Biomass upgrading for aviation fuel production

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomass Aviation Fuel Background and Objectives

Aviation has been actively seeking sustainable alternatives to conventional jet fuels due to increasing environmental concerns and regulatory pressures. Biomass-derived aviation fuels represent a promising pathway toward reducing the carbon footprint of the aviation sector, which contributes approximately 2-3% of global carbon dioxide emissions. The evolution of biomass upgrading technologies for aviation fuel production has progressed significantly over the past two decades, transitioning from conceptual research to commercial-scale demonstrations.

The technical trajectory began with first-generation biofuels derived from food crops, which faced sustainability criticisms due to competition with food production. This led to the development of second-generation technologies utilizing lignocellulosic biomass, agricultural residues, and forestry waste. More recently, third-generation approaches have emerged, focusing on algae and other non-food feedstocks with higher energy densities and lower land-use requirements.

Current technological objectives center on developing economically viable and scalable processes for converting diverse biomass feedstocks into drop-in aviation fuels that meet stringent ASTM specifications. These fuels must be compatible with existing aircraft engines and fuel infrastructure without requiring modifications, while delivering comparable or superior performance characteristics to conventional jet fuel.

Key technical goals include improving conversion efficiency to reduce production costs, enhancing catalyst performance and longevity, minimizing hydrogen consumption in hydroprocessing steps, and optimizing process integration. Additionally, there is significant focus on developing flexible technologies capable of processing multiple feedstock types to ensure supply chain resilience and adaptability to regional biomass availability.

The environmental objectives are equally important, aiming for substantial greenhouse gas emission reductions compared to fossil-derived jet fuels. The industry targets achieving 50-80% lifecycle carbon emission reductions, with aspirations toward carbon-neutral or even carbon-negative production pathways through carbon capture integration and sustainable feedstock management practices.

Regulatory frameworks worldwide are increasingly supporting these objectives through policies like the European Union's ReFuelEU Aviation initiative, which mandates increasing percentages of sustainable aviation fuels, and the U.S. Sustainable Aviation Fuel Grand Challenge, which aims to scale up production to 3 billion gallons annually by 2030. These initiatives create both technical imperatives and market opportunities for biomass upgrading technologies.

The ultimate goal is establishing a mature, cost-competitive biomass-to-aviation fuel industry capable of supplying a significant portion of global jet fuel demand, estimated at approximately 330 billion liters annually, while simultaneously contributing to climate change mitigation efforts and creating sustainable economic opportunities throughout the supply chain.

The technical trajectory began with first-generation biofuels derived from food crops, which faced sustainability criticisms due to competition with food production. This led to the development of second-generation technologies utilizing lignocellulosic biomass, agricultural residues, and forestry waste. More recently, third-generation approaches have emerged, focusing on algae and other non-food feedstocks with higher energy densities and lower land-use requirements.

Current technological objectives center on developing economically viable and scalable processes for converting diverse biomass feedstocks into drop-in aviation fuels that meet stringent ASTM specifications. These fuels must be compatible with existing aircraft engines and fuel infrastructure without requiring modifications, while delivering comparable or superior performance characteristics to conventional jet fuel.

Key technical goals include improving conversion efficiency to reduce production costs, enhancing catalyst performance and longevity, minimizing hydrogen consumption in hydroprocessing steps, and optimizing process integration. Additionally, there is significant focus on developing flexible technologies capable of processing multiple feedstock types to ensure supply chain resilience and adaptability to regional biomass availability.

The environmental objectives are equally important, aiming for substantial greenhouse gas emission reductions compared to fossil-derived jet fuels. The industry targets achieving 50-80% lifecycle carbon emission reductions, with aspirations toward carbon-neutral or even carbon-negative production pathways through carbon capture integration and sustainable feedstock management practices.

Regulatory frameworks worldwide are increasingly supporting these objectives through policies like the European Union's ReFuelEU Aviation initiative, which mandates increasing percentages of sustainable aviation fuels, and the U.S. Sustainable Aviation Fuel Grand Challenge, which aims to scale up production to 3 billion gallons annually by 2030. These initiatives create both technical imperatives and market opportunities for biomass upgrading technologies.

The ultimate goal is establishing a mature, cost-competitive biomass-to-aviation fuel industry capable of supplying a significant portion of global jet fuel demand, estimated at approximately 330 billion liters annually, while simultaneously contributing to climate change mitigation efforts and creating sustainable economic opportunities throughout the supply chain.

Market Analysis for Sustainable Aviation Fuels

The sustainable aviation fuel (SAF) market is experiencing unprecedented growth driven by increasing environmental concerns and regulatory pressures in the aviation industry. Currently, SAF represents less than 0.1% of global jet fuel consumption, but market projections indicate exponential growth potential. The global SAF market was valued at approximately $219 million in 2021 and is expected to reach $15.7 billion by 2030, growing at a CAGR of 60.8% during the forecast period.

Key market drivers include stringent emission regulations, particularly the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) implemented by the International Civil Aviation Organization (ICAO), which aims to stabilize CO2 emissions at 2020 levels. Additionally, major airlines have committed to net-zero carbon emissions by 2050, creating substantial demand for sustainable alternatives to conventional jet fuel.

Regional analysis reveals Europe as the current market leader, accounting for approximately 39% of global SAF production capacity. This dominance stems from progressive policies such as the European Union's "Fit for 55" package, which mandates increasing SAF blend percentages starting at 2% in 2025 and reaching 63% by 2050. North America follows closely, with significant investments in production facilities and supportive government initiatives like the U.S. Sustainable Aviation Fuel Grand Challenge.

Consumer sentiment is increasingly favorable toward sustainable travel options, with surveys indicating that 65% of passengers are willing to pay premium prices for flights using SAF. This trend is particularly pronounced among younger demographics and business travelers, creating market pull alongside regulatory push factors.

Price dynamics remain a critical market barrier, with SAF currently costing 3-5 times more than conventional jet fuel. However, economies of scale and technological advancements in biomass conversion processes are expected to reduce this premium significantly over the next decade. Industry analysts project price parity could be achieved by 2035-2040 with continued technological innovation and supportive policy frameworks.

Supply chain considerations reveal significant opportunities for agricultural sectors and waste management industries to become feedstock suppliers for SAF production. The market currently favors waste-based feedstocks (used cooking oil, agricultural residues) due to their lower costs and superior lifecycle emission profiles compared to purpose-grown energy crops.

Investment trends show accelerating capital flows into the sector, with over $2.4 billion invested in SAF production facilities in 2022 alone. Major oil companies, airlines, and dedicated biofuel producers are forming strategic partnerships to secure feedstock supply chains and scale up production capacity to meet anticipated demand growth.

Key market drivers include stringent emission regulations, particularly the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) implemented by the International Civil Aviation Organization (ICAO), which aims to stabilize CO2 emissions at 2020 levels. Additionally, major airlines have committed to net-zero carbon emissions by 2050, creating substantial demand for sustainable alternatives to conventional jet fuel.

Regional analysis reveals Europe as the current market leader, accounting for approximately 39% of global SAF production capacity. This dominance stems from progressive policies such as the European Union's "Fit for 55" package, which mandates increasing SAF blend percentages starting at 2% in 2025 and reaching 63% by 2050. North America follows closely, with significant investments in production facilities and supportive government initiatives like the U.S. Sustainable Aviation Fuel Grand Challenge.

Consumer sentiment is increasingly favorable toward sustainable travel options, with surveys indicating that 65% of passengers are willing to pay premium prices for flights using SAF. This trend is particularly pronounced among younger demographics and business travelers, creating market pull alongside regulatory push factors.

