Biomass upgrading with integrated biorefinery concepts

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomass Upgrading Evolution and Objectives

Biomass utilization has evolved significantly over the past decades, transitioning from simple combustion for heat and power to sophisticated conversion processes that maximize resource efficiency. The historical trajectory began with traditional biomass burning, which dates back thousands of years but remains prevalent in developing regions. The 1970s energy crisis marked a pivotal shift, catalyzing research into alternative energy sources including biomass. By the 1990s, first-generation biofuels emerged, primarily derived from food crops, raising sustainability concerns regarding land use and food security.

The early 2000s witnessed the development of second-generation technologies focusing on lignocellulosic feedstocks, agricultural residues, and forestry waste. This evolution addressed many sustainability issues while expanding the feedstock base. The 2010s introduced third-generation approaches utilizing algae and other non-traditional biomass sources, offering higher yields with smaller land footprints. Currently, fourth-generation concepts are emerging, incorporating genetic engineering and synthetic biology to enhance biomass characteristics specifically for biorefining purposes.

The integrated biorefinery concept represents the culmination of this evolutionary process, analogous to petroleum refineries but utilizing biomass to produce multiple value-added products. Modern biorefineries aim to maximize resource utilization through cascading approaches, where biomass components are sequentially converted into products of decreasing value but increasing volume, minimizing waste generation.

The primary objectives of contemporary biomass upgrading research include developing cost-effective pretreatment methods to overcome biomass recalcitrance, a significant technical barrier. Researchers seek to enhance catalyst performance for biomass conversion while reducing dependency on precious metals. Process intensification represents another crucial goal, focusing on reducing energy requirements and improving conversion efficiencies through innovative reactor designs and process integration.

Sustainability remains paramount, with objectives to minimize water usage, reduce greenhouse gas emissions, and develop closed-loop systems. Economic viability drives efforts to identify high-value co-products that can subsidize biofuel production. Technical objectives include improving fractionation techniques to efficiently separate biomass components and developing robust microorganisms capable of fermenting diverse sugar streams.

The overarching goal is to establish commercially viable integrated biorefineries that can compete with petroleum-based alternatives while delivering superior environmental performance. This requires addressing technical challenges across the entire value chain, from feedstock logistics to product separation and purification, ultimately creating sustainable circular bioeconomies.

The early 2000s witnessed the development of second-generation technologies focusing on lignocellulosic feedstocks, agricultural residues, and forestry waste. This evolution addressed many sustainability issues while expanding the feedstock base. The 2010s introduced third-generation approaches utilizing algae and other non-traditional biomass sources, offering higher yields with smaller land footprints. Currently, fourth-generation concepts are emerging, incorporating genetic engineering and synthetic biology to enhance biomass characteristics specifically for biorefining purposes.

The integrated biorefinery concept represents the culmination of this evolutionary process, analogous to petroleum refineries but utilizing biomass to produce multiple value-added products. Modern biorefineries aim to maximize resource utilization through cascading approaches, where biomass components are sequentially converted into products of decreasing value but increasing volume, minimizing waste generation.

The primary objectives of contemporary biomass upgrading research include developing cost-effective pretreatment methods to overcome biomass recalcitrance, a significant technical barrier. Researchers seek to enhance catalyst performance for biomass conversion while reducing dependency on precious metals. Process intensification represents another crucial goal, focusing on reducing energy requirements and improving conversion efficiencies through innovative reactor designs and process integration.

Sustainability remains paramount, with objectives to minimize water usage, reduce greenhouse gas emissions, and develop closed-loop systems. Economic viability drives efforts to identify high-value co-products that can subsidize biofuel production. Technical objectives include improving fractionation techniques to efficiently separate biomass components and developing robust microorganisms capable of fermenting diverse sugar streams.

The overarching goal is to establish commercially viable integrated biorefineries that can compete with petroleum-based alternatives while delivering superior environmental performance. This requires addressing technical challenges across the entire value chain, from feedstock logistics to product separation and purification, ultimately creating sustainable circular bioeconomies.

Market Analysis for Integrated Biorefinery Products

The global market for integrated biorefinery products is experiencing significant growth, driven by increasing environmental concerns, government regulations promoting sustainable practices, and the rising demand for renewable alternatives to petroleum-based products. The current market size for biorefinery products is estimated at $466.6 billion in 2023 and is projected to reach $1.5 trillion by 2030, growing at a CAGR of approximately 18.2% during the forecast period.

