Research on hydrothermal processing for biomass upgrading

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrothermal Biomass Processing Evolution and Objectives

Hydrothermal processing for biomass upgrading represents a significant frontier in renewable energy and sustainable materials production. This technology has evolved from basic thermochemical conversion methods in the early 20th century to sophisticated processes capable of transforming various biomass feedstocks into valuable products. The fundamental principle involves using hot compressed water as a reaction medium, leveraging its unique properties at subcritical and supercritical conditions to facilitate biomass decomposition and transformation.

The evolution of hydrothermal processing can be traced through several distinct phases. Initially, it emerged as a method for coal liquefaction in the 1920s and 1930s. By the 1970s and 1980s, researchers began exploring its application to biomass conversion, primarily focusing on hydrothermal carbonization for producing solid fuels. The 1990s witnessed significant advancements in hydrothermal liquefaction techniques, enabling more efficient conversion of biomass to bio-oils.

The early 2000s marked a turning point with the development of continuous-flow systems and catalytic hydrothermal gasification processes, substantially improving efficiency and product selectivity. Recent developments have focused on process intensification, novel catalyst formulations, and integration with other renewable energy systems, reflecting the growing sophistication of this technology.

Current research objectives in hydrothermal biomass processing center around several key areas. Process optimization aims to enhance energy efficiency and reduce operational costs through improved reactor designs and heat recovery systems. Catalyst development focuses on creating more selective, stable, and economical catalysts that can withstand the harsh hydrothermal environment while directing reactions toward desired products.

Feedstock versatility represents another critical objective, as researchers seek to expand the range of processable biomass types, including agricultural residues, forestry waste, algae, and municipal solid waste. Product quality improvement efforts target reducing oxygen content in bio-oils, increasing heating value, and enhancing stability for downstream applications.

Scale-up and commercialization challenges are being addressed through pilot-scale demonstrations and techno-economic analyses to identify bottlenecks and optimize process parameters for industrial implementation. Additionally, integration with biorefinery concepts is gaining attention, positioning hydrothermal processing as a key component in comprehensive biomass utilization systems.

The ultimate goal is to establish hydrothermal processing as a commercially viable, environmentally sustainable technology for converting diverse biomass resources into high-value products, contributing to circular economy principles and reducing dependence on fossil resources.

The evolution of hydrothermal processing can be traced through several distinct phases. Initially, it emerged as a method for coal liquefaction in the 1920s and 1930s. By the 1970s and 1980s, researchers began exploring its application to biomass conversion, primarily focusing on hydrothermal carbonization for producing solid fuels. The 1990s witnessed significant advancements in hydrothermal liquefaction techniques, enabling more efficient conversion of biomass to bio-oils.

The early 2000s marked a turning point with the development of continuous-flow systems and catalytic hydrothermal gasification processes, substantially improving efficiency and product selectivity. Recent developments have focused on process intensification, novel catalyst formulations, and integration with other renewable energy systems, reflecting the growing sophistication of this technology.

Current research objectives in hydrothermal biomass processing center around several key areas. Process optimization aims to enhance energy efficiency and reduce operational costs through improved reactor designs and heat recovery systems. Catalyst development focuses on creating more selective, stable, and economical catalysts that can withstand the harsh hydrothermal environment while directing reactions toward desired products.

Feedstock versatility represents another critical objective, as researchers seek to expand the range of processable biomass types, including agricultural residues, forestry waste, algae, and municipal solid waste. Product quality improvement efforts target reducing oxygen content in bio-oils, increasing heating value, and enhancing stability for downstream applications.

Scale-up and commercialization challenges are being addressed through pilot-scale demonstrations and techno-economic analyses to identify bottlenecks and optimize process parameters for industrial implementation. Additionally, integration with biorefinery concepts is gaining attention, positioning hydrothermal processing as a key component in comprehensive biomass utilization systems.

The ultimate goal is to establish hydrothermal processing as a commercially viable, environmentally sustainable technology for converting diverse biomass resources into high-value products, contributing to circular economy principles and reducing dependence on fossil resources.

