Alkyl Advances in Flow Chemistry Techniques

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flow Chemistry Evolution

Flow chemistry has undergone significant evolution since its inception in the early 2000s. Initially, the technique was primarily used for simple organic reactions, but it has rapidly expanded to encompass a wide range of chemical processes. The early stages of flow chemistry focused on continuous-flow microreactors, which offered improved heat and mass transfer compared to traditional batch processes.

As the field progressed, researchers began to explore more complex reaction systems and develop advanced reactor designs. The introduction of multi-step flow synthesis in the mid-2000s marked a significant milestone, enabling the production of complex molecules in a continuous manner. This advancement paved the way for the integration of flow chemistry into pharmaceutical and fine chemical manufacturing processes.

The late 2000s and early 2010s saw a surge in the development of automated flow systems. These systems incorporated inline analysis and real-time optimization, allowing for more efficient and precise control of reaction conditions. The integration of machine learning and artificial intelligence further enhanced the capabilities of flow chemistry, enabling predictive modeling and autonomous optimization of reaction parameters.

In recent years, the focus has shifted towards scalability and industrial applications. The development of modular and reconfigurable flow systems has facilitated the transition from laboratory-scale experiments to pilot and production-scale operations. This has been particularly important in the pharmaceutical industry, where continuous manufacturing has gained traction as a more efficient and cost-effective alternative to batch processing.

The evolution of flow chemistry has also been closely tied to advancements in enabling technologies. Improvements in pump technology, reactor materials, and inline analytical tools have expanded the range of reactions that can be performed in flow. For example, the development of high-pressure reactors has allowed for supercritical fluid reactions, while the integration of photochemistry and electrochemistry into flow systems has opened up new synthetic possibilities.

More recently, the field has seen a growing interest in sustainable and green chemistry applications. Flow chemistry has proven to be an effective tool for intensifying processes, reducing waste, and improving energy efficiency. The development of bio-based and renewable feedstocks compatible with flow systems has further contributed to the sustainability aspect of this technology.

Looking ahead, the evolution of flow chemistry is likely to continue in several directions. The integration of artificial intelligence and machine learning is expected to play an increasingly important role in reaction optimization and process control. Additionally, the development of novel reactor designs, such as 3D-printed reactors and microfluidic devices, promises to further expand the capabilities of flow chemistry in both research and industrial settings.

As the field progressed, researchers began to explore more complex reaction systems and develop advanced reactor designs. The introduction of multi-step flow synthesis in the mid-2000s marked a significant milestone, enabling the production of complex molecules in a continuous manner. This advancement paved the way for the integration of flow chemistry into pharmaceutical and fine chemical manufacturing processes.

The late 2000s and early 2010s saw a surge in the development of automated flow systems. These systems incorporated inline analysis and real-time optimization, allowing for more efficient and precise control of reaction conditions. The integration of machine learning and artificial intelligence further enhanced the capabilities of flow chemistry, enabling predictive modeling and autonomous optimization of reaction parameters.

In recent years, the focus has shifted towards scalability and industrial applications. The development of modular and reconfigurable flow systems has facilitated the transition from laboratory-scale experiments to pilot and production-scale operations. This has been particularly important in the pharmaceutical industry, where continuous manufacturing has gained traction as a more efficient and cost-effective alternative to batch processing.

The evolution of flow chemistry has also been closely tied to advancements in enabling technologies. Improvements in pump technology, reactor materials, and inline analytical tools have expanded the range of reactions that can be performed in flow. For example, the development of high-pressure reactors has allowed for supercritical fluid reactions, while the integration of photochemistry and electrochemistry into flow systems has opened up new synthetic possibilities.

More recently, the field has seen a growing interest in sustainable and green chemistry applications. Flow chemistry has proven to be an effective tool for intensifying processes, reducing waste, and improving energy efficiency. The development of bio-based and renewable feedstocks compatible with flow systems has further contributed to the sustainability aspect of this technology.

Looking ahead, the evolution of flow chemistry is likely to continue in several directions. The integration of artificial intelligence and machine learning is expected to play an increasingly important role in reaction optimization and process control. Additionally, the development of novel reactor designs, such as 3D-printed reactors and microfluidic devices, promises to further expand the capabilities of flow chemistry in both research and industrial settings.

