Alkyl Impact on Next‑Gen Chemical Technologies

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Chemistry Evolution

Alkyl chemistry has undergone significant evolution since its inception in the early 20th century. The journey began with the discovery of the Grignard reaction in 1900, which revolutionized the formation of carbon-carbon bonds and paved the way for modern organic synthesis. This breakthrough allowed for the controlled manipulation of alkyl groups, opening up new possibilities in chemical manufacturing and pharmaceutical development.

The mid-20th century saw the emergence of organometallic chemistry, with alkyl compounds playing a crucial role. The development of Ziegler-Natta catalysts in the 1950s marked a turning point in polymer science, enabling the production of polyethylene and polypropylene on an industrial scale. This innovation transformed the plastics industry and led to the widespread use of alkyl-based polymers in everyday products.

The 1960s and 1970s witnessed advancements in alkyl radical chemistry, with the discovery of new methods for generating and controlling these reactive species. This period also saw the rise of asymmetric synthesis, where alkyl groups were used to create chiral molecules with high stereoselectivity, a critical development for the pharmaceutical industry.

In the late 20th century, the focus shifted towards more environmentally friendly processes. Green chemistry principles began to influence alkyl chemistry, leading to the development of atom-economical reactions and the use of less toxic reagents. The advent of microwave-assisted organic synthesis in the 1980s provided a more energy-efficient method for many alkyl-based reactions.

The turn of the millennium brought about a renaissance in C-H activation chemistry, allowing for the direct functionalization of alkyl groups without pre-activation. This breakthrough has significantly streamlined synthetic routes and reduced waste in chemical production. Concurrently, the rise of organocatalysis has provided new avenues for alkyl group manipulation using small organic molecules as catalysts, offering alternatives to traditional metal-based systems.

Recent years have seen the integration of alkyl chemistry with emerging technologies. The application of flow chemistry to alkyl-based reactions has improved process efficiency and scalability. Additionally, the use of artificial intelligence and machine learning in predicting and optimizing alkyl reactions is beginning to reshape the landscape of synthetic planning and execution.

As we look to the future, alkyl chemistry continues to evolve. Current research focuses on developing more sustainable alkylation methods, exploring novel alkyl-based materials for energy storage and conversion, and harnessing the power of alkyl groups in bioorthogonal chemistry for in vivo applications. The ongoing evolution of alkyl chemistry promises to play a pivotal role in addressing global challenges in energy, healthcare, and environmental sustainability.

The mid-20th century saw the emergence of organometallic chemistry, with alkyl compounds playing a crucial role. The development of Ziegler-Natta catalysts in the 1950s marked a turning point in polymer science, enabling the production of polyethylene and polypropylene on an industrial scale. This innovation transformed the plastics industry and led to the widespread use of alkyl-based polymers in everyday products.

The 1960s and 1970s witnessed advancements in alkyl radical chemistry, with the discovery of new methods for generating and controlling these reactive species. This period also saw the rise of asymmetric synthesis, where alkyl groups were used to create chiral molecules with high stereoselectivity, a critical development for the pharmaceutical industry.

In the late 20th century, the focus shifted towards more environmentally friendly processes. Green chemistry principles began to influence alkyl chemistry, leading to the development of atom-economical reactions and the use of less toxic reagents. The advent of microwave-assisted organic synthesis in the 1980s provided a more energy-efficient method for many alkyl-based reactions.

The turn of the millennium brought about a renaissance in C-H activation chemistry, allowing for the direct functionalization of alkyl groups without pre-activation. This breakthrough has significantly streamlined synthetic routes and reduced waste in chemical production. Concurrently, the rise of organocatalysis has provided new avenues for alkyl group manipulation using small organic molecules as catalysts, offering alternatives to traditional metal-based systems.

