How reactor design affects biomass upgrading performance

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomass Upgrading Reactor Design Evolution

The evolution of biomass upgrading reactor design has undergone significant transformations over the past decades, reflecting advancements in engineering principles and a deeper understanding of biomass conversion mechanisms. Initial reactor designs in the 1970s and 1980s were primarily adapted from petroleum refining technologies, with fixed-bed reactors being the dominant configuration. These early designs suffered from numerous limitations when processing biomass feedstocks, including channeling, plugging, and poor heat transfer characteristics.

The 1990s marked a shift toward fluidized bed reactor systems, which offered superior heat and mass transfer properties. This evolution was driven by the recognition that biomass, unlike petroleum feedstocks, contains high oxygen content and requires different processing conditions. Fluidized bed reactors allowed for better temperature control and more uniform contact between catalysts and biomass-derived compounds, significantly improving conversion efficiencies.

By the early 2000s, continuous flow reactors gained prominence, enabling higher throughput and better scalability for industrial applications. These systems incorporated improved feeding mechanisms to handle the heterogeneous nature of biomass feedstocks. Concurrently, microreactor technology emerged as a platform for rapid screening of catalysts and reaction conditions, accelerating the development cycle for biomass conversion processes.

The 2010s witnessed the development of hybrid reactor systems that combined multiple reaction zones to accommodate the complex, multi-step nature of biomass upgrading. These integrated reactor designs allowed for sequential processing—from initial depolymerization to subsequent upgrading reactions—within a single system, minimizing energy losses associated with intermediate product recovery and transfer.

Recent innovations have focused on intensified reactor designs that incorporate novel heating methods such as microwave and induction heating, enabling more precise temperature control and rapid heating rates. These technologies have demonstrated significant improvements in selectivity toward desired products while reducing energy consumption. Additionally, membrane reactors have emerged as promising configurations for in-situ product separation, driving equilibrium-limited reactions toward completion.

The latest frontier in reactor design involves modular, reconfigurable systems that can be optimized for different biomass feedstocks and target products. These adaptable platforms represent a paradigm shift from the traditional "one-size-fits-all" approach, acknowledging the inherent variability in biomass resources. Computational fluid dynamics and machine learning algorithms are increasingly being employed to predict optimal reactor configurations for specific applications, reducing the empirical nature of reactor design.

The 1990s marked a shift toward fluidized bed reactor systems, which offered superior heat and mass transfer properties. This evolution was driven by the recognition that biomass, unlike petroleum feedstocks, contains high oxygen content and requires different processing conditions. Fluidized bed reactors allowed for better temperature control and more uniform contact between catalysts and biomass-derived compounds, significantly improving conversion efficiencies.

By the early 2000s, continuous flow reactors gained prominence, enabling higher throughput and better scalability for industrial applications. These systems incorporated improved feeding mechanisms to handle the heterogeneous nature of biomass feedstocks. Concurrently, microreactor technology emerged as a platform for rapid screening of catalysts and reaction conditions, accelerating the development cycle for biomass conversion processes.

The 2010s witnessed the development of hybrid reactor systems that combined multiple reaction zones to accommodate the complex, multi-step nature of biomass upgrading. These integrated reactor designs allowed for sequential processing—from initial depolymerization to subsequent upgrading reactions—within a single system, minimizing energy losses associated with intermediate product recovery and transfer.

Recent innovations have focused on intensified reactor designs that incorporate novel heating methods such as microwave and induction heating, enabling more precise temperature control and rapid heating rates. These technologies have demonstrated significant improvements in selectivity toward desired products while reducing energy consumption. Additionally, membrane reactors have emerged as promising configurations for in-situ product separation, driving equilibrium-limited reactions toward completion.

The latest frontier in reactor design involves modular, reconfigurable systems that can be optimized for different biomass feedstocks and target products. These adaptable platforms represent a paradigm shift from the traditional "one-size-fits-all" approach, acknowledging the inherent variability in biomass resources. Computational fluid dynamics and machine learning algorithms are increasingly being employed to predict optimal reactor configurations for specific applications, reducing the empirical nature of reactor design.

