How product selectivity is tuned in catalytic biomass upgrading

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalytic Biomass Upgrading Background and Objectives

Catalytic biomass upgrading represents a pivotal frontier in sustainable energy and chemical production, emerging as a response to the growing concerns over fossil fuel depletion and environmental degradation. This technology has evolved significantly over the past three decades, transitioning from rudimentary thermal conversion processes to sophisticated catalytic systems capable of selectively transforming biomass into high-value chemicals and fuels. The historical trajectory reveals a shift from first-generation biofuels derived from food crops to advanced processes utilizing lignocellulosic biomass, agricultural residues, and waste materials.

The fundamental challenge in biomass upgrading lies in its complex, oxygen-rich molecular structure, which necessitates deoxygenation and selective bond cleavage to yield desired products. Product selectivity—the ability to direct conversion pathways toward specific high-value compounds—has emerged as the critical factor determining economic viability and commercial adoption of these technologies.

Current technological trends indicate a convergence of heterogeneous catalysis, biocatalysis, and process intensification strategies. Researchers are increasingly focusing on developing multifunctional catalysts capable of orchestrating cascade reactions in one-pot systems, thereby enhancing efficiency and selectivity. Computational modeling and high-throughput experimentation are accelerating catalyst discovery and optimization, enabling more precise tuning of product distributions.

The primary technical objectives in this field encompass several dimensions. First, developing catalytic systems with enhanced selectivity toward platform chemicals such as 5-hydroxymethylfurfural (HMF), levulinic acid, and γ-valerolactone. Second, designing robust catalysts resistant to deactivation by water, impurities, and carbon deposition—common challenges in biomass processing environments. Third, establishing scalable processes that maintain selectivity advantages at industrial production volumes.

Additionally, there is growing emphasis on understanding the fundamental mechanisms governing selectivity in biomass conversion reactions. This includes elucidating the roles of catalyst surface properties, pore architecture, active site distribution, and reaction conditions in directing reaction pathways. Such mechanistic insights are essential for rational catalyst design and process optimization.

The ultimate goal extends beyond technical feasibility to economic viability—developing catalytic upgrading technologies that can compete with petroleum-based processes while delivering superior environmental performance. This necessitates holistic approaches that consider feedstock variability, process integration, and downstream separation challenges alongside catalyst performance metrics.

The fundamental challenge in biomass upgrading lies in its complex, oxygen-rich molecular structure, which necessitates deoxygenation and selective bond cleavage to yield desired products. Product selectivity—the ability to direct conversion pathways toward specific high-value compounds—has emerged as the critical factor determining economic viability and commercial adoption of these technologies.

Current technological trends indicate a convergence of heterogeneous catalysis, biocatalysis, and process intensification strategies. Researchers are increasingly focusing on developing multifunctional catalysts capable of orchestrating cascade reactions in one-pot systems, thereby enhancing efficiency and selectivity. Computational modeling and high-throughput experimentation are accelerating catalyst discovery and optimization, enabling more precise tuning of product distributions.

The primary technical objectives in this field encompass several dimensions. First, developing catalytic systems with enhanced selectivity toward platform chemicals such as 5-hydroxymethylfurfural (HMF), levulinic acid, and γ-valerolactone. Second, designing robust catalysts resistant to deactivation by water, impurities, and carbon deposition—common challenges in biomass processing environments. Third, establishing scalable processes that maintain selectivity advantages at industrial production volumes.

Additionally, there is growing emphasis on understanding the fundamental mechanisms governing selectivity in biomass conversion reactions. This includes elucidating the roles of catalyst surface properties, pore architecture, active site distribution, and reaction conditions in directing reaction pathways. Such mechanistic insights are essential for rational catalyst design and process optimization.

The ultimate goal extends beyond technical feasibility to economic viability—developing catalytic upgrading technologies that can compete with petroleum-based processes while delivering superior environmental performance. This necessitates holistic approaches that consider feedstock variability, process integration, and downstream separation challenges alongside catalyst performance metrics.

Market Analysis for Selective Biomass Conversion Products

The global market for selective biomass conversion products is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable alternatives to petroleum-based products. The market size for bio-based chemicals derived from selective biomass conversion was valued at approximately $8.7 billion in 2022 and is projected to reach $16.2 billion by 2028, growing at a CAGR of 10.9% during the forecast period.

Regionally, North America currently leads the market with about 35% share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth due to rapid industrialization, increasing government support for green technologies, and growing consumer awareness about sustainable products.

Key market segments for selective biomass conversion products include biofuels, biochemicals, biomaterials, and pharmaceuticals. Among these, biochemicals represent the largest segment, accounting for approximately 40% of the market share. This includes platform chemicals like levulinic acid, 5-hydroxymethylfurfural (5-HMF), and furan derivatives that serve as building blocks for various industrial applications.

The demand for selectively converted biomass products is particularly strong in the packaging industry, where bio-based plastics are gaining traction as alternatives to conventional plastics. The market for bio-based packaging materials is growing at 13.5% annually, driven by stringent regulations against single-use plastics and changing consumer preferences.

Consumer goods manufacturers are increasingly incorporating bio-based chemicals in their products to meet sustainability goals and respond to consumer demand for environmentally friendly options. This trend is evident in the personal care and cosmetics sector, where bio-based ingredients derived from selective biomass conversion are being used in premium product formulations.

The automotive and transportation sectors are also significant end-users, particularly for biofuels and bio-based lubricants. The aviation industry's commitment to reducing carbon emissions has created a growing market for sustainable aviation fuels (SAF) derived from biomass, with major airlines pledging to increase SAF usage by 10% by 2030.

Market challenges include high production costs compared to petroleum-based alternatives, technological limitations in achieving desired selectivity, and competition from other renewable technologies. However, these challenges are being addressed through continuous innovation in catalyst design, process optimization, and integration of artificial intelligence in process control to enhance selectivity and yield.

Regionally, North America currently leads the market with about 35% share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth due to rapid industrialization, increasing government support for green technologies, and growing consumer awareness about sustainable products.

Key market segments for selective biomass conversion products include biofuels, biochemicals, biomaterials, and pharmaceuticals. Among these, biochemicals represent the largest segment, accounting for approximately 40% of the market share. This includes platform chemicals like levulinic acid, 5-hydroxymethylfurfural (5-HMF), and furan derivatives that serve as building blocks for various industrial applications.

The demand for selectively converted biomass products is particularly strong in the packaging industry, where bio-based plastics are gaining traction as alternatives to conventional plastics. The market for bio-based packaging materials is growing at 13.5% annually, driven by stringent regulations against single-use plastics and changing consumer preferences.

Consumer goods manufacturers are increasingly incorporating bio-based chemicals in their products to meet sustainability goals and respond to consumer demand for environmentally friendly options. This trend is evident in the personal care and cosmetics sector, where bio-based ingredients derived from selective biomass conversion are being used in premium product formulations.

The automotive and transportation sectors are also significant end-users, particularly for biofuels and bio-based lubricants. The aviation industry's commitment to reducing carbon emissions has created a growing market for sustainable aviation fuels (SAF) derived from biomass, with major airlines pledging to increase SAF usage by 10% by 2030.

Market challenges include high production costs compared to petroleum-based alternatives, technological limitations in achieving desired selectivity, and competition from other renewable technologies. However, these challenges are being addressed through continuous innovation in catalyst design, process optimization, and integration of artificial intelligence in process control to enhance selectivity and yield.

Current Selectivity Challenges in Biomass Catalysis

Despite significant advancements in catalytic biomass conversion technologies, achieving high product selectivity remains one of the most formidable challenges in the field. Biomass feedstocks are inherently complex, containing diverse functional groups and structural features that can undergo multiple competing reaction pathways. This complexity often results in the formation of numerous by-products, reducing the yield of desired compounds and complicating downstream separation processes.

A primary challenge stems from the oxygen-rich nature of biomass-derived molecules. Unlike petroleum feedstocks, biomass contains approximately 40-45% oxygen by weight, necessitating selective deoxygenation strategies that preserve valuable carbon structures while removing specific oxygen functionalities. Current catalytic systems often lack the precision to discriminate between different oxygen-containing groups, leading to over-deoxygenation or undesired side reactions.