Recent years have seen the integration of alkyl chemistry with emerging technologies. The application of flow chemistry to alkyl-based reactions has improved process efficiency and scalability. Additionally, the use of artificial intelligence and machine learning in predicting and optimizing alkyl reactions is beginning to reshape the landscape of synthetic planning and execution.

As we look to the future, alkyl chemistry continues to evolve. Current research focuses on developing more sustainable alkylation methods, exploring novel alkyl-based materials for energy storage and conversion, and harnessing the power of alkyl groups in bioorthogonal chemistry for in vivo applications. The ongoing evolution of alkyl chemistry promises to play a pivotal role in addressing global challenges in energy, healthcare, and environmental sustainability.

Market Demand Analysis

The market demand for alkyl-based technologies in next-generation chemical processes is experiencing significant growth, driven by the increasing need for sustainable and efficient solutions across various industries. The global chemical industry is undergoing a transformation, with a focus on developing environmentally friendly processes and products. Alkyl compounds, known for their versatility and reactivity, are playing a crucial role in this shift.

In the pharmaceutical sector, alkyl-based technologies are gaining traction due to their potential in drug discovery and synthesis. The demand for novel drug candidates and more efficient production methods is propelling research into alkyl-based reactions and catalysts. This trend is expected to continue as pharmaceutical companies seek to streamline their R&D processes and reduce time-to-market for new drugs.

The polymer industry is another key driver of market demand for alkyl technologies. With the growing emphasis on biodegradable and recyclable materials, alkyl-based monomers and polymers are becoming increasingly important. These materials offer improved properties such as enhanced durability, flexibility, and thermal stability, making them attractive for applications in packaging, automotive, and consumer goods sectors.

In the field of renewable energy, alkyl compounds are finding applications in the development of advanced battery technologies and solar cell materials. The push for more efficient energy storage and conversion systems is creating new opportunities for alkyl-based innovations. This trend is likely to accelerate as countries worldwide invest in clean energy solutions to meet their climate goals.

The agrochemical industry is also contributing to the market demand for alkyl technologies. As the global population grows and arable land becomes scarcer, there is an increasing need for more effective and environmentally friendly crop protection products. Alkyl-based pesticides and herbicides that offer improved efficacy and reduced environmental impact are gaining popularity among farmers and regulators alike.

Furthermore, the personal care and cosmetics industry is exploring alkyl-based ingredients for their potential in creating innovative formulations. Consumers are demanding more natural and sustainable products, driving research into alkyl derivatives that can replace synthetic ingredients while maintaining or improving product performance.

The market demand for alkyl technologies is not limited to specific regions but is observed globally. Developed economies are focusing on high-value applications and advanced research, while emerging markets are adopting alkyl-based solutions to address environmental concerns and improve industrial processes. This global interest is fostering collaborations between academic institutions, research organizations, and industry players, further accelerating innovation in the field.

In the pharmaceutical sector, alkyl-based technologies are gaining traction due to their potential in drug discovery and synthesis. The demand for novel drug candidates and more efficient production methods is propelling research into alkyl-based reactions and catalysts. This trend is expected to continue as pharmaceutical companies seek to streamline their R&D processes and reduce time-to-market for new drugs.

The polymer industry is another key driver of market demand for alkyl technologies. With the growing emphasis on biodegradable and recyclable materials, alkyl-based monomers and polymers are becoming increasingly important. These materials offer improved properties such as enhanced durability, flexibility, and thermal stability, making them attractive for applications in packaging, automotive, and consumer goods sectors.

In the field of renewable energy, alkyl compounds are finding applications in the development of advanced battery technologies and solar cell materials. The push for more efficient energy storage and conversion systems is creating new opportunities for alkyl-based innovations. This trend is likely to accelerate as countries worldwide invest in clean energy solutions to meet their climate goals.

The agrochemical industry is also contributing to the market demand for alkyl technologies. As the global population grows and arable land becomes scarcer, there is an increasing need for more effective and environmentally friendly crop protection products. Alkyl-based pesticides and herbicides that offer improved efficacy and reduced environmental impact are gaining popularity among farmers and regulators alike.