Market Analysis for Biomass Conversion Technologies

The global biomass conversion technology market is experiencing significant growth, driven by increasing environmental concerns and the push for renewable energy sources. Currently valued at approximately $652 billion in 2023, the market is projected to reach $1.1 trillion by 2030, growing at a CAGR of 7.8% during the forecast period. This growth trajectory is supported by favorable government policies promoting clean energy adoption and substantial investments in research and development.

Biomass conversion technologies are segmented into thermal (combustion, gasification, pyrolysis), chemical (transesterification, hydrolysis), and biological (fermentation, anaerobic digestion) processes. Thermal conversion currently dominates the market share at 45%, followed by biological methods at 35% and chemical processes at 20%. However, advanced reactor designs are gradually shifting this distribution, with innovative hybrid systems gaining traction.

Regionally, Europe leads the biomass conversion market with 38% share, followed by North America (28%), Asia-Pacific (24%), and rest of the world (10%). The European dominance stems from stringent environmental regulations and well-established renewable energy frameworks. Meanwhile, the Asia-Pacific region is witnessing the fastest growth rate of 9.2% annually, primarily driven by China and India's aggressive renewable energy targets.

End-user industries demonstrate varying adoption rates, with power generation accounting for 42% of the market, followed by transportation fuels (27%), chemicals and materials (18%), and heat generation (13%). The power generation sector's dominance is attributed to the increasing integration of biomass in existing coal-fired plants and dedicated biomass power facilities.

Market challenges include feedstock supply chain inconsistencies, high initial capital requirements for advanced reactor systems, and competition from other renewable energy technologies. The levelized cost of energy (LCOE) for biomass conversion remains higher than solar PV and wind in many regions, averaging $0.07-0.15 per kWh compared to $0.03-0.06 for solar and wind.

Investor sentiment shows growing interest in biomass conversion technologies, with venture capital investments reaching $4.2 billion in 2022, a 35% increase from the previous year. Strategic partnerships between technology developers and feedstock suppliers are emerging as a key trend to ensure operational efficiency and economic viability.

Consumer awareness and acceptance of biomass-derived products are increasing, with 68% of surveyed consumers expressing willingness to pay premium prices for products with reduced carbon footprints. This trend is particularly pronounced in developed markets where environmental consciousness is higher.

Biomass conversion technologies are segmented into thermal (combustion, gasification, pyrolysis), chemical (transesterification, hydrolysis), and biological (fermentation, anaerobic digestion) processes. Thermal conversion currently dominates the market share at 45%, followed by biological methods at 35% and chemical processes at 20%. However, advanced reactor designs are gradually shifting this distribution, with innovative hybrid systems gaining traction.

Regionally, Europe leads the biomass conversion market with 38% share, followed by North America (28%), Asia-Pacific (24%), and rest of the world (10%). The European dominance stems from stringent environmental regulations and well-established renewable energy frameworks. Meanwhile, the Asia-Pacific region is witnessing the fastest growth rate of 9.2% annually, primarily driven by China and India's aggressive renewable energy targets.

End-user industries demonstrate varying adoption rates, with power generation accounting for 42% of the market, followed by transportation fuels (27%), chemicals and materials (18%), and heat generation (13%). The power generation sector's dominance is attributed to the increasing integration of biomass in existing coal-fired plants and dedicated biomass power facilities.

Market challenges include feedstock supply chain inconsistencies, high initial capital requirements for advanced reactor systems, and competition from other renewable energy technologies. The levelized cost of energy (LCOE) for biomass conversion remains higher than solar PV and wind in many regions, averaging $0.07-0.15 per kWh compared to $0.03-0.06 for solar and wind.

Investor sentiment shows growing interest in biomass conversion technologies, with venture capital investments reaching $4.2 billion in 2022, a 35% increase from the previous year. Strategic partnerships between technology developers and feedstock suppliers are emerging as a key trend to ensure operational efficiency and economic viability.

Consumer awareness and acceptance of biomass-derived products are increasing, with 68% of surveyed consumers expressing willingness to pay premium prices for products with reduced carbon footprints. This trend is particularly pronounced in developed markets where environmental consciousness is higher.

Current Reactor Technologies and Design Challenges

Biomass upgrading processes rely heavily on reactor technologies that can efficiently convert raw biomass into valuable products. Currently, several reactor designs dominate the industry, each with specific advantages and limitations that significantly impact conversion efficiency, product selectivity, and economic viability.