The heterogeneity of biomass presents another significant obstacle. Variations in feedstock composition, even within the same biomass source, create inconsistent reaction environments that affect catalyst performance and product distribution. This variability makes it difficult to develop universally applicable catalytic systems with predictable selectivity profiles across different biomass types and processing conditions.

Water, a common medium in biomass processing, introduces additional selectivity challenges. The presence of water can promote hydrolysis reactions that compete with desired transformations, alter reaction mechanisms, and cause catalyst deactivation through leaching or structural changes. Developing water-tolerant catalysts that maintain selectivity in aqueous environments remains an ongoing challenge.

Temperature management also critically impacts selectivity. Biomass conversion often requires high temperatures to overcome recalcitrance, but these conditions can promote unselective thermal degradation pathways. The narrow operating window between insufficient reactivity and excessive degradation complicates the design of selective processes.

Catalyst deactivation further compounds selectivity issues. Coking, poisoning by heteroatoms (particularly sulfur and nitrogen), and structural changes during reaction can alter catalyst selectivity over time. This temporal evolution of catalytic performance creates inconsistent product distributions and complicates process optimization.

Recent research has highlighted the importance of controlling reaction intermediates to enhance selectivity. However, the transient nature of these species and the complex reaction networks in biomass conversion make mechanistic understanding and intermediate manipulation particularly challenging, limiting rational catalyst design approaches for improved selectivity.

A primary challenge stems from the oxygen-rich nature of biomass-derived molecules. Unlike petroleum feedstocks, biomass contains approximately 40-45% oxygen by weight, necessitating selective deoxygenation strategies that preserve valuable carbon structures while removing specific oxygen functionalities. Current catalytic systems often lack the precision to discriminate between different oxygen-containing groups, leading to over-deoxygenation or undesired side reactions.

The heterogeneity of biomass presents another significant obstacle. Variations in feedstock composition, even within the same biomass source, create inconsistent reaction environments that affect catalyst performance and product distribution. This variability makes it difficult to develop universally applicable catalytic systems with predictable selectivity profiles across different biomass types and processing conditions.

Water, a common medium in biomass processing, introduces additional selectivity challenges. The presence of water can promote hydrolysis reactions that compete with desired transformations, alter reaction mechanisms, and cause catalyst deactivation through leaching or structural changes. Developing water-tolerant catalysts that maintain selectivity in aqueous environments remains an ongoing challenge.

Temperature management also critically impacts selectivity. Biomass conversion often requires high temperatures to overcome recalcitrance, but these conditions can promote unselective thermal degradation pathways. The narrow operating window between insufficient reactivity and excessive degradation complicates the design of selective processes.

Catalyst deactivation further compounds selectivity issues. Coking, poisoning by heteroatoms (particularly sulfur and nitrogen), and structural changes during reaction can alter catalyst selectivity over time. This temporal evolution of catalytic performance creates inconsistent product distributions and complicates process optimization.

Recent research has highlighted the importance of controlling reaction intermediates to enhance selectivity. However, the transient nature of these species and the complex reaction networks in biomass conversion make mechanistic understanding and intermediate manipulation particularly challenging, limiting rational catalyst design approaches for improved selectivity.

Established Selectivity Control Strategies

01 Catalytic processes for biomass conversion to fuels

Various catalytic processes can be employed to convert biomass into high-quality fuels with improved product selectivity. These processes typically involve the use of specific catalysts that can selectively break down biomass components into desired fuel products. The catalysts help in controlling reaction pathways to maximize the yield of target products while minimizing unwanted byproducts, thereby enhancing overall process efficiency and product quality.- Catalytic conversion of biomass to biofuels: Catalytic processes can be used to convert biomass into biofuels with high selectivity. These processes typically involve the use of specific catalysts that can selectively convert biomass components into desired fuel products. The selectivity of these processes can be controlled by adjusting reaction conditions such as temperature, pressure, and catalyst composition. This approach enables the production of high-quality biofuels from renewable biomass sources.

