Comparing Carbon Tetrachloride to Emerging Solvent Alternatives

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CCl4 and Alternatives: Background and Objectives

Carbon tetrachloride (CCl4) has been a widely used solvent in various industrial applications for decades. Its unique properties, including non-flammability, high solvency power, and chemical stability, made it an attractive choice for many processes. However, concerns about its environmental impact and human health risks have led to a global effort to phase out its use and find suitable alternatives.

The primary objective of this technical research report is to compare carbon tetrachloride with emerging solvent alternatives, evaluating their efficacy, safety profiles, and environmental impacts. This comparison aims to identify potential replacements that can match or exceed the performance of CCl4 while addressing the associated health and environmental concerns.

The evolution of solvent technology has been driven by increasing awareness of environmental issues and stricter regulations. The Montreal Protocol, implemented in 1989, marked a significant milestone in this journey by mandating the phase-out of ozone-depleting substances, including CCl4. This agreement has accelerated research into alternative solvents and spurred innovation in green chemistry.

Current trends in solvent development focus on sustainability, reduced toxicity, and improved process efficiency. Emerging alternatives to CCl4 include both traditional organic solvents with improved environmental profiles and novel classes of solvents such as ionic liquids, supercritical fluids, and bio-based solvents. Each of these alternatives presents unique advantages and challenges in terms of performance, cost, and environmental impact.

The technical goals of this research include assessing the physicochemical properties of CCl4 alternatives, their performance in various applications, and their potential for large-scale industrial adoption. Key parameters to be evaluated include solvency power, volatility, thermal stability, reactivity, and compatibility with common materials and processes.

Furthermore, this study aims to analyze the life cycle impacts of these alternative solvents, considering factors such as production methods, energy requirements, recyclability, and end-of-life disposal. This comprehensive approach will provide a holistic view of the sustainability and long-term viability of each alternative.

By examining the current state of solvent technology and exploring future developments, this report seeks to guide decision-making processes for industries transitioning away from CCl4. It will highlight the most promising alternatives, potential areas for further research and development, and strategies for overcoming implementation challenges.

The primary objective of this technical research report is to compare carbon tetrachloride with emerging solvent alternatives, evaluating their efficacy, safety profiles, and environmental impacts. This comparison aims to identify potential replacements that can match or exceed the performance of CCl4 while addressing the associated health and environmental concerns.

The evolution of solvent technology has been driven by increasing awareness of environmental issues and stricter regulations. The Montreal Protocol, implemented in 1989, marked a significant milestone in this journey by mandating the phase-out of ozone-depleting substances, including CCl4. This agreement has accelerated research into alternative solvents and spurred innovation in green chemistry.

Current trends in solvent development focus on sustainability, reduced toxicity, and improved process efficiency. Emerging alternatives to CCl4 include both traditional organic solvents with improved environmental profiles and novel classes of solvents such as ionic liquids, supercritical fluids, and bio-based solvents. Each of these alternatives presents unique advantages and challenges in terms of performance, cost, and environmental impact.

The technical goals of this research include assessing the physicochemical properties of CCl4 alternatives, their performance in various applications, and their potential for large-scale industrial adoption. Key parameters to be evaluated include solvency power, volatility, thermal stability, reactivity, and compatibility with common materials and processes.

Furthermore, this study aims to analyze the life cycle impacts of these alternative solvents, considering factors such as production methods, energy requirements, recyclability, and end-of-life disposal. This comprehensive approach will provide a holistic view of the sustainability and long-term viability of each alternative.

By examining the current state of solvent technology and exploring future developments, this report seeks to guide decision-making processes for industries transitioning away from CCl4. It will highlight the most promising alternatives, potential areas for further research and development, and strategies for overcoming implementation challenges.

Market Demand for Green Solvents

The global market for green solvents has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations on volatile organic compounds (VOCs) emissions. This shift towards more sustainable alternatives has created a substantial demand for eco-friendly solvents across various industries, including paints and coatings, pharmaceuticals, cosmetics, and industrial cleaning.

The traditional use of carbon tetrachloride as a solvent has been phased out in many applications due to its ozone-depleting properties and potential health hazards. This has opened up opportunities for emerging solvent alternatives that offer similar performance characteristics while being more environmentally benign. The market for these green solvents is expected to continue its upward trajectory, with projections indicating robust growth over the next decade.