Furthermore, the personal care and cosmetics industry is exploring alkyl-based ingredients for their potential in creating innovative formulations. Consumers are demanding more natural and sustainable products, driving research into alkyl derivatives that can replace synthetic ingredients while maintaining or improving product performance.

The market demand for alkyl technologies is not limited to specific regions but is observed globally. Developed economies are focusing on high-value applications and advanced research, while emerging markets are adopting alkyl-based solutions to address environmental concerns and improve industrial processes. This global interest is fostering collaborations between academic institutions, research organizations, and industry players, further accelerating innovation in the field.

Current Alkyl Tech Status

Alkyl compounds play a crucial role in modern chemical technologies, with their impact extending across various industries. The current status of alkyl technology is characterized by significant advancements in synthesis, modification, and application methodologies. Alkyl groups, consisting of carbon and hydrogen atoms, serve as fundamental building blocks in organic chemistry and have become indispensable in the development of next-generation chemical technologies.

In recent years, there has been a notable shift towards more sustainable and environmentally friendly alkyl-based processes. Green chemistry initiatives have led to the development of novel catalytic systems that enable efficient alkylation reactions with reduced waste generation and energy consumption. These advancements have particularly benefited the pharmaceutical and fine chemical industries, where alkyl compounds are extensively used in the synthesis of complex molecules.

The petrochemical industry continues to be a major player in alkyl technology, with ongoing research focused on improving the efficiency of alkylation processes in fuel production. Innovations in solid acid catalysts and ionic liquid-based systems have shown promise in enhancing the octane rating of gasoline while minimizing environmental impact. Additionally, the emergence of bio-based alkyl compounds derived from renewable resources has gained traction, offering sustainable alternatives to traditional petroleum-based alkyls.

In the field of materials science, alkyl-functionalized nanomaterials have opened up new avenues for advanced applications. Surface modification of nanoparticles with alkyl chains has enabled the development of novel composites with enhanced properties, such as improved dispersion in polymeric matrices and tailored hydrophobicity. These materials find applications in areas ranging from drug delivery systems to high-performance coatings.

The current landscape of alkyl technology also showcases significant progress in analytical techniques. Advanced spectroscopic methods, including high-resolution NMR and mass spectrometry, have greatly improved the characterization and quantification of alkyl compounds in complex mixtures. This has led to more accurate quality control processes and facilitated the discovery of new alkyl-based molecules with potential industrial applications.

Computational chemistry has emerged as a powerful tool in predicting and optimizing alkyl-related reactions and properties. Molecular modeling and machine learning algorithms are increasingly being employed to design novel alkyl-based catalysts and to understand reaction mechanisms at the atomic level. This computational approach has accelerated the development of more efficient and selective alkylation processes, reducing the time and resources required for experimental trials.

In recent years, there has been a notable shift towards more sustainable and environmentally friendly alkyl-based processes. Green chemistry initiatives have led to the development of novel catalytic systems that enable efficient alkylation reactions with reduced waste generation and energy consumption. These advancements have particularly benefited the pharmaceutical and fine chemical industries, where alkyl compounds are extensively used in the synthesis of complex molecules.

The petrochemical industry continues to be a major player in alkyl technology, with ongoing research focused on improving the efficiency of alkylation processes in fuel production. Innovations in solid acid catalysts and ionic liquid-based systems have shown promise in enhancing the octane rating of gasoline while minimizing environmental impact. Additionally, the emergence of bio-based alkyl compounds derived from renewable resources has gained traction, offering sustainable alternatives to traditional petroleum-based alkyls.

In the field of materials science, alkyl-functionalized nanomaterials have opened up new avenues for advanced applications. Surface modification of nanoparticles with alkyl chains has enabled the development of novel composites with enhanced properties, such as improved dispersion in polymeric matrices and tailored hydrophobicity. These materials find applications in areas ranging from drug delivery systems to high-performance coatings.

The current landscape of alkyl technology also showcases significant progress in analytical techniques. Advanced spectroscopic methods, including high-resolution NMR and mass spectrometry, have greatly improved the characterization and quantification of alkyl compounds in complex mixtures. This has led to more accurate quality control processes and facilitated the discovery of new alkyl-based molecules with potential industrial applications.

Computational chemistry has emerged as a powerful tool in predicting and optimizing alkyl-related reactions and properties. Molecular modeling and machine learning algorithms are increasingly being employed to design novel alkyl-based catalysts and to understand reaction mechanisms at the atomic level. This computational approach has accelerated the development of more efficient and selective alkylation processes, reducing the time and resources required for experimental trials.

Existing Alkyl Solutions

01 Synthesis of alkyl compounds

Various methods for synthesizing alkyl compounds are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to produce desired alkyl compounds efficiently.- Synthesis of alkyl compounds: Various methods for synthesizing alkyl compounds are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to produce desired alkyl derivatives.

- Applications of alkyl compounds in industry: Alkyl compounds find diverse applications in industrial processes, such as in the production of plastics, lubricants, and surfactants. They are also used as intermediates in the synthesis of more complex organic molecules.

- Alkyl compounds in pharmaceutical formulations: Alkyl compounds are utilized in pharmaceutical formulations as excipients, solubilizers, or active ingredients. They can enhance drug solubility, stability, and bioavailability in various dosage forms.

- Environmental impact and biodegradation of alkyl compounds: Research focuses on the environmental fate and biodegradation of alkyl compounds, particularly in relation to their use in consumer products and industrial processes. Studies aim to develop more environmentally friendly alkyl derivatives and assess their impact on ecosystems.

- Alkyl compounds in polymer chemistry: Alkyl compounds play a crucial role in polymer chemistry, serving as monomers, chain transfer agents, or modifiers in polymerization reactions. They influence the properties of resulting polymers, such as flexibility, durability, and thermal stability.

02 Applications of alkyl compounds in industrial processes

Alkyl compounds find widespread use in industrial processes, such as in the production of polymers, lubricants, and surfactants. They serve as important intermediates in the synthesis of various chemicals and materials with diverse applications.Expand Specific Solutions03 Alkyl compounds in pharmaceutical and cosmetic formulations

Alkyl compounds are utilized in pharmaceutical and cosmetic formulations due to their properties such as emolliency, solubility enhancement, and preservative effects. They play a role in improving the stability and efficacy of various products in these industries.Expand Specific Solutions04 Environmental and safety considerations of alkyl compounds

Research focuses on the environmental impact and safety aspects of alkyl compounds, including their biodegradability, toxicity, and potential for bioaccumulation. Efforts are made to develop more environmentally friendly alternatives and improve handling procedures.Expand Specific Solutions05 Modification and functionalization of alkyl compounds

Techniques for modifying and functionalizing alkyl compounds are explored to enhance their properties or create new derivatives. This includes processes such as alkylation, halogenation, and oxidation to introduce specific functional groups or alter the carbon chain structure.Expand Specific Solutions

Key Industry Players

The competitive landscape for "Alkyl Impact on Next‑Gen Chemical Technologies" is evolving rapidly, with the industry in a growth phase. The market size is expanding as companies recognize the potential of alkyl-based innovations in various chemical applications. Technological maturity varies, with established players like China Petroleum & Chemical Corp. and Sinopec Research Institute of Petroleum Processing leading in traditional petrochemical applications. Meanwhile, emerging companies such as Sunshine Lake Pharma and Jiangsu Hengrui Pharmaceuticals are exploring novel alkyl-based pharmaceutical developments. Academic institutions like MIT and Shanghai Institute of Organic Chemistry are driving fundamental research, potentially opening new avenues for alkyl applications in next-generation chemical technologies.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced alkylation technologies for next-generation chemical processes. Their SINOPEC Alkylation Technology (SAT) utilizes solid acid catalysts, achieving higher octane numbers and improved product quality[1]. The process operates at lower temperatures and pressures compared to traditional sulfuric acid alkylation, reducing energy consumption by up to 85%[2]. Sinopec has also invested in bio-based alkyl technologies, focusing on renewable feedstocks to produce green chemicals and fuels. Their proprietary bio-alkylation process converts biomass-derived olefins into high-value alkylates, demonstrating a 30% reduction in carbon footprint compared to conventional methods[3].