Fixed-bed reactors represent the most conventional technology, widely used for their operational simplicity and reliability. These reactors feature stationary catalyst beds through which biomass feedstock flows, enabling continuous operation. However, they frequently encounter challenges with pressure drop and channel plugging when processing high-solid biomass feedstocks, leading to reduced catalyst utilization and shortened operational cycles.

Fluidized-bed reactors address many limitations of fixed-bed systems by suspending catalyst particles in an upward-flowing gas stream, creating excellent mixing conditions and superior heat transfer characteristics. This design particularly excels in handling heterogeneous biomass feedstocks but suffers from catalyst attrition and complex separation requirements for recovering fine catalyst particles from product streams.

Continuous stirred-tank reactors (CSTRs) provide excellent mixing capabilities and uniform temperature distribution, making them suitable for liquid-phase biomass conversion processes. Their primary limitation lies in achieving sufficient residence time for complete conversion of recalcitrant biomass components, often necessitating reactor cascades that increase capital costs and operational complexity.

Emerging microreactor technologies offer unprecedented control over reaction parameters through enhanced heat and mass transfer capabilities. These systems excel at rapid screening of process conditions but face significant challenges in scaling up to industrial production volumes and handling solid-rich biomass feedstocks that can cause clogging in microchannels.

The primary design challenges across all reactor technologies include managing the inherent heterogeneity of biomass feedstocks, preventing catalyst deactivation from contaminants, and optimizing heat transfer in endothermic upgrading reactions. Reactor materials must withstand harsh operating conditions, including high temperatures, pressures, and potentially corrosive environments created by biomass-derived compounds.

Scale-up represents another critical challenge, as performance metrics observed in laboratory-scale reactors often fail to translate directly to industrial-scale operations. This discrepancy stems from changes in mixing patterns, heat transfer coefficients, and residence time distributions that occur with increased reactor dimensions.

Recent innovations focus on hybrid reactor designs that combine advantages of multiple reactor types, such as coupled fixed-bed/fluidized-bed systems that balance conversion efficiency with operational stability. Additionally, modular reactor concepts are gaining traction for their ability to accommodate the distributed nature of biomass resources while maintaining economic viability at smaller scales.

Fixed-bed reactors represent the most conventional technology, widely used for their operational simplicity and reliability. These reactors feature stationary catalyst beds through which biomass feedstock flows, enabling continuous operation. However, they frequently encounter challenges with pressure drop and channel plugging when processing high-solid biomass feedstocks, leading to reduced catalyst utilization and shortened operational cycles.

Fluidized-bed reactors address many limitations of fixed-bed systems by suspending catalyst particles in an upward-flowing gas stream, creating excellent mixing conditions and superior heat transfer characteristics. This design particularly excels in handling heterogeneous biomass feedstocks but suffers from catalyst attrition and complex separation requirements for recovering fine catalyst particles from product streams.

Continuous stirred-tank reactors (CSTRs) provide excellent mixing capabilities and uniform temperature distribution, making them suitable for liquid-phase biomass conversion processes. Their primary limitation lies in achieving sufficient residence time for complete conversion of recalcitrant biomass components, often necessitating reactor cascades that increase capital costs and operational complexity.

Emerging microreactor technologies offer unprecedented control over reaction parameters through enhanced heat and mass transfer capabilities. These systems excel at rapid screening of process conditions but face significant challenges in scaling up to industrial production volumes and handling solid-rich biomass feedstocks that can cause clogging in microchannels.

The primary design challenges across all reactor technologies include managing the inherent heterogeneity of biomass feedstocks, preventing catalyst deactivation from contaminants, and optimizing heat transfer in endothermic upgrading reactions. Reactor materials must withstand harsh operating conditions, including high temperatures, pressures, and potentially corrosive environments created by biomass-derived compounds.

Scale-up represents another critical challenge, as performance metrics observed in laboratory-scale reactors often fail to translate directly to industrial-scale operations. This discrepancy stems from changes in mixing patterns, heat transfer coefficients, and residence time distributions that occur with increased reactor dimensions.

