Comparative lifecycle assessment of biomass upgrading routes

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomass Upgrading Evolution and Objectives

Biomass upgrading technologies have evolved significantly over the past decades, transitioning from simple combustion methods to sophisticated conversion processes that maximize energy efficiency and minimize environmental impacts. The historical trajectory began with direct combustion for heat and power generation, which, while straightforward, offered limited efficiency and produced substantial emissions. The 1970s energy crisis catalyzed research into alternative energy sources, propelling biomass upgrading into scientific focus.

The 1980s and 1990s witnessed the emergence of first-generation biofuels, primarily derived from food crops. These technologies, though innovative, raised concerns about food security and land use competition. This led to the development of second-generation processes in the early 2000s, focusing on lignocellulosic biomass and agricultural residues, thereby addressing sustainability concerns while expanding feedstock options.

Recent technological advancements have introduced third-generation biomass upgrading routes utilizing algae and microbial biomass, offering higher yields and reduced environmental footprints. Concurrently, thermochemical processes like pyrolysis, gasification, and hydrothermal liquefaction have been refined, enabling more efficient conversion of biomass into valuable products such as bio-oil, syngas, and biochar.

The primary objective of contemporary biomass upgrading research is to develop economically viable and environmentally sustainable processes that can compete with fossil fuel-based alternatives. This includes enhancing conversion efficiencies, reducing energy inputs, and minimizing greenhouse gas emissions across the entire lifecycle. Researchers aim to optimize each stage of the biomass value chain, from feedstock selection and cultivation to final product distribution.

Another critical goal is the development of integrated biorefinery concepts that maximize resource utilization through the production of multiple value-added products from a single feedstock. This approach mirrors petroleum refineries but utilizes renewable resources, potentially yielding fuels, chemicals, materials, and energy simultaneously.

Looking forward, the field is trending toward carbon-negative technologies that not only replace fossil fuels but actively remove carbon dioxide from the atmosphere. This includes biomass upgrading routes coupled with carbon capture and storage (BECCS), which could play a pivotal role in climate change mitigation strategies. Additionally, there is growing interest in developing flexible processes capable of handling diverse and variable feedstocks, thereby enhancing resilience and adaptability in biomass supply chains.

The 1980s and 1990s witnessed the emergence of first-generation biofuels, primarily derived from food crops. These technologies, though innovative, raised concerns about food security and land use competition. This led to the development of second-generation processes in the early 2000s, focusing on lignocellulosic biomass and agricultural residues, thereby addressing sustainability concerns while expanding feedstock options.

Recent technological advancements have introduced third-generation biomass upgrading routes utilizing algae and microbial biomass, offering higher yields and reduced environmental footprints. Concurrently, thermochemical processes like pyrolysis, gasification, and hydrothermal liquefaction have been refined, enabling more efficient conversion of biomass into valuable products such as bio-oil, syngas, and biochar.

The primary objective of contemporary biomass upgrading research is to develop economically viable and environmentally sustainable processes that can compete with fossil fuel-based alternatives. This includes enhancing conversion efficiencies, reducing energy inputs, and minimizing greenhouse gas emissions across the entire lifecycle. Researchers aim to optimize each stage of the biomass value chain, from feedstock selection and cultivation to final product distribution.

Another critical goal is the development of integrated biorefinery concepts that maximize resource utilization through the production of multiple value-added products from a single feedstock. This approach mirrors petroleum refineries but utilizes renewable resources, potentially yielding fuels, chemicals, materials, and energy simultaneously.

Looking forward, the field is trending toward carbon-negative technologies that not only replace fossil fuels but actively remove carbon dioxide from the atmosphere. This includes biomass upgrading routes coupled with carbon capture and storage (BECCS), which could play a pivotal role in climate change mitigation strategies. Additionally, there is growing interest in developing flexible processes capable of handling diverse and variable feedstocks, thereby enhancing resilience and adaptability in biomass supply chains.

Market Analysis for Biomass Valorization Technologies

The global biomass valorization market is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable alternatives to fossil fuels. Currently valued at approximately $429.13 billion in 2023, the market is projected to reach $806.8 billion by 2032, growing at a CAGR of 7.3% during the forecast period. This growth trajectory is supported by favorable government policies promoting renewable energy sources and circular economy principles across major economies.

Biomass upgrading technologies are gaining traction across diverse sectors, with bioenergy representing the largest market segment at 45% of total market share. Biochemicals and biomaterials follow with 30% and 25% respectively. The transportation sector remains the primary end-user, accounting for 38% of biomass-derived products, followed by industrial applications (27%), residential heating (20%), and electricity generation (15%).

Regionally, Europe leads the biomass valorization market with approximately 35% market share, driven by stringent environmental regulations and ambitious renewable energy targets. North America follows at 28%, with the Asia-Pacific region showing the fastest growth rate at 9.2% annually, primarily led by China and India's expanding renewable energy portfolios and industrial applications.

Consumer demand patterns indicate increasing preference for sustainable products, with 67% of global consumers willing to pay premium prices for environmentally friendly alternatives. This trend is particularly pronounced in developed economies where environmental awareness is higher. Corporate sustainability commitments are further driving demand, with over 300 multinational corporations pledging to reduce carbon footprints through integration of bio-based materials and fuels.

Market challenges include high initial capital requirements for biomass processing facilities, with average setup costs ranging from $50-200 million depending on technology and scale. Supply chain complexities present another significant barrier, as biomass collection, transportation, and storage require sophisticated logistics networks to ensure consistent feedstock quality and availability.

Emerging market opportunities exist in integrated biorefineries capable of producing multiple value-added products from single feedstock sources. The agricultural waste segment shows particular promise, with an estimated 140 million tons of agricultural residues available annually in the United States alone, representing a largely untapped resource for valorization.

Biomass upgrading technologies are gaining traction across diverse sectors, with bioenergy representing the largest market segment at 45% of total market share. Biochemicals and biomaterials follow with 30% and 25% respectively. The transportation sector remains the primary end-user, accounting for 38% of biomass-derived products, followed by industrial applications (27%), residential heating (20%), and electricity generation (15%).

Regionally, Europe leads the biomass valorization market with approximately 35% market share, driven by stringent environmental regulations and ambitious renewable energy targets. North America follows at 28%, with the Asia-Pacific region showing the fastest growth rate at 9.2% annually, primarily led by China and India's expanding renewable energy portfolios and industrial applications.

Consumer demand patterns indicate increasing preference for sustainable products, with 67% of global consumers willing to pay premium prices for environmentally friendly alternatives. This trend is particularly pronounced in developed economies where environmental awareness is higher. Corporate sustainability commitments are further driving demand, with over 300 multinational corporations pledging to reduce carbon footprints through integration of bio-based materials and fuels.

Market challenges include high initial capital requirements for biomass processing facilities, with average setup costs ranging from $50-200 million depending on technology and scale. Supply chain complexities present another significant barrier, as biomass collection, transportation, and storage require sophisticated logistics networks to ensure consistent feedstock quality and availability.

Emerging market opportunities exist in integrated biorefineries capable of producing multiple value-added products from single feedstock sources. The agricultural waste segment shows particular promise, with an estimated 140 million tons of agricultural residues available annually in the United States alone, representing a largely untapped resource for valorization.

Global Status and Barriers in Biomass Conversion

Biomass conversion technologies have evolved significantly over the past decades, with global implementation varying widely across regions. Currently, first-generation biofuels dominate commercial applications, particularly bioethanol from corn and sugarcane and biodiesel from vegetable oils. Second-generation technologies utilizing lignocellulosic feedstocks have progressed beyond pilot scale in North America and Europe, while third-generation approaches using algal biomass remain predominantly in research phases.

The geographical distribution of biomass conversion facilities reveals significant disparities. The United States, Brazil, and European Union lead in commercial-scale implementation, collectively accounting for approximately 85% of global biofuel production. Emerging economies like China and India are rapidly expanding their biomass conversion capabilities, though primarily focused on first-generation technologies. Sub-Saharan Africa and Southeast Asia possess abundant biomass resources but lack the technological infrastructure for advanced conversion processes.

Despite technological advancements, numerous barriers impede widespread adoption of efficient biomass upgrading routes. Technical challenges include feedstock variability affecting process stability, catalyst deactivation in thermochemical pathways, and high enzyme costs in biochemical conversion routes. The energy intensity of biomass drying and pretreatment processes significantly impacts lifecycle efficiency, often compromising the net environmental benefits of biomass-derived products.

Economic barriers present substantial obstacles, with capital expenditure requirements for advanced conversion facilities ranging from $200-600 million USD. Operating costs remain high compared to fossil-based alternatives, particularly when oil prices are low. The absence of carbon pricing mechanisms in many regions further disadvantages biomass pathways in economic comparisons. Additionally, supply chain logistics for biomass collection, storage, and transportation can represent 20-40% of total production costs.

Regulatory frameworks vary substantially across jurisdictions, creating market uncertainties for potential investors. Inconsistent sustainability criteria and certification schemes complicate international trade of biomass-derived products. Land use policies and competing demands for agricultural resources create tensions between food security and bioenergy production objectives in many regions.

Public perception issues also persist, with concerns about indirect land use change, food vs. fuel debates, and uncertainties regarding the actual carbon benefits of various biomass conversion pathways. These social acceptance challenges often translate into political hesitancy to provide the long-term policy support necessary for industry development.

Addressing these multifaceted barriers requires integrated approaches combining technological innovation, policy harmonization, and stakeholder engagement to realize the potential environmental benefits identified in lifecycle assessments of biomass upgrading routes.

The geographical distribution of biomass conversion facilities reveals significant disparities. The United States, Brazil, and European Union lead in commercial-scale implementation, collectively accounting for approximately 85% of global biofuel production. Emerging economies like China and India are rapidly expanding their biomass conversion capabilities, though primarily focused on first-generation technologies. Sub-Saharan Africa and Southeast Asia possess abundant biomass resources but lack the technological infrastructure for advanced conversion processes.

Despite technological advancements, numerous barriers impede widespread adoption of efficient biomass upgrading routes. Technical challenges include feedstock variability affecting process stability, catalyst deactivation in thermochemical pathways, and high enzyme costs in biochemical conversion routes. The energy intensity of biomass drying and pretreatment processes significantly impacts lifecycle efficiency, often compromising the net environmental benefits of biomass-derived products.

Economic barriers present substantial obstacles, with capital expenditure requirements for advanced conversion facilities ranging from $200-600 million USD. Operating costs remain high compared to fossil-based alternatives, particularly when oil prices are low. The absence of carbon pricing mechanisms in many regions further disadvantages biomass pathways in economic comparisons. Additionally, supply chain logistics for biomass collection, storage, and transportation can represent 20-40% of total production costs.

Regulatory frameworks vary substantially across jurisdictions, creating market uncertainties for potential investors. Inconsistent sustainability criteria and certification schemes complicate international trade of biomass-derived products. Land use policies and competing demands for agricultural resources create tensions between food security and bioenergy production objectives in many regions.

Public perception issues also persist, with concerns about indirect land use change, food vs. fuel debates, and uncertainties regarding the actual carbon benefits of various biomass conversion pathways. These social acceptance challenges often translate into political hesitancy to provide the long-term policy support necessary for industry development.

Addressing these multifaceted barriers requires integrated approaches combining technological innovation, policy harmonization, and stakeholder engagement to realize the potential environmental benefits identified in lifecycle assessments of biomass upgrading routes.

Current Lifecycle Assessment Methodologies for Biomass

01 Lifecycle assessment methodologies for biomass upgrading

Various methodologies are employed to assess the environmental impact of biomass upgrading processes throughout their lifecycle. These assessments evaluate factors such as carbon footprint, energy efficiency, and resource utilization from feedstock production to final product use. Advanced computational models help quantify environmental impacts and identify optimization opportunities in biomass conversion pathways, enabling more sustainable process development.- Lifecycle assessment methodologies for biomass upgrading: Various methodologies and frameworks have been developed for conducting lifecycle assessments of biomass upgrading processes. These methodologies help evaluate the environmental impacts, energy efficiency, and sustainability of different biomass conversion routes. The assessment typically includes analysis of resource consumption, emissions, and overall environmental footprint throughout the entire lifecycle of biomass upgrading processes, from feedstock cultivation to final product use.

- Thermochemical conversion pathways assessment: Thermochemical conversion pathways for biomass upgrading, such as pyrolysis, gasification, and liquefaction, are evaluated through lifecycle assessments to determine their environmental impacts and efficiency. These assessments consider energy inputs, greenhouse gas emissions, and resource utilization across the entire process chain. The analysis helps identify the most sustainable thermochemical routes for converting biomass into valuable fuels and chemicals.

- Biochemical conversion routes sustainability analysis: Lifecycle assessments of biochemical conversion routes for biomass upgrading focus on processes like fermentation, anaerobic digestion, and enzymatic hydrolysis. These assessments evaluate the environmental performance, energy efficiency, and carbon footprint of converting biomass into biofuels and biochemicals through biological processes. The analysis considers factors such as water usage, nutrient recycling, and waste management throughout the entire conversion pathway.

- Computational tools and models for biomass lifecycle assessment: Advanced computational tools and models have been developed to facilitate comprehensive lifecycle assessments of biomass upgrading routes. These tools integrate data analysis, process simulation, and environmental impact modeling to evaluate different biomass conversion pathways. The computational approaches enable more accurate prediction of lifecycle impacts, optimization of process parameters, and comparison of alternative upgrading routes based on sustainability metrics.

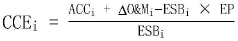

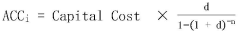

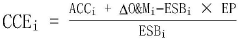

- Integration of economic factors in biomass upgrading lifecycle assessment: Comprehensive lifecycle assessments of biomass upgrading routes increasingly incorporate economic factors alongside environmental considerations. These integrated assessments evaluate the economic viability, cost-effectiveness, and market potential of different biomass conversion pathways. The analysis considers factors such as capital investment, operational costs, product value, and potential revenue streams to provide a holistic view of sustainability that balances environmental and economic dimensions.

02 Thermochemical conversion routes for biomass upgrading

Thermochemical processes convert biomass into valuable products through high-temperature treatments. These include pyrolysis, gasification, and hydrothermal liquefaction, which transform biomass into bio-oils, syngas, and other energy-dense products. The lifecycle assessment of these routes considers energy inputs, greenhouse gas emissions, and the quality of resulting products, helping to determine the most environmentally favorable conversion pathways.Expand Specific Solutions03 Biochemical conversion pathways for biomass valorization

Biochemical conversion utilizes biological agents like enzymes and microorganisms to transform biomass into valuable products. These processes include fermentation, anaerobic digestion, and enzymatic hydrolysis, which can produce biofuels, chemicals, and materials. Lifecycle assessments of these pathways evaluate factors such as water usage, enzyme production impacts, and waste stream management to determine overall environmental performance.Expand Specific Solutions04 Computational frameworks for biomass upgrading assessment

Advanced computational frameworks enable comprehensive analysis of biomass upgrading routes. These systems integrate process modeling, environmental impact assessment, and economic evaluation to provide holistic insights. Machine learning and data analytics enhance these frameworks by identifying patterns and optimization opportunities across different biomass feedstocks and conversion technologies, supporting more informed decision-making in biorefinery development.Expand Specific Solutions05 Integration of sustainability metrics in biomass upgrading

Comprehensive sustainability metrics are increasingly integrated into biomass upgrading assessments. These metrics go beyond traditional environmental indicators to include social and economic factors such as job creation, rural development, and technology accessibility. This holistic approach helps identify biomass upgrading routes that not only minimize environmental impacts but also maximize societal benefits and economic viability across the entire value chain.Expand Specific Solutions