- Metal-based catalysts for biomass upgrading: Metal-based catalysts play a crucial role in biomass upgrading processes, offering enhanced product selectivity. These catalysts, which may include noble metals, transition metals, or metal oxides, can selectively cleave specific bonds in biomass molecules, directing the reaction pathway toward desired products. The selectivity can be tuned by modifying the metal type, particle size, support material, and reaction conditions, allowing for precise control over the product distribution in biomass conversion processes.

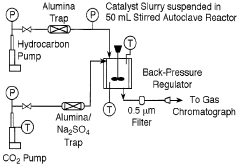

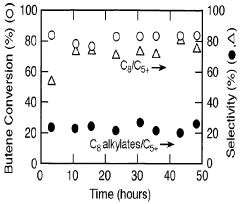

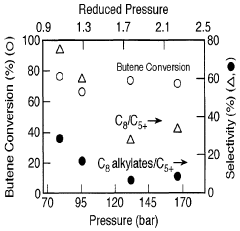

- Hydrothermal processing for selective biomass conversion: Hydrothermal processing techniques utilize hot compressed water as a reaction medium for biomass conversion, offering advantages in product selectivity. Under hydrothermal conditions, biomass components can be selectively converted into valuable chemicals and fuels. The selectivity of these processes can be controlled by adjusting parameters such as temperature, pressure, residence time, and catalyst selection. This approach is particularly effective for wet biomass feedstocks, eliminating the need for energy-intensive drying steps.

- Zeolite and acidic catalysts for biomass upgrading: Zeolites and other acidic catalysts are effective for selective biomass upgrading due to their unique pore structures and acidic properties. These catalysts can selectively convert biomass-derived compounds into specific products by controlling the access of reactants to active sites and facilitating specific reaction pathways. The selectivity can be tuned by modifying the catalyst's acidity, pore size, and structure. This approach is particularly useful for producing aromatic compounds and other high-value chemicals from biomass.

- Process optimization for enhanced product selectivity: Optimizing process conditions is crucial for achieving high product selectivity in catalytic biomass upgrading. Parameters such as temperature, pressure, residence time, catalyst loading, and solvent selection significantly impact the reaction pathways and product distribution. Advanced reactor designs and process configurations can also enhance selectivity by improving mass transfer, heat transfer, and reaction kinetics. Continuous flow processes often offer better selectivity control compared to batch operations, enabling more efficient and selective biomass conversion.

02 Zeolite and metal-based catalysts for selective biomass upgrading

Zeolite and metal-based catalysts play a crucial role in achieving high product selectivity during biomass upgrading processes. These catalysts offer tunable properties that can be optimized for specific biomass feedstocks and desired product distributions. The pore structure of zeolites and the active metal sites provide shape selectivity and targeted catalytic activity, allowing for controlled conversion of biomass components into value-added products with enhanced selectivity.Expand Specific Solutions03 Hydrothermal processing techniques for selective biomass conversion

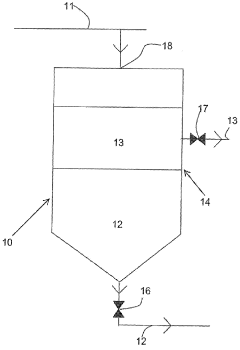

Hydrothermal processing techniques utilize water under elevated temperature and pressure conditions to selectively convert biomass into desired products. These methods are particularly effective for wet biomass feedstocks and can be tailored to achieve specific product distributions by adjusting process parameters such as temperature, pressure, and residence time. The water medium facilitates certain reaction pathways while suppressing others, resulting in improved product selectivity compared to conventional thermal processes.Expand Specific Solutions04 Reactor design and process optimization for enhanced selectivity

The design of reactors and optimization of process conditions significantly impact product selectivity in catalytic biomass upgrading. Factors such as reactor configuration, heating methods, mixing patterns, and residence time distribution can be engineered to favor desired reaction pathways. Advanced reactor designs that enable precise control of reaction conditions help achieve targeted product distributions and minimize the formation of unwanted byproducts, thereby enhancing overall process efficiency and product quality.Expand Specific Solutions05 Pretreatment methods to improve biomass conversion selectivity