One of the key drivers of this market demand is the growing awareness among consumers and businesses about the environmental impact of conventional solvents. This has led to a shift in preferences towards products that use eco-friendly ingredients, including green solvents. Additionally, government regulations and international agreements, such as the Montreal Protocol, have played a crucial role in accelerating the adoption of alternative solvents.

The industrial sector, particularly manufacturing and processing industries, represents a significant portion of the demand for green solvents. These industries are increasingly seeking alternatives to carbon tetrachloride and other harmful solvents to comply with environmental regulations and improve workplace safety. The automotive and aerospace sectors, for instance, are adopting water-based and bio-based solvents in their production processes, contributing to the overall market growth.

In the consumer goods sector, the demand for green solvents is being driven by the rising popularity of natural and organic products. Cosmetics, personal care, and household cleaning products are increasingly incorporating bio-based solvents to appeal to environmentally conscious consumers. This trend is expected to continue, further boosting the market for sustainable solvent alternatives.

The pharmaceutical industry is another major contributor to the growing demand for green solvents. With increasing focus on sustainable manufacturing practices and the need for safer drug formulations, pharmaceutical companies are exploring alternative solvents that can replace traditional, potentially harmful options like carbon tetrachloride. This shift is not only driven by environmental concerns but also by the potential for improved product quality and reduced production costs in the long term.

The traditional use of carbon tetrachloride as a solvent has been phased out in many applications due to its ozone-depleting properties and potential health hazards. This has opened up opportunities for emerging solvent alternatives that offer similar performance characteristics while being more environmentally benign. The market for these green solvents is expected to continue its upward trajectory, with projections indicating robust growth over the next decade.

One of the key drivers of this market demand is the growing awareness among consumers and businesses about the environmental impact of conventional solvents. This has led to a shift in preferences towards products that use eco-friendly ingredients, including green solvents. Additionally, government regulations and international agreements, such as the Montreal Protocol, have played a crucial role in accelerating the adoption of alternative solvents.

The industrial sector, particularly manufacturing and processing industries, represents a significant portion of the demand for green solvents. These industries are increasingly seeking alternatives to carbon tetrachloride and other harmful solvents to comply with environmental regulations and improve workplace safety. The automotive and aerospace sectors, for instance, are adopting water-based and bio-based solvents in their production processes, contributing to the overall market growth.

In the consumer goods sector, the demand for green solvents is being driven by the rising popularity of natural and organic products. Cosmetics, personal care, and household cleaning products are increasingly incorporating bio-based solvents to appeal to environmentally conscious consumers. This trend is expected to continue, further boosting the market for sustainable solvent alternatives.

The pharmaceutical industry is another major contributor to the growing demand for green solvents. With increasing focus on sustainable manufacturing practices and the need for safer drug formulations, pharmaceutical companies are exploring alternative solvents that can replace traditional, potentially harmful options like carbon tetrachloride. This shift is not only driven by environmental concerns but also by the potential for improved product quality and reduced production costs in the long term.

Current Challenges in Solvent Technology

The solvent industry is currently facing several significant challenges, primarily driven by environmental concerns, regulatory pressures, and the need for more sustainable alternatives. One of the most pressing issues is the phasing out of traditional solvents like carbon tetrachloride, which have been widely used but are now recognized as harmful to both human health and the environment.

Carbon tetrachloride, once a popular solvent in various industrial applications, has been largely banned due to its ozone-depleting properties and potential carcinogenicity. This has created a urgent need for safer and more environmentally friendly alternatives. However, finding suitable replacements that match the performance characteristics of carbon tetrachloride while meeting stringent environmental and safety standards has proven to be a complex task.

Another major challenge is the increasing regulatory pressure on volatile organic compounds (VOCs) emissions. Many conventional solvents are classified as VOCs, which contribute to air pollution and the formation of ground-level ozone. As a result, industries are being compelled to adopt low-VOC or VOC-free solvents, which often require significant process modifications and can impact product quality.

The push towards greener chemistry has also highlighted the need for bio-based and renewable solvents. While promising, these alternatives often face challenges in terms of cost-effectiveness, scalability, and performance consistency compared to their petrochemical-based counterparts. Developing economically viable production processes for these sustainable solvents remains a significant hurdle.

Water-based systems are gaining traction as potential replacements for organic solvents in many applications. However, they often require the use of surfactants or co-solvents to achieve the desired properties, which can introduce new complexities in formulation and processing. Additionally, water-based systems may not be suitable for all applications, particularly those involving water-sensitive materials or processes.