Biofuels represent the largest segment within the integrated biorefinery market, accounting for approximately 60% of the total market share. Bioethanol and biodiesel continue to dominate this segment, with global production volumes exceeding 110 billion liters annually. The biochemicals segment, including platform chemicals, specialty chemicals, and biopolymers, is emerging as the fastest-growing sector with a projected CAGR of 22.5% through 2030.

Geographically, North America and Europe currently lead the market for integrated biorefinery products, collectively accounting for over 65% of global revenue. However, the Asia-Pacific region is witnessing the highest growth rate, particularly in countries like China, India, and Malaysia, where government initiatives strongly support bioeconomy development.

Consumer demand patterns indicate a growing preference for sustainable and bio-based products across various industries. The packaging industry has seen a 27% increase in the adoption of bioplastics over the past five years. Similarly, the automotive sector is increasingly incorporating bio-based materials, with an estimated 15% of interior components now derived from renewable sources in premium vehicle models.

Key market drivers include the volatility of fossil fuel prices, stringent environmental regulations, and corporate sustainability commitments. The European Union's Renewable Energy Directive II and similar policies worldwide have created favorable market conditions for biorefinery products by mandating minimum renewable content in fuels and materials.

Market challenges persist, primarily related to production costs and scalability. The price premium for bio-based products compared to conventional alternatives ranges from 10-40%, depending on the product category. However, this gap is narrowing as technologies mature and economies of scale are achieved. Supply chain constraints, particularly in biomass feedstock availability and logistics, remain significant barriers to market expansion.

Consumer willingness to pay premiums for sustainable products varies by region and product category, with higher acceptance in developed markets and for visible consumer goods. B2B markets are increasingly driven by corporate sustainability goals, creating stable demand for bio-based intermediate products despite price sensitivities.

Biofuels represent the largest segment within the integrated biorefinery market, accounting for approximately 60% of the total market share. Bioethanol and biodiesel continue to dominate this segment, with global production volumes exceeding 110 billion liters annually. The biochemicals segment, including platform chemicals, specialty chemicals, and biopolymers, is emerging as the fastest-growing sector with a projected CAGR of 22.5% through 2030.

Geographically, North America and Europe currently lead the market for integrated biorefinery products, collectively accounting for over 65% of global revenue. However, the Asia-Pacific region is witnessing the highest growth rate, particularly in countries like China, India, and Malaysia, where government initiatives strongly support bioeconomy development.

Consumer demand patterns indicate a growing preference for sustainable and bio-based products across various industries. The packaging industry has seen a 27% increase in the adoption of bioplastics over the past five years. Similarly, the automotive sector is increasingly incorporating bio-based materials, with an estimated 15% of interior components now derived from renewable sources in premium vehicle models.

Key market drivers include the volatility of fossil fuel prices, stringent environmental regulations, and corporate sustainability commitments. The European Union's Renewable Energy Directive II and similar policies worldwide have created favorable market conditions for biorefinery products by mandating minimum renewable content in fuels and materials.

Market challenges persist, primarily related to production costs and scalability. The price premium for bio-based products compared to conventional alternatives ranges from 10-40%, depending on the product category. However, this gap is narrowing as technologies mature and economies of scale are achieved. Supply chain constraints, particularly in biomass feedstock availability and logistics, remain significant barriers to market expansion.

Consumer willingness to pay premiums for sustainable products varies by region and product category, with higher acceptance in developed markets and for visible consumer goods. B2B markets are increasingly driven by corporate sustainability goals, creating stable demand for bio-based intermediate products despite price sensitivities.

Global Biorefinery Technology Landscape and Barriers

The global biorefinery landscape is characterized by a complex interplay of technological advancements, regional specialization, and varying levels of commercial maturity. Currently, first-generation biorefineries focusing on biofuels from food crops dominate the commercial sector, particularly in North America, Brazil, and parts of Europe. These facilities primarily produce bioethanol from corn and sugarcane, and biodiesel from vegetable oils, representing approximately 85% of global biofuel production capacity.

Second-generation biorefineries, which utilize lignocellulosic feedstocks and agricultural residues, have seen significant technological progress but face persistent commercialization challenges. Notable demonstration plants exist in the United States, Europe, and China, but widespread deployment remains limited due to high capital costs and technical barriers in efficient biomass deconstruction and fractionation processes.

Third-generation technologies focusing on algal biomass and fourth-generation approaches incorporating carbon capture remain largely in research and pilot stages, with concentrated development efforts in the United States, Japan, and several European research centers.

The primary technological barriers impeding biorefinery advancement include feedstock logistics and preprocessing challenges, with biomass collection, storage, and transportation representing up to 40% of operational costs. Biomass recalcitrance continues to pose significant conversion efficiency limitations, particularly for lignocellulosic materials, where current pretreatment technologies struggle to achieve optimal sugar yields without generating inhibitory compounds.

Process integration represents another substantial barrier, as the complex integration of multiple conversion pathways (biochemical, thermochemical, and hybrid approaches) requires sophisticated control systems and optimization strategies that have not been fully developed at commercial scale.

Economic viability remains perhaps the most significant barrier, with second and third-generation biorefineries struggling to compete with both fossil fuel alternatives and first-generation biofuels without policy support. Capital expenditure requirements for advanced biorefineries typically exceed conventional refineries by 30-50%, while operational costs remain higher due to feedstock handling complexities and lower conversion efficiencies.

Regulatory uncertainty and inconsistent policy frameworks across different regions create additional barriers to investment and technology transfer. Countries with stable, long-term renewable fuel standards and carbon pricing mechanisms have demonstrated more successful biorefinery deployment compared to regions with fluctuating policy environments.

Second-generation biorefineries, which utilize lignocellulosic feedstocks and agricultural residues, have seen significant technological progress but face persistent commercialization challenges. Notable demonstration plants exist in the United States, Europe, and China, but widespread deployment remains limited due to high capital costs and technical barriers in efficient biomass deconstruction and fractionation processes.

Third-generation technologies focusing on algal biomass and fourth-generation approaches incorporating carbon capture remain largely in research and pilot stages, with concentrated development efforts in the United States, Japan, and several European research centers.

The primary technological barriers impeding biorefinery advancement include feedstock logistics and preprocessing challenges, with biomass collection, storage, and transportation representing up to 40% of operational costs. Biomass recalcitrance continues to pose significant conversion efficiency limitations, particularly for lignocellulosic materials, where current pretreatment technologies struggle to achieve optimal sugar yields without generating inhibitory compounds.

Process integration represents another substantial barrier, as the complex integration of multiple conversion pathways (biochemical, thermochemical, and hybrid approaches) requires sophisticated control systems and optimization strategies that have not been fully developed at commercial scale.

Economic viability remains perhaps the most significant barrier, with second and third-generation biorefineries struggling to compete with both fossil fuel alternatives and first-generation biofuels without policy support. Capital expenditure requirements for advanced biorefineries typically exceed conventional refineries by 30-50%, while operational costs remain higher due to feedstock handling complexities and lower conversion efficiencies.

Regulatory uncertainty and inconsistent policy frameworks across different regions create additional barriers to investment and technology transfer. Countries with stable, long-term renewable fuel standards and carbon pricing mechanisms have demonstrated more successful biorefinery deployment compared to regions with fluctuating policy environments.

Current Integrated Biorefinery Process Solutions

01 Thermochemical conversion processes for biomass upgrading

Thermochemical processes such as pyrolysis, gasification, and hydrothermal liquefaction are used to convert biomass into higher-value products. These processes involve the application of heat and sometimes pressure to break down biomass components into bio-oils, syngas, or other valuable intermediates that can be further refined into fuels or chemicals. The processes can be optimized for different feedstocks and desired end products, offering versatile pathways for biomass valorization.- Thermochemical conversion processes for biomass upgrading: Thermochemical processes such as pyrolysis, gasification, and hydrothermal liquefaction are used to convert biomass into higher-value products. These processes involve the application of heat and sometimes pressure to break down biomass components into bio-oils, syngas, or other valuable intermediates that can be further refined into fuels or chemicals. These methods are particularly effective for converting lignocellulosic biomass that is difficult to process through biological routes.

