Investigating Carbon Tetrachloride's Role in Hazardous Waste Management

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CCl4 in Waste Management: Background and Objectives

Carbon tetrachloride (CCl4) has been a subject of significant concern in hazardous waste management due to its persistent nature and potential environmental impact. The compound, once widely used in various industrial applications, has been phased out in many countries due to its ozone-depleting properties and toxicity. However, its legacy in waste streams and contaminated sites continues to pose challenges for environmental management and remediation efforts.

The evolution of CCl4 in waste management reflects broader trends in environmental policy and technological advancement. Initially utilized for its non-flammable properties in fire extinguishers and as a cleaning agent, CCl4's widespread industrial use led to its accumulation in the environment. The recognition of its harmful effects prompted international action, culminating in the Montreal Protocol, which significantly restricted its production and use.

Current objectives in managing CCl4 waste focus on several key areas. Firstly, there is a pressing need to develop more effective detection and monitoring techniques to accurately assess CCl4 contamination levels in various environmental matrices. This includes improving analytical methods for soil, water, and air sampling to enable more precise risk assessments and inform remediation strategies.

Secondly, research efforts are directed towards enhancing remediation technologies specifically tailored for CCl4 contamination. Traditional methods such as pump-and-treat systems have shown limited efficacy due to CCl4's low solubility and tendency to form dense non-aqueous phase liquids (DNAPLs). Therefore, innovative approaches like in-situ chemical reduction, bioremediation, and thermal treatment are being explored to improve removal efficiency and reduce treatment costs.

Another critical objective is the development of sustainable disposal methods for CCl4-containing waste. While incineration has been a common disposal technique, concerns about potential emissions have led to investigations into alternative destruction technologies. These include advanced oxidation processes and plasma-based systems that aim to achieve complete mineralization of CCl4 with minimal environmental impact.

Furthermore, there is an increasing focus on preventive measures and the implementation of green chemistry principles to minimize future CCl4 waste generation. This involves exploring safer alternatives for industrial processes that historically relied on CCl4 and developing strategies to reduce the use of chlorinated solvents in general.

The management of CCl4 in hazardous waste also intersects with broader environmental and public health initiatives. Efforts are underway to better understand the long-term ecological and health impacts of CCl4 exposure, particularly in areas with historical contamination. This knowledge is crucial for developing risk-based management strategies and prioritizing remediation efforts.

The evolution of CCl4 in waste management reflects broader trends in environmental policy and technological advancement. Initially utilized for its non-flammable properties in fire extinguishers and as a cleaning agent, CCl4's widespread industrial use led to its accumulation in the environment. The recognition of its harmful effects prompted international action, culminating in the Montreal Protocol, which significantly restricted its production and use.

Current objectives in managing CCl4 waste focus on several key areas. Firstly, there is a pressing need to develop more effective detection and monitoring techniques to accurately assess CCl4 contamination levels in various environmental matrices. This includes improving analytical methods for soil, water, and air sampling to enable more precise risk assessments and inform remediation strategies.

Secondly, research efforts are directed towards enhancing remediation technologies specifically tailored for CCl4 contamination. Traditional methods such as pump-and-treat systems have shown limited efficacy due to CCl4's low solubility and tendency to form dense non-aqueous phase liquids (DNAPLs). Therefore, innovative approaches like in-situ chemical reduction, bioremediation, and thermal treatment are being explored to improve removal efficiency and reduce treatment costs.

Another critical objective is the development of sustainable disposal methods for CCl4-containing waste. While incineration has been a common disposal technique, concerns about potential emissions have led to investigations into alternative destruction technologies. These include advanced oxidation processes and plasma-based systems that aim to achieve complete mineralization of CCl4 with minimal environmental impact.

Furthermore, there is an increasing focus on preventive measures and the implementation of green chemistry principles to minimize future CCl4 waste generation. This involves exploring safer alternatives for industrial processes that historically relied on CCl4 and developing strategies to reduce the use of chlorinated solvents in general.

The management of CCl4 in hazardous waste also intersects with broader environmental and public health initiatives. Efforts are underway to better understand the long-term ecological and health impacts of CCl4 exposure, particularly in areas with historical contamination. This knowledge is crucial for developing risk-based management strategies and prioritizing remediation efforts.

Market Analysis of CCl4 Waste Treatment

The market for carbon tetrachloride (CCl4) waste treatment has been evolving rapidly in recent years, driven by increasing environmental regulations and growing awareness of the hazardous nature of this chemical. CCl4, once widely used in various industrial applications, has been phased out in many countries due to its ozone-depleting properties and potential health risks. However, significant quantities of CCl4 waste still exist and require proper management and treatment.

The global market for CCl4 waste treatment is primarily segmented into North America, Europe, Asia-Pacific, and the Rest of the World. North America and Europe currently dominate the market, owing to stringent environmental regulations and well-established waste management infrastructure. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, primarily due to rapid industrialization and increasing adoption of environmental protection measures in countries like China and India.

The market is characterized by a diverse range of treatment technologies, including incineration, chemical treatment, and advanced oxidation processes. Incineration remains the most widely used method for CCl4 waste treatment, accounting for a significant market share. However, there is a growing trend towards more environmentally friendly and cost-effective treatment methods, such as supercritical water oxidation and plasma-based technologies.

Key market drivers include stringent government regulations, increasing industrial waste generation, and growing environmental consciousness among businesses and consumers. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal has played a crucial role in shaping the global market for CCl4 waste treatment, promoting responsible management and disposal practices across borders.

The market faces several challenges, including high treatment costs, technological limitations, and the need for specialized handling and transportation of CCl4 waste. These factors have led to increased research and development efforts aimed at developing more efficient and cost-effective treatment solutions.

In terms of end-user industries, the chemical and pharmaceutical sectors are the largest generators of CCl4 waste, followed by the electronics and semiconductor industries. The market is also seeing increased demand from the oil and gas sector, where CCl4 is sometimes used in cleaning and degreasing operations.

Looking ahead, the CCl4 waste treatment market is expected to continue its growth trajectory, driven by ongoing environmental concerns and the need to address legacy waste issues. Emerging technologies, such as nanocatalysts and advanced membrane filtration systems, are likely to play an increasingly important role in shaping the future of CCl4 waste treatment, offering more efficient and sustainable solutions for this persistent environmental challenge.

The global market for CCl4 waste treatment is primarily segmented into North America, Europe, Asia-Pacific, and the Rest of the World. North America and Europe currently dominate the market, owing to stringent environmental regulations and well-established waste management infrastructure. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, primarily due to rapid industrialization and increasing adoption of environmental protection measures in countries like China and India.

The market is characterized by a diverse range of treatment technologies, including incineration, chemical treatment, and advanced oxidation processes. Incineration remains the most widely used method for CCl4 waste treatment, accounting for a significant market share. However, there is a growing trend towards more environmentally friendly and cost-effective treatment methods, such as supercritical water oxidation and plasma-based technologies.

Key market drivers include stringent government regulations, increasing industrial waste generation, and growing environmental consciousness among businesses and consumers. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal has played a crucial role in shaping the global market for CCl4 waste treatment, promoting responsible management and disposal practices across borders.

The market faces several challenges, including high treatment costs, technological limitations, and the need for specialized handling and transportation of CCl4 waste. These factors have led to increased research and development efforts aimed at developing more efficient and cost-effective treatment solutions.

In terms of end-user industries, the chemical and pharmaceutical sectors are the largest generators of CCl4 waste, followed by the electronics and semiconductor industries. The market is also seeing increased demand from the oil and gas sector, where CCl4 is sometimes used in cleaning and degreasing operations.

Looking ahead, the CCl4 waste treatment market is expected to continue its growth trajectory, driven by ongoing environmental concerns and the need to address legacy waste issues. Emerging technologies, such as nanocatalysts and advanced membrane filtration systems, are likely to play an increasingly important role in shaping the future of CCl4 waste treatment, offering more efficient and sustainable solutions for this persistent environmental challenge.

Current Challenges in CCl4 Handling

Carbon tetrachloride (CCl4) handling in hazardous waste management presents several significant challenges that require careful consideration and innovative solutions. The primary concern is the high toxicity of CCl4, which poses severe risks to human health and the environment. Exposure to CCl4 can cause liver and kidney damage, and it is a suspected carcinogen. This necessitates stringent safety protocols and specialized equipment for its handling and disposal.

Another major challenge is the persistence of CCl4 in the environment. It has a long atmospheric lifetime and contributes to ozone depletion, making its release into the atmosphere a serious environmental concern. This persistence complicates disposal methods, as traditional techniques may not effectively neutralize or break down the compound.