Price dynamics remain a critical market barrier, with SAF currently costing 3-5 times more than conventional jet fuel. However, economies of scale and technological advancements in biomass conversion processes are expected to reduce this premium significantly over the next decade. Industry analysts project price parity could be achieved by 2035-2040 with continued technological innovation and supportive policy frameworks.

Supply chain considerations reveal significant opportunities for agricultural sectors and waste management industries to become feedstock suppliers for SAF production. The market currently favors waste-based feedstocks (used cooking oil, agricultural residues) due to their lower costs and superior lifecycle emission profiles compared to purpose-grown energy crops.

Investment trends show accelerating capital flows into the sector, with over $2.4 billion invested in SAF production facilities in 2022 alone. Major oil companies, airlines, and dedicated biofuel producers are forming strategic partnerships to secure feedstock supply chains and scale up production capacity to meet anticipated demand growth.

Technical Barriers in Biomass-to-Jet Fuel Conversion

Despite significant advancements in biomass-to-jet fuel conversion technologies, several critical technical barriers continue to impede widespread commercial implementation. The heterogeneous nature of biomass feedstocks presents a fundamental challenge, as variations in composition (cellulose, hemicellulose, lignin ratios) and physical properties necessitate complex preprocessing and create inconsistent conversion efficiencies. This feedstock variability directly impacts product quality and process economics, making standardization difficult.

Thermochemical conversion pathways face specific challenges including catalyst deactivation due to impurities, high energy requirements, and carbon efficiency losses. Fast pyrolysis processes struggle with oxygen removal from bio-oils without significant hydrogen consumption, while gasification routes encounter difficulties in syngas cleaning and Fischer-Tropsch synthesis optimization for aviation fuel specifications.

Biochemical conversion routes, particularly those utilizing fermentation, face limitations in metabolic efficiency when producing longer hydrocarbon chains required for jet fuel. Microbial strains capable of directly producing aviation-range hydrocarbons demonstrate limited yields and productivity rates that fall short of commercial viability thresholds.

Upgrading intermediate products to meet stringent aviation fuel specifications represents another significant barrier. Aviation fuels require specific properties including energy density, cold flow performance, and thermal stability that are challenging to achieve through biomass conversion. Current upgrading processes often require extensive hydroprocessing, resulting in high hydrogen consumption and reduced overall carbon efficiency.

Scale-up challenges persist across all conversion pathways. Laboratory-scale successes frequently encounter unforeseen complications during pilot and demonstration phases, particularly regarding heat and mass transfer limitations, catalyst performance at scale, and equipment durability under real-world conditions. These scaling issues significantly impact capital and operating costs.

Process integration and optimization remain underdeveloped, with many technologies operating as discrete steps rather than as integrated systems. This fragmentation leads to efficiency losses at process interfaces and increases overall energy consumption. Additionally, current technologies struggle to effectively utilize all biomass fractions, with lignin valorization representing a particular challenge.

Economic barriers compound technical challenges, as current conversion pathways typically result in production costs 2-3 times higher than conventional jet fuel. This cost differential is driven by capital-intensive equipment requirements, process inefficiencies, and the need for extensive product upgrading to meet specifications. Addressing these interconnected technical barriers requires coordinated research across multiple disciplines and value chain stages.

Thermochemical conversion pathways face specific challenges including catalyst deactivation due to impurities, high energy requirements, and carbon efficiency losses. Fast pyrolysis processes struggle with oxygen removal from bio-oils without significant hydrogen consumption, while gasification routes encounter difficulties in syngas cleaning and Fischer-Tropsch synthesis optimization for aviation fuel specifications.

Biochemical conversion routes, particularly those utilizing fermentation, face limitations in metabolic efficiency when producing longer hydrocarbon chains required for jet fuel. Microbial strains capable of directly producing aviation-range hydrocarbons demonstrate limited yields and productivity rates that fall short of commercial viability thresholds.

Upgrading intermediate products to meet stringent aviation fuel specifications represents another significant barrier. Aviation fuels require specific properties including energy density, cold flow performance, and thermal stability that are challenging to achieve through biomass conversion. Current upgrading processes often require extensive hydroprocessing, resulting in high hydrogen consumption and reduced overall carbon efficiency.

Scale-up challenges persist across all conversion pathways. Laboratory-scale successes frequently encounter unforeseen complications during pilot and demonstration phases, particularly regarding heat and mass transfer limitations, catalyst performance at scale, and equipment durability under real-world conditions. These scaling issues significantly impact capital and operating costs.

Process integration and optimization remain underdeveloped, with many technologies operating as discrete steps rather than as integrated systems. This fragmentation leads to efficiency losses at process interfaces and increases overall energy consumption. Additionally, current technologies struggle to effectively utilize all biomass fractions, with lignin valorization representing a particular challenge.

Economic barriers compound technical challenges, as current conversion pathways typically result in production costs 2-3 times higher than conventional jet fuel. This cost differential is driven by capital-intensive equipment requirements, process inefficiencies, and the need for extensive product upgrading to meet specifications. Addressing these interconnected technical barriers requires coordinated research across multiple disciplines and value chain stages.

Current Biomass Conversion Pathways for Aviation Fuels

01 Thermochemical conversion processes for biomass upgrading

Thermochemical processes such as pyrolysis, gasification, and hydrothermal liquefaction are used to convert biomass into higher-value fuels and chemicals. These processes involve the application of heat and sometimes pressure to break down biomass components into more useful forms. The resulting products can include bio-oils, syngas, and solid biochar, which can be further refined into transportation fuels or chemical feedstocks.- Thermochemical conversion processes for biomass upgrading: Thermochemical processes such as pyrolysis, gasification, and hydrothermal liquefaction are used to convert biomass into higher-value fuels and chemicals. These processes involve the application of heat and sometimes pressure to break down biomass components into more valuable products. The resulting bio-oils, syngas, or char can be further refined into transportation fuels, chemicals, or other energy products.

- Catalytic upgrading of biomass: Catalysts play a crucial role in biomass upgrading by enhancing reaction rates, improving selectivity, and enabling conversion under milder conditions. Various catalysts including zeolites, metal oxides, and supported noble metals are employed to facilitate deoxygenation, hydrogenation, and other chemical transformations of biomass-derived compounds. Catalytic processes can significantly improve the quality and yield of biofuels and biochemicals from biomass feedstocks.

- Biochemical conversion methods for biomass upgrading: Biochemical conversion utilizes enzymes, microorganisms, or biological systems to transform biomass into valuable products. These methods include fermentation, enzymatic hydrolysis, and anaerobic digestion. Biochemical approaches often operate under mild conditions and can be highly selective, making them suitable for producing specific chemicals, biofuels, and materials from various biomass feedstocks.

- Integrated biorefinery systems for biomass processing: Integrated biorefinery systems combine multiple conversion technologies and processes to maximize the value extracted from biomass feedstocks. These systems often incorporate both thermochemical and biochemical conversion methods, along with separation and purification steps, to produce a range of fuels, chemicals, and materials. The integration of different processes can improve overall efficiency, reduce waste, and enhance the economic viability of biomass upgrading.

- Pretreatment methods for biomass upgrading: Pretreatment techniques are essential for breaking down the recalcitrant structure of biomass before further processing. Methods include physical (grinding, milling), chemical (acid, alkali, solvent treatments), physicochemical (steam explosion, ammonia fiber explosion), and biological pretreatments. These processes disrupt the lignocellulosic structure, increase surface area, and improve accessibility to cellulose and hemicellulose, enhancing the efficiency of subsequent conversion processes.