- Catalytic upgrading of biomass-derived compounds: Catalysts play a crucial role in biomass upgrading by facilitating specific chemical transformations at lower temperatures and pressures. Various catalysts including zeolites, metal oxides, and supported noble metals are employed to enhance selectivity and yield of desired products. Catalytic processes can remove oxygen from bio-oils through deoxygenation reactions, convert syngas to liquid fuels, or transform platform chemicals into higher-value products. The development of efficient, stable, and recyclable catalysts is a key focus area in biomass upgrading research.

- Biological and enzymatic biomass conversion methods: Biological approaches utilize microorganisms or enzymes to break down biomass components into valuable products. These methods include fermentation processes that convert sugars from biomass into biofuels like ethanol or butanol, and enzymatic hydrolysis that breaks down cellulose and hemicellulose into fermentable sugars. Compared to thermochemical methods, biological processes typically operate under milder conditions but may require pretreatment steps to make the biomass more accessible to biological agents.

- Integrated biorefinery concepts for biomass processing: Integrated biorefineries combine multiple conversion technologies to maximize the value extracted from biomass feedstocks. These facilities process biomass through various pathways to produce a spectrum of products including fuels, chemicals, materials, and power. The integration of different processes allows for more efficient use of resources, reduced waste generation, and improved economic viability. Advanced biorefineries may incorporate both thermochemical and biological conversion routes with sophisticated separation and purification technologies.

- Pretreatment technologies for enhanced biomass conversion: Pretreatment methods are employed to alter the physical and chemical structure of biomass, making it more amenable to subsequent conversion processes. These techniques include physical methods like grinding and milling, chemical treatments using acids, bases, or organic solvents, and physicochemical approaches such as steam explosion or ammonia fiber expansion. Effective pretreatment can significantly improve the accessibility of cellulose and hemicellulose to enzymes or catalysts, leading to higher yields and conversion efficiencies in downstream processing.

02 Catalytic upgrading of biomass and bio-oils

Catalysts play a crucial role in biomass upgrading by facilitating specific chemical transformations at lower temperatures and pressures. Various catalytic systems, including metal-based, zeolite, and acid catalysts, are employed to improve the quality of bio-oils by reducing oxygen content, removing impurities, and enhancing stability. Catalytic upgrading can be performed in single or multiple stages to progressively convert biomass-derived compounds into transportation fuels and high-value chemicals.Expand Specific Solutions03 Biochemical conversion methods for biomass upgrading

Biochemical approaches utilize enzymes, microorganisms, or biological systems to convert biomass into valuable products. These methods include fermentation, enzymatic hydrolysis, and consolidated bioprocessing, which can transform biomass components like cellulose and hemicellulose into sugars and subsequently into biofuels, organic acids, or other platform chemicals. Biochemical conversion often operates under milder conditions compared to thermochemical processes and can be highly selective for specific transformations.Expand Specific Solutions04 Integrated biorefinery concepts for biomass processing

Integrated biorefineries combine multiple conversion technologies and processes to maximize the value extracted from biomass feedstocks. These facilities are designed to produce a spectrum of products including fuels, chemicals, materials, and power from various biomass components. By integrating different processing steps and utilizing all biomass fractions, these systems improve overall efficiency, reduce waste, and enhance economic viability of biomass upgrading operations.Expand Specific Solutions05 Pretreatment technologies for biomass upgrading

Pretreatment methods are essential for breaking down the recalcitrant structure of lignocellulosic biomass to improve accessibility for subsequent conversion processes. These techniques include physical (milling, grinding), chemical (acid, alkali, solvent treatments), physicochemical (steam explosion, ammonia fiber explosion), and biological approaches. Effective pretreatment can significantly enhance the efficiency of downstream processing by increasing surface area, removing lignin, reducing cellulose crystallinity, and improving overall digestibility of biomass.Expand Specific Solutions