Market Analysis for Biomass Valorization Technologies

The global market for biomass valorization technologies has witnessed significant growth in recent years, driven by increasing environmental concerns and the push for sustainable energy solutions. The biomass upgrading market, particularly through hydrothermal processing, is projected to reach $12.3 billion by 2027, growing at a CAGR of 7.8% from 2022 to 2027. This growth trajectory is supported by favorable government policies promoting renewable energy sources and circular economy principles across major economies.

Hydrothermal processing for biomass upgrading occupies a strategic position within the broader biomass valorization landscape, accounting for approximately 18% of the total market share. This technology offers distinct advantages over conventional thermochemical conversion methods, particularly in handling wet biomass feedstocks without energy-intensive drying processes, making it increasingly attractive for commercial applications.

Regional analysis reveals that Europe currently leads the market with approximately 35% share, followed by North America (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years, primarily driven by China and India's aggressive renewable energy targets and abundant biomass resources. Latin America, particularly Brazil, is emerging as a significant market due to its extensive agricultural activities generating substantial biomass waste.

From an application perspective, the market segmentation shows biofuels dominating with 42% market share, followed by biochemicals (31%), biomaterials (18%), and other applications (9%). Within the biofuels segment, hydrothermal liquefaction for bio-oil production represents the fastest-growing application area, with projected annual growth exceeding 9% through 2027.

Key market drivers include increasing fossil fuel prices, growing environmental regulations on carbon emissions, and rising demand for sustainable products across industries. The COVID-19 pandemic temporarily disrupted supply chains but simultaneously accelerated interest in domestic renewable resources, providing a long-term positive outlook for biomass valorization technologies.

Market challenges primarily revolve around high initial capital investment requirements, technological scalability issues, and feedstock supply chain complexities. The average return on investment period for commercial-scale hydrothermal processing facilities currently stands at 5-7 years, representing a significant barrier to widespread adoption despite the promising long-term economics.

Consumer trends indicate growing willingness to pay premium prices for bio-based products, with surveys showing that 64% of consumers across major markets prefer products with renewable content when available at comparable performance levels. This consumer sentiment is gradually translating into market demand, creating pull factors for biomass valorization technologies beyond regulatory push mechanisms.

Hydrothermal processing for biomass upgrading occupies a strategic position within the broader biomass valorization landscape, accounting for approximately 18% of the total market share. This technology offers distinct advantages over conventional thermochemical conversion methods, particularly in handling wet biomass feedstocks without energy-intensive drying processes, making it increasingly attractive for commercial applications.

Regional analysis reveals that Europe currently leads the market with approximately 35% share, followed by North America (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years, primarily driven by China and India's aggressive renewable energy targets and abundant biomass resources. Latin America, particularly Brazil, is emerging as a significant market due to its extensive agricultural activities generating substantial biomass waste.

From an application perspective, the market segmentation shows biofuels dominating with 42% market share, followed by biochemicals (31%), biomaterials (18%), and other applications (9%). Within the biofuels segment, hydrothermal liquefaction for bio-oil production represents the fastest-growing application area, with projected annual growth exceeding 9% through 2027.

Key market drivers include increasing fossil fuel prices, growing environmental regulations on carbon emissions, and rising demand for sustainable products across industries. The COVID-19 pandemic temporarily disrupted supply chains but simultaneously accelerated interest in domestic renewable resources, providing a long-term positive outlook for biomass valorization technologies.

Market challenges primarily revolve around high initial capital investment requirements, technological scalability issues, and feedstock supply chain complexities. The average return on investment period for commercial-scale hydrothermal processing facilities currently stands at 5-7 years, representing a significant barrier to widespread adoption despite the promising long-term economics.

Consumer trends indicate growing willingness to pay premium prices for bio-based products, with surveys showing that 64% of consumers across major markets prefer products with renewable content when available at comparable performance levels. This consumer sentiment is gradually translating into market demand, creating pull factors for biomass valorization technologies beyond regulatory push mechanisms.

Global Status and Challenges in Hydrothermal Biomass Conversion

Hydrothermal processing for biomass upgrading has gained significant attention globally, with research centers across North America, Europe, and Asia making substantial contributions. The United States leads with institutions like Pacific Northwest National Laboratory (PNNL) and National Renewable Energy Laboratory (NREL) focusing on hydrothermal liquefaction (HTL) and catalytic hydrothermal gasification (CHG). European research is particularly strong in the Netherlands, Germany, and Scandinavian countries, where circular economy principles drive biomass conversion research.