The volatility of CCl4 presents additional handling difficulties. Its high vapor pressure means it readily evaporates at room temperature, increasing the risk of inhalation exposure and making containment more challenging. This property also complicates storage and transportation, requiring specialized containers and handling procedures to prevent accidental releases.

CCl4's chemical stability poses challenges in treatment and disposal. It is resistant to many conventional chemical degradation methods, limiting the options for safe destruction or conversion into less harmful substances. This stability necessitates the development of advanced treatment technologies, which can be costly and energy-intensive.

The regulatory landscape surrounding CCl4 adds another layer of complexity to its management. Strict regulations govern its use, storage, and disposal, requiring extensive documentation, permitting, and compliance measures. These regulations, while necessary for safety and environmental protection, can create logistical and administrative burdens for waste management facilities.

Cross-contamination is a significant concern in CCl4 handling. Its ability to dissolve many organic compounds means it can easily pick up other contaminants, potentially creating more complex and hazardous waste mixtures. This complicates waste characterization and treatment processes, often requiring multi-step approaches to ensure complete and safe disposal.

The cost associated with proper CCl4 handling and disposal is substantial. Specialized equipment, trained personnel, and advanced treatment technologies all contribute to high operational expenses. This economic factor can sometimes lead to improper handling or illegal disposal practices, particularly in regions with less stringent enforcement of environmental regulations.

Lastly, the legacy of historical CCl4 contamination presents ongoing challenges. Many sites contaminated by past industrial use or improper disposal require extensive remediation efforts. These projects are often complex, long-term, and costly, involving groundwater treatment, soil vapor extraction, and long-term monitoring programs.

Another major challenge is the persistence of CCl4 in the environment. It has a long atmospheric lifetime and contributes to ozone depletion, making its release into the atmosphere a serious environmental concern. This persistence complicates disposal methods, as traditional techniques may not effectively neutralize or break down the compound.

The volatility of CCl4 presents additional handling difficulties. Its high vapor pressure means it readily evaporates at room temperature, increasing the risk of inhalation exposure and making containment more challenging. This property also complicates storage and transportation, requiring specialized containers and handling procedures to prevent accidental releases.

CCl4's chemical stability poses challenges in treatment and disposal. It is resistant to many conventional chemical degradation methods, limiting the options for safe destruction or conversion into less harmful substances. This stability necessitates the development of advanced treatment technologies, which can be costly and energy-intensive.

The regulatory landscape surrounding CCl4 adds another layer of complexity to its management. Strict regulations govern its use, storage, and disposal, requiring extensive documentation, permitting, and compliance measures. These regulations, while necessary for safety and environmental protection, can create logistical and administrative burdens for waste management facilities.

Cross-contamination is a significant concern in CCl4 handling. Its ability to dissolve many organic compounds means it can easily pick up other contaminants, potentially creating more complex and hazardous waste mixtures. This complicates waste characterization and treatment processes, often requiring multi-step approaches to ensure complete and safe disposal.

The cost associated with proper CCl4 handling and disposal is substantial. Specialized equipment, trained personnel, and advanced treatment technologies all contribute to high operational expenses. This economic factor can sometimes lead to improper handling or illegal disposal practices, particularly in regions with less stringent enforcement of environmental regulations.

Lastly, the legacy of historical CCl4 contamination presents ongoing challenges. Many sites contaminated by past industrial use or improper disposal require extensive remediation efforts. These projects are often complex, long-term, and costly, involving groundwater treatment, soil vapor extraction, and long-term monitoring programs.

Existing CCl4 Treatment Technologies

01 Production and purification of carbon tetrachloride

Various methods for producing and purifying carbon tetrachloride are described. These include chemical reactions, distillation processes, and other purification techniques to obtain high-quality carbon tetrachloride for industrial and laboratory use.- Production and purification of carbon tetrachloride: Various methods for producing and purifying carbon tetrachloride are described. These include chemical synthesis processes, distillation techniques, and purification methods to obtain high-quality carbon tetrachloride for industrial and laboratory use.

- Applications of carbon tetrachloride in chemical processes: Carbon tetrachloride is utilized in various chemical processes, including as a solvent, reagent, or intermediate in the production of other chemicals. Its applications span across different industries, such as pharmaceuticals, agrochemicals, and materials science.