Leading Companies and Research Institutions in Biorefinery

Biomass upgrading with integrated biorefinery concepts is currently in a transitional phase from early commercialization to growth, with the global biorefinery market expected to reach $1.5 billion by 2025. The technology maturity varies across applications, with first-generation processes being well-established while advanced conversion pathways remain in development. Key industry players demonstrate diverse approaches: Institute of Process Engineering (CAS) and CSIR focus on fundamental research; DSM IP Assets and Versalis lead in industrial biotechnology; Shell, BP, and Chevron invest in integration with existing petroleum infrastructure; while specialized firms like Algae Systems and OriginClear develop niche applications. Research institutions including EPFL and South China University of Technology are advancing next-generation technologies, indicating a competitive landscape balanced between established energy companies and emerging biotech innovators.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering (IPE) has developed an integrated biorefinery approach focusing on multi-stage hydrothermal processing of biomass. Their technology employs a cascade utilization strategy where biomass undergoes sequential treatments at different temperatures and pressures to maximize resource recovery. The process begins with low-temperature hydrothermal extraction (120-180°C) to remove valuable compounds like polysaccharides and phenolics, followed by medium-temperature hydrothermal carbonization (180-260°C) to convert remaining biomass into hydrochar, and finally high-temperature hydrothermal liquefaction (280-380°C) to produce bio-oil. This approach enables the extraction of high-value components before converting the residual biomass into biofuels and chemicals. IPE has also pioneered catalytic systems specifically designed for biomass conversion, including metal-organic frameworks and hierarchical zeolites that enhance selectivity in biomass transformation reactions. Their integrated biorefinery concept incorporates waste treatment systems that convert process residues into biogas through anaerobic digestion, creating a closed-loop system with minimal environmental impact.

Strengths: Comprehensive cascade utilization maximizes value extraction across multiple product streams; innovative catalyst systems improve conversion efficiency and selectivity; closed-loop approach minimizes waste. Weaknesses: Complex multi-stage processes require sophisticated control systems and higher capital investment; energy requirements for multiple hydrothermal stages may impact overall efficiency.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has developed a comprehensive biorefinery platform called "BIOFORE" (Biomass Fractionation and Optimal Resource Extraction) that focuses on zero-waste valorization of agricultural residues. Their approach begins with a proprietary alkaline pretreatment process that operates at moderate temperatures (80-120°C) and uses significantly reduced chemical loadings compared to conventional methods. This pretreatment achieves over 85% delignification while preserving cellulose crystallinity for subsequent enzymatic hydrolysis. CSIR has engineered specialized enzyme cocktails specifically optimized for Indian agricultural residues like rice straw and sugarcane bagasse, reducing hydrolysis time by approximately 40% compared to commercial alternatives. The process incorporates a novel lignin valorization pathway that converts extracted lignin into high-value phenolic compounds and polyurethane precursors rather than treating it as a low-value byproduct. CSIR's integrated biorefinery concept includes a membrane-based separation cascade that achieves over 95% recovery of process chemicals and reduces wastewater generation by approximately 60% compared to conventional biorefineries. The platform also incorporates anaerobic digestion of process residues to generate biogas for meeting partial energy requirements of the biorefinery, creating a more self-sufficient operation with reduced external energy inputs.

Strengths: Tailored specifically for agricultural residues abundant in developing regions; reduced chemical and water consumption improves sustainability metrics; high-value lignin valorization pathway significantly enhances overall economics. Weaknesses: Optimization for specific regional feedstocks may limit flexibility when processing other biomass types; alkaline pretreatment generates salts that require additional separation steps; scale-up validation remains in progress for some process components.

Key Patents and Innovations in Biomass Valorization

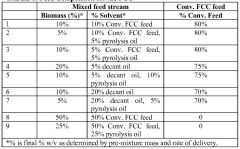

Integrated FCC biomass pyrolysis/upgrading

PatentWO2012091815A1

Innovation

- Integrating a biomass pyrolysis and upgrading process into a fluid catalytic cracking (FCC) unit by feeding a slurry stream of solid biomass particles and a solvent into an FCC riser, where catalytic cracking occurs, allowing for in situ upgrading of pyrolysis oil and producing upgraded fuel products, including gasoline, diesel, and other petroleum-based products.