02 Catalytic upgrading of biomass-derived compounds

Catalysts play a crucial role in biomass upgrading by facilitating specific chemical transformations at lower temperatures and pressures. Various catalytic systems, including metal-based catalysts, zeolites, and supported metal catalysts, are employed to enhance reaction selectivity and yield. These catalysts help in deoxygenation, hydrogenation, and other conversion processes that transform biomass-derived compounds into fuels and chemicals with properties similar to petroleum-derived products.Expand Specific Solutions03 Biological and enzymatic biomass conversion methods

Biological approaches utilize microorganisms or enzymes to break down biomass components into valuable products. These methods include fermentation, anaerobic digestion, and enzymatic hydrolysis, which can operate under mild conditions with high selectivity. The processes can convert biomass into biofuels like ethanol and butanol, as well as platform chemicals such as organic acids and alcohols that serve as building blocks for various industrial applications.Expand Specific Solutions04 Integrated biorefinery approaches for biomass valorization

Integrated biorefineries combine multiple conversion technologies to maximize the value extracted from biomass feedstocks. These facilities process biomass through a series of operations to produce a spectrum of products including fuels, power, chemicals, and materials. By utilizing various fractions of the biomass and integrating process streams, biorefineries can achieve higher overall efficiency and economic viability compared to single-product systems.Expand Specific Solutions05 Pretreatment methods for enhanced biomass conversion

Pretreatment techniques are essential for breaking down the recalcitrant structure of lignocellulosic biomass to improve accessibility for subsequent conversion processes. Methods include physical (milling, grinding), chemical (acid, alkali, solvent treatments), physicochemical (steam explosion, ammonia fiber explosion), and biological pretreatments. These processes disrupt the lignin structure, reduce cellulose crystallinity, and increase the surface area of biomass materials, leading to more efficient conversion in downstream processes.Expand Specific Solutions

Leading Organizations in Sustainable Aviation Fuel Industry

Biomass upgrading for aviation fuel production is currently in an early commercialization phase, with the market expected to grow significantly as the aviation industry seeks sustainable alternatives to conventional jet fuel. The global sustainable aviation fuel market is projected to reach approximately $15 billion by 2030, driven by stringent emission regulations and corporate sustainability commitments. Leading research institutions like Dalian Institute of Chemical Physics and Beijing University of Chemical Technology are advancing catalytic conversion technologies, while commercial players including Shell, Phillips 66, and Chevron are scaling up production capabilities. Chinese entities demonstrate strong research momentum, while Western companies like UPM-Kymmene and REG Synthetic Fuels focus on commercialization pathways. Technical challenges remain in feedstock variability management and process optimization for commercial-scale production.

Dalian Institute of Chemical Physics of CAS

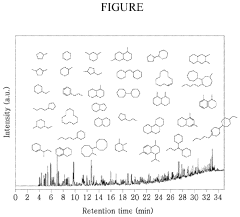

Technical Solution: The Dalian Institute has pioneered an innovative catalytic pyrolysis approach for converting lignocellulosic biomass to aviation fuel. Their technology employs a two-stage catalytic system: first using modified HZSM-5 zeolite catalysts for initial biomass decomposition and deoxygenation, followed by a second stage using bifunctional metal-acid catalysts for hydrogenation and carbon chain restructuring. This approach achieves remarkable oxygen removal (>98%) while maintaining carbon efficiency around 55-60%. Their process operates at moderate temperatures (400-500°C) and pressures (2-5 MPa), reducing energy requirements compared to conventional gasification routes. The Institute has developed proprietary catalyst formulations incorporating rare earth elements that significantly enhance catalyst stability and resistance to deactivation from biomass impurities. Their technology can process various agricultural residues including corn stover, rice husks, and forestry waste. Laboratory and pilot demonstrations have produced aviation fuel meeting China's No. 3 jet fuel specifications with yields of approximately 25% based on biomass input, with additional valuable co-products including aromatics and diesel-range hydrocarbons.