Leading Organizations in Biomass Conversion Industry

The biomass upgrading routes market is in a growth phase, characterized by increasing investments in sustainable energy solutions. The global market size for biomass conversion technologies is expanding rapidly, driven by environmental regulations and renewable energy targets. From a technological maturity perspective, the landscape shows varying degrees of development. Companies like Shell (through subsidiaries Shell Internationale Research, Shell Oil Co., and Shell Canada) have established significant presence with mature conversion technologies, while JGC Corp. and Chevron U.S.A. are leveraging their energy expertise to advance biomass upgrading processes. Specialized players such as Ensyn Renewables and Earth Care Products are developing niche technologies, while research institutions like Alliance for Sustainable Energy and UT-Battelle are driving innovation. State-owned entities including State Grid Corp. of China and Tokyo Electric Power are increasingly investing in biomass technologies to diversify their energy portfolios.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell Internationale Research Maatschappij BV has developed comprehensive biomass upgrading technologies focusing on thermochemical conversion pathways. Their approach includes advanced pyrolysis techniques that convert biomass into bio-oil at temperatures around 500°C in the absence of oxygen, followed by catalytic upgrading to produce drop-in biofuels. Shell has implemented a proprietary hydroprocessing technology that removes oxygen from bio-oils through catalytic reactions with hydrogen, significantly improving fuel quality and stability. Their lifecycle assessment methodology incorporates both direct and indirect land use changes, accounting for biomass cultivation, harvesting, transportation, conversion processes, and end-use applications. Shell's research indicates that their biomass-to-liquids pathway can achieve greenhouse gas reductions of 60-90% compared to conventional fossil fuels when utilizing agricultural residues and sustainable forestry byproducts as feedstock.

Strengths: Extensive global R&D infrastructure and integration capabilities with existing petroleum refining assets allow for efficient scaling. Their hydroprocessing technology achieves higher energy density products than competing methods. Weaknesses: Higher capital investment requirements compared to biochemical routes and relatively high hydrogen consumption in the upgrading process increases overall carbon footprint.

Alliance for Sustainable Energy LLC

Technical Solution: Alliance for Sustainable Energy LLC, which manages the National Renewable Energy Laboratory (NREL), has pioneered comprehensive lifecycle assessment frameworks for biomass upgrading pathways. Their approach integrates both biochemical and thermochemical conversion routes, with particular emphasis on lignocellulosic feedstock utilization. The Alliance has developed sophisticated models that track carbon flows throughout the entire biomass value chain, from cultivation to end-use. Their research has demonstrated that biochemical pathways utilizing enzymatic hydrolysis followed by fermentation can achieve carbon intensity reductions of 70-85% for cellulosic ethanol compared to gasoline. For thermochemical routes, they've optimized gasification processes that convert biomass to syngas (CO and H2), which can then be catalytically upgraded to various fuels and chemicals. Their lifecycle assessments incorporate detailed analysis of water consumption, land use impacts, and air emissions across different biomass upgrading technologies, providing a holistic sustainability evaluation framework that has become an industry standard.

Strengths: Unparalleled technical expertise in multiple conversion pathways and access to advanced analytical facilities enables comprehensive comparative assessments. Their models account for regional variations in biomass availability and processing conditions. Weaknesses: Their assessment frameworks sometimes require extensive data inputs that may not be readily available for emerging technologies or developing regions.

Critical Technologies in Biomass Upgrading Pathways

Two step amine absorption process for removal co2/h2s from biogas

PatentPendingUS20240017205A1

Innovation

- A biogas upgrading method involving two absorption steps with differing pressures, where the biogas stream is first absorbed at a lower pressure to remove a significant portion of carbon dioxide and hydrogen sulphide, followed by a second absorption step at higher pressure to further purify the gas, with the regenerated liquid streams being reused to reduce energy consumption and increase absorption efficiency.

Cement green low-carbon optimization evaluation model based on co-processing

PatentInactiveCN118071204A

Innovation

- Provides a cement green low-carbon optimization evaluation model based on co-processing, including a path setting module, an evaluation module and an input module. It combines energy efficiency improvement, fuel substitution, raw material substitution, mixed material proportion improvement, CCUS technology application and policy influence paths. Scenario analysis, screening energy-saving technologies, assessing environmental impacts, optimizing resource utilization and reducing emissions.

Environmental Impact Metrics Across Conversion Routes

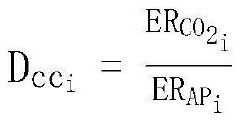

The assessment of environmental impacts across different biomass conversion pathways requires standardized metrics to enable meaningful comparisons. Life Cycle Assessment (LCA) serves as the primary framework for quantifying these impacts, with greenhouse gas (GHG) emissions typically measured in CO2-equivalent units being the most commonly reported metric. However, comprehensive environmental evaluation demands consideration of multiple impact categories beyond carbon footprint.