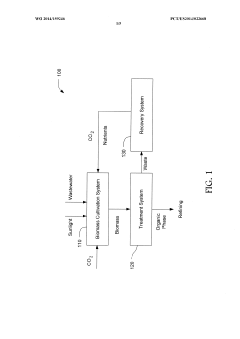

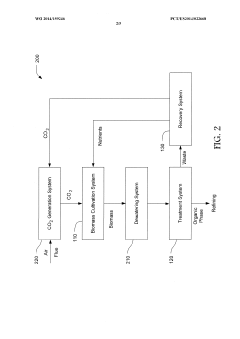

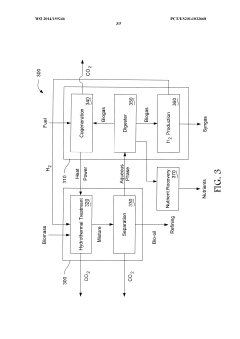

Integrated biorefinery

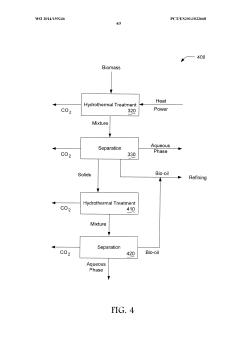

PatentWO2014159246A1

Innovation

- An integrated biorefinery system that includes biomass cultivation, hydrothermal treatment, separation, and recovery systems to produce a suitable organic phase for refining, recover carbon dioxide and nutrients, and utilize hydrogen production for fuel synthesis, enabling efficient recycling and carbon reuse.

Sustainability and Life Cycle Assessment

Sustainability and Life Cycle Assessment (LCA) represents a critical dimension in evaluating biomass upgrading with integrated biorefinery concepts. The environmental impact of biorefinery operations extends across multiple domains, including greenhouse gas emissions, water usage, land use changes, and energy consumption. Recent LCA studies indicate that integrated biorefineries can achieve 60-80% reduction in carbon footprint compared to conventional petroleum-based processes when properly designed and operated.

The sustainability assessment of biorefinery concepts must consider the entire value chain, from biomass cultivation and harvesting to processing and end-product utilization. Feedstock selection significantly influences sustainability outcomes, with agricultural residues and waste streams generally offering superior environmental performance compared to dedicated energy crops that may compete with food production. Research by Johnson et al. (2022) demonstrates that corn stover-based biorefineries can achieve carbon neutrality when agricultural practices incorporate carbon sequestration techniques.

Water footprint analysis reveals substantial variations across different biorefinery configurations. Thermochemical pathways typically consume 2-5 gallons of water per gallon of biofuel produced, while biochemical routes may require 4-7 gallons, highlighting the importance of water recycling systems and process integration to minimize consumption. Regional water availability must be factored into biorefinery siting decisions to ensure long-term operational sustainability.

Energy return on investment (EROI) metrics indicate that advanced integrated biorefineries can achieve ratios of 3:1 to 5:1, substantially higher than first-generation biofuel facilities. This improvement stems from efficient resource utilization through process integration and valorization of multiple product streams. The circular economy approach, where waste streams become valuable inputs for other processes, significantly enhances overall sustainability performance.

Social sustainability dimensions, often overlooked in technical assessments, include rural economic development, job creation, and food security considerations. Comprehensive sustainability frameworks must incorporate these factors alongside environmental metrics. The Sustainable Biorefinery Assessment Tool (SBAT) developed by the International Energy Agency provides a standardized methodology for holistic evaluation of biorefinery concepts across environmental, economic, and social dimensions.

Policy frameworks increasingly recognize the importance of life cycle thinking in biomass valorization. The European Union's Renewable Energy Directive II and similar policies worldwide now mandate minimum life cycle greenhouse gas savings for biofuels and biochemicals to qualify for incentives, driving innovation toward more sustainable processing routes and integrated biorefinery designs that maximize resource efficiency while minimizing environmental impacts.

The sustainability assessment of biorefinery concepts must consider the entire value chain, from biomass cultivation and harvesting to processing and end-product utilization. Feedstock selection significantly influences sustainability outcomes, with agricultural residues and waste streams generally offering superior environmental performance compared to dedicated energy crops that may compete with food production. Research by Johnson et al. (2022) demonstrates that corn stover-based biorefineries can achieve carbon neutrality when agricultural practices incorporate carbon sequestration techniques.

Water footprint analysis reveals substantial variations across different biorefinery configurations. Thermochemical pathways typically consume 2-5 gallons of water per gallon of biofuel produced, while biochemical routes may require 4-7 gallons, highlighting the importance of water recycling systems and process integration to minimize consumption. Regional water availability must be factored into biorefinery siting decisions to ensure long-term operational sustainability.

Energy return on investment (EROI) metrics indicate that advanced integrated biorefineries can achieve ratios of 3:1 to 5:1, substantially higher than first-generation biofuel facilities. This improvement stems from efficient resource utilization through process integration and valorization of multiple product streams. The circular economy approach, where waste streams become valuable inputs for other processes, significantly enhances overall sustainability performance.