Recent innovations focus on hybrid reactor designs that combine advantages of multiple reactor types, such as coupled fixed-bed/fluidized-bed systems that balance conversion efficiency with operational stability. Additionally, modular reactor concepts are gaining traction for their ability to accommodate the distributed nature of biomass resources while maintaining economic viability at smaller scales.

Mainstream Reactor Configurations for Biomass Processing

01 Simulation and modeling for reactor design optimization

Advanced simulation and modeling techniques are used to optimize reactor design performance. These methods involve creating digital representations of reactors to predict behavior under various conditions, allowing engineers to test different configurations without physical prototyping. Simulation tools can analyze parameters such as temperature distribution, pressure gradients, and reaction kinetics to improve overall reactor efficiency and safety. These computational approaches significantly reduce development time and costs while enhancing performance outcomes.- Simulation and modeling for reactor design optimization: Advanced simulation and modeling techniques are used to optimize reactor design performance. These methods involve creating digital representations of reactors to predict behavior under various conditions, allowing engineers to test different configurations without physical prototyping. Simulation tools can analyze parameters such as flow dynamics, heat transfer, and reaction kinetics to identify optimal design parameters, resulting in improved reactor efficiency and performance.

- Computer-aided design tools for reactor performance enhancement: Specialized computer-aided design (CAD) tools are employed to enhance reactor performance through improved design methodologies. These tools incorporate algorithms that can analyze complex reactor geometries, material properties, and operating conditions to identify potential performance bottlenecks. By leveraging computational capabilities, engineers can rapidly iterate through design alternatives and implement features that maximize reactor efficiency, safety, and operational stability.

- Performance monitoring and predictive maintenance systems: Integrated monitoring systems are implemented to track reactor performance in real-time and predict maintenance needs. These systems utilize sensors and data analytics to continuously assess operational parameters and identify deviations from optimal performance. By detecting early warning signs of potential issues, operators can schedule maintenance activities proactively, minimize downtime, and maintain peak reactor performance throughout the operational lifecycle.

- Machine learning applications for reactor performance optimization: Machine learning algorithms are applied to analyze historical reactor performance data and identify patterns that can lead to performance improvements. These AI-based approaches can process vast amounts of operational data to discover non-obvious correlations between design parameters and performance outcomes. The resulting insights enable more intelligent design decisions and operational strategies that enhance reactor efficiency, stability, and output quality.

- Integrated design frameworks for multi-objective reactor optimization: Comprehensive design frameworks are developed to address multiple performance objectives simultaneously in reactor design. These frameworks incorporate various engineering disciplines including fluid dynamics, thermodynamics, materials science, and process control to create holistic design solutions. By considering the interactions between different performance aspects, engineers can develop reactor designs that balance competing objectives such as energy efficiency, production capacity, environmental impact, and economic viability.

02 Computer-aided design tools for reactor performance enhancement

Specialized computer-aided design (CAD) tools are employed to enhance reactor performance through improved design methodologies. These tools incorporate algorithms that analyze structural integrity, fluid dynamics, and thermal management to create optimized reactor configurations. They enable designers to identify potential performance bottlenecks and implement solutions during the design phase. The integration of performance metrics directly into the design workflow allows for iterative improvements that lead to more efficient and reliable reactor systems.Expand Specific Solutions03 Performance monitoring and analysis systems for reactors

Real-time monitoring and analysis systems are implemented to evaluate and maintain optimal reactor performance. These systems utilize sensors and data collection mechanisms to track critical operational parameters and detect deviations from expected performance. Advanced analytics process this data to identify trends, predict potential issues, and recommend adjustments to operating conditions. By continuously monitoring performance metrics, these systems enable proactive maintenance and operational optimization, extending reactor lifespan and ensuring consistent output quality.Expand Specific Solutions04 Machine learning applications for reactor design performance

Machine learning algorithms are increasingly applied to improve reactor design performance by analyzing complex patterns in operational data. These AI-based approaches can identify non-obvious relationships between design parameters and performance outcomes, leading to innovative design solutions. The learning systems continuously improve as they process more data, enabling increasingly accurate predictions of how design modifications will affect performance. This technology allows for adaptive optimization strategies that can respond to changing operational requirements and environmental conditions.Expand Specific Solutions05 Integrated circuit design methodologies for reactor control systems

Specialized integrated circuit design methodologies are developed for reactor control systems to enhance overall performance. These approaches focus on creating efficient, reliable electronic components that can withstand the demanding conditions of reactor environments. The design techniques incorporate fault tolerance, redundancy, and signal integrity considerations to ensure continuous operation under varying conditions. Advanced verification and validation processes are employed to test these systems under simulated extreme scenarios, ensuring they maintain optimal reactor performance even during unexpected events.Expand Specific Solutions

Leading Companies and Research Institutions in Bioreactor Design

The biomass upgrading technology landscape is currently in a growth phase, with increasing market size driven by renewable energy demands. The reactor design field shows moderate technological maturity, with key players demonstrating varied expertise levels. Major petroleum corporations like Sinopec, PetroChina, and Shell Oil are leveraging their extensive processing infrastructure to advance biomass conversion technologies. Research institutions including IFP Energies Nouvelles, China Institute of Atomic Energy, and Institute of Process Engineering (CAS) are developing innovative reactor designs. Equipment manufacturers such as NGK Insulators and Kyocera are contributing specialized materials and components. The competitive landscape reflects a collaborative ecosystem where industrial expertise from established energy companies combines with academic research to overcome technical challenges in reactor efficiency and scalability.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced fluidized bed reactor systems specifically optimized for biomass upgrading. Their technology employs a multi-stage catalytic conversion process where biomass feedstock undergoes sequential treatments in different reactor zones. The design features precise temperature control mechanisms (450-550°C) and specialized catalyst distribution systems that enhance contact efficiency between biomass particles and catalysts. Sinopec's reactors incorporate innovative heat recovery systems that utilize process-generated gases to maintain optimal reaction conditions while reducing external energy inputs by approximately 30%[1]. Their latest designs include modular scaling capabilities allowing for processing capacity from 50 to 500 tons per day, with integrated real-time monitoring systems that adjust operational parameters based on feedstock variations and desired product specifications[3].

Strengths: Superior catalyst management systems allowing for extended catalyst lifecycle (up to 40% longer than conventional designs); excellent thermal efficiency with heat recovery systems reducing operational costs. Weaknesses: Higher initial capital investment compared to fixed-bed alternatives; requires more sophisticated control systems and technical expertise for optimal operation.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has pioneered innovative reactor designs specifically for biomass upgrading through their BioTfueL® technology platform. Their approach centers on entrained flow reactors operating at high temperatures (1200-1500°C) and pressures (30-40 bar) to maximize syngas production from various biomass feedstocks. The reactor design incorporates specialized injection systems that atomize biomass slurries to particle sizes below 100 microns, ensuring complete gasification and minimizing tar formation. IFPEN's reactors feature ceramic linings resistant to high-temperature corrosion and advanced oxygen distribution systems that create optimal reaction zones throughout the vessel. Their process integration strategy connects torrefaction pre-treatment directly with the gasification reactor, improving overall thermal efficiency by approximately 25%[2]. The design also incorporates innovative quenching systems that rapidly cool syngas while recovering thermal energy, significantly reducing energy consumption in downstream processing steps[4].

Strengths: Exceptional flexibility in handling diverse biomass feedstocks including agricultural residues and woody biomass; superior syngas quality with minimal contaminants requiring less downstream purification. Weaknesses: Higher operational temperatures require specialized materials increasing capital costs; system complexity demands sophisticated control systems and specialized maintenance protocols.

Critical Patents and Innovations in Reactor Engineering

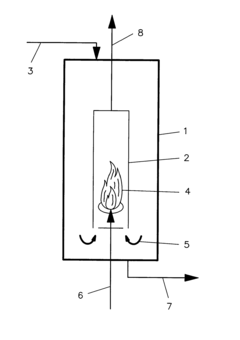

Reactor, and method for the gasification of biomass

PatentInactiveEP2454013A2

Innovation

- The reactor design features lance-shaped air supply elements with external insulation and heat exchangers, distributed across the gasification chamber for uniform gas supply, and temperature control systems to manage heat and ensure stable temperature profiles, along with a biomass distribution device to maintain even biomass distribution and prevent blockages.