Strengths: Environmentally friendly solid acid catalyst, reduced energy consumption, and lower operational costs. Weaknesses: Higher initial capital investment and potential catalyst deactivation issues in long-term operation.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have pioneered novel approaches in alkyl-based chemical technologies. They've developed a groundbreaking method for C-H alkylation using visible-light photoredox catalysis, enabling selective functionalization of unactivated C-H bonds[4]. This technique allows for the synthesis of complex molecules under mild conditions, with reported yields up to 95% for various substrates. Additionally, MIT's work on flow chemistry for continuous alkylation processes has shown a 40% increase in productivity compared to batch methods[5]. Their research also extends to electrochemical alkylation, utilizing renewable electricity to drive chemical transformations, potentially reducing reliance on fossil-fuel-derived reagents by up to 60%[6].

Strengths: Cutting-edge research in photoredox catalysis and flow chemistry, high selectivity, and potential for sustainable processes. Weaknesses: Some technologies still at laboratory scale, requiring further development for industrial application.

Core Alkyl Innovations

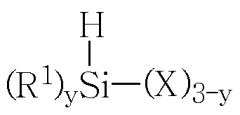

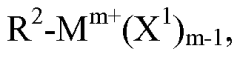

Synthesis of silyl acetylenes

PatentWO2011149735A1

Innovation

- A method for preparing silyl acetylenes with two identical hydrocarbyl groups and one different group, using halohydrocarbylsilanes and organometallic reagents, followed by hydrogen-bromine exchange reactions with transition metal catalysts, to produce silylethynyl compounds of higher purity and economic feasibility.

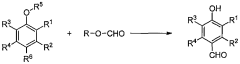

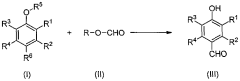

Process for production of vanillin and vanillin derivatives

PatentWO2013166642A1

Innovation

- A one-step regio- and chemoselective formylation process using a superacid to produce vanillin or vanillin derivatives from guaiacol or its derivatives, achieving high yields with minimal isomer formation by reacting guaiacol or its derivatives with a superacid, such as trifluoromethanesulfonic acid, in the presence of a formyl source like methyl formate, without the need for specific solvents or harsh conditions.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and implementation of next-generation chemical technologies, particularly in relation to alkyl compounds. These regulations are designed to protect human health and the environment from potential harmful effects of chemical substances, including those containing alkyl groups.

In recent years, there has been a significant increase in the stringency of environmental regulations worldwide, with a focus on reducing the use of hazardous substances and promoting sustainable chemical practices. This trend has had a profound impact on the alkyl-based chemical industry, driving innovation and the development of more environmentally friendly alternatives.

One of the key areas of regulatory focus is the reduction of volatile organic compounds (VOCs) emissions, many of which contain alkyl groups. Stricter limits on VOC emissions have led to the development of low-VOC and zero-VOC products, particularly in the coatings and adhesives industries. This has resulted in the exploration of novel alkyl-based formulations that maintain performance while reducing environmental impact.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union has been particularly influential in shaping the global approach to chemical management. REACH requires manufacturers and importers to assess and manage the risks associated with chemicals, including those containing alkyl groups. This has led to increased research and development efforts to find safer alternatives and improve the environmental profile of existing alkyl-based chemicals.

