificates, and pass necessary Select and optional video database for video matching.

Risk Assessment Tools

Risk assessment tools play a crucial role in incorporating carbon tetrachloride into safety training programs. These tools enable organizations to systematically identify, evaluate, and prioritize potential hazards associated with the use, handling, and storage of this toxic chemical.

One of the primary risk assessment tools is the Hazard Identification and Risk Assessment (HIRA) matrix. This tool helps safety professionals categorize the likelihood and severity of potential incidents involving carbon tetrachloride. By assigning numerical values to these factors, organizations can quantify risks and allocate resources accordingly.

Another valuable tool is the Job Safety Analysis (JSA), which breaks down tasks involving carbon tetrachloride into individual steps. For each step, potential hazards are identified, and appropriate control measures are recommended. This process ensures that workers are aware of specific risks associated with their duties and are equipped with the necessary knowledge to mitigate them.

The Failure Mode and Effects Analysis (FMEA) is particularly useful for assessing the potential failure modes of equipment and processes involving carbon tetrachloride. This tool helps identify critical points where failures could lead to chemical exposure or release, allowing for the implementation of preventive measures.

Quantitative risk assessment tools, such as Fault Tree Analysis (FTA) and Event Tree Analysis (ETA), provide a more detailed understanding of the potential accident scenarios involving carbon tetrachloride. These tools help safety trainers illustrate complex cause-and-effect relationships and emphasize the importance of following safety protocols.

Exposure modeling tools, like the EPA's AERMOD or CALPUFF, can be incorporated into safety training to demonstrate how carbon tetrachloride might disperse in the event of a release. This visual representation helps workers understand the potential impact of a chemical incident and reinforces the importance of proper handling and emergency response procedures.

Personal protective equipment (PPE) selection tools, such as the NIOSH PPE-Info database, assist in determining the appropriate level of protection required when working with carbon tetrachloride. These tools can be integrated into training programs to ensure workers understand the importance of proper PPE selection and use.

Lastly, incident investigation tools like the Root Cause Analysis (RCA) can be used in safety training to analyze past incidents involving carbon tetrachloride. By examining these case studies, trainees can learn from previous mistakes and understand the importance of adhering to safety protocols.

One of the primary risk assessment tools is the Hazard Identification and Risk Assessment (HIRA) matrix. This tool helps safety professionals categorize the likelihood and severity of potential incidents involving carbon tetrachloride. By assigning numerical values to these factors, organizations can quantify risks and allocate resources accordingly.

Another valuable tool is the Job Safety Analysis (JSA), which breaks down tasks involving carbon tetrachloride into individual steps. For each step, potential hazards are identified, and appropriate control measures are recommended. This process ensures that workers are aware of specific risks associated with their duties and are equipped with the necessary knowledge to mitigate them.

The Failure Mode and Effects Analysis (FMEA) is particularly useful for assessing the potential failure modes of equipment and processes involving carbon tetrachloride. This tool helps identify critical points where failures could lead to chemical exposure or release, allowing for the implementation of preventive measures.

Quantitative risk assessment tools, such as Fault Tree Analysis (FTA) and Event Tree Analysis (ETA), provide a more detailed understanding of the potential accident scenarios involving carbon tetrachloride. These tools help safety trainers illustrate complex cause-and-effect relationships and emphasize the importance of following safety protocols.

Exposure modeling tools, like the EPA's AERMOD or CALPUFF, can be incorporated into safety training to demonstrate how carbon tetrachloride might disperse in the event of a release. This visual representation helps workers understand the potential impact of a chemical incident and reinforces the importance of proper handling and emergency response procedures.

Personal protective equipment (PPE) selection tools, such as the NIOSH PPE-Info database, assist in determining the appropriate level of protection required when working with carbon tetrachloride. These tools can be integrated into training programs to ensure workers understand the importance of proper PPE selection and use.

Lastly, incident investigation tools like the Root Cause Analysis (RCA) can be used in safety training to analyze past incidents involving carbon tetrachloride. By examining these case studies, trainees can learn from previous mistakes and understand the importance of adhering to safety protocols.

Emergency Response Plans

Emergency response plans are crucial components of safety training programs involving carbon tetrachloride. These plans should be comprehensive, addressing potential scenarios related to carbon tetrachloride exposure, spills, or releases. The first step in developing an effective emergency response plan is to conduct a thorough risk assessment, identifying all potential hazards associated with carbon tetrachloride use in the workplace.

The plan should clearly outline evacuation procedures, specifying primary and secondary evacuation routes, assembly points, and methods for accounting for all personnel. It is essential to designate specific roles and responsibilities for emergency response team members, including first responders, communication coordinators, and medical personnel.

Proper personal protective equipment (PPE) requirements must be detailed in the plan, including respiratory protection, chemical-resistant suits, and appropriate gloves. The plan should also specify the location and proper use of emergency equipment such as eyewash stations, safety showers, and spill containment materials.

Communication protocols are vital in emergency situations. The plan should establish clear lines of communication, including methods for alerting employees, notifying emergency services, and informing relevant authorities. Regular drills and simulations should be conducted to ensure all employees are familiar with the emergency response procedures and can execute them effectively under pressure.

Decontamination procedures specific to carbon tetrachloride exposure should be outlined in detail. This includes steps for removing contaminated clothing, proper washing techniques, and guidelines for seeking medical attention. The plan should also address proper disposal methods for contaminated materials and cleanup procedures for spills of various sizes.

Coordination with local emergency services is essential. The plan should include contact information for relevant authorities and outline procedures for working with external responders. It is important to provide these services with facility layouts, chemical inventories, and other pertinent information to facilitate an effective response.

Post-incident procedures should be included in the plan, covering incident reporting, investigation protocols, and steps for reviewing and updating the emergency response plan based on lessons learned. This ensures continuous improvement of safety measures and emergency preparedness.

Regular review and updates of the emergency response plan are necessary to maintain its effectiveness. This should include periodic reassessment of risks, incorporation of new technologies or best practices, and adjustments based on changes in regulations or workplace conditions.

The plan should clearly outline evacuation procedures, specifying primary and secondary evacuation routes, assembly points, and methods for accounting for all personnel. It is essential to designate specific roles and responsibilities for emergency response team members, including first responders, communication coordinators, and medical personnel.

Proper personal protective equipment (PPE) requirements must be detailed in the plan, including respiratory protection, chemical-resistant suits, and appropriate gloves. The plan should also specify the location and proper use of emergency equipment such as eyewash stations, safety showers, and spill containment materials.

Communication protocols are vital in emergency situations. The plan should establish clear lines of communication, including methods for alerting employees, notifying emergency services, and informing relevant authorities. Regular drills and simulations should be conducted to ensure all employees are familiar with the emergency response procedures and can execute them effectively under pressure.

Decontamination procedures specific to carbon tetrachloride exposure should be outlined in detail. This includes steps for removing contaminated clothing, proper washing techniques, and guidelines for seeking medical attention. The plan should also address proper disposal methods for contaminated materials and cleanup procedures for spills of various sizes.

Coordination with local emergency services is essential. The plan should include contact information for relevant authorities and outline procedures for working with external responders. It is important to provide these services with facility layouts, chemical inventories, and other pertinent information to facilitate an effective response.

Post-incident procedures should be included in the plan, covering incident reporting, investigation protocols, and steps for reviewing and updating the emergency response plan based on lessons learned. This ensures continuous improvement of safety measures and emergency preparedness.

Regular review and updates of the emergency response plan are necessary to maintain its effectiveness. This should include periodic reassessment of risks, incorporation of new technologies or best practices, and adjustments based on changes in regulations or workplace conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!