Market Demand Analysis

The market demand for flow chemistry techniques, particularly in alkyl advances, has been experiencing significant growth in recent years. This surge is driven by the increasing need for more efficient, sustainable, and cost-effective chemical synthesis processes across various industries. The pharmaceutical sector, in particular, has shown a strong interest in flow chemistry due to its potential to streamline drug discovery and development processes.

The global flow chemistry market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 10% over the next five years. This growth is attributed to the advantages offered by flow chemistry techniques, including improved reaction control, enhanced safety, and reduced environmental impact. The alkyl advances in flow chemistry are particularly attractive to industries seeking to optimize their production processes and reduce waste generation.

In the pharmaceutical industry, the demand for continuous flow reactors and microreactors has been steadily increasing. These technologies enable the synthesis of complex molecules with greater precision and efficiency, leading to shorter development timelines and reduced production costs. The ability to perform multistep syntheses in a continuous flow system has also garnered significant attention from pharmaceutical companies looking to streamline their manufacturing processes.

The fine chemicals and specialty chemicals sectors have also shown a growing interest in flow chemistry techniques for alkyl reactions. These industries are increasingly adopting continuous flow processes to improve product quality, reduce reaction times, and minimize the use of hazardous reagents. The demand for flow chemistry equipment and services in these sectors is expected to grow substantially in the coming years.

Environmental concerns and stringent regulations have further fueled the market demand for flow chemistry techniques. The ability to perform reactions with smaller quantities of reagents and solvents aligns well with the principles of green chemistry. This has led to increased adoption of flow chemistry in the production of agrochemicals, polymers, and other industrial chemicals.

The academic and research sectors have also contributed to the growing market demand for flow chemistry techniques. Universities and research institutions are investing in flow chemistry equipment to explore new synthetic methodologies and develop more efficient processes. This trend is expected to drive innovation in the field and create new opportunities for technology providers.

Geographically, North America and Europe currently dominate the flow chemistry market, with Asia-Pacific showing the highest growth potential. The increasing focus on research and development activities in emerging economies, coupled with the growing pharmaceutical and chemical industries in these regions, is expected to drive significant market growth in the coming years.

The global flow chemistry market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 10% over the next five years. This growth is attributed to the advantages offered by flow chemistry techniques, including improved reaction control, enhanced safety, and reduced environmental impact. The alkyl advances in flow chemistry are particularly attractive to industries seeking to optimize their production processes and reduce waste generation.

In the pharmaceutical industry, the demand for continuous flow reactors and microreactors has been steadily increasing. These technologies enable the synthesis of complex molecules with greater precision and efficiency, leading to shorter development timelines and reduced production costs. The ability to perform multistep syntheses in a continuous flow system has also garnered significant attention from pharmaceutical companies looking to streamline their manufacturing processes.

The fine chemicals and specialty chemicals sectors have also shown a growing interest in flow chemistry techniques for alkyl reactions. These industries are increasingly adopting continuous flow processes to improve product quality, reduce reaction times, and minimize the use of hazardous reagents. The demand for flow chemistry equipment and services in these sectors is expected to grow substantially in the coming years.

Environmental concerns and stringent regulations have further fueled the market demand for flow chemistry techniques. The ability to perform reactions with smaller quantities of reagents and solvents aligns well with the principles of green chemistry. This has led to increased adoption of flow chemistry in the production of agrochemicals, polymers, and other industrial chemicals.

The academic and research sectors have also contributed to the growing market demand for flow chemistry techniques. Universities and research institutions are investing in flow chemistry equipment to explore new synthetic methodologies and develop more efficient processes. This trend is expected to drive innovation in the field and create new opportunities for technology providers.

Geographically, North America and Europe currently dominate the flow chemistry market, with Asia-Pacific showing the highest growth potential. The increasing focus on research and development activities in emerging economies, coupled with the growing pharmaceutical and chemical industries in these regions, is expected to drive significant market growth in the coming years.