The development of ionic liquids and supercritical fluids as novel solvents has shown promise in various fields. However, these technologies face challenges in terms of high production costs, limited understanding of their long-term environmental impacts, and the need for specialized equipment and handling procedures.

Lastly, the solvent industry is grappling with the challenge of balancing performance, cost, and sustainability. Many emerging solvent alternatives, while more environmentally friendly, may not match the efficiency or cost-effectiveness of traditional solvents. This creates a significant barrier to widespread adoption, particularly in cost-sensitive industries.

Carbon tetrachloride, once a popular solvent in various industrial applications, has been largely banned due to its ozone-depleting properties and potential carcinogenicity. This has created a urgent need for safer and more environmentally friendly alternatives. However, finding suitable replacements that match the performance characteristics of carbon tetrachloride while meeting stringent environmental and safety standards has proven to be a complex task.

Another major challenge is the increasing regulatory pressure on volatile organic compounds (VOCs) emissions. Many conventional solvents are classified as VOCs, which contribute to air pollution and the formation of ground-level ozone. As a result, industries are being compelled to adopt low-VOC or VOC-free solvents, which often require significant process modifications and can impact product quality.

The push towards greener chemistry has also highlighted the need for bio-based and renewable solvents. While promising, these alternatives often face challenges in terms of cost-effectiveness, scalability, and performance consistency compared to their petrochemical-based counterparts. Developing economically viable production processes for these sustainable solvents remains a significant hurdle.

Water-based systems are gaining traction as potential replacements for organic solvents in many applications. However, they often require the use of surfactants or co-solvents to achieve the desired properties, which can introduce new complexities in formulation and processing. Additionally, water-based systems may not be suitable for all applications, particularly those involving water-sensitive materials or processes.

The development of ionic liquids and supercritical fluids as novel solvents has shown promise in various fields. However, these technologies face challenges in terms of high production costs, limited understanding of their long-term environmental impacts, and the need for specialized equipment and handling procedures.

Lastly, the solvent industry is grappling with the challenge of balancing performance, cost, and sustainability. Many emerging solvent alternatives, while more environmentally friendly, may not match the efficiency or cost-effectiveness of traditional solvents. This creates a significant barrier to widespread adoption, particularly in cost-sensitive industries.

Existing Alternative Solvent Solutions

01 Alternatives to carbon tetrachloride in chemical processes

Various solvents are being explored as alternatives to carbon tetrachloride in chemical processes due to environmental and health concerns. These alternatives aim to provide similar solvent properties while reducing toxicity and environmental impact. Research focuses on developing safer and more sustainable options for industrial applications.- Alternatives to carbon tetrachloride in chemical processes: Various solvents and processes are being developed as alternatives to carbon tetrachloride in chemical reactions and industrial applications. These alternatives aim to reduce environmental impact and health risks associated with carbon tetrachloride use while maintaining or improving process efficiency.

- Carbon tetrachloride in historical industrial applications: Carbon tetrachloride has been widely used in various industrial processes historically, including as a solvent, cleaning agent, and in the production of refrigerants. Understanding its past applications provides context for the development of safer alternatives.

- Environmental and health concerns of carbon tetrachloride: The use of carbon tetrachloride has been associated with significant environmental and health risks, including ozone depletion and potential carcinogenicity. These concerns have driven the search for safer alternative solvents and processes in various industries.

- Green solvents and sustainable alternatives: Research is focused on developing green solvents and sustainable alternatives to carbon tetrachloride. These include bio-based solvents, ionic liquids, and supercritical fluids, which offer improved environmental profiles and reduced toxicity while maintaining solvent effectiveness.

- Innovative technologies for solvent-free processes: Emerging technologies are being developed to eliminate the need for solvents altogether in certain processes where carbon tetrachloride was previously used. These solvent-free approaches include mechanochemical methods, solid-state reactions, and advanced catalytic processes.