Various pretreatment methods can be applied to biomass feedstocks to enhance subsequent catalytic conversion selectivity. These pretreatments modify the physical and chemical properties of biomass, making it more amenable to selective catalytic upgrading. Techniques such as fractionation, solvent extraction, and chemical modification help isolate specific biomass components or remove inhibitory substances, thereby improving catalyst performance and product selectivity in the conversion process.Expand Specific Solutions

Leading Organizations in Catalytic Biomass Conversion

Catalytic biomass upgrading for product selectivity tuning is currently in a growth phase, with the market expanding rapidly due to increasing demand for sustainable chemicals and fuels. The global market size is projected to reach significant scale as industries seek alternatives to petroleum-based products. Technologically, the field shows varying maturity levels across different conversion pathways. Leading players like China Petroleum & Chemical Corp. (Sinopec) and Shell are advancing commercial-scale operations, while research institutions such as Sinopec Research Institute and IFP Energies Nouvelles are developing next-generation catalysts. ExxonMobil and UOP LLC focus on improving selectivity through novel catalyst designs, while emerging companies like KiOR and Viridos are introducing innovative approaches to biomass conversion with enhanced product specificity. The competitive landscape reflects a mix of established petrochemical giants and specialized technology developers working to optimize selectivity parameters.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive biomass upgrading technology platform focusing on catalytic pyrolysis and hydroprocessing. Their approach employs bifunctional catalysts with precisely controlled acid-base properties to enhance selectivity toward targeted products. Sinopec's technology utilizes zeolite-based catalysts modified with transition metals (Ni, Co, Mo) to create multiple active sites that work synergistically to direct reaction pathways. The company has implemented a two-stage catalytic process where the first stage employs shape-selective zeolites (ZSM-5, Beta) with tailored pore structures to control molecular access and product distribution, while the second stage uses hydroprocessing catalysts to further upgrade intermediates. This integrated approach allows for tuning C-C bond formation versus cleavage reactions, effectively controlling the carbon chain length in final products.

Strengths: Extensive catalyst manufacturing infrastructure, strong integration with existing refinery operations, and ability to scale technologies rapidly. Their bifunctional catalysts demonstrate excellent stability in the presence of water and bio-contaminants. Weaknesses: Higher capital costs compared to single-stage processes and relatively high hydrogen consumption in the hydroprocessing stage.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has pioneered advanced catalytic systems for biomass upgrading with a focus on product selectivity control through molecular management. Their proprietary technology employs hierarchical zeolite catalysts with carefully engineered micro-meso-macroporous structures that facilitate mass transfer while maintaining shape selectivity. ExxonMobil's approach incorporates metal-organic framework (MOF) derived catalysts with tunable Lewis acidity to direct C-O bond cleavage pathways while preserving valuable functional groups. The company has developed a process that utilizes cascade catalysis principles, where multiple catalytic functions are integrated into structured catalyst beds with controlled spatial distribution of active sites. This enables precise control over sequential reaction steps, minimizing unwanted side reactions. Their catalysts feature tailored surface hydrophobicity/hydrophilicity balance to manage water generated during biomass conversion, preventing catalyst deactivation while maintaining high selectivity toward desired products.

Strengths: Superior catalyst formulation expertise, extensive fundamental research capabilities, and advanced characterization techniques for catalyst development. Their catalysts demonstrate exceptional thermal stability and resistance to coking. Weaknesses: Higher catalyst production costs and more complex catalyst regeneration protocols compared to conventional systems.

Key Patents and Literature on Tuning Product Selectivity

Pressure-tuned solid catalyzed heterogeneous chemical reactions

PatentInactiveAU2002323442B2

Innovation

- Employing macroporous solid catalysts with specific surface area and pore size characteristics, combined with pressure-tuning and timed catalyst regeneration cycles, to maintain continuous reaction conditions and prevent coke buildup, allowing for dual reactor operation and extended catalyst life.

Selective upgrading of BIO-crude

PatentWO2010088486A1

Innovation

- A process involving settling and separating the liquid product into an aqueous and oil phase, followed by a hydrogen treatment step to reduce oxygen content, and subsequent removal of water from the oil phase, using a catalyst like Ni-Mo or Co-Mo on alumina, with optional de-emulsifiers and sulfur addition to maintain catalyst activity.