Strengths: Lower energy requirements compared to gasification-based approaches due to moderate operating conditions. The catalyst system demonstrates excellent resistance to common biomass contaminants like alkali metals and sulfur compounds. The process produces valuable chemical co-products improving overall economics. Weaknesses: Catalyst manufacturing involves relatively expensive components potentially increasing production costs. The technology has been demonstrated primarily at laboratory and small pilot scales, requiring further scale-up validation.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed an integrated biomass-to-jet fuel technology pathway called IH2 (Integrated Hydropyrolysis and Hydroconversion) that converts biomass directly to hydrocarbon transportation fuels. The process involves catalytic hydropyrolysis of biomass in a hydrogen-rich environment, followed by hydroconversion to produce drop-in fuels including aviation fuel. The technology can process various feedstocks including forest residues, agricultural waste, and energy crops. Shell's process achieves carbon conversion efficiencies of up to 70% with minimal water usage compared to conventional processes. The company has demonstrated the technology at pilot scale with plans for commercial deployment, achieving ASTM certification for their sustainable aviation fuel (SAF) products. Shell has also invested in advanced catalysts that improve selectivity toward jet fuel range hydrocarbons while minimizing unwanted byproducts.

Strengths: High carbon efficiency (up to 70%), flexibility in feedstock utilization, and production of drop-in fuels requiring no engine modifications. The process generates minimal waste streams and has lower water requirements than competing technologies. Weaknesses: Requires significant hydrogen input which may increase operational costs and potentially reduce overall carbon benefits if hydrogen is not produced from renewable sources.

Key Patents and Innovations in Biomass Upgrading Processes

Preparation of biofuel from biomass

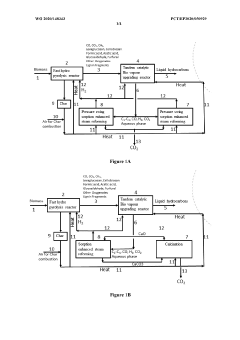

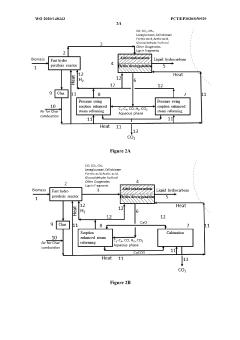

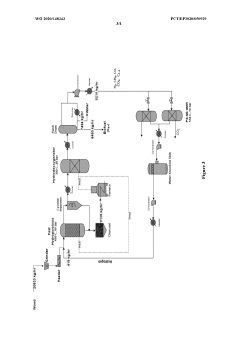

PatentWO2020148343A2

Innovation

- The process involves fast hydropyrolysis or fast pyrolysis of biomass followed by sorption enhanced steam reforming to generate hydrogen, which is then used in a fixed bed tandem catalytic-upgrading reactor with C-C coupling and hydrodeoxygenation catalysts to produce high yields of C5+ hydrocarbons and aromatics, suitable for jet fuel, at low temperatures and pressures.

Catalyst for aviation fuel production from bio-oil, method for preparation of the same and method for bio-oil upgrading using the same

PatentActiveUS20240165589A1

Innovation

- A composite inorganic oxide catalyst comprising lanthanum (La), nickel (Ni), titanium (Ti), and cerium (Ce) is used in a two-step reaction process, where a metal catalyst supported on carbon is used for the first step and the composite oxide catalyst for the second step, to break C-C and C-O bonds and remove oxygen atoms, thereby increasing the efficiency and preventing reactor clogging.

Environmental Impact Assessment of Biomass-Derived Aviation Fuels

The environmental impact assessment of biomass-derived aviation fuels reveals significant potential for reducing greenhouse gas emissions compared to conventional petroleum-based jet fuels. Life cycle analyses indicate that biomass-derived aviation fuels can achieve carbon emission reductions ranging from 50% to 80%, depending on feedstock selection, conversion technology, and supply chain optimization. These substantial reductions stem primarily from the carbon sequestration that occurs during biomass growth, effectively offsetting emissions released during combustion.

Water usage represents a critical environmental consideration in biomass fuel production. First-generation biofuels derived from food crops typically require 2,500-3,500 liters of water per liter of fuel produced. In contrast, advanced biomass pathways utilizing agricultural residues, forestry waste, or algae demonstrate more favorable water footprints, with requirements potentially reduced by 30-60% compared to crop-based alternatives.