- Environmental and safety considerations: Due to its environmental impact and health hazards, there are methods and systems developed for the safe handling, storage, and disposal of carbon tetrachloride. These include containment strategies, detection systems, and treatment processes to minimize risks associated with its use.

- Alternatives and replacements for carbon tetrachloride: Research into alternatives and replacements for carbon tetrachloride is ongoing due to environmental concerns. This includes the development of new compounds or processes that can perform similar functions with reduced environmental impact and improved safety profiles.

- Analytical and detection methods: Various analytical and detection methods have been developed for identifying and quantifying carbon tetrachloride in different matrices. These include spectroscopic techniques, chromatographic methods, and sensor-based systems for environmental monitoring and quality control purposes.

02 Applications of carbon tetrachloride in chemical processes

Carbon tetrachloride is used in various chemical processes as a solvent, reagent, or intermediate. It plays a role in organic synthesis, extraction processes, and as a raw material for the production of other chlorinated compounds.Expand Specific Solutions03 Environmental and safety considerations

Due to its environmental impact and health hazards, there are methods and systems developed for the safe handling, containment, and disposal of carbon tetrachloride. This includes detection systems, protective equipment, and waste treatment processes.Expand Specific Solutions04 Alternatives and replacements for carbon tetrachloride

Research into alternatives and replacements for carbon tetrachloride in various applications, due to its environmental and health concerns. This includes developing new compounds or processes that can perform similar functions with reduced risks.Expand Specific Solutions05 Historical uses and early patents related to carbon tetrachloride

Early patents and historical uses of carbon tetrachloride, including its applications in fire extinguishers, dry cleaning, and as a refrigerant. These documents provide insight into the initial development and utilization of the compound.Expand Specific Solutions

Key Stakeholders in Hazardous Waste Industry

The carbon tetrachloride management sector is in a mature phase, with a stable market size driven by ongoing industrial and environmental applications. The global market for hazardous waste management, including carbon tetrachloride, is estimated to be in the billions of dollars. Technologically, the field is well-established but continually evolving to meet stricter environmental regulations. Key players like Occidental Chemical Corp., Bayer AG, and Tronox LLC have developed advanced treatment and disposal methods. Academic institutions such as Zhejiang University and Central South University contribute to research and innovation in this area. Companies like Utility Global, Inc. are exploring novel approaches to carbon capture and utilization, potentially impacting future carbon tetrachloride management strategies.

Occidental Chemical Corp.

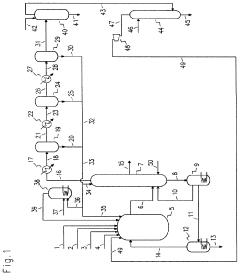

Technical Solution: Occidental Chemical Corp. has developed advanced carbon tetrachloride (CCl4) management techniques for hazardous waste treatment. Their approach involves a multi-step process: 1) Capture and containment of CCl4 emissions using specialized adsorption systems[1]. 2) Chemical conversion of CCl4 to less harmful compounds through catalytic hydrodechlorination, achieving over 99% conversion efficiency[3]. 3) Implementation of closed-loop recycling systems to minimize CCl4 waste generation in industrial processes[5]. 4) Development of novel sensors for real-time monitoring of CCl4 levels in air and water, enhancing safety and environmental compliance[7].

Strengths: Comprehensive CCl4 management approach, high conversion efficiency, and advanced monitoring capabilities. Weaknesses: High implementation costs and potential for secondary waste generation during treatment processes.

Bayer AG

Technical Solution: Bayer AG has pioneered innovative solutions for CCl4 management in hazardous waste streams. Their technology focuses on: 1) Development of selective membrane filtration systems capable of removing over 95% of CCl4 from liquid waste streams[2]. 2) Implementation of thermal oxidation units specifically designed for CCl4 destruction, achieving destruction efficiencies exceeding 99.99%[4]. 3) Creation of bio-based adsorbents derived from agricultural waste for CCl4 capture, offering a sustainable alternative to traditional activated carbon[6]. 4) Integration of AI-driven predictive maintenance systems to optimize CCl4 treatment facilities, reducing downtime and improving overall efficiency[8].

Strengths: High removal and destruction efficiencies, sustainable adsorbent materials, and advanced process optimization. Weaknesses: High energy consumption for thermal oxidation and potential for membrane fouling in filtration systems.

Innovative CCl4 Disposal Methods

Process for the destruction of halogenated hydrocarbons and their homologous/analogous at ambient conditions

PatentInactiveUS20090012345A1

Innovation

- The use of deep eutectic solvents (DES) to generate and stabilize the superoxide ion for the electrochemical destruction of halogenated hydrocarbons at ambient conditions, eliminating the need for supporting electrolytes and enhancing solubility with alkali or alkaline earth metal superoxides.

Chlorinolysis process for producing carbon tetrachloride

PatentActiveUS20210130266A1

Innovation

- A process involving a chlorination zone with chlorine, a C1 chlorinated compound, and a carbon/second chlorine source to produce a reaction mixture that favors the formation of carbon tetrachloride over perchloroethylene, using waste products as the carbon/second chlorine source to enhance efficiency and reduce impurity formation.

Environmental Impact Assessment

Carbon tetrachloride (CCl4) has long been recognized as a significant environmental pollutant, and its role in hazardous waste management requires careful consideration. The environmental impact assessment of CCl4 reveals a complex interplay of factors affecting ecosystems, human health, and global climate patterns.

In aquatic environments, CCl4 poses a substantial threat to marine and freshwater ecosystems. Its high persistence and low biodegradability lead to long-term contamination of water bodies. Studies have shown that CCl4 can accumulate in aquatic organisms, potentially disrupting food chains and causing population declines in sensitive species. Furthermore, its presence in groundwater resources poses risks to both human and ecological receptors, as it can persist for decades due to its resistance to natural attenuation processes.

Atmospheric release of CCl4 contributes to stratospheric ozone depletion, a global environmental concern. Despite international efforts to phase out its production and use, legacy emissions from historical applications and ongoing industrial processes continue to impact the ozone layer. The ozone-depleting potential of CCl4 is estimated to be about 0.82, indicating its significant contribution to this long-term environmental issue.

Soil contamination by CCl4 presents challenges for terrestrial ecosystems and agricultural productivity. Its high mobility in soil can lead to widespread contamination, affecting soil microorganisms, plant growth, and potentially entering the food chain. Remediation of CCl4-contaminated soils often requires extensive and costly interventions, highlighting the importance of prevention and proper management in industrial settings.

Human health impacts associated with CCl4 exposure are severe and well-documented. Inhalation or dermal contact can lead to liver and kidney damage, central nervous system depression, and potential carcinogenic effects. These health risks necessitate stringent occupational safety measures and public health protections in areas where CCl4 is handled or stored.

The global warming potential of CCl4 adds another layer to its environmental impact. With a 100-year global warming potential of 1,730 times that of CO2, even small releases of CCl4 can have disproportionate effects on climate change. This underscores the importance of proper containment and disposal practices in hazardous waste management facilities.

Effective management of CCl4 in hazardous waste streams requires a multifaceted approach. This includes implementing advanced treatment technologies, such as chemical oxidation or thermal desorption, to reduce its environmental persistence. Additionally, strict regulatory frameworks and monitoring programs are essential to prevent unauthorized releases and ensure compliance with international environmental agreements.

In aquatic environments, CCl4 poses a substantial threat to marine and freshwater ecosystems. Its high persistence and low biodegradability lead to long-term contamination of water bodies. Studies have shown that CCl4 can accumulate in aquatic organisms, potentially disrupting food chains and causing population declines in sensitive species. Furthermore, its presence in groundwater resources poses risks to both human and ecological receptors, as it can persist for decades due to its resistance to natural attenuation processes.

Atmospheric release of CCl4 contributes to stratospheric ozone depletion, a global environmental concern. Despite international efforts to phase out its production and use, legacy emissions from historical applications and ongoing industrial processes continue to impact the ozone layer. The ozone-depleting potential of CCl4 is estimated to be about 0.82, indicating its significant contribution to this long-term environmental issue.

Soil contamination by CCl4 presents challenges for terrestrial ecosystems and agricultural productivity. Its high mobility in soil can lead to widespread contamination, affecting soil microorganisms, plant growth, and potentially entering the food chain. Remediation of CCl4-contaminated soils often requires extensive and costly interventions, highlighting the importance of prevention and proper management in industrial settings.