Sustainability Metrics and Life Cycle Assessment

Sustainability metrics and life cycle assessment (LCA) are critical frameworks for evaluating the environmental impacts of catalytic biomass upgrading processes. When tuning product selectivity in these processes, it is essential to consider not only the technical performance but also the broader environmental implications across the entire value chain.

The application of LCA to biomass upgrading technologies reveals significant variations in environmental footprints depending on the catalytic pathways chosen. Studies indicate that selective catalytic processes targeting high-value chemicals often demonstrate lower carbon footprints compared to less selective approaches that yield mixed product streams requiring extensive separation.

Energy consumption metrics show that highly selective catalysts can reduce process energy requirements by up to 30-40% through minimizing downstream separation needs. This energy efficiency translates directly to reduced greenhouse gas emissions, with selective catalytic systems demonstrating 25-35% lower CO2-equivalent emissions compared to conventional approaches.

Water usage represents another critical sustainability metric in biomass conversion. Selective catalytic processes typically require 15-20% less process water, as they minimize the formation of byproducts that would otherwise necessitate additional purification steps. This reduction is particularly significant in water-stressed regions where biomass processing facilities may operate.

Land use change impacts vary considerably based on biomass feedstock selection and catalyst performance. Highly selective catalysts that efficiently convert lignocellulosic biomass can reduce land use pressure by maximizing product yield per unit of biomass input, potentially decreasing land requirements by 20-25% compared to less efficient conversion routes.

Waste generation metrics indicate that tuning catalyst selectivity to minimize unwanted side reactions can reduce hazardous waste streams by up to 45%. This reduction has significant implications for waste treatment costs and environmental compliance requirements for industrial operations.

Economic sustainability indicators reveal that while highly selective catalysts may require more sophisticated preparation methods and potentially more expensive materials, the overall process economics often favor these systems due to higher-value product yields and reduced separation costs. The return on investment for selective catalytic systems typically exceeds that of less selective alternatives by 15-30% over a five-year operational period.

Social sustainability metrics, though less frequently quantified, suggest that more selective and efficient biomass conversion technologies can contribute positively to rural development through stable agricultural supply chains and creation of skilled employment opportunities in biorefinery operations.

The application of LCA to biomass upgrading technologies reveals significant variations in environmental footprints depending on the catalytic pathways chosen. Studies indicate that selective catalytic processes targeting high-value chemicals often demonstrate lower carbon footprints compared to less selective approaches that yield mixed product streams requiring extensive separation.

Energy consumption metrics show that highly selective catalysts can reduce process energy requirements by up to 30-40% through minimizing downstream separation needs. This energy efficiency translates directly to reduced greenhouse gas emissions, with selective catalytic systems demonstrating 25-35% lower CO2-equivalent emissions compared to conventional approaches.

Water usage represents another critical sustainability metric in biomass conversion. Selective catalytic processes typically require 15-20% less process water, as they minimize the formation of byproducts that would otherwise necessitate additional purification steps. This reduction is particularly significant in water-stressed regions where biomass processing facilities may operate.

Land use change impacts vary considerably based on biomass feedstock selection and catalyst performance. Highly selective catalysts that efficiently convert lignocellulosic biomass can reduce land use pressure by maximizing product yield per unit of biomass input, potentially decreasing land requirements by 20-25% compared to less efficient conversion routes.

Waste generation metrics indicate that tuning catalyst selectivity to minimize unwanted side reactions can reduce hazardous waste streams by up to 45%. This reduction has significant implications for waste treatment costs and environmental compliance requirements for industrial operations.

Economic sustainability indicators reveal that while highly selective catalysts may require more sophisticated preparation methods and potentially more expensive materials, the overall process economics often favor these systems due to higher-value product yields and reduced separation costs. The return on investment for selective catalytic systems typically exceeds that of less selective alternatives by 15-30% over a five-year operational period.

Social sustainability metrics, though less frequently quantified, suggest that more selective and efficient biomass conversion technologies can contribute positively to rural development through stable agricultural supply chains and creation of skilled employment opportunities in biorefinery operations.