Land use change impacts vary significantly across biomass feedstock types. Direct land conversion for energy crop cultivation can trigger substantial carbon debts, potentially requiring decades to achieve net climate benefits. However, utilizing marginal lands, agricultural residues, or waste streams largely mitigates these concerns while avoiding competition with food production systems. Recent studies indicate that thoughtfully implemented biomass aviation fuel production could utilize approximately 5-15% of available agricultural residues without disrupting food security or ecosystem services.

Air quality implications of biomass-derived aviation fuels demonstrate mixed results. While these fuels typically produce fewer particulate emissions and sulfur compounds during combustion compared to conventional jet fuel, certain production pathways may generate localized air pollutants during processing stages. Advanced catalytic conversion technologies have demonstrated 40-60% reductions in criteria pollutants compared to first-generation thermochemical processes.

Biodiversity considerations remain paramount when scaling biomass production systems. Monoculture energy crop cultivation presents potential ecological risks, whereas integrated agroforestry approaches and strategic use of native perennial species can enhance habitat diversity and ecosystem resilience. Recent field studies document up to 35% increases in pollinator populations and soil microbial diversity in well-designed biomass cultivation systems compared to conventional agriculture.

Waste management across the biomass-to-aviation fuel value chain presents both challenges and opportunities. Process residues can be valorized through biochar production, nutrient recycling, or energy recovery, potentially creating closed-loop systems that minimize environmental footprints while maximizing resource efficiency. Advanced biorefineries have demonstrated capabilities to reduce waste streams by 50-70% compared to earlier generation facilities.

Water usage represents a critical environmental consideration in biomass fuel production. First-generation biofuels derived from food crops typically require 2,500-3,500 liters of water per liter of fuel produced. In contrast, advanced biomass pathways utilizing agricultural residues, forestry waste, or algae demonstrate more favorable water footprints, with requirements potentially reduced by 30-60% compared to crop-based alternatives.

Land use change impacts vary significantly across biomass feedstock types. Direct land conversion for energy crop cultivation can trigger substantial carbon debts, potentially requiring decades to achieve net climate benefits. However, utilizing marginal lands, agricultural residues, or waste streams largely mitigates these concerns while avoiding competition with food production systems. Recent studies indicate that thoughtfully implemented biomass aviation fuel production could utilize approximately 5-15% of available agricultural residues without disrupting food security or ecosystem services.

Air quality implications of biomass-derived aviation fuels demonstrate mixed results. While these fuels typically produce fewer particulate emissions and sulfur compounds during combustion compared to conventional jet fuel, certain production pathways may generate localized air pollutants during processing stages. Advanced catalytic conversion technologies have demonstrated 40-60% reductions in criteria pollutants compared to first-generation thermochemical processes.

Biodiversity considerations remain paramount when scaling biomass production systems. Monoculture energy crop cultivation presents potential ecological risks, whereas integrated agroforestry approaches and strategic use of native perennial species can enhance habitat diversity and ecosystem resilience. Recent field studies document up to 35% increases in pollinator populations and soil microbial diversity in well-designed biomass cultivation systems compared to conventional agriculture.

Waste management across the biomass-to-aviation fuel value chain presents both challenges and opportunities. Process residues can be valorized through biochar production, nutrient recycling, or energy recovery, potentially creating closed-loop systems that minimize environmental footprints while maximizing resource efficiency. Advanced biorefineries have demonstrated capabilities to reduce waste streams by 50-70% compared to earlier generation facilities.

Regulatory Framework and Certification Standards for Bio-Jet Fuels

The regulatory landscape for bio-jet fuels represents a complex framework of international standards, national policies, and industry certifications that collectively govern the production, distribution, and use of sustainable aviation fuels (SAFs). The International Civil Aviation Organization (ICAO) has established the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), which recognizes specific biomass-derived jet fuels as eligible for carbon emission reduction credits, creating a significant market incentive for biomass upgrading technologies.

