Analysis of lignin valorization in biomass upgrading processes

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lignin Valorization Background and Objectives

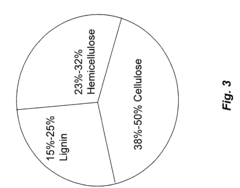

Lignin, the second most abundant natural polymer after cellulose, represents approximately 15-30% of lignocellulosic biomass by weight and contains up to 40% of its energy content. Historically, lignin has been underutilized in biomass processing, often burned for heat and power generation in pulp and paper industries. This approach fails to capitalize on lignin's potential as a renewable source of aromatic compounds and high-value chemicals, which are currently derived predominantly from fossil resources.

The evolution of lignin valorization technologies has progressed through several distinct phases. Initially, lignin was viewed primarily as a waste product or low-value fuel. The 1970s and 1980s saw early research into lignin's chemical structure and potential applications, though commercial viability remained limited. Since the early 2000s, significant advances in analytical techniques, catalysis, and biorefinery concepts have accelerated lignin valorization research, driven by sustainability imperatives and the search for petroleum alternatives.

Current technological trends in lignin valorization include catalytic depolymerization, oxidative valorization, biological conversion pathways, and integration of lignin processing into biorefinery operations. These approaches aim to overcome lignin's recalcitrant nature and heterogeneous structure, which have historically presented major challenges to its efficient utilization.

The primary objectives of lignin valorization in biomass upgrading processes are multifaceted. First, to develop economically viable processes for converting lignin into high-value products, thereby improving the overall economics of biorefineries. Second, to reduce dependence on fossil resources for aromatic compounds and specialty chemicals. Third, to minimize waste and environmental impact by utilizing all components of biomass effectively.

Technical goals include developing selective depolymerization methods that preserve valuable aromatic structures, designing catalysts specifically tailored to lignin's complex structure, establishing efficient separation techniques for lignin-derived products, and creating integrated processes that minimize energy consumption and waste generation.

The successful valorization of lignin represents a critical step toward sustainable biorefinery operations and circular bioeconomy principles. By transforming what has traditionally been a low-value byproduct into valuable chemicals and materials, lignin valorization has the potential to significantly enhance the economic viability of biomass processing while contributing to reduced carbon emissions and fossil resource dependence.

The evolution of lignin valorization technologies has progressed through several distinct phases. Initially, lignin was viewed primarily as a waste product or low-value fuel. The 1970s and 1980s saw early research into lignin's chemical structure and potential applications, though commercial viability remained limited. Since the early 2000s, significant advances in analytical techniques, catalysis, and biorefinery concepts have accelerated lignin valorization research, driven by sustainability imperatives and the search for petroleum alternatives.

Current technological trends in lignin valorization include catalytic depolymerization, oxidative valorization, biological conversion pathways, and integration of lignin processing into biorefinery operations. These approaches aim to overcome lignin's recalcitrant nature and heterogeneous structure, which have historically presented major challenges to its efficient utilization.

The primary objectives of lignin valorization in biomass upgrading processes are multifaceted. First, to develop economically viable processes for converting lignin into high-value products, thereby improving the overall economics of biorefineries. Second, to reduce dependence on fossil resources for aromatic compounds and specialty chemicals. Third, to minimize waste and environmental impact by utilizing all components of biomass effectively.

Technical goals include developing selective depolymerization methods that preserve valuable aromatic structures, designing catalysts specifically tailored to lignin's complex structure, establishing efficient separation techniques for lignin-derived products, and creating integrated processes that minimize energy consumption and waste generation.

The successful valorization of lignin represents a critical step toward sustainable biorefinery operations and circular bioeconomy principles. By transforming what has traditionally been a low-value byproduct into valuable chemicals and materials, lignin valorization has the potential to significantly enhance the economic viability of biomass processing while contributing to reduced carbon emissions and fossil resource dependence.

Market Analysis for Lignin-Derived Products

The global lignin market is experiencing significant growth, valued at approximately $954 million in 2022 and projected to reach $1.3 billion by 2027, with a compound annual growth rate (CAGR) of 6.4%. This growth is primarily driven by increasing awareness of sustainable alternatives to petroleum-based products and the rising demand for eco-friendly materials across various industries.

The lignin-derived products market can be segmented into several key categories. Vanillin, a popular food flavoring agent derived from lignin, holds a substantial market share with global demand exceeding 30,000 tons annually. Lignin-based carbon fibers represent another high-value segment, particularly attractive to automotive and aerospace industries seeking lightweight, sustainable materials for fuel efficiency improvements.

Phenolic compounds derived from lignin are gaining traction in the resin and adhesive markets, where they serve as bio-based alternatives to traditional phenol-formaldehyde products. This segment is growing at approximately 7.2% annually, driven by stringent environmental regulations limiting formaldehyde emissions in construction materials.

Geographically, Europe leads the lignin valorization market with approximately 35% market share, followed by North America (28%) and Asia-Pacific (25%). The European dominance stems from progressive environmental policies and strong research infrastructure supporting bio-based economies. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization and increasing environmental awareness in countries like China and India.

End-user industries for lignin-derived products show varying adoption rates. The construction sector currently represents the largest consumer segment (32%), utilizing lignin in concrete admixtures and as a binder in engineered wood products. The pharmaceutical and cosmetic industries are emerging as promising markets, with lignin derivatives being explored for applications in drug delivery systems and natural cosmetic formulations.

Market challenges include price competition with petroleum-based alternatives, which still maintain cost advantages in many applications. Additionally, inconsistent lignin quality from different biomass sources and extraction methods creates standardization difficulties for industrial applications. These challenges are gradually being addressed through technological advancements in lignin extraction and purification processes.

Consumer trends indicate growing preference for sustainable, bio-based products, creating favorable market conditions for lignin-derived alternatives. This shift is particularly evident in packaging materials, where lignin-based biodegradable plastics are gaining market acceptance despite premium pricing.

The lignin-derived products market can be segmented into several key categories. Vanillin, a popular food flavoring agent derived from lignin, holds a substantial market share with global demand exceeding 30,000 tons annually. Lignin-based carbon fibers represent another high-value segment, particularly attractive to automotive and aerospace industries seeking lightweight, sustainable materials for fuel efficiency improvements.

Phenolic compounds derived from lignin are gaining traction in the resin and adhesive markets, where they serve as bio-based alternatives to traditional phenol-formaldehyde products. This segment is growing at approximately 7.2% annually, driven by stringent environmental regulations limiting formaldehyde emissions in construction materials.

Geographically, Europe leads the lignin valorization market with approximately 35% market share, followed by North America (28%) and Asia-Pacific (25%). The European dominance stems from progressive environmental policies and strong research infrastructure supporting bio-based economies. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization and increasing environmental awareness in countries like China and India.

End-user industries for lignin-derived products show varying adoption rates. The construction sector currently represents the largest consumer segment (32%), utilizing lignin in concrete admixtures and as a binder in engineered wood products. The pharmaceutical and cosmetic industries are emerging as promising markets, with lignin derivatives being explored for applications in drug delivery systems and natural cosmetic formulations.

Market challenges include price competition with petroleum-based alternatives, which still maintain cost advantages in many applications. Additionally, inconsistent lignin quality from different biomass sources and extraction methods creates standardization difficulties for industrial applications. These challenges are gradually being addressed through technological advancements in lignin extraction and purification processes.

Consumer trends indicate growing preference for sustainable, bio-based products, creating favorable market conditions for lignin-derived alternatives. This shift is particularly evident in packaging materials, where lignin-based biodegradable plastics are gaining market acceptance despite premium pricing.

Current Challenges in Lignin Conversion Technologies

Despite significant advancements in lignin valorization research, numerous technical challenges continue to impede the widespread commercial implementation of lignin conversion technologies. The heterogeneous and complex structure of lignin presents a fundamental obstacle, as its irregular three-dimensional network of phenylpropanoid units connected by various C-O and C-C bonds makes selective depolymerization exceptionally difficult. This structural complexity varies significantly depending on biomass source and extraction method, further complicating the development of universally applicable conversion processes.

Current thermochemical conversion methods face significant limitations. Pyrolysis processes, while effective at breaking down lignin, typically yield complex bio-oil mixtures requiring extensive downstream separation and purification. Gasification achieves high conversion rates but sacrifices the valuable aromatic structure of lignin, reducing potential value creation. Hydrothermal liquefaction struggles with catalyst deactivation due to char formation and requires high-pressure equipment that increases capital costs.

