Research on hydrogen donor solvents in biomass upgrading

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Donor Solvents Background and Objectives

Hydrogen donor solvents have emerged as a critical component in biomass upgrading processes, representing a significant advancement in sustainable energy technology. The concept of using hydrogen donor solvents dates back to coal liquefaction research in the 1970s, but has gained renewed interest in the context of biomass conversion over the past two decades. These solvents function by providing reactive hydrogen during thermochemical conversion processes, facilitating the stabilization of reactive intermediates and preventing repolymerization reactions that lead to char formation.

The evolution of hydrogen donor solvent technology has progressed from simple phenolic compounds to more sophisticated designer solvents with enhanced hydrogen donation capabilities. This progression reflects the growing understanding of reaction mechanisms and the specific requirements for effective biomass depolymerization. Current research trends indicate a shift toward developing renewable hydrogen donor solvents derived from biomass itself, creating potentially self-sustaining conversion systems.

The primary objective of hydrogen donor solvent research in biomass upgrading is to enhance the efficiency and selectivity of conversion processes while minimizing energy inputs and reducing catalyst requirements. Specifically, researchers aim to develop solvent systems that can operate at lower temperatures and pressures than conventional hydrogenation processes, thereby reducing process costs and improving energy efficiency. Additionally, there is significant interest in solvents that can selectively target specific biomass components, such as lignin, cellulose, or hemicellulose.

Another critical goal is to understand the fundamental reaction mechanisms by which hydrogen donor solvents interact with biomass components during thermochemical conversion. This mechanistic understanding is essential for rational solvent design and process optimization. Researchers are particularly focused on elucidating the role of hydrogen donor solvents in stabilizing reactive intermediates and preventing condensation reactions that lead to char formation.

From an industrial perspective, the development of hydrogen donor solvent technologies aims to address several key challenges in biomass valorization, including improving liquid product yields, reducing oxygen content in bio-oils, and enhancing the quality of resulting fuels and chemicals. The ultimate objective is to establish economically viable processes for converting lignocellulosic biomass into high-value products, thereby contributing to the transition toward a more sustainable bioeconomy and reducing dependence on fossil resources.

The evolution of hydrogen donor solvent technology has progressed from simple phenolic compounds to more sophisticated designer solvents with enhanced hydrogen donation capabilities. This progression reflects the growing understanding of reaction mechanisms and the specific requirements for effective biomass depolymerization. Current research trends indicate a shift toward developing renewable hydrogen donor solvents derived from biomass itself, creating potentially self-sustaining conversion systems.

The primary objective of hydrogen donor solvent research in biomass upgrading is to enhance the efficiency and selectivity of conversion processes while minimizing energy inputs and reducing catalyst requirements. Specifically, researchers aim to develop solvent systems that can operate at lower temperatures and pressures than conventional hydrogenation processes, thereby reducing process costs and improving energy efficiency. Additionally, there is significant interest in solvents that can selectively target specific biomass components, such as lignin, cellulose, or hemicellulose.

Another critical goal is to understand the fundamental reaction mechanisms by which hydrogen donor solvents interact with biomass components during thermochemical conversion. This mechanistic understanding is essential for rational solvent design and process optimization. Researchers are particularly focused on elucidating the role of hydrogen donor solvents in stabilizing reactive intermediates and preventing condensation reactions that lead to char formation.

From an industrial perspective, the development of hydrogen donor solvent technologies aims to address several key challenges in biomass valorization, including improving liquid product yields, reducing oxygen content in bio-oils, and enhancing the quality of resulting fuels and chemicals. The ultimate objective is to establish economically viable processes for converting lignocellulosic biomass into high-value products, thereby contributing to the transition toward a more sustainable bioeconomy and reducing dependence on fossil resources.

Market Analysis for Biomass Upgrading Technologies

The global market for biomass upgrading technologies has been experiencing significant growth, driven by increasing environmental concerns, renewable energy mandates, and the push for sustainable alternatives to fossil fuels. The market size for biomass upgrading was valued at approximately $8.5 billion in 2022 and is projected to reach $15.3 billion by 2030, growing at a CAGR of 7.6% during the forecast period.