Technical Challenges

Flow chemistry has revolutionized the field of organic synthesis, offering numerous advantages over traditional batch processes. However, despite its potential, several technical challenges persist in the implementation and optimization of flow chemistry techniques, particularly in the context of alkyl advances.

One of the primary challenges is the management of multiphase reactions. Many alkyl-based transformations involve heterogeneous mixtures, which can lead to clogging and uneven flow distribution in microreactors. This issue is particularly pronounced when dealing with solid reagents or products, as they can accumulate and obstruct narrow channels, compromising the efficiency and reproducibility of the process.

Temperature control presents another significant hurdle in flow chemistry. While the high surface-to-volume ratio of microreactors allows for rapid heat transfer, maintaining precise and uniform temperature profiles across the entire reaction pathway remains challenging. This is especially critical for temperature-sensitive alkyl reactions, where even slight variations can lead to unwanted side products or reduced yields.

The scaling up of flow processes from laboratory to industrial scale poses a considerable technical challenge. As the dimensions of reactors increase, issues such as heat and mass transfer limitations become more pronounced, potentially altering reaction kinetics and product distributions. Developing scalable flow systems that maintain the advantages of microreactors while accommodating larger volumes is an ongoing area of research.

Mixing efficiency is another critical factor in flow chemistry, particularly for fast reactions involving alkyl species. Achieving rapid and uniform mixing in continuous flow systems can be challenging, especially when dealing with viscous or immiscible reagents. Insufficient mixing can lead to concentration gradients and inconsistent reaction outcomes, affecting the overall yield and selectivity of alkyl transformations.

The integration of in-line analysis and real-time monitoring techniques presents both an opportunity and a challenge in flow chemistry. While these technologies offer the potential for rapid optimization and quality control, their implementation in continuous flow systems requires careful consideration of factors such as response time, sensitivity, and compatibility with the flow environment.

Handling highly reactive or unstable alkyl intermediates in flow systems poses unique challenges. The short residence times in microreactors can be advantageous for controlling these species, but designing robust systems that can safely and efficiently manage such reactive compounds requires specialized equipment and expertise.

Finally, the development of sustainable and green flow chemistry processes for alkyl transformations remains a significant challenge. While flow chemistry inherently offers advantages in terms of efficiency and waste reduction, further innovations are needed to minimize solvent use, incorporate renewable feedstocks, and develop more environmentally benign catalytic systems for alkyl chemistry in continuous flow.

One of the primary challenges is the management of multiphase reactions. Many alkyl-based transformations involve heterogeneous mixtures, which can lead to clogging and uneven flow distribution in microreactors. This issue is particularly pronounced when dealing with solid reagents or products, as they can accumulate and obstruct narrow channels, compromising the efficiency and reproducibility of the process.

Temperature control presents another significant hurdle in flow chemistry. While the high surface-to-volume ratio of microreactors allows for rapid heat transfer, maintaining precise and uniform temperature profiles across the entire reaction pathway remains challenging. This is especially critical for temperature-sensitive alkyl reactions, where even slight variations can lead to unwanted side products or reduced yields.

The scaling up of flow processes from laboratory to industrial scale poses a considerable technical challenge. As the dimensions of reactors increase, issues such as heat and mass transfer limitations become more pronounced, potentially altering reaction kinetics and product distributions. Developing scalable flow systems that maintain the advantages of microreactors while accommodating larger volumes is an ongoing area of research.

Mixing efficiency is another critical factor in flow chemistry, particularly for fast reactions involving alkyl species. Achieving rapid and uniform mixing in continuous flow systems can be challenging, especially when dealing with viscous or immiscible reagents. Insufficient mixing can lead to concentration gradients and inconsistent reaction outcomes, affecting the overall yield and selectivity of alkyl transformations.

The integration of in-line analysis and real-time monitoring techniques presents both an opportunity and a challenge in flow chemistry. While these technologies offer the potential for rapid optimization and quality control, their implementation in continuous flow systems requires careful consideration of factors such as response time, sensitivity, and compatibility with the flow environment.

Handling highly reactive or unstable alkyl intermediates in flow systems poses unique challenges. The short residence times in microreactors can be advantageous for controlling these species, but designing robust systems that can safely and efficiently manage such reactive compounds requires specialized equipment and expertise.