Catalytic approaches encounter persistent challenges related to catalyst stability and selectivity. Heterogeneous catalysts often suffer from rapid deactivation due to coke formation and poisoning by sulfur compounds present in technical lignins. Homogeneous catalysts, while sometimes more selective, present recovery difficulties that limit industrial scalability. The development of catalysts that can selectively cleave specific bonds while preserving desired structural features remains an unresolved challenge.

Biological conversion routes using enzymes and microorganisms show promise but face significant hurdles. Lignin-degrading enzymes typically demonstrate low activity rates and insufficient stability under industrial conditions. The specificity of biological systems also limits their applicability across different lignin types. Additionally, the inhibitory effects of lignin degradation products on microbial growth create further complications for biological processing routes.

Process integration and techno-economic barriers represent another critical challenge area. Most current lignin valorization technologies remain economically unfeasible when scaled up, with high energy inputs, expensive catalysts, and complex separation processes contributing to prohibitive costs. The integration of lignin conversion into existing biorefinery operations presents additional technical challenges related to process compatibility and waste stream management.

Analytical limitations further hinder progress, as characterizing lignin's complex structure and tracking conversion products requires sophisticated techniques that are often time-consuming and expensive. This impedes rapid technology development and optimization cycles. The lack of standardized methods for evaluating lignin conversion efficiency across different technologies also complicates comparative assessments and benchmarking efforts.

Current thermochemical conversion methods face significant limitations. Pyrolysis processes, while effective at breaking down lignin, typically yield complex bio-oil mixtures requiring extensive downstream separation and purification. Gasification achieves high conversion rates but sacrifices the valuable aromatic structure of lignin, reducing potential value creation. Hydrothermal liquefaction struggles with catalyst deactivation due to char formation and requires high-pressure equipment that increases capital costs.

Catalytic approaches encounter persistent challenges related to catalyst stability and selectivity. Heterogeneous catalysts often suffer from rapid deactivation due to coke formation and poisoning by sulfur compounds present in technical lignins. Homogeneous catalysts, while sometimes more selective, present recovery difficulties that limit industrial scalability. The development of catalysts that can selectively cleave specific bonds while preserving desired structural features remains an unresolved challenge.

Biological conversion routes using enzymes and microorganisms show promise but face significant hurdles. Lignin-degrading enzymes typically demonstrate low activity rates and insufficient stability under industrial conditions. The specificity of biological systems also limits their applicability across different lignin types. Additionally, the inhibitory effects of lignin degradation products on microbial growth create further complications for biological processing routes.

Process integration and techno-economic barriers represent another critical challenge area. Most current lignin valorization technologies remain economically unfeasible when scaled up, with high energy inputs, expensive catalysts, and complex separation processes contributing to prohibitive costs. The integration of lignin conversion into existing biorefinery operations presents additional technical challenges related to process compatibility and waste stream management.

Analytical limitations further hinder progress, as characterizing lignin's complex structure and tracking conversion products requires sophisticated techniques that are often time-consuming and expensive. This impedes rapid technology development and optimization cycles. The lack of standardized methods for evaluating lignin conversion efficiency across different technologies also complicates comparative assessments and benchmarking efforts.

Current Lignin Depolymerization Strategies

01 Catalytic conversion of lignin to valuable chemicals

Various catalytic processes can be employed to convert lignin into high-value chemicals. These processes typically involve breaking down the complex lignin structure into simpler aromatic compounds through methods such as hydrogenolysis, oxidation, or depolymerization. Catalysts including metals, metal oxides, and supported catalysts facilitate these transformations under specific reaction conditions, enabling the production of phenolic compounds, aromatic monomers, and other platform chemicals that serve as building blocks for various industrial applications.- Catalytic depolymerization of lignin: Catalytic processes can be employed to break down lignin into valuable smaller molecules. These methods typically involve the use of specific catalysts under controlled conditions to cleave the complex lignin structure. The resulting products can include aromatic compounds, phenols, and other high-value chemicals that serve as building blocks for various industrial applications. This approach represents a significant pathway for converting lignin waste into commercially viable products.