02 Carbon tetrachloride in historical industrial applications

Carbon tetrachloride has been widely used in various industrial applications historically, including as a solvent, cleaning agent, and in the production of refrigerants. Understanding its past uses provides context for the development of alternatives and highlights the need for safer substitutes in modern industry.Expand Specific Solutions03 Environmental and health impacts of carbon tetrachloride

The use of carbon tetrachloride has been associated with significant environmental and health risks, including ozone depletion and potential carcinogenicity. These concerns have driven the search for safer alternatives and the implementation of regulations to limit its use in various applications.Expand Specific Solutions04 Green solvents and eco-friendly alternatives

Research is focusing on developing green solvents and eco-friendly alternatives to replace carbon tetrachloride. These include bio-based solvents, ionic liquids, and supercritical fluids. The aim is to find solutions that are not only effective but also sustainable and environmentally benign.Expand Specific Solutions05 Innovative technologies for solvent-free processes

Emerging technologies are being developed to eliminate the need for solvents altogether in certain processes where carbon tetrachloride was previously used. These solvent-free approaches aim to reduce environmental impact and improve process efficiency through innovative chemical and engineering solutions.Expand Specific Solutions

Key Players in Solvent Industry

The market for alternatives to carbon tetrachloride is in a transitional phase, driven by increasing environmental regulations and sustainability concerns. The global market for green solvents is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, with companies like 3M, Honeywell, and Mainstream Engineering leading innovation in developing safer, more environmentally friendly solvents. These companies are investing heavily in R&D to improve the performance and cost-effectiveness of alternative solvents. Academic institutions such as Caltech and the National University of Singapore are also contributing to the technological maturity through fundamental research. While some alternatives have reached commercial viability, ongoing research suggests that the technology is still evolving, with potential for further improvements in efficiency and applicability across various industries.

3M Innovative Properties Co.

Technical Solution: 3M has developed innovative alternatives to carbon tetrachloride, focusing on hydrofluoroethers (HFEs) as environmentally friendly solvents. Their HFE-7100 and HFE-7200 series offer excellent solvency for a wide range of applications, including precision cleaning, heat transfer, and as carrier solvents for specialty coatings[1]. These HFEs have zero ozone depletion potential and low global warming potential compared to carbon tetrachloride[2]. 3M's technology involves optimizing the molecular structure of HFEs to achieve desired properties such as low toxicity, non-flammability, and high materials compatibility[3]. The company has also developed formulations that combine HFEs with other co-solvents to enhance cleaning performance while maintaining environmental benefits[4].

Strengths: Low environmental impact, versatile applications, high safety profile. Weaknesses: Higher cost compared to traditional solvents, may require equipment modifications for some applications.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered the development of Solstice® solvents as alternatives to carbon tetrachloride. These solvents are based on hydrofluoroolefin (HFO) technology, which offers ultra-low global warming potential and zero ozone depletion potential[5]. Solstice Performance Fluid (PF) is particularly notable, providing excellent solvency power for precision cleaning applications in electronics, medical devices, and aerospace industries[6]. Honeywell's approach involves tailoring the molecular structure of HFOs to optimize performance while minimizing environmental impact. The company has also developed specialized formulations that combine Solstice solvents with other components to enhance cleaning efficiency and drying speed[7]. Honeywell's technology includes advanced distillation and recycling systems to maximize solvent recovery and reduce operational costs[8].

Strengths: Excellent environmental profile, high cleaning performance, compatibility with existing equipment. Weaknesses: May have higher initial costs, requires proper handling and storage procedures.

Innovations in Green Solvent Chemistry

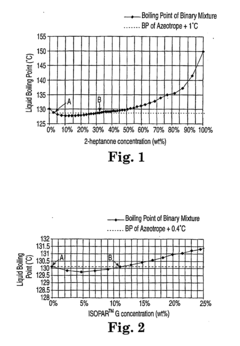

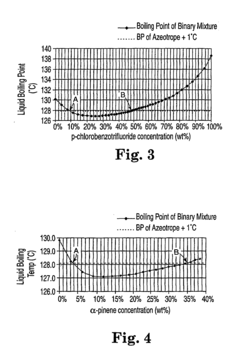

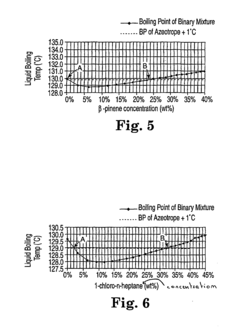

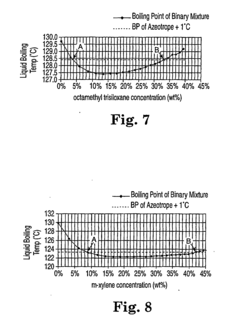

Azeotrope-like compositions and their use

PatentInactiveEP1303584B1

Innovation

- The development of azeotrope and azeotrope-like compositions consisting of a hydrofluoroether, specifically 3-ethoxy-perfluoro(2-methylhexane), combined with various organic solvents like alkanes, esters, and siloxanes, which form stable mixtures with constant boiling points, providing effective solvency and non-flammability while having short atmospheric lifetimes.