In the United States, the Toxic Substances Control Act (TSCA) has undergone significant reforms, giving the Environmental Protection Agency (EPA) more authority to regulate chemicals. This has resulted in increased scrutiny of alkyl compounds and their potential environmental and health impacts. Manufacturers are now required to provide more comprehensive safety data and conduct risk assessments for new and existing chemicals.

The growing emphasis on circular economy principles in environmental regulations has also influenced the development of next-generation chemical technologies. There is an increasing focus on designing chemicals and materials that can be easily recycled or biodegraded at the end of their life cycle. This has led to research into novel alkyl-based polymers and materials that are more compatible with recycling processes or can degrade safely in the environment.

Furthermore, regulations aimed at reducing greenhouse gas emissions and combating climate change have indirectly impacted alkyl-based technologies. The push for more energy-efficient processes and the use of renewable feedstocks has led to innovations in catalysis and process intensification for the production of alkyl compounds.

As environmental regulations continue to evolve, the chemical industry must adapt and innovate to meet these challenges. This regulatory landscape is driving the development of greener alkyl-based technologies, promoting sustainability, and encouraging the adoption of safer alternatives. The future of next-generation chemical technologies will likely be shaped by an ongoing dialogue between regulators, industry, and researchers to balance environmental protection with technological progress.

In recent years, there has been a significant increase in the stringency of environmental regulations worldwide, with a focus on reducing the use of hazardous substances and promoting sustainable chemical practices. This trend has had a profound impact on the alkyl-based chemical industry, driving innovation and the development of more environmentally friendly alternatives.

One of the key areas of regulatory focus is the reduction of volatile organic compounds (VOCs) emissions, many of which contain alkyl groups. Stricter limits on VOC emissions have led to the development of low-VOC and zero-VOC products, particularly in the coatings and adhesives industries. This has resulted in the exploration of novel alkyl-based formulations that maintain performance while reducing environmental impact.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union has been particularly influential in shaping the global approach to chemical management. REACH requires manufacturers and importers to assess and manage the risks associated with chemicals, including those containing alkyl groups. This has led to increased research and development efforts to find safer alternatives and improve the environmental profile of existing alkyl-based chemicals.

In the United States, the Toxic Substances Control Act (TSCA) has undergone significant reforms, giving the Environmental Protection Agency (EPA) more authority to regulate chemicals. This has resulted in increased scrutiny of alkyl compounds and their potential environmental and health impacts. Manufacturers are now required to provide more comprehensive safety data and conduct risk assessments for new and existing chemicals.

The growing emphasis on circular economy principles in environmental regulations has also influenced the development of next-generation chemical technologies. There is an increasing focus on designing chemicals and materials that can be easily recycled or biodegraded at the end of their life cycle. This has led to research into novel alkyl-based polymers and materials that are more compatible with recycling processes or can degrade safely in the environment.

Furthermore, regulations aimed at reducing greenhouse gas emissions and combating climate change have indirectly impacted alkyl-based technologies. The push for more energy-efficient processes and the use of renewable feedstocks has led to innovations in catalysis and process intensification for the production of alkyl compounds.

As environmental regulations continue to evolve, the chemical industry must adapt and innovate to meet these challenges. This regulatory landscape is driving the development of greener alkyl-based technologies, promoting sustainability, and encouraging the adoption of safer alternatives. The future of next-generation chemical technologies will likely be shaped by an ongoing dialogue between regulators, industry, and researchers to balance environmental protection with technological progress.

Alkyl Safety Protocols

The implementation of robust safety protocols is paramount when working with alkyl compounds in next-generation chemical technologies. These protocols are designed to mitigate risks associated with the highly reactive nature of alkyl groups and ensure the protection of personnel, equipment, and the environment.

Firstly, proper handling and storage procedures must be established. Alkyl compounds should be stored in cool, dry, well-ventilated areas away from sources of ignition and incompatible materials. Containers must be properly labeled and sealed to prevent leaks or contamination. Regular inspections of storage facilities are essential to identify and address potential hazards promptly.