Finally, the development of sustainable and green flow chemistry processes for alkyl transformations remains a significant challenge. While flow chemistry inherently offers advantages in terms of efficiency and waste reduction, further innovations are needed to minimize solvent use, incorporate renewable feedstocks, and develop more environmentally benign catalytic systems for alkyl chemistry in continuous flow.

Current Flow Solutions

01 Continuous flow reactors for alkyl synthesis

Continuous flow reactors are being utilized for alkyl synthesis, offering advantages such as improved reaction control, enhanced safety, and increased efficiency. These systems allow for precise temperature and pressure control, enabling the optimization of reaction conditions for various alkylation processes.- Continuous flow reactors for alkylation processes: Continuous flow reactors are being utilized for alkylation reactions, offering advantages such as improved control over reaction conditions, enhanced safety, and increased efficiency. These systems allow for precise temperature and pressure control, enabling the optimization of alkylation processes and potentially leading to higher yields and product quality.

- Microfluidic devices for alkyl compound synthesis: Microfluidic devices are being developed and applied in the synthesis of alkyl compounds. These miniaturized systems offer benefits such as reduced reagent consumption, faster reaction times, and improved heat and mass transfer. The use of microfluidic technology in alkylation reactions can lead to more efficient and sustainable chemical processes.

- Automated flow chemistry systems for alkylation: Automated flow chemistry systems are being designed specifically for alkylation reactions. These systems integrate various components such as pumps, mixers, and inline analysis tools to streamline the alkylation process. Automation allows for real-time monitoring and adjustment of reaction parameters, potentially leading to improved reproducibility and scalability of alkylation reactions.

- Novel catalysts for flow alkylation processes: Research is being conducted on the development of novel catalysts specifically designed for flow alkylation processes. These catalysts aim to improve reaction rates, selectivity, and yield in continuous flow systems. The use of heterogeneous catalysts in flow reactors can potentially overcome limitations associated with traditional batch alkylation processes.

- In-line monitoring and analysis techniques for flow alkylation: Advanced in-line monitoring and analysis techniques are being integrated into flow chemistry systems for alkylation reactions. These techniques allow for real-time data collection on reaction progress, product formation, and impurity profiles. The ability to monitor reactions in real-time enables rapid optimization of process parameters and can lead to improved product quality and process efficiency.

02 Microfluidic devices for alkyl compound production

Microfluidic devices are being developed for the synthesis of alkyl compounds, allowing for precise control over reaction parameters and enabling rapid screening of reaction conditions. These devices offer advantages such as reduced reagent consumption, improved heat and mass transfer, and the potential for high-throughput experimentation.Expand Specific Solutions03 Automated flow chemistry systems for alkylation reactions

Automated flow chemistry systems are being designed specifically for alkylation reactions, incorporating features such as in-line analysis, real-time optimization, and self-adjusting parameters. These systems can improve reproducibility, reduce manual handling, and accelerate the development of new alkylation processes.Expand Specific Solutions04 Novel catalysts for flow-based alkylation

Research is focused on developing novel catalysts tailored for flow-based alkylation reactions. These catalysts are designed to enhance selectivity, increase reaction rates, and improve overall process efficiency in continuous flow systems. Efforts are being made to create heterogeneous catalysts that are compatible with flow chemistry setups.Expand Specific Solutions05 Process intensification techniques for alkyl synthesis

Process intensification techniques are being applied to alkyl synthesis in flow chemistry, including the use of static mixers, structured reactors, and multifunctional reactors. These approaches aim to enhance mixing, heat transfer, and mass transfer, leading to improved yields and selectivities in alkylation reactions.Expand Specific Solutions