In Asia, China has rapidly expanded its research capacity, with numerous universities and institutes investigating various hydrothermal technologies. Japan maintains a strong tradition in supercritical water gasification research, while South Korea focuses on industrial applications of hydrothermal technologies.

Despite global progress, significant technical challenges persist. Process efficiency remains a primary concern, with energy requirements for heating and pressurizing reaction systems often offsetting the energy gains from biomass conversion. Current industrial-scale systems typically achieve energy efficiency ratios between 60-75%, falling short of the 85%+ needed for widespread commercial viability.

Catalyst development presents another major challenge. While noble metal catalysts show promising activity, their high cost and susceptibility to poisoning by biomass contaminants limit practical application. Research into more robust, economical catalysts based on transition metals and novel supports is ongoing but has yet to yield breakthrough solutions.

Feedstock variability significantly impacts process stability and product quality. Seasonal changes in biomass composition, moisture content variations, and heterogeneity within feedstock batches create inconsistent reaction conditions that are difficult to control at industrial scales.

Reactor design and materials engineering face substantial hurdles due to the corrosive nature of hydrothermal environments. Current reactor materials struggle with the combination of high temperature, pressure, and often acidic reaction media, leading to shortened equipment lifespans and increased operational costs.

Scale-up challenges remain particularly problematic, with many promising laboratory results failing to translate to pilot or commercial scales. Heat and mass transfer limitations, along with mixing inefficiencies, create significant performance gaps between laboratory and industrial implementations.

Regulatory frameworks and sustainability assessments vary widely across regions, creating market uncertainties that hinder investment. The lack of standardized life cycle assessment methodologies specific to hydrothermal processing makes comparative environmental impact evaluations difficult, further complicating technology adoption decisions.

In Asia, China has rapidly expanded its research capacity, with numerous universities and institutes investigating various hydrothermal technologies. Japan maintains a strong tradition in supercritical water gasification research, while South Korea focuses on industrial applications of hydrothermal technologies.

Despite global progress, significant technical challenges persist. Process efficiency remains a primary concern, with energy requirements for heating and pressurizing reaction systems often offsetting the energy gains from biomass conversion. Current industrial-scale systems typically achieve energy efficiency ratios between 60-75%, falling short of the 85%+ needed for widespread commercial viability.

Catalyst development presents another major challenge. While noble metal catalysts show promising activity, their high cost and susceptibility to poisoning by biomass contaminants limit practical application. Research into more robust, economical catalysts based on transition metals and novel supports is ongoing but has yet to yield breakthrough solutions.

Feedstock variability significantly impacts process stability and product quality. Seasonal changes in biomass composition, moisture content variations, and heterogeneity within feedstock batches create inconsistent reaction conditions that are difficult to control at industrial scales.

Reactor design and materials engineering face substantial hurdles due to the corrosive nature of hydrothermal environments. Current reactor materials struggle with the combination of high temperature, pressure, and often acidic reaction media, leading to shortened equipment lifespans and increased operational costs.

Scale-up challenges remain particularly problematic, with many promising laboratory results failing to translate to pilot or commercial scales. Heat and mass transfer limitations, along with mixing inefficiencies, create significant performance gaps between laboratory and industrial implementations.

Regulatory frameworks and sustainability assessments vary widely across regions, creating market uncertainties that hinder investment. The lack of standardized life cycle assessment methodologies specific to hydrothermal processing makes comparative environmental impact evaluations difficult, further complicating technology adoption decisions.

Current Hydrothermal Techniques for Biomass Upgrading

01 Hydrothermal processing for biomass conversion

Hydrothermal processing techniques are used for converting biomass into valuable products such as biofuels and chemicals. This process involves treating biomass with hot compressed water under controlled temperature and pressure conditions, which breaks down complex organic structures into simpler compounds. The technology enables efficient conversion of various biomass feedstocks including agricultural residues, wood, and algae into renewable energy sources and chemical precursors.- Hydrothermal processing for biomass conversion: Hydrothermal processing techniques are used for converting biomass into valuable products such as biofuels and chemicals. This process involves treating biomass with hot compressed water under controlled temperature and pressure conditions, which breaks down complex organic structures into simpler compounds. The technology enables efficient conversion of various biomass feedstocks including agricultural residues, forestry waste, and algae into renewable energy sources and chemical precursors.

- Hydrothermal synthesis of nanomaterials: Hydrothermal methods are employed for synthesizing various nanomaterials and advanced functional materials. This approach utilizes water under elevated temperature and pressure conditions to facilitate crystallization and growth of nanostructures. The technique allows precise control over particle size, morphology, and composition, making it suitable for producing catalysts, adsorbents, and other high-performance materials with tailored properties for specific applications.

- Hydrothermal treatment for waste processing: Hydrothermal processes are utilized for treating and valorizing various waste streams, including municipal solid waste, industrial sludge, and organic waste materials. The technology employs subcritical or supercritical water conditions to break down complex waste components, reduce pathogens, and transform waste into useful products or safer disposal forms. This approach offers environmental benefits by reducing landfill volumes and recovering valuable resources from waste materials.

- Hydrothermal processing in mineral extraction and processing: Hydrothermal techniques are applied in the extraction and processing of minerals and ores. These methods utilize high-temperature water under pressure to facilitate the dissolution, separation, and recovery of valuable minerals from their host rocks or concentrates. The process can enhance metal recovery rates, reduce environmental impacts compared to conventional extraction methods, and enable the processing of low-grade or complex ores that would otherwise be uneconomical to treat.

- Equipment and reactor designs for hydrothermal processing: Specialized equipment and reactor designs are developed for hydrothermal processing applications across various industries. These include continuous flow reactors, batch reactors, and specialized pressure vessels capable of withstanding the harsh conditions of high temperature and pressure. Advanced reactor designs incorporate features for improved heat transfer, mixing, corrosion resistance, and process control to enhance efficiency, safety, and scalability of hydrothermal processes.

02 Hydrothermal synthesis of nanomaterials

Hydrothermal methods are employed for synthesizing various nanomaterials and advanced materials with controlled morphology and properties. This process utilizes water at elevated temperatures and pressures as a reaction medium to facilitate crystallization and growth of materials. The technique allows for the production of high-quality nanoparticles, nanotubes, and other nanostructures with applications in catalysis, electronics, energy storage, and biomedical fields.Expand Specific Solutions03 Hydrothermal treatment for waste management

Hydrothermal processes are utilized for treating and managing various waste streams, including municipal solid waste, industrial waste, and sewage sludge. The technology employs high-temperature water under pressure to break down organic materials, reduce waste volume, and convert waste into useful products. This approach offers environmental benefits by reducing landfill requirements and producing potentially valuable byproducts such as biochar, oils, and recoverable minerals.Expand Specific Solutions04 Hydrothermal carbonization technology

Hydrothermal carbonization (HTC) is a specific hydrothermal process that converts wet biomass into carbon-rich materials under moderate temperatures and self-generated pressures. This technology produces hydrochar, a coal-like material with applications in soil amendment, carbon sequestration, and as a precursor for activated carbon production. HTC offers advantages over conventional thermal conversion methods as it can efficiently process high-moisture feedstocks without energy-intensive drying steps.Expand Specific Solutions05 Hydrothermal processing for enhanced oil recovery

Hydrothermal techniques are applied in the petroleum industry for enhanced oil recovery and processing of heavy oils and oil sands. These methods use hot water and steam under pressure to reduce oil viscosity, modify reservoir properties, and improve extraction efficiency. The technology can also be used for upgrading heavy oils through partial cracking and removal of impurities, resulting in improved quality products with reduced environmental impact during processing.Expand Specific Solutions