Water consumption metrics vary significantly between thermochemical and biochemical conversion routes. Thermochemical processes like gasification and pyrolysis generally require 2-5 gallons of water per gallon of biofuel produced, while biochemical pathways such as fermentation may consume 6-10 gallons, primarily for feedstock cultivation and processing. Advanced water recycling technologies have demonstrated potential to reduce consumption by 30-40% in pilot-scale operations.

Land use change impacts represent another critical metric, with indirect land use change (ILUC) factors ranging from 10-40 gCO2e/MJ for first-generation biofuels. Second-generation pathways utilizing agricultural residues or forestry waste typically exhibit significantly lower ILUC factors of 0-15 gCO2e/MJ, highlighting the environmental advantage of waste-to-energy conversion routes.

Acidification potential, measured in SO2-equivalent units, varies considerably across conversion technologies. Thermochemical routes typically generate 0.5-2.0 g SO2-eq per MJ of fuel produced, while biochemical pathways often result in 0.3-1.5 g SO2-eq/MJ, with variations largely dependent on catalyst selection and process optimization.

Eutrophication impacts, quantified in phosphate-equivalent units, are particularly relevant for biomass cultivation phases. Conversion routes utilizing dedicated energy crops may contribute 0.1-0.3 g PO4-eq/MJ, while waste-based pathways typically reduce these impacts by 40-60%.

Particulate matter formation, measured in PM2.5-equivalent units, represents a localized environmental concern. Fast pyrolysis routes typically emit 0.05-0.15 g PM2.5-eq/MJ, while gasification pathways may generate 0.08-0.20 g PM2.5-eq/MJ, with significant variations based on feedstock properties and emission control technologies.

Energy return on investment (EROI) serves as a critical efficiency metric, with biochemical pathways typically achieving ratios of 1.5-3.0, while advanced thermochemical routes demonstrate higher potential with EROI values of 2.0-5.0 under optimized conditions. This metric highlights the superior energy efficiency of certain thermochemical conversion technologies when properly implemented.

Water consumption metrics vary significantly between thermochemical and biochemical conversion routes. Thermochemical processes like gasification and pyrolysis generally require 2-5 gallons of water per gallon of biofuel produced, while biochemical pathways such as fermentation may consume 6-10 gallons, primarily for feedstock cultivation and processing. Advanced water recycling technologies have demonstrated potential to reduce consumption by 30-40% in pilot-scale operations.

Land use change impacts represent another critical metric, with indirect land use change (ILUC) factors ranging from 10-40 gCO2e/MJ for first-generation biofuels. Second-generation pathways utilizing agricultural residues or forestry waste typically exhibit significantly lower ILUC factors of 0-15 gCO2e/MJ, highlighting the environmental advantage of waste-to-energy conversion routes.

Acidification potential, measured in SO2-equivalent units, varies considerably across conversion technologies. Thermochemical routes typically generate 0.5-2.0 g SO2-eq per MJ of fuel produced, while biochemical pathways often result in 0.3-1.5 g SO2-eq/MJ, with variations largely dependent on catalyst selection and process optimization.

Eutrophication impacts, quantified in phosphate-equivalent units, are particularly relevant for biomass cultivation phases. Conversion routes utilizing dedicated energy crops may contribute 0.1-0.3 g PO4-eq/MJ, while waste-based pathways typically reduce these impacts by 40-60%.

Particulate matter formation, measured in PM2.5-equivalent units, represents a localized environmental concern. Fast pyrolysis routes typically emit 0.05-0.15 g PM2.5-eq/MJ, while gasification pathways may generate 0.08-0.20 g PM2.5-eq/MJ, with significant variations based on feedstock properties and emission control technologies.

Energy return on investment (EROI) serves as a critical efficiency metric, with biochemical pathways typically achieving ratios of 1.5-3.0, while advanced thermochemical routes demonstrate higher potential with EROI values of 2.0-5.0 under optimized conditions. This metric highlights the superior energy efficiency of certain thermochemical conversion technologies when properly implemented.