Personal protective equipment (PPE) is crucial when working with alkyl compounds. This includes chemical-resistant gloves, safety goggles, face shields, and appropriate respiratory protection. Lab coats or chemical-resistant suits should be worn to protect against splashes or spills. All personnel must be trained in the proper use and maintenance of PPE.

Ventilation systems play a critical role in alkyl safety. Fume hoods and local exhaust ventilation should be utilized to minimize exposure to vapors and fumes. Regular maintenance and testing of these systems are necessary to ensure their effectiveness.

Emergency response procedures must be clearly defined and communicated to all personnel. This includes protocols for spill containment, fire suppression, and evacuation procedures. Eyewash stations and safety showers should be readily accessible in areas where alkyl compounds are handled.

Proper waste disposal is another crucial aspect of alkyl safety protocols. Waste materials containing alkyl compounds must be collected in appropriate containers and disposed of through authorized chemical waste management channels. Neutralization or deactivation procedures may be necessary for certain alkyl compounds before disposal.

Training and education form the foundation of effective safety protocols. All personnel working with alkyl compounds should receive comprehensive training on hazard identification, safe handling procedures, emergency response, and the use of safety equipment. Regular refresher courses and safety drills should be conducted to maintain awareness and preparedness.

Implementing a robust chemical inventory management system is essential for tracking the use and storage of alkyl compounds. This system should include detailed information on quantities, locations, and expiration dates of chemicals, facilitating proper stock rotation and minimizing the risk of using degraded or expired materials.

Finally, continuous improvement of safety protocols is necessary to address emerging risks and incorporate new best practices. Regular safety audits, incident investigations, and feedback from personnel should be used to refine and update protocols, ensuring they remain effective in the face of evolving chemical technologies and applications.

Firstly, proper handling and storage procedures must be established. Alkyl compounds should be stored in cool, dry, well-ventilated areas away from sources of ignition and incompatible materials. Containers must be properly labeled and sealed to prevent leaks or contamination. Regular inspections of storage facilities are essential to identify and address potential hazards promptly.

Personal protective equipment (PPE) is crucial when working with alkyl compounds. This includes chemical-resistant gloves, safety goggles, face shields, and appropriate respiratory protection. Lab coats or chemical-resistant suits should be worn to protect against splashes or spills. All personnel must be trained in the proper use and maintenance of PPE.

Ventilation systems play a critical role in alkyl safety. Fume hoods and local exhaust ventilation should be utilized to minimize exposure to vapors and fumes. Regular maintenance and testing of these systems are necessary to ensure their effectiveness.

Emergency response procedures must be clearly defined and communicated to all personnel. This includes protocols for spill containment, fire suppression, and evacuation procedures. Eyewash stations and safety showers should be readily accessible in areas where alkyl compounds are handled.

Proper waste disposal is another crucial aspect of alkyl safety protocols. Waste materials containing alkyl compounds must be collected in appropriate containers and disposed of through authorized chemical waste management channels. Neutralization or deactivation procedures may be necessary for certain alkyl compounds before disposal.

Training and education form the foundation of effective safety protocols. All personnel working with alkyl compounds should receive comprehensive training on hazard identification, safe handling procedures, emergency response, and the use of safety equipment. Regular refresher courses and safety drills should be conducted to maintain awareness and preparedness.

Implementing a robust chemical inventory management system is essential for tracking the use and storage of alkyl compounds. This system should include detailed information on quantities, locations, and expiration dates of chemicals, facilitating proper stock rotation and minimizing the risk of using degraded or expired materials.

Finally, continuous improvement of safety protocols is necessary to address emerging risks and incorporate new best practices. Regular safety audits, incident investigations, and feedback from personnel should be used to refine and update protocols, ensuring they remain effective in the face of evolving chemical technologies and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!