Key Industry Players

The field of alkyl advances in flow chemistry techniques is experiencing rapid growth, with the market expanding as industries recognize the potential for increased efficiency and sustainability. The technology is in a transitional phase, moving from early adoption to more widespread implementation. Market size is projected to grow significantly, driven by demand in pharmaceuticals, fine chemicals, and petrochemicals sectors. Technological maturity varies, with companies like China Petroleum & Chemical Corp., Total Petrochemicals & Refining USA, Inc., and Dow Global Technologies LLC leading in innovation and commercial applications. Smaller players and research institutions, such as the University of Liege and Korea Institute of Energy Research, are contributing to advancements, particularly in catalyst development and process optimization. The competitive landscape is characterized by a mix of established petrochemical giants and specialized chemical companies, with increasing collaborations between industry and academia.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant advances in flow chemistry techniques for alkyl processes. They have developed a continuous-flow microreactor system for the alkylation of isobutane with olefins, which has shown improved efficiency and product quality compared to traditional batch processes[1]. The system utilizes a novel catalyst that enhances selectivity and reduces side reactions. Sinopec has also implemented inline analytical techniques for real-time monitoring and control of the alkylation process, allowing for rapid optimization of reaction conditions[3]. Additionally, they have explored the use of ionic liquids as catalysts in flow systems for alkylation reactions, which has demonstrated potential for reducing environmental impact and improving product yields[5].

Strengths: Improved efficiency, better product quality, and reduced environmental impact. Weaknesses: Potential high initial investment costs and challenges in scaling up the technology for large-scale production.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has made substantial progress in flow chemistry techniques for alkyl-related processes. They have developed a modular flow reactor system that allows for precise control of reaction parameters such as temperature, pressure, and residence time[2]. This system has been successfully applied to various alkylation reactions, including the production of specialty chemicals and polymers. Dow has also implemented advanced process analytical technology (PAT) in their flow chemistry setups, enabling real-time monitoring and adjustment of reaction conditions[4]. Furthermore, they have explored the use of 3D-printed reactor components to create custom-designed flow paths for specific alkylation reactions, optimizing mixing and heat transfer[6].

Strengths: Precise control over reaction parameters, versatility in application, and potential for customization. Weaknesses: Complexity of the system may require specialized training for operators.

Innovative Alkylation

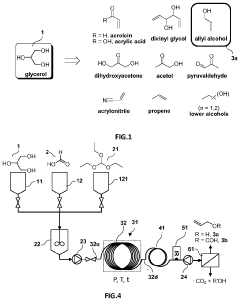

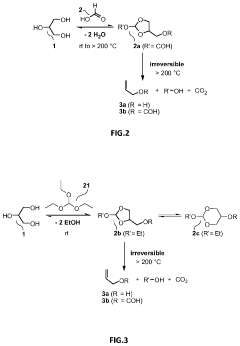

Process for the production of allyl compounds by deoxydehydration of glycerol

PatentActiveUS20200071248A1

Innovation

- A continuous-flow process involving the deoxydehydration of glycerol by mixing it with a carboxylic acid or triethyl orthoester, such as triethyl orthoformate, to form a reactive solution with reduced viscosity, allowing efficient flow through microreactor channels at moderate temperatures and pressures, producing allyl compounds like allyl alcohol and allyl formate with high yields.

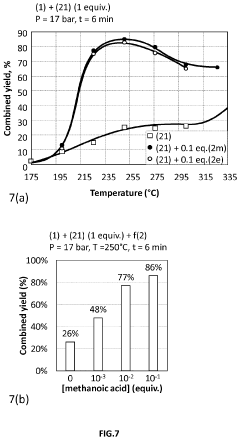

Improvements to flow apparatus

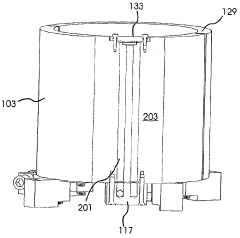

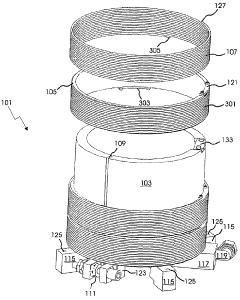

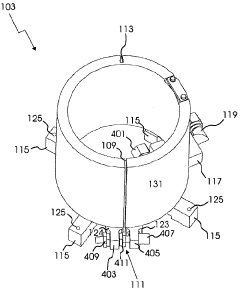

PatentInactiveGB2454294B

Innovation

- Detachable support means for optimized thermal contact between tubular reaction vessel and heat-transfer element.