Policy Frameworks Influencing Biomass Utilization

Policy frameworks across the globe significantly shape the development and implementation of biomass upgrading technologies. The European Union leads with its Renewable Energy Directive (RED II), which mandates 32% renewable energy by 2030 and includes specific provisions for advanced biofuels. This directive creates a structured market for biomass-derived products and incentivizes lifecycle assessment considerations in production pathways.

In the United States, the Renewable Fuel Standard (RFS) program establishes volume requirements for different categories of biofuels, with greenhouse gas reduction thresholds that directly influence upgrading route selection. The 2018 Farm Bill further strengthened support for biomass utilization through programs like the Biomass Crop Assistance Program (BCAP) and Bioenergy Program for Advanced Biofuels.

China's 13th Five-Year Plan emphasizes biomass energy development, targeting 30 million tons of biofuel production by 2030. Their policies increasingly focus on agricultural waste utilization, addressing both energy security and environmental pollution concerns through biomass upgrading pathways.

Carbon pricing mechanisms represent another critical policy instrument affecting biomass upgrading economics. The EU Emissions Trading System (ETS) and similar schemes in Canada and California create financial incentives for lower-carbon pathways by internalizing environmental externalities. These mechanisms effectively improve the competitive position of biomass upgrading routes with favorable lifecycle assessments.

Sustainability certification schemes, though often voluntary, increasingly influence market access. Systems like the International Sustainability and Carbon Certification (ISCC) and Roundtable on Sustainable Biomaterials (RSB) evaluate lifecycle impacts across environmental, social, and economic dimensions, creating market differentiation for biomass products with superior sustainability profiles.

Regional development policies also shape biomass utilization landscapes. Rural development initiatives in Brazil's ProRenova program support sugarcane cultivation for bioenergy, while India's National Biofuel Policy promotes integrated biorefineries in agricultural regions, creating localized biomass value chains with distinct lifecycle implications.

The policy landscape remains dynamic, with increasing integration of circular economy principles. The EU Circular Economy Action Plan exemplifies this trend, promoting cascading use of biomass resources and incentivizing upgrading routes that maximize resource efficiency across multiple lifecycle stages. This evolution suggests future policy frameworks will increasingly evaluate biomass upgrading routes through comprehensive lifecycle assessment methodologies that capture broader sustainability dimensions beyond carbon accounting.

In the United States, the Renewable Fuel Standard (RFS) program establishes volume requirements for different categories of biofuels, with greenhouse gas reduction thresholds that directly influence upgrading route selection. The 2018 Farm Bill further strengthened support for biomass utilization through programs like the Biomass Crop Assistance Program (BCAP) and Bioenergy Program for Advanced Biofuels.

China's 13th Five-Year Plan emphasizes biomass energy development, targeting 30 million tons of biofuel production by 2030. Their policies increasingly focus on agricultural waste utilization, addressing both energy security and environmental pollution concerns through biomass upgrading pathways.

Carbon pricing mechanisms represent another critical policy instrument affecting biomass upgrading economics. The EU Emissions Trading System (ETS) and similar schemes in Canada and California create financial incentives for lower-carbon pathways by internalizing environmental externalities. These mechanisms effectively improve the competitive position of biomass upgrading routes with favorable lifecycle assessments.

Sustainability certification schemes, though often voluntary, increasingly influence market access. Systems like the International Sustainability and Carbon Certification (ISCC) and Roundtable on Sustainable Biomaterials (RSB) evaluate lifecycle impacts across environmental, social, and economic dimensions, creating market differentiation for biomass products with superior sustainability profiles.

Regional development policies also shape biomass utilization landscapes. Rural development initiatives in Brazil's ProRenova program support sugarcane cultivation for bioenergy, while India's National Biofuel Policy promotes integrated biorefineries in agricultural regions, creating localized biomass value chains with distinct lifecycle implications.

The policy landscape remains dynamic, with increasing integration of circular economy principles. The EU Circular Economy Action Plan exemplifies this trend, promoting cascading use of biomass resources and incentivizing upgrading routes that maximize resource efficiency across multiple lifecycle stages. This evolution suggests future policy frameworks will increasingly evaluate biomass upgrading routes through comprehensive lifecycle assessment methodologies that capture broader sustainability dimensions beyond carbon accounting.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!