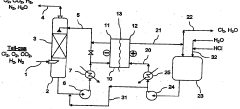

Apparatus and process for electrochemical chlorine recovery

PatentInactiveCA2579364A1

Innovation

- Proposing alternative absorbent compounds like dichlorotoluene and chlorinated derivatives of benzotrifluoride to replace carbon tetrachloride, addressing environmental concerns.

- Utilizing permselective membranes to separate chlorine from other gases, potentially improving efficiency and reducing environmental impact.

- Employing various chemical reactions (e.g., with sulfur, hydrogen, or water) to recover chlorine in different forms, offering flexibility in chlorine recovery processes.

Environmental Impact Assessment

The environmental impact assessment of carbon tetrachloride (CCl4) compared to emerging solvent alternatives reveals significant differences in their ecological footprints. Carbon tetrachloride, once widely used in various industrial applications, has been phased out in many countries due to its severe environmental consequences. This compound is a potent ozone-depleting substance, contributing to the depletion of the Earth's protective ozone layer. Its long atmospheric lifetime and high global warming potential also make it a significant contributor to climate change.

In contrast, emerging solvent alternatives are designed with environmental sustainability in mind. These new solvents often have lower ozone depletion potential and reduced global warming impact. Many are biodegradable or can be easily recycled, minimizing their long-term presence in the environment. Some alternatives, such as supercritical CO2 or bio-based solvents, offer the added benefit of being derived from renewable resources, further reducing their overall environmental impact.

Water pollution is another critical aspect of the environmental assessment. Carbon tetrachloride, when released into aquatic ecosystems, can persist for long periods and bioaccumulate in marine organisms. This persistence leads to long-term ecological damage and potential health risks for humans through the food chain. Emerging alternatives generally exhibit lower toxicity to aquatic life and reduced persistence in water bodies, mitigating these risks.

Soil contamination is also a significant concern with traditional solvents like carbon tetrachloride. When spilled or improperly disposed of, CCl4 can leach into soil, contaminating groundwater and affecting soil ecosystems. Many new solvent alternatives are designed to have lower soil mobility and faster degradation rates, reducing the risk of long-term soil and groundwater contamination.

The production and disposal processes of solvents also factor into their environmental impact. Carbon tetrachloride production involves energy-intensive processes and hazardous chemicals, contributing to air pollution and industrial waste. In contrast, the manufacture of many alternative solvents employs greener chemistry principles, often requiring less energy and producing fewer harmful byproducts. Additionally, the disposal of CCl4 is challenging and potentially harmful, while many new solvents can be more easily treated or recycled at the end of their life cycle.

Overall, the shift from carbon tetrachloride to emerging solvent alternatives represents a significant improvement in environmental stewardship. While no solvent is entirely without impact, the new generation of alternatives offers a more balanced approach, addressing global environmental concerns while still meeting industrial and commercial needs. This transition aligns with broader sustainability goals and regulatory trends towards more environmentally friendly chemical use in industry and consumer products.

In contrast, emerging solvent alternatives are designed with environmental sustainability in mind. These new solvents often have lower ozone depletion potential and reduced global warming impact. Many are biodegradable or can be easily recycled, minimizing their long-term presence in the environment. Some alternatives, such as supercritical CO2 or bio-based solvents, offer the added benefit of being derived from renewable resources, further reducing their overall environmental impact.

Water pollution is another critical aspect of the environmental assessment. Carbon tetrachloride, when released into aquatic ecosystems, can persist for long periods and bioaccumulate in marine organisms. This persistence leads to long-term ecological damage and potential health risks for humans through the food chain. Emerging alternatives generally exhibit lower toxicity to aquatic life and reduced persistence in water bodies, mitigating these risks.

Soil contamination is also a significant concern with traditional solvents like carbon tetrachloride. When spilled or improperly disposed of, CCl4 can leach into soil, contaminating groundwater and affecting soil ecosystems. Many new solvent alternatives are designed to have lower soil mobility and faster degradation rates, reducing the risk of long-term soil and groundwater contamination.

The production and disposal processes of solvents also factor into their environmental impact. Carbon tetrachloride production involves energy-intensive processes and hazardous chemicals, contributing to air pollution and industrial waste. In contrast, the manufacture of many alternative solvents employs greener chemistry principles, often requiring less energy and producing fewer harmful byproducts. Additionally, the disposal of CCl4 is challenging and potentially harmful, while many new solvents can be more easily treated or recycled at the end of their life cycle.

Overall, the shift from carbon tetrachloride to emerging solvent alternatives represents a significant improvement in environmental stewardship. While no solvent is entirely without impact, the new generation of alternatives offers a more balanced approach, addressing global environmental concerns while still meeting industrial and commercial needs. This transition aligns with broader sustainability goals and regulatory trends towards more environmentally friendly chemical use in industry and consumer products.

Regulatory Framework for Solvent Use

The regulatory framework for solvent use has undergone significant changes in recent decades, primarily driven by environmental and health concerns. Carbon tetrachloride, once widely used, has been phased out in many applications due to its ozone-depleting properties and toxicity. This shift has led to the development and adoption of alternative solvents, subject to stringent regulations.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating solvent use. Under the Toxic Substances Control Act (TSCA), the EPA has the authority to restrict or ban chemicals that pose unreasonable risks to human health or the environment. The Clean Air Act also regulates the use of volatile organic compounds (VOCs) in solvents, aiming to reduce air pollution and smog formation.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which requires manufacturers and importers to register chemical substances and provide safety data. This comprehensive framework has significantly impacted solvent use across industries, promoting the adoption of safer alternatives.

Globally, the Montreal Protocol has been instrumental in phasing out ozone-depleting substances, including certain solvents. This international treaty has led to the development of new, ozone-friendly solvent alternatives and has influenced national regulations worldwide.

Many countries have established occupational exposure limits for various solvents, including emerging alternatives. These limits are regularly reviewed and updated based on new scientific evidence, ensuring worker safety in industrial settings.

The regulatory landscape also encourages the development of green solvents derived from renewable resources. Initiatives such as the EPA's Safer Choice program in the US and the EU's Eco-label promote the use of environmentally preferable solvents, providing incentives for manufacturers to innovate in this direction.

As emerging solvent alternatives enter the market, they undergo rigorous safety assessments. Regulatory bodies evaluate their potential environmental impact, toxicity, and long-term effects before approving their use. This process ensures that new solvents meet stringent safety and environmental standards.

The transition from traditional solvents like carbon tetrachloride to newer alternatives has also been influenced by industry-specific regulations. For instance, the pharmaceutical industry must comply with Good Manufacturing Practices (GMP), which impact solvent selection in drug production processes.

As environmental concerns continue to grow, regulations are expected to become increasingly stringent. This trend will likely accelerate the development and adoption of safer, more sustainable solvent alternatives across various industries, reshaping the solvent market and driving innovation in green chemistry.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating solvent use. Under the Toxic Substances Control Act (TSCA), the EPA has the authority to restrict or ban chemicals that pose unreasonable risks to human health or the environment. The Clean Air Act also regulates the use of volatile organic compounds (VOCs) in solvents, aiming to reduce air pollution and smog formation.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which requires manufacturers and importers to register chemical substances and provide safety data. This comprehensive framework has significantly impacted solvent use across industries, promoting the adoption of safer alternatives.

Globally, the Montreal Protocol has been instrumental in phasing out ozone-depleting substances, including certain solvents. This international treaty has led to the development of new, ozone-friendly solvent alternatives and has influenced national regulations worldwide.

Many countries have established occupational exposure limits for various solvents, including emerging alternatives. These limits are regularly reviewed and updated based on new scientific evidence, ensuring worker safety in industrial settings.

The regulatory landscape also encourages the development of green solvents derived from renewable resources. Initiatives such as the EPA's Safer Choice program in the US and the EU's Eco-label promote the use of environmentally preferable solvents, providing incentives for manufacturers to innovate in this direction.

As emerging solvent alternatives enter the market, they undergo rigorous safety assessments. Regulatory bodies evaluate their potential environmental impact, toxicity, and long-term effects before approving their use. This process ensures that new solvents meet stringent safety and environmental standards.

The transition from traditional solvents like carbon tetrachloride to newer alternatives has also been influenced by industry-specific regulations. For instance, the pharmaceutical industry must comply with Good Manufacturing Practices (GMP), which impact solvent selection in drug production processes.

As environmental concerns continue to grow, regulations are expected to become increasingly stringent. This trend will likely accelerate the development and adoption of safer, more sustainable solvent alternatives across various industries, reshaping the solvent market and driving innovation in green chemistry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!