- Design allowing heat-transfer element or support means to substantially surround the other, enhancing heat transfer efficiency.

- Incorporation of expansion slots and channels in the heat transfer element to accommodate thermal expansion and contraction.

Green Chemistry Impact

The impact of flow chemistry techniques on green chemistry has been significant, revolutionizing the way chemical processes are conducted and contributing to more sustainable practices in the industry. Flow chemistry, with its continuous-flow reactors and precise control over reaction parameters, aligns well with the principles of green chemistry by reducing waste, improving energy efficiency, and enhancing safety.

One of the key benefits of flow chemistry in the context of green chemistry is the reduction of solvent usage. Continuous-flow systems often require smaller volumes of solvents compared to traditional batch processes, leading to decreased environmental impact and reduced costs associated with solvent disposal. Additionally, the improved heat and mass transfer in flow reactors allows for more efficient use of energy, contributing to overall process sustainability.

Flow chemistry techniques have also enabled the development of more selective and atom-efficient reactions. The precise control over reaction conditions in flow systems allows for optimized reaction pathways, minimizing the formation of unwanted by-products and improving overall yield. This not only reduces waste but also simplifies downstream purification processes, further enhancing the environmental friendliness of chemical production.

The integration of flow chemistry with other green chemistry technologies has led to innovative solutions for sustainable chemical manufacturing. For example, the combination of flow reactors with photochemistry has opened up new avenues for clean and efficient synthesis using light as a renewable energy source. Similarly, the use of supercritical fluids as reaction media in flow systems has provided environmentally benign alternatives to traditional organic solvents.

Flow chemistry has also played a crucial role in the development of safer chemical processes. The small reaction volumes and improved heat dissipation in flow reactors reduce the risks associated with handling hazardous or highly exothermic reactions. This enhanced safety profile aligns with the green chemistry principle of designing inherently safer chemical processes.

Furthermore, the scalability of flow chemistry techniques has facilitated the implementation of green chemistry principles in industrial settings. Continuous-flow processes can be more easily scaled up from laboratory to production scale, maintaining the benefits of improved efficiency and reduced environmental impact. This scalability has encouraged the adoption of greener chemical processes in various industries, from pharmaceuticals to fine chemicals production.

In conclusion, the advances in flow chemistry techniques have significantly contributed to the realization of green chemistry goals. By enabling more efficient, safer, and environmentally friendly chemical processes, flow chemistry has become an essential tool in the pursuit of sustainable chemical manufacturing practices.

One of the key benefits of flow chemistry in the context of green chemistry is the reduction of solvent usage. Continuous-flow systems often require smaller volumes of solvents compared to traditional batch processes, leading to decreased environmental impact and reduced costs associated with solvent disposal. Additionally, the improved heat and mass transfer in flow reactors allows for more efficient use of energy, contributing to overall process sustainability.

Flow chemistry techniques have also enabled the development of more selective and atom-efficient reactions. The precise control over reaction conditions in flow systems allows for optimized reaction pathways, minimizing the formation of unwanted by-products and improving overall yield. This not only reduces waste but also simplifies downstream purification processes, further enhancing the environmental friendliness of chemical production.

The integration of flow chemistry with other green chemistry technologies has led to innovative solutions for sustainable chemical manufacturing. For example, the combination of flow reactors with photochemistry has opened up new avenues for clean and efficient synthesis using light as a renewable energy source. Similarly, the use of supercritical fluids as reaction media in flow systems has provided environmentally benign alternatives to traditional organic solvents.

Flow chemistry has also played a crucial role in the development of safer chemical processes. The small reaction volumes and improved heat dissipation in flow reactors reduce the risks associated with handling hazardous or highly exothermic reactions. This enhanced safety profile aligns with the green chemistry principle of designing inherently safer chemical processes.

Furthermore, the scalability of flow chemistry techniques has facilitated the implementation of green chemistry principles in industrial settings. Continuous-flow processes can be more easily scaled up from laboratory to production scale, maintaining the benefits of improved efficiency and reduced environmental impact. This scalability has encouraged the adoption of greener chemical processes in various industries, from pharmaceuticals to fine chemicals production.