- Conversion of lignin to biofuels and biochemicals: Lignin can be transformed into renewable biofuels and biochemicals through various conversion technologies. These processes typically involve breaking down lignin's complex structure to produce liquid fuels, fuel additives, or platform chemicals. Methods may include hydrothermal processing, pyrolysis, or fermentation approaches. The resulting products can serve as sustainable alternatives to petroleum-derived fuels and chemicals, contributing to reduced carbon footprints in various industries.

- Polymer applications of modified lignin: Lignin can be chemically modified to enhance its compatibility with polymer systems, allowing it to serve as a renewable component in various polymer applications. These modifications may include functionalization, grafting, or other chemical treatments that improve lignin's properties. The modified lignin can be incorporated into adhesives, resins, composites, and other polymer materials, reducing dependence on petroleum-based components while potentially enhancing certain material properties such as UV resistance or thermal stability.

- Fractionation and extraction techniques for lignin processing: Various fractionation and extraction methods can be employed to isolate and process lignin from biomass or industrial waste streams. These techniques may include solvent extraction, membrane filtration, precipitation, or other separation processes designed to obtain lignin fractions with specific properties. The resulting lignin streams can be further processed into value-added products. Effective fractionation is often a critical first step in lignin valorization, as it can significantly impact the quality and consistency of downstream products.

- Lignin-derived carbon materials: Lignin can serve as a renewable precursor for various carbon materials with high-value applications. Through processes such as carbonization, activation, or templating, lignin can be transformed into activated carbons, carbon fibers, carbon dots, or other carbon-based materials. These products find applications in areas such as environmental remediation, energy storage, reinforcement materials, and advanced electronics. The use of lignin as a carbon precursor offers a sustainable alternative to petroleum-based carbon sources while potentially valorizing a major byproduct of the pulp and paper industry.

02 Lignin depolymerization techniques

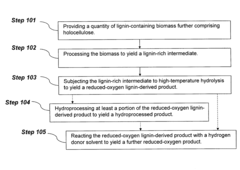

Lignin depolymerization involves breaking down the complex lignin polymer into smaller, more valuable fragments. Various techniques are employed including thermal processes (pyrolysis, gasification), chemical methods (acid/base hydrolysis, oxidative depolymerization), and biological approaches using enzymes or microorganisms. These techniques aim to cleave the β-O-4 and other linkages in lignin to produce monomeric and oligomeric products that can be further processed into fuels, chemicals, and materials, thereby enhancing the economic value of lignin as a renewable resource.Expand Specific Solutions03 Production of biopolymers and materials from lignin

Lignin can be transformed into various biopolymers and materials with enhanced properties. Through chemical modification, functionalization, or blending with other polymers, lignin can be incorporated into adhesives, resins, coatings, composites, and carbon fibers. These lignin-based materials often exhibit improved mechanical properties, thermal stability, and environmental sustainability compared to petroleum-derived alternatives. The development of these materials represents a significant avenue for lignin valorization by creating higher-value products from this abundant biopolymer.Expand Specific Solutions04 Biorefinery approaches for lignin valorization

Biorefinery approaches integrate lignin valorization into comprehensive biomass processing systems. These approaches involve the extraction, fractionation, and conversion of lignin alongside other biomass components (cellulose, hemicellulose) to maximize resource utilization and economic value. Advanced biorefinery concepts employ cascading conversion strategies where lignin undergoes sequential transformations to produce multiple products with increasing value. This holistic approach enhances the overall economics of biomass processing while reducing waste and environmental impact.Expand Specific Solutions05 Lignin-derived fuels and energy applications

Lignin can be converted into various fuels and energy products through thermochemical and biological processes. These include the production of bio-oils through pyrolysis, synthesis gas through gasification, and liquid fuels through hydrodeoxygenation. Additionally, lignin can be directly used as a solid fuel or processed into fuel pellets with enhanced energy density. These applications provide pathways for utilizing lignin as a renewable energy source, contributing to reduced dependence on fossil fuels and lower greenhouse gas emissions.Expand Specific Solutions

Key Industrial Players in Biomass Upgrading

Lignin valorization in biomass upgrading processes is currently in a transitional phase from early-stage research to commercial implementation. The global market for lignin-derived products is projected to reach $1.12 billion by 2027, growing at a CAGR of 5.9%. Technologically, the field shows varying maturity levels across different conversion pathways. Leading players like DuPont de Nemours and China Petroleum & Chemical Corp. are advancing catalytic depolymerization techniques, while research institutions such as Purdue Research Foundation and Northeast Forestry University focus on enzymatic approaches. UPM-Kymmene and VTT are pioneering biorefinery integration strategies. Academic-industry partnerships, exemplified by Wisconsin Alumni Research Foundation's collaborations, are accelerating technology transfer from laboratory to commercial scale.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed an integrated biorefinery approach for lignin valorization that focuses on extracting maximum value from biomass feedstocks. Their technology platform combines pretreatment processes that preserve lignin structure with selective catalytic conversion pathways. DuPont's proprietary APEX (Accelerated Polymer Extraction) process uses green solvents to fractionate biomass, separating cellulose, hemicellulose, and lignin while maintaining the native structure of lignin polymers. This preserved structure enables higher yields in downstream conversion. Their catalytic approach employs bimetallic catalysts (typically Pd-Zn or Ni-Cu on mesoporous supports) that selectively cleave specific lignin bonds while preserving aromatic rings, achieving monomer yields of 25-35% from hardwood lignins. DuPont has also developed enzymatic processes using engineered laccases that can perform selective oxidation of lignin under mild conditions, enabling production of specialty chemicals like vanillin and syringaldehyde with yields up to 8-10% based on lignin weight.

Strengths: Extensive experience in industrial biotechnology and chemical processing enables integration of biological and thermochemical conversion routes. Strong intellectual property portfolio and commercialization capabilities accelerate technology deployment. Weaknesses: Focus on higher-value specialty chemicals from lignin creates market volume limitations compared to fuel or bulk chemical applications. Their processes often require relatively pure lignin streams, limiting compatibility with some industrial lignin sources.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced catalytic depolymerization technologies for lignin valorization, focusing on hydrogenolysis and oxidative processes. Their approach involves a two-stage catalytic system that first breaks down lignin's complex structure using metal-supported catalysts (typically Ni, Pd, or Ru on carbon supports) followed by selective conversion to high-value aromatics and phenolic compounds. Sinopec has implemented continuous-flow reactors operating at moderate temperatures (250-350°C) and hydrogen pressures (2-10 MPa) that achieve lignin conversion rates exceeding 85% with aromatic monomer yields of 20-30%. Their technology integrates with existing petroleum refining infrastructure, allowing for co-processing of lignin-derived bio-oils with conventional petroleum streams, creating a pathway for renewable carbon integration into their chemical production.

Strengths: Extensive catalysis expertise and existing refinery infrastructure that can be leveraged for scaling up lignin valorization processes. Their integrated approach allows for gradual transition from fossil to renewable carbon sources. Weaknesses: Their processes still require significant hydrogen input (often from fossil sources) and face challenges with catalyst deactivation due to lignin's heterogeneous nature and impurities.

Critical Patents in Lignin Conversion Processes

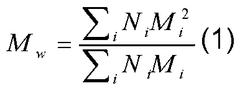

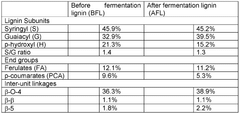

Lignin compositions for improved bioprocess utilization

PatentWO2025035142A1

Innovation

- A method involving multiple steps: washing lignin with an aqueous fluid, acid treatment, cellulase treatment, and fermentation to produce a crosslinked high molecular weight lignin, which can be used to create composite materials with improved properties.

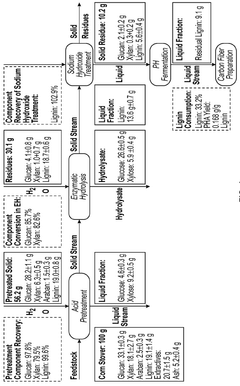

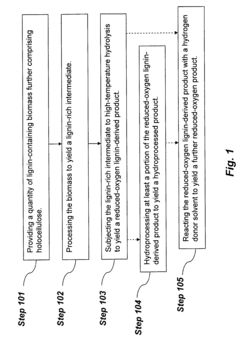

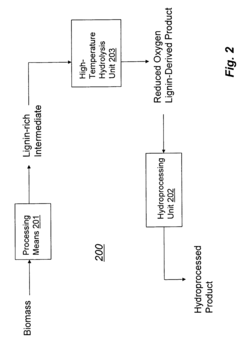

Lignin upgrading for hydroprocessing to biofuel

PatentActiveUS8486161B2

Innovation

- Processing lignin-containing biomass to reduce its oxygen content through high-temperature hydrolysis, resulting in a reduced-oxygen lignin-derived product that can be hydroprocessed into a biofuel suitable for transportation use, potentially integrated with other processes for synergistic benefits.

Environmental Impact Assessment of Lignin Processing

The environmental implications of lignin processing represent a critical dimension in the sustainable development of biomass valorization technologies. Traditional lignin extraction and processing methods have historically been associated with significant environmental burdens, including high energy consumption, chemical waste generation, and greenhouse gas emissions. The kraft pulping process, widely used in the paper industry, typically requires substantial amounts of sodium hydroxide and sodium sulfide, resulting in sulfur-containing waste streams that necessitate extensive treatment.

Recent advancements in lignin processing technologies have demonstrated promising reductions in environmental footprints. Organosolv processes utilizing renewable solvents like ethanol have shown 30-40% lower carbon emissions compared to conventional methods. Similarly, ionic liquid-based extraction techniques minimize water usage by up to 60% while significantly reducing hazardous waste generation. These improvements align with global sustainability goals and increasingly stringent environmental regulations governing industrial processes.

Water consumption represents another significant environmental concern in lignin processing. Conventional methods typically require 80-100 liters of water per kilogram of lignin extracted, contributing to water scarcity issues in regions where biomass processing facilities operate. Advanced membrane filtration systems and closed-loop water recycling technologies have demonstrated potential to reduce water requirements by 50-70%, though implementation costs remain a barrier to widespread adoption.

The carbon balance of lignin valorization processes varies considerably depending on the specific technologies employed. Life cycle assessments indicate that lignin-derived products can achieve carbon footprint reductions of 40-60% compared to petroleum-based alternatives when optimized processing routes are utilized. However, these benefits can be negated if energy-intensive separation and purification steps are required, highlighting the importance of holistic process design that considers environmental impacts across the entire value chain.

Land use changes associated with increased biomass cultivation for lignin extraction present additional environmental challenges. Sustainable forestry practices and the utilization of agricultural residues can mitigate these impacts, but careful monitoring and certification systems are essential to prevent unintended consequences such as biodiversity loss or competition with food production.

Regulatory frameworks governing lignin processing are evolving rapidly, with particular emphasis on emissions control, waste management, and resource efficiency. The implementation of Best Available Techniques (BAT) standards in Europe and similar approaches in North America and Asia is driving continuous improvement in environmental performance across the lignin processing industry, though significant regional variations in enforcement and compliance remain.

Recent advancements in lignin processing technologies have demonstrated promising reductions in environmental footprints. Organosolv processes utilizing renewable solvents like ethanol have shown 30-40% lower carbon emissions compared to conventional methods. Similarly, ionic liquid-based extraction techniques minimize water usage by up to 60% while significantly reducing hazardous waste generation. These improvements align with global sustainability goals and increasingly stringent environmental regulations governing industrial processes.

Water consumption represents another significant environmental concern in lignin processing. Conventional methods typically require 80-100 liters of water per kilogram of lignin extracted, contributing to water scarcity issues in regions where biomass processing facilities operate. Advanced membrane filtration systems and closed-loop water recycling technologies have demonstrated potential to reduce water requirements by 50-70%, though implementation costs remain a barrier to widespread adoption.

The carbon balance of lignin valorization processes varies considerably depending on the specific technologies employed. Life cycle assessments indicate that lignin-derived products can achieve carbon footprint reductions of 40-60% compared to petroleum-based alternatives when optimized processing routes are utilized. However, these benefits can be negated if energy-intensive separation and purification steps are required, highlighting the importance of holistic process design that considers environmental impacts across the entire value chain.

Land use changes associated with increased biomass cultivation for lignin extraction present additional environmental challenges. Sustainable forestry practices and the utilization of agricultural residues can mitigate these impacts, but careful monitoring and certification systems are essential to prevent unintended consequences such as biodiversity loss or competition with food production.