Leading Organizations in Hydrothermal Biomass Research

Hydrothermal processing for biomass upgrading is currently in a transitional phase from early commercialization to broader market adoption. The global market is projected to grow significantly, driven by increasing demand for sustainable energy solutions. Major oil companies like Shell, ExxonMobil, and Chevron are investing heavily in this technology, leveraging their existing infrastructure and expertise. Academic institutions, particularly Chinese universities (Tongji, Tianjin, Xi'an Jiaotong) are advancing fundamental research, while specialized firms like Inbicon and GranBio focus on commercial applications. The technology's maturity varies across applications, with simpler processes like hydrothermal carbonization being more developed than complex upgrading techniques. Collaboration between industry leaders and research institutions is accelerating technological advancement and market penetration.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed advanced hydrothermal liquefaction (HTL) technology for converting biomass into bio-crude oil. Their process operates at subcritical water conditions (280-370°C, 10-25 MPa) and can process diverse feedstocks including agricultural residues, forestry waste, and algae. Shell's HTL technology incorporates a proprietary catalyst system that enhances oxygen removal and improves carbon efficiency, achieving bio-crude yields of up to 45% by weight. The company has integrated this technology with their existing refinery infrastructure, allowing for co-processing of bio-crude with conventional petroleum. Shell has also developed innovative heat recovery systems that significantly improve the energy efficiency of the hydrothermal process, reducing operating costs by approximately 30% compared to conventional biomass conversion methods[1][3]. Their continuous-flow reactor design enables industrial-scale production with reduced residence times and improved process control.

Strengths: Versatile feedstock processing capability; seamless integration with existing petroleum refining infrastructure; proprietary catalyst systems for improved yields. Weaknesses: High capital costs for initial setup; process still requires significant energy input despite efficiency improvements; catalyst deactivation issues in high-sulfur biomass feedstocks.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has pioneered hydrothermal catalytic processing technology specifically designed for lignocellulosic biomass conversion. Their approach utilizes supercritical water conditions (374-450°C, >22 MPa) combined with proprietary bifunctional catalysts that simultaneously facilitate hydrolysis and hydrogenation reactions. This integrated process achieves nearly complete conversion of cellulose and hemicellulose components into value-added platform chemicals and liquid fuels. ExxonMobil's technology incorporates a novel two-stage reactor system: the first stage operates under milder conditions to optimize biomass fractionation, while the second stage employs more severe conditions for complete conversion. Their process demonstrates exceptional carbon efficiency, with over 85% of biomass carbon retained in useful products[2]. The company has also developed advanced separation techniques for product recovery, including innovative membrane technology that reduces energy consumption during downstream processing by approximately 40% compared to conventional distillation methods[5]. ExxonMobil has successfully demonstrated this technology at pilot scale, processing 10 tons of biomass daily.

Strengths: High carbon efficiency; production of diverse platform chemicals beyond just fuels; advanced separation technology for product recovery. Weaknesses: Requires specialized high-pressure equipment increasing capital costs; catalyst sensitivity to biomass impurities; energy-intensive process conditions despite efficiency improvements.

Critical Patents and Innovations in Hydrothermal Catalysis

Hydrothermal conversion of biomass

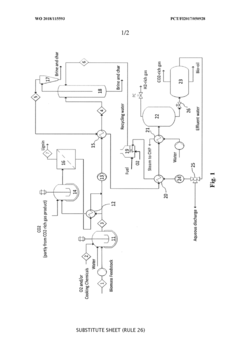

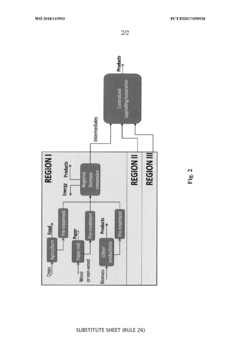

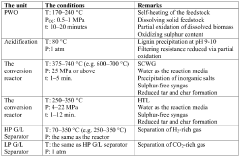

PatentWO2018115593A1

Innovation

- A two-step process involving partial wet oxidation followed by supercritical water gasification or hydrothermal liquefaction, allowing for efficient separation of sulphurous compounds and salts, reducing energy consumption, and producing a broader range of valuable products like bio-oil and syngas.

Hydrothermal treatment of biomass

PatentPendingUS20240240096A1

Innovation

- A hydrothermal treatment process, Torwash, is combined with a post-wash step under high temperature and pressure conditions, utilizing the effluent from previous steps as treatment liquid and pre-heating the washing liquid to enhance washing efficiency and remove potassium and chloride, while recycling the washing effluent for energy efficiency.