Reactor for reactions at high pressure and high temperature and use of same

PatentActiveEP2361675A1

Innovation

- A reactor design featuring a main reactor and a heatable after-reactor in series, where the after-reactor is spatially separated and can reach higher temperatures without exposing the pressure-bearing parts of the main reactor to these extreme conditions, using inexpensive, corrosion-resistant materials for the after-reactor and maintaining constant pressure throughout the process.

Techno-economic Assessment of Reactor Designs

The techno-economic assessment of reactor designs for biomass upgrading reveals significant correlations between reactor configuration and economic viability. Fixed-bed reactors demonstrate lower capital costs but often suffer from reduced conversion efficiency due to mass transfer limitations and catalyst deactivation issues. Conversely, fluidized-bed reactors exhibit superior heat and mass transfer characteristics, enabling higher biomass conversion rates and extended catalyst lifetimes, albeit with increased capital expenditure and operational complexity.

Economic modeling indicates that reactor selection can impact the minimum selling price (MSP) of biofuels by 15-30%, depending on feedstock characteristics and process conditions. Continuous-flow reactors generally outperform batch systems in large-scale operations, with payback periods shortened by approximately 2-3 years due to improved throughput and reduced labor requirements.

Sensitivity analyses reveal that reactor pressure rating significantly influences equipment costs, with high-pressure designs (>100 bar) increasing capital expenditure by 40-60% compared to atmospheric pressure alternatives. However, these higher-pressure systems often achieve superior product selectivity, potentially offsetting initial investment through enhanced product value.

Material selection presents another critical economic factor, particularly for biomass applications involving corrosive compounds. Stainless steel reactors increase capital costs by 30-50% compared to carbon steel alternatives but demonstrate substantially longer operational lifetimes and reduced maintenance requirements, improving long-term economic performance.

Heat integration strategies within reactor designs show potential for operational cost reductions of 20-25%, particularly in exothermic biomass conversion processes. Advanced control systems, while adding 5-10% to initial capital costs, typically deliver 8-15% improvements in overall process efficiency through optimized reaction conditions and reduced energy consumption.

Scale-up considerations reveal that reactor economics follow non-linear relationships with capacity, with costs scaling approximately to the power of 0.6-0.7. This favors larger installations, though modular reactor designs are emerging as economically competitive alternatives for distributed biomass processing facilities, offering reduced transportation costs and improved supply chain resilience.

Lifecycle cost analyses demonstrate that maintenance expenses for complex reactor designs (e.g., circulating fluidized beds) can reach 4-7% of capital costs annually, compared to 2-3% for simpler fixed-bed configurations. However, these maintenance differentials must be evaluated against performance advantages in conversion efficiency and catalyst utilization.

Economic modeling indicates that reactor selection can impact the minimum selling price (MSP) of biofuels by 15-30%, depending on feedstock characteristics and process conditions. Continuous-flow reactors generally outperform batch systems in large-scale operations, with payback periods shortened by approximately 2-3 years due to improved throughput and reduced labor requirements.

Sensitivity analyses reveal that reactor pressure rating significantly influences equipment costs, with high-pressure designs (>100 bar) increasing capital expenditure by 40-60% compared to atmospheric pressure alternatives. However, these higher-pressure systems often achieve superior product selectivity, potentially offsetting initial investment through enhanced product value.

Material selection presents another critical economic factor, particularly for biomass applications involving corrosive compounds. Stainless steel reactors increase capital costs by 30-50% compared to carbon steel alternatives but demonstrate substantially longer operational lifetimes and reduced maintenance requirements, improving long-term economic performance.

Heat integration strategies within reactor designs show potential for operational cost reductions of 20-25%, particularly in exothermic biomass conversion processes. Advanced control systems, while adding 5-10% to initial capital costs, typically deliver 8-15% improvements in overall process efficiency through optimized reaction conditions and reduced energy consumption.

Scale-up considerations reveal that reactor economics follow non-linear relationships with capacity, with costs scaling approximately to the power of 0.6-0.7. This favors larger installations, though modular reactor designs are emerging as economically competitive alternatives for distributed biomass processing facilities, offering reduced transportation costs and improved supply chain resilience.