Social sustainability dimensions, often overlooked in technical assessments, include rural economic development, job creation, and food security considerations. Comprehensive sustainability frameworks must incorporate these factors alongside environmental metrics. The Sustainable Biorefinery Assessment Tool (SBAT) developed by the International Energy Agency provides a standardized methodology for holistic evaluation of biorefinery concepts across environmental, economic, and social dimensions.

Policy frameworks increasingly recognize the importance of life cycle thinking in biomass valorization. The European Union's Renewable Energy Directive II and similar policies worldwide now mandate minimum life cycle greenhouse gas savings for biofuels and biochemicals to qualify for incentives, driving innovation toward more sustainable processing routes and integrated biorefinery designs that maximize resource efficiency while minimizing environmental impacts.

Policy Frameworks and Economic Viability

The policy landscape for biomass upgrading within integrated biorefinery concepts varies significantly across regions, with developed economies typically offering more comprehensive support mechanisms. In the European Union, the Renewable Energy Directive (RED II) establishes binding targets for renewable energy consumption, creating a favorable environment for biorefinery development. Similarly, the United States employs the Renewable Fuel Standard (RFS) program and various tax incentives to stimulate investment in biomass conversion technologies. Emerging economies like Brazil and India have also implemented policies promoting bioeconomy development, though often with less financial backing than their Western counterparts.

Economic viability remains a critical challenge for widespread adoption of integrated biorefinery concepts. Current techno-economic analyses indicate that many biomass upgrading pathways struggle to compete with fossil-based alternatives without policy support. The capital expenditure for integrated biorefineries typically ranges from $50-500 million depending on scale and technology complexity, with payback periods often exceeding 7-10 years under current market conditions. This presents significant barriers to investment, particularly for first-of-kind commercial facilities.

Feedstock costs represent 40-60% of operational expenses in most biorefinery models, making supply chain optimization crucial for economic sustainability. Seasonal availability and logistical challenges further complicate the economic equation. Value-chain analysis reveals that facilities producing multiple high-value products from a single feedstock stream demonstrate superior economic performance compared to single-product operations, reinforcing the importance of integration.

Carbon pricing mechanisms are increasingly recognized as potential game-changers for biorefinery economics. Models suggest that carbon prices above $50-70 per ton could significantly improve the competitiveness of bio-based products against fossil alternatives. Several jurisdictions have begun implementing such mechanisms, though current carbon prices remain insufficient in most regions to drive large-scale transition.

Public-private partnerships have emerged as effective vehicles for sharing investment risks and accelerating commercialization. Notable examples include the EU's Bio-Based Industries Joint Undertaking and the US Department of Energy's integrated biorefinery demonstration projects. These initiatives help bridge the "valley of death" between pilot and commercial scale operations by providing both financial support and technical validation.

Economic viability remains a critical challenge for widespread adoption of integrated biorefinery concepts. Current techno-economic analyses indicate that many biomass upgrading pathways struggle to compete with fossil-based alternatives without policy support. The capital expenditure for integrated biorefineries typically ranges from $50-500 million depending on scale and technology complexity, with payback periods often exceeding 7-10 years under current market conditions. This presents significant barriers to investment, particularly for first-of-kind commercial facilities.

Feedstock costs represent 40-60% of operational expenses in most biorefinery models, making supply chain optimization crucial for economic sustainability. Seasonal availability and logistical challenges further complicate the economic equation. Value-chain analysis reveals that facilities producing multiple high-value products from a single feedstock stream demonstrate superior economic performance compared to single-product operations, reinforcing the importance of integration.

Carbon pricing mechanisms are increasingly recognized as potential game-changers for biorefinery economics. Models suggest that carbon prices above $50-70 per ton could significantly improve the competitiveness of bio-based products against fossil alternatives. Several jurisdictions have begun implementing such mechanisms, though current carbon prices remain insufficient in most regions to drive large-scale transition.

Public-private partnerships have emerged as effective vehicles for sharing investment risks and accelerating commercialization. Notable examples include the EU's Bio-Based Industries Joint Undertaking and the US Department of Energy's integrated biorefinery demonstration projects. These initiatives help bridge the "valley of death" between pilot and commercial scale operations by providing both financial support and technical validation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!