In conclusion, the advances in flow chemistry techniques have significantly contributed to the realization of green chemistry goals. By enabling more efficient, safer, and environmentally friendly chemical processes, flow chemistry has become an essential tool in the pursuit of sustainable chemical manufacturing practices.

Scale-up Strategies

Scale-up strategies in flow chemistry techniques for alkyl advances require careful consideration of various factors to ensure successful implementation at larger scales. One key approach is the use of modular and scalable reactor designs that allow for easy expansion without compromising reaction efficiency. These designs often incorporate parallel flow paths or numbering-up strategies, where multiple smaller reactors are connected in series or parallel to increase overall throughput.

Another important aspect of scale-up is the optimization of heat and mass transfer. As reaction volumes increase, maintaining uniform temperature distribution and efficient mixing becomes more challenging. Advanced heat exchange systems, such as microstructured heat exchangers or plate-type reactors, can be employed to enhance heat transfer capabilities. Similarly, static mixers or specially designed mixing elements can be integrated into the flow path to ensure adequate mixing even at larger scales.

Process control and automation play a crucial role in successful scale-up. Implementing robust control systems that can monitor and adjust reaction parameters in real-time is essential for maintaining consistent product quality and yield. This may include the use of in-line analytics, such as spectroscopic techniques or flow sensors, to provide continuous feedback on reaction progress and product characteristics.

Material selection and equipment design must also be carefully considered during scale-up. Corrosion-resistant materials and high-pressure-rated components may be necessary to withstand the increased demands of larger-scale operations. Additionally, the design of pumps, valves, and other auxiliary equipment must be scaled appropriately to handle increased flow rates and pressures.

Safety considerations become increasingly important as scale increases. Implementing proper safety measures, such as pressure relief systems, containment strategies, and emergency shutdown protocols, is critical. Risk assessments should be conducted at each stage of scale-up to identify and mitigate potential hazards associated with larger reaction volumes and increased energy requirements.

Finally, process intensification techniques can be leveraged to improve efficiency and reduce equipment footprint during scale-up. This may involve the use of multifunctional reactors that combine reaction and separation steps, or the implementation of novel reactor designs that enhance mass and heat transfer capabilities. By carefully addressing these aspects, researchers and engineers can successfully scale up alkyl advances in flow chemistry techniques, paving the way for industrial-scale applications and improved production processes.

Another important aspect of scale-up is the optimization of heat and mass transfer. As reaction volumes increase, maintaining uniform temperature distribution and efficient mixing becomes more challenging. Advanced heat exchange systems, such as microstructured heat exchangers or plate-type reactors, can be employed to enhance heat transfer capabilities. Similarly, static mixers or specially designed mixing elements can be integrated into the flow path to ensure adequate mixing even at larger scales.

Process control and automation play a crucial role in successful scale-up. Implementing robust control systems that can monitor and adjust reaction parameters in real-time is essential for maintaining consistent product quality and yield. This may include the use of in-line analytics, such as spectroscopic techniques or flow sensors, to provide continuous feedback on reaction progress and product characteristics.

Material selection and equipment design must also be carefully considered during scale-up. Corrosion-resistant materials and high-pressure-rated components may be necessary to withstand the increased demands of larger-scale operations. Additionally, the design of pumps, valves, and other auxiliary equipment must be scaled appropriately to handle increased flow rates and pressures.

Safety considerations become increasingly important as scale increases. Implementing proper safety measures, such as pressure relief systems, containment strategies, and emergency shutdown protocols, is critical. Risk assessments should be conducted at each stage of scale-up to identify and mitigate potential hazards associated with larger reaction volumes and increased energy requirements.

Finally, process intensification techniques can be leveraged to improve efficiency and reduce equipment footprint during scale-up. This may involve the use of multifunctional reactors that combine reaction and separation steps, or the implementation of novel reactor designs that enhance mass and heat transfer capabilities. By carefully addressing these aspects, researchers and engineers can successfully scale up alkyl advances in flow chemistry techniques, paving the way for industrial-scale applications and improved production processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!