Regulatory frameworks governing lignin processing are evolving rapidly, with particular emphasis on emissions control, waste management, and resource efficiency. The implementation of Best Available Techniques (BAT) standards in Europe and similar approaches in North America and Asia is driving continuous improvement in environmental performance across the lignin processing industry, though significant regional variations in enforcement and compliance remain.

Techno-economic Analysis of Lignin Biorefinery Models

The techno-economic analysis of lignin biorefinery models reveals significant potential for value creation through strategic processing pathways. Current economic assessments indicate that lignin valorization can increase biorefinery profitability by 30-45% when integrated with existing cellulosic ethanol or pulp and paper operations. The capital expenditure requirements for lignin extraction and upgrading facilities range from $50-120 million USD, depending on scale and technology selection, with larger installations benefiting from economies of scale.

Operational expenditures are primarily driven by energy costs (35-40%), catalysts and chemicals (25-30%), and labor (15-20%). The minimum selling price for lignin-derived products varies significantly: $1,200-2,500/ton for phenolic compounds, $1,800-3,000/ton for carbon fiber precursors, and $800-1,500/ton for polyurethane foam components. These price points reflect current technological limitations and market conditions.

Sensitivity analyses demonstrate that feedstock cost, conversion efficiency, and product yield are the most influential factors affecting economic viability. A 10% improvement in conversion efficiency can reduce production costs by approximately 15-20%, highlighting the importance of continued technological development. The internal rate of return (IRR) for most lignin biorefinery models currently ranges from 8-15%, with payback periods of 5-8 years.

Different biorefinery configurations show varying economic performance. The integrated pulp mill biorefinery model demonstrates superior economics with potential IRRs of 12-18%, while standalone lignin processing facilities struggle to achieve IRRs above 10% under current market conditions. Co-product revenue streams are essential, with optimal models deriving 40-60% of revenue from high-value lignin products and the remainder from traditional outputs.

Market risk assessment indicates moderate to high volatility in end-product markets, particularly for novel lignin applications. Price premiums for bio-based alternatives to petrochemical products remain inconsistent, though regulatory incentives in certain regions can significantly improve economic outcomes. Carbon pricing mechanisms, when applied, can improve IRR by 2-4 percentage points.

The most economically promising lignin valorization pathways currently include phenolic resins for adhesives, BTX (benzene, toluene, xylene) production, and certain specialty chemicals. Carbon fiber production, while technically promising, requires further cost reductions of approximately 30-40% to achieve widespread commercial viability in lignin biorefinery models.

Operational expenditures are primarily driven by energy costs (35-40%), catalysts and chemicals (25-30%), and labor (15-20%). The minimum selling price for lignin-derived products varies significantly: $1,200-2,500/ton for phenolic compounds, $1,800-3,000/ton for carbon fiber precursors, and $800-1,500/ton for polyurethane foam components. These price points reflect current technological limitations and market conditions.

Sensitivity analyses demonstrate that feedstock cost, conversion efficiency, and product yield are the most influential factors affecting economic viability. A 10% improvement in conversion efficiency can reduce production costs by approximately 15-20%, highlighting the importance of continued technological development. The internal rate of return (IRR) for most lignin biorefinery models currently ranges from 8-15%, with payback periods of 5-8 years.

Different biorefinery configurations show varying economic performance. The integrated pulp mill biorefinery model demonstrates superior economics with potential IRRs of 12-18%, while standalone lignin processing facilities struggle to achieve IRRs above 10% under current market conditions. Co-product revenue streams are essential, with optimal models deriving 40-60% of revenue from high-value lignin products and the remainder from traditional outputs.

Market risk assessment indicates moderate to high volatility in end-product markets, particularly for novel lignin applications. Price premiums for bio-based alternatives to petrochemical products remain inconsistent, though regulatory incentives in certain regions can significantly improve economic outcomes. Carbon pricing mechanisms, when applied, can improve IRR by 2-4 percentage points.

The most economically promising lignin valorization pathways currently include phenolic resins for adhesives, BTX (benzene, toluene, xylene) production, and certain specialty chemicals. Carbon fiber production, while technically promising, requires further cost reductions of approximately 30-40% to achieve widespread commercial viability in lignin biorefinery models.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!