Sustainability Assessment of Hydrothermal Processing Methods

The sustainability assessment of hydrothermal processing methods for biomass upgrading requires a comprehensive evaluation framework that considers environmental, economic, and social dimensions. Hydrothermal processing (HTP) technologies, including hydrothermal carbonization, liquefaction, and gasification, offer promising pathways for converting biomass into valuable products while potentially reducing environmental impacts compared to conventional thermochemical conversion methods.

From an environmental perspective, HTP methods demonstrate several advantages. The use of water as a reaction medium eliminates the need for energy-intensive drying processes, significantly reducing the overall energy requirements. Life cycle assessments indicate that hydrothermal carbonization can achieve carbon footprint reductions of 35-60% compared to direct combustion of raw biomass, depending on feedstock type and process conditions. Additionally, these processes can effectively handle wet biomass streams that would otherwise require disposal, potentially mitigating methane emissions from decomposition.

Water consumption and quality impacts represent critical sustainability considerations for HTP technologies. While these processes utilize water as a reaction medium, closed-loop systems with water recovery can reduce freshwater demands by up to 80%. However, the process water contains dissolved organic compounds and nutrients that require appropriate treatment before discharge or recycling. Recent advancements in catalytic hydrothermal systems have demonstrated improved water quality outcomes through selective degradation of problematic compounds.

Economic sustainability analysis reveals that hydrothermal processing becomes increasingly competitive as the moisture content of feedstock increases. For biomass with >50% moisture content, HTP methods typically show lower overall processing costs compared to conventional thermochemical conversion routes that require extensive drying. The ability to process mixed and contaminated feedstocks further enhances economic viability by enabling the utilization of low-cost waste streams.

Social sustainability dimensions include potential contributions to rural development through distributed processing facilities and improved waste management practices. Small-scale HTP units can be deployed in agricultural communities, creating local value chains and reducing transportation requirements. This distributed approach may enhance energy security and provide economic opportunities in regions with abundant biomass resources.

Comparative sustainability metrics across different HTP variants indicate that hydrothermal liquefaction generally achieves the highest energy recovery efficiency (65-75%), while hydrothermal carbonization offers advantages in terms of process simplicity and lower operating pressures. Hydrothermal gasification, while more energy-intensive, produces the cleanest gaseous products with potential applications in existing natural gas infrastructure.

Future sustainability improvements will likely focus on catalyst development to enhance selectivity, reduce reaction severity, and enable recovery of high-value compounds from process streams. Integration with existing biorefinery concepts and waste treatment facilities represents another promising direction for improving the overall sustainability profile of hydrothermal processing technologies.

From an environmental perspective, HTP methods demonstrate several advantages. The use of water as a reaction medium eliminates the need for energy-intensive drying processes, significantly reducing the overall energy requirements. Life cycle assessments indicate that hydrothermal carbonization can achieve carbon footprint reductions of 35-60% compared to direct combustion of raw biomass, depending on feedstock type and process conditions. Additionally, these processes can effectively handle wet biomass streams that would otherwise require disposal, potentially mitigating methane emissions from decomposition.

Water consumption and quality impacts represent critical sustainability considerations for HTP technologies. While these processes utilize water as a reaction medium, closed-loop systems with water recovery can reduce freshwater demands by up to 80%. However, the process water contains dissolved organic compounds and nutrients that require appropriate treatment before discharge or recycling. Recent advancements in catalytic hydrothermal systems have demonstrated improved water quality outcomes through selective degradation of problematic compounds.

Economic sustainability analysis reveals that hydrothermal processing becomes increasingly competitive as the moisture content of feedstock increases. For biomass with >50% moisture content, HTP methods typically show lower overall processing costs compared to conventional thermochemical conversion routes that require extensive drying. The ability to process mixed and contaminated feedstocks further enhances economic viability by enabling the utilization of low-cost waste streams.

Social sustainability dimensions include potential contributions to rural development through distributed processing facilities and improved waste management practices. Small-scale HTP units can be deployed in agricultural communities, creating local value chains and reducing transportation requirements. This distributed approach may enhance energy security and provide economic opportunities in regions with abundant biomass resources.