ASTM International plays a pivotal role through its D7566 standard, which outlines specifications for aviation turbine fuel containing synthesized hydrocarbons. This standard includes several annexes that approve specific production pathways for bio-jet fuels, including Fischer-Tropsch Synthetic Paraffinic Kerosene (FT-SPK), Hydroprocessed Esters and Fatty Acids (HEFA), and Alcohol-to-Jet (ATJ). Each pathway requires rigorous testing and validation before receiving certification, creating a significant barrier to entry for new biomass upgrading technologies.

The European Union's Renewable Energy Directive (RED II) and the U.S. Renewable Fuel Standard (RFS) provide additional regulatory frameworks that impact bio-jet fuel development. These policies establish sustainability criteria for biomass feedstocks and set targets for renewable fuel incorporation into transportation fuel pools, directly influencing investment in biomass upgrading technologies for aviation applications.

Certification processes typically involve extensive fuel property testing, engine compatibility assessments, and lifecycle greenhouse gas emission analyses. The Commercial Aviation Alternative Fuels Initiative (CAAFI) has developed a "Fuel Readiness Level" framework that guides developers through the certification process, from initial concept to commercial deployment. This framework helps stakeholders understand the technical and regulatory hurdles that must be overcome at each development stage.

Emerging trends in regulatory frameworks include the development of book-and-claim systems for SAF accounting, allowing airlines to purchase the environmental attributes of bio-jet fuels separately from the physical fuel. Additionally, there is growing emphasis on lifecycle sustainability criteria beyond carbon emissions, including water usage, land-use change impacts, and biodiversity considerations in biomass production.

The harmonization of global standards remains a significant challenge, with variations in certification requirements across different jurisdictions creating market fragmentation. Industry stakeholders are advocating for greater alignment of these frameworks to reduce compliance costs and accelerate the commercialization of biomass upgrading technologies for aviation fuel production.

ASTM International plays a pivotal role through its D7566 standard, which outlines specifications for aviation turbine fuel containing synthesized hydrocarbons. This standard includes several annexes that approve specific production pathways for bio-jet fuels, including Fischer-Tropsch Synthetic Paraffinic Kerosene (FT-SPK), Hydroprocessed Esters and Fatty Acids (HEFA), and Alcohol-to-Jet (ATJ). Each pathway requires rigorous testing and validation before receiving certification, creating a significant barrier to entry for new biomass upgrading technologies.

The European Union's Renewable Energy Directive (RED II) and the U.S. Renewable Fuel Standard (RFS) provide additional regulatory frameworks that impact bio-jet fuel development. These policies establish sustainability criteria for biomass feedstocks and set targets for renewable fuel incorporation into transportation fuel pools, directly influencing investment in biomass upgrading technologies for aviation applications.

Certification processes typically involve extensive fuel property testing, engine compatibility assessments, and lifecycle greenhouse gas emission analyses. The Commercial Aviation Alternative Fuels Initiative (CAAFI) has developed a "Fuel Readiness Level" framework that guides developers through the certification process, from initial concept to commercial deployment. This framework helps stakeholders understand the technical and regulatory hurdles that must be overcome at each development stage.

Emerging trends in regulatory frameworks include the development of book-and-claim systems for SAF accounting, allowing airlines to purchase the environmental attributes of bio-jet fuels separately from the physical fuel. Additionally, there is growing emphasis on lifecycle sustainability criteria beyond carbon emissions, including water usage, land-use change impacts, and biodiversity considerations in biomass production.

The harmonization of global standards remains a significant challenge, with variations in certification requirements across different jurisdictions creating market fragmentation. Industry stakeholders are advocating for greater alignment of these frameworks to reduce compliance costs and accelerate the commercialization of biomass upgrading technologies for aviation fuel production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!