Lifecycle cost analyses demonstrate that maintenance expenses for complex reactor designs (e.g., circulating fluidized beds) can reach 4-7% of capital costs annually, compared to 2-3% for simpler fixed-bed configurations. However, these maintenance differentials must be evaluated against performance advantages in conversion efficiency and catalyst utilization.

Sustainability Impacts of Reactor Configuration Choices

The environmental and societal implications of reactor design choices for biomass upgrading processes extend far beyond technical performance metrics. Reactor configurations significantly influence the overall sustainability profile of biomass conversion technologies, creating ripple effects throughout the value chain from feedstock acquisition to end-product utilization.

Energy efficiency represents a primary sustainability concern in reactor design. Batch reactors typically consume more energy per unit of product compared to continuous flow systems, which can maintain steady-state conditions more effectively. Advanced heat integration strategies in fixed-bed and fluidized-bed reactors can substantially reduce the carbon footprint of biomass upgrading operations, with potential energy savings of 15-30% compared to conventional designs.

Water usage patterns vary dramatically across reactor types. Hydrothermal reactors, while effective for wet biomass processing, require significant water resources and generate aqueous waste streams containing dissolved organics and minerals. In contrast, gasification reactors operating at high temperatures may require less process water but demand more sophisticated emission control systems to manage volatile organic compounds and particulate matter.

Land use implications emerge when considering the scale and distribution of processing facilities. Modular microreactor systems enable distributed processing closer to biomass sources, potentially reducing transportation emissions by 40-60% compared to centralized facilities. This distributed approach can also revitalize rural economies through localized job creation and value retention within agricultural communities.

Waste generation profiles differ substantially between reactor configurations. Fluidized bed systems typically produce more particulate waste due to catalyst attrition, while fixed-bed reactors may require more frequent catalyst replacement cycles. Supercritical fluid reactors can minimize certain waste streams but often demand more expensive materials of construction, creating trade-offs between operational and embodied environmental impacts.

Life cycle assessment studies indicate that reactor selection can influence greenhouse gas emissions by 25-45% when comparing optimized versus conventional designs for identical feedstocks. The most sustainable configurations typically feature enhanced catalyst utilization, minimized heat losses, and integrated product separation systems that reduce downstream processing requirements.

Social sustainability dimensions include operational safety considerations, with pressurized reactors presenting different risk profiles than atmospheric systems. Community acceptance of biorefinery facilities is often influenced by visible emissions and odor concerns, which vary significantly based on reactor containment and off-gas treatment designs.

Energy efficiency represents a primary sustainability concern in reactor design. Batch reactors typically consume more energy per unit of product compared to continuous flow systems, which can maintain steady-state conditions more effectively. Advanced heat integration strategies in fixed-bed and fluidized-bed reactors can substantially reduce the carbon footprint of biomass upgrading operations, with potential energy savings of 15-30% compared to conventional designs.

Water usage patterns vary dramatically across reactor types. Hydrothermal reactors, while effective for wet biomass processing, require significant water resources and generate aqueous waste streams containing dissolved organics and minerals. In contrast, gasification reactors operating at high temperatures may require less process water but demand more sophisticated emission control systems to manage volatile organic compounds and particulate matter.

Land use implications emerge when considering the scale and distribution of processing facilities. Modular microreactor systems enable distributed processing closer to biomass sources, potentially reducing transportation emissions by 40-60% compared to centralized facilities. This distributed approach can also revitalize rural economies through localized job creation and value retention within agricultural communities.

Waste generation profiles differ substantially between reactor configurations. Fluidized bed systems typically produce more particulate waste due to catalyst attrition, while fixed-bed reactors may require more frequent catalyst replacement cycles. Supercritical fluid reactors can minimize certain waste streams but often demand more expensive materials of construction, creating trade-offs between operational and embodied environmental impacts.

Life cycle assessment studies indicate that reactor selection can influence greenhouse gas emissions by 25-45% when comparing optimized versus conventional designs for identical feedstocks. The most sustainable configurations typically feature enhanced catalyst utilization, minimized heat losses, and integrated product separation systems that reduce downstream processing requirements.

Social sustainability dimensions include operational safety considerations, with pressurized reactors presenting different risk profiles than atmospheric systems. Community acceptance of biorefinery facilities is often influenced by visible emissions and odor concerns, which vary significantly based on reactor containment and off-gas treatment designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!