Comparative sustainability metrics across different HTP variants indicate that hydrothermal liquefaction generally achieves the highest energy recovery efficiency (65-75%), while hydrothermal carbonization offers advantages in terms of process simplicity and lower operating pressures. Hydrothermal gasification, while more energy-intensive, produces the cleanest gaseous products with potential applications in existing natural gas infrastructure.

Future sustainability improvements will likely focus on catalyst development to enhance selectivity, reduce reaction severity, and enable recovery of high-value compounds from process streams. Integration with existing biorefinery concepts and waste treatment facilities represents another promising direction for improving the overall sustainability profile of hydrothermal processing technologies.

Techno-economic Analysis of Scaled Implementation

The techno-economic analysis of scaled implementation for hydrothermal processing (HTP) of biomass reveals significant economic potential when transitioning from laboratory to industrial scale. Initial capital expenditure for commercial-scale HTP facilities ranges from $20-50 million, depending on processing capacity and technology configuration, with facilities capable of processing 100-500 tons of biomass daily representing the most economically viable scale.

Operating costs demonstrate notable economies of scale, with processing costs decreasing from approximately $120-150 per ton at pilot scale to $60-80 per ton at commercial scale. Energy consumption represents 30-40% of operational expenses, highlighting the importance of process optimization and heat recovery systems. The implementation of closed-loop water systems can reduce freshwater requirements by up to 70%, significantly improving both environmental performance and operational economics.

Payback periods for industrial-scale HTP facilities typically range from 5-8 years, with internal rates of return between 12-18% depending on feedstock costs, product portfolio, and market conditions. Facilities producing higher-value products such as biocrude oil for refineries or specialized chemicals demonstrate substantially better financial performance than those focused solely on solid biofuels.

Sensitivity analysis indicates that feedstock cost fluctuations impact profitability most significantly, with a 20% increase in biomass costs potentially reducing profit margins by 15-25%. Product diversification strategies that incorporate multiple value streams from the same feedstock can mitigate this risk, improving overall economic resilience.

Regional economic factors substantially influence implementation viability. Areas with abundant agricultural or forestry waste streams, existing biorefinery infrastructure, or supportive policy frameworks demonstrate 25-40% better economic performance metrics. Carbon pricing mechanisms, when present, can improve project economics by 10-15% through monetization of greenhouse gas emission reductions compared to fossil fuel alternatives.

Scale-up challenges include maintaining process efficiency across increasing volumes, with pilot studies showing 5-10% efficiency losses during initial scale-up phases. Engineering solutions such as improved reactor designs and advanced process control systems have demonstrated potential to recover 60-80% of these efficiency losses, significantly improving the economics of scaled implementation.

Operating costs demonstrate notable economies of scale, with processing costs decreasing from approximately $120-150 per ton at pilot scale to $60-80 per ton at commercial scale. Energy consumption represents 30-40% of operational expenses, highlighting the importance of process optimization and heat recovery systems. The implementation of closed-loop water systems can reduce freshwater requirements by up to 70%, significantly improving both environmental performance and operational economics.

Payback periods for industrial-scale HTP facilities typically range from 5-8 years, with internal rates of return between 12-18% depending on feedstock costs, product portfolio, and market conditions. Facilities producing higher-value products such as biocrude oil for refineries or specialized chemicals demonstrate substantially better financial performance than those focused solely on solid biofuels.

Sensitivity analysis indicates that feedstock cost fluctuations impact profitability most significantly, with a 20% increase in biomass costs potentially reducing profit margins by 15-25%. Product diversification strategies that incorporate multiple value streams from the same feedstock can mitigate this risk, improving overall economic resilience.

Regional economic factors substantially influence implementation viability. Areas with abundant agricultural or forestry waste streams, existing biorefinery infrastructure, or supportive policy frameworks demonstrate 25-40% better economic performance metrics. Carbon pricing mechanisms, when present, can improve project economics by 10-15% through monetization of greenhouse gas emission reductions compared to fossil fuel alternatives.

Scale-up challenges include maintaining process efficiency across increasing volumes, with pilot studies showing 5-10% efficiency losses during initial scale-up phases. Engineering solutions such as improved reactor designs and advanced process control systems have demonstrated potential to recover 60-80% of these efficiency losses, significantly improving the economics of scaled implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!