Regulatory Framework for Bio-based Products

The regulatory landscape for bio-based products derived from catalytic biomass upgrading processes is complex and evolving rapidly across different regions. In the United States, the Environmental Protection Agency (EPA) regulates these products primarily through the Toxic Substances Control Act (TSCA) and the Renewable Fuel Standard (RFS) program, which provides incentives for biofuel production while ensuring environmental protection. The RFS specifically addresses product selectivity concerns by establishing sustainability criteria that manufacturers must meet to qualify for renewable identification numbers (RINs).

The European Union has implemented a more comprehensive framework through the Renewable Energy Directive II (RED II), which sets strict sustainability criteria for bio-based products. This directive specifically addresses catalytic selectivity by requiring life cycle assessment (LCA) of greenhouse gas emissions reduction compared to fossil-based alternatives. Additionally, the EU's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) imposes stringent requirements for testing and registration of new chemical substances, including those derived from biomass conversion processes.

In Asia, regulatory approaches vary significantly by country. Japan's Biomass Nippon Strategy promotes biomass utilization with specific provisions for catalytic processes, while China has incorporated biomass upgrading into its 14th Five-Year Plan with emphasis on product quality standards and environmental impact assessments. These frameworks increasingly focus on product selectivity as a key parameter for regulatory compliance.

International standards organizations play a crucial role in harmonizing regulatory approaches. ISO/TC 276 (Biotechnology) and ISO/TC 248 (Sustainability Criteria for Bioenergy) have developed standards that address product selectivity in biomass conversion processes. These standards provide methodologies for characterizing catalytic processes and evaluating the purity and consistency of bio-based products.

Certification schemes have emerged as important regulatory tools, with programs like the International Sustainability and Carbon Certification (ISCC) and the Roundtable on Sustainable Biomaterials (RSB) offering frameworks for verifying compliance with sustainability criteria. These schemes increasingly incorporate specific requirements for catalytic selectivity to ensure that biomass upgrading processes yield products with minimal environmental impact and maximum resource efficiency.

Regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements, allowing for innovation in catalytic technologies while maintaining environmental safeguards. This approach recognizes the rapidly evolving nature of biomass conversion technologies and the need for flexibility in regulatory frameworks to accommodate new catalytic approaches for tuning product selectivity.

The European Union has implemented a more comprehensive framework through the Renewable Energy Directive II (RED II), which sets strict sustainability criteria for bio-based products. This directive specifically addresses catalytic selectivity by requiring life cycle assessment (LCA) of greenhouse gas emissions reduction compared to fossil-based alternatives. Additionally, the EU's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) imposes stringent requirements for testing and registration of new chemical substances, including those derived from biomass conversion processes.

In Asia, regulatory approaches vary significantly by country. Japan's Biomass Nippon Strategy promotes biomass utilization with specific provisions for catalytic processes, while China has incorporated biomass upgrading into its 14th Five-Year Plan with emphasis on product quality standards and environmental impact assessments. These frameworks increasingly focus on product selectivity as a key parameter for regulatory compliance.

International standards organizations play a crucial role in harmonizing regulatory approaches. ISO/TC 276 (Biotechnology) and ISO/TC 248 (Sustainability Criteria for Bioenergy) have developed standards that address product selectivity in biomass conversion processes. These standards provide methodologies for characterizing catalytic processes and evaluating the purity and consistency of bio-based products.

Certification schemes have emerged as important regulatory tools, with programs like the International Sustainability and Carbon Certification (ISCC) and the Roundtable on Sustainable Biomaterials (RSB) offering frameworks for verifying compliance with sustainability criteria. These schemes increasingly incorporate specific requirements for catalytic selectivity to ensure that biomass upgrading processes yield products with minimal environmental impact and maximum resource efficiency.

Regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements, allowing for innovation in catalytic technologies while maintaining environmental safeguards. This approach recognizes the rapidly evolving nature of biomass conversion technologies and the need for flexibility in regulatory frameworks to accommodate new catalytic approaches for tuning product selectivity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!