Human health impacts associated with CCl4 exposure are severe and well-documented. Inhalation or dermal contact can lead to liver and kidney damage, central nervous system depression, and potential carcinogenic effects. These health risks necessitate stringent occupational safety measures and public health protections in areas where CCl4 is handled or stored.

The global warming potential of CCl4 adds another layer to its environmental impact. With a 100-year global warming potential of 1,730 times that of CO2, even small releases of CCl4 can have disproportionate effects on climate change. This underscores the importance of proper containment and disposal practices in hazardous waste management facilities.

Effective management of CCl4 in hazardous waste streams requires a multifaceted approach. This includes implementing advanced treatment technologies, such as chemical oxidation or thermal desorption, to reduce its environmental persistence. Additionally, strict regulatory frameworks and monitoring programs are essential to prevent unauthorized releases and ensure compliance with international environmental agreements.

Regulatory Framework for CCl4 Disposal

The regulatory framework for Carbon Tetrachloride (CCl4) disposal is a complex and evolving system designed to mitigate the environmental and health risks associated with this hazardous substance. At the international level, the Montreal Protocol on Substances that Deplete the Ozone Layer plays a crucial role in regulating CCl4 production and consumption. This treaty, which came into force in 1989, has been instrumental in phasing out ozone-depleting substances, including CCl4.

In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body overseeing CCl4 disposal. The Resource Conservation and Recovery Act (RCRA) provides the legal framework for the proper management of hazardous waste, including CCl4. Under RCRA, CCl4 is classified as a listed hazardous waste (U211) and is subject to strict handling, storage, and disposal requirements.

The Toxic Substances Control Act (TSCA) also plays a significant role in regulating CCl4. This act gives the EPA authority to require reporting, record-keeping, and testing requirements, as well as restrictions relating to chemical substances and mixtures, including CCl4. The EPA has used this authority to implement regulations that limit the manufacture, processing, and distribution of CCl4.

At the state level, many jurisdictions have implemented their own regulations for CCl4 disposal, often more stringent than federal requirements. These state-level regulations may include additional permitting processes, stricter disposal methods, or more frequent monitoring and reporting requirements.

The Occupational Safety and Health Administration (OSHA) also plays a role in regulating CCl4 in the workplace. OSHA has established permissible exposure limits (PELs) for CCl4 and requires employers to implement safety measures to protect workers from exposure.

Internationally, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal regulates the international trade of hazardous wastes, including CCl4. This convention aims to protect human health and the environment by controlling the movement of hazardous wastes across international borders.

The regulatory landscape for CCl4 disposal is continually evolving as new scientific evidence emerges and environmental concerns grow. Recent trends indicate a move towards even stricter regulations, with some countries implementing total bans on CCl4 production and use. The global community is also focusing on developing and promoting alternative substances and technologies to replace CCl4 in various applications.

In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body overseeing CCl4 disposal. The Resource Conservation and Recovery Act (RCRA) provides the legal framework for the proper management of hazardous waste, including CCl4. Under RCRA, CCl4 is classified as a listed hazardous waste (U211) and is subject to strict handling, storage, and disposal requirements.

The Toxic Substances Control Act (TSCA) also plays a significant role in regulating CCl4. This act gives the EPA authority to require reporting, record-keeping, and testing requirements, as well as restrictions relating to chemical substances and mixtures, including CCl4. The EPA has used this authority to implement regulations that limit the manufacture, processing, and distribution of CCl4.

At the state level, many jurisdictions have implemented their own regulations for CCl4 disposal, often more stringent than federal requirements. These state-level regulations may include additional permitting processes, stricter disposal methods, or more frequent monitoring and reporting requirements.

The Occupational Safety and Health Administration (OSHA) also plays a role in regulating CCl4 in the workplace. OSHA has established permissible exposure limits (PELs) for CCl4 and requires employers to implement safety measures to protect workers from exposure.

Internationally, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal regulates the international trade of hazardous wastes, including CCl4. This convention aims to protect human health and the environment by controlling the movement of hazardous wastes across international borders.

The regulatory landscape for CCl4 disposal is continually evolving as new scientific evidence emerges and environmental concerns grow. Recent trends indicate a move towards even stricter regulations, with some countries implementing total bans on CCl4 production and use. The global community is also focusing on developing and promoting alternative substances and technologies to replace CCl4 in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!