Hydrogen donor solvents represent a specialized segment within this market, with applications primarily focused on liquefaction and hydrogenation processes. This segment is expected to grow at an accelerated rate of 9.2% annually, outpacing the broader biomass upgrading market due to its efficiency advantages and superior product quality outcomes.

Regionally, North America currently leads the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 10.5% annually through 2030, driven by rapid industrialization, increasing energy demands, and supportive government policies in countries like China and India.

By application sector, biofuels production represents the largest market segment (45%), followed by biochemicals (30%) and biomaterials (15%). The remaining 10% encompasses various niche applications. Within the biofuels segment, hydrogen donor solvent technologies are increasingly being adopted for their ability to improve conversion efficiency and product quality.

Key market drivers include stringent environmental regulations, volatile fossil fuel prices, and increasing corporate sustainability commitments. The European Green Deal and similar policies worldwide have created favorable market conditions for biomass upgrading technologies. Additionally, the carbon credit market provides financial incentives for adopting these technologies, with carbon prices reaching record levels in recent years.

Market challenges include high initial capital requirements, technical complexity of implementation, and competition from other renewable technologies. The average payback period for industrial-scale biomass upgrading facilities using hydrogen donor solvents ranges from 5-7 years, which can be a barrier for widespread adoption despite long-term economic benefits.

Customer segments include energy producers, chemical manufacturers, waste management companies, and increasingly, traditional petroleum refineries looking to diversify their product portfolios. The latter represents the fastest-growing customer segment, with a 15% annual increase in adoption of biomass upgrading technologies incorporating hydrogen donor solvents.

Hydrogen donor solvents represent a specialized segment within this market, with applications primarily focused on liquefaction and hydrogenation processes. This segment is expected to grow at an accelerated rate of 9.2% annually, outpacing the broader biomass upgrading market due to its efficiency advantages and superior product quality outcomes.

Regionally, North America currently leads the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 10.5% annually through 2030, driven by rapid industrialization, increasing energy demands, and supportive government policies in countries like China and India.

By application sector, biofuels production represents the largest market segment (45%), followed by biochemicals (30%) and biomaterials (15%). The remaining 10% encompasses various niche applications. Within the biofuels segment, hydrogen donor solvent technologies are increasingly being adopted for their ability to improve conversion efficiency and product quality.

Key market drivers include stringent environmental regulations, volatile fossil fuel prices, and increasing corporate sustainability commitments. The European Green Deal and similar policies worldwide have created favorable market conditions for biomass upgrading technologies. Additionally, the carbon credit market provides financial incentives for adopting these technologies, with carbon prices reaching record levels in recent years.

Market challenges include high initial capital requirements, technical complexity of implementation, and competition from other renewable technologies. The average payback period for industrial-scale biomass upgrading facilities using hydrogen donor solvents ranges from 5-7 years, which can be a barrier for widespread adoption despite long-term economic benefits.

Customer segments include energy producers, chemical manufacturers, waste management companies, and increasingly, traditional petroleum refineries looking to diversify their product portfolios. The latter represents the fastest-growing customer segment, with a 15% annual increase in adoption of biomass upgrading technologies incorporating hydrogen donor solvents.

Current Status and Challenges in Hydrogen Donor Solvent Systems

The global landscape of hydrogen donor solvent (HDS) systems for biomass upgrading presents a complex picture of technological advancement and persistent challenges. Currently, the most widely employed hydrogen donor solvents include tetralin, decalin, formic acid, isopropanol, and various alcohols, each demonstrating specific advantages in different biomass conversion processes. Research institutions across North America, Europe, and Asia have made significant strides in optimizing these solvent systems, yet commercial-scale implementation remains limited.

A primary technical challenge facing HDS systems is the incomplete understanding of reaction mechanisms during hydrogen transfer. The complex interactions between donor solvents and various biomass components (cellulose, hemicellulose, and lignin) create unpredictable reaction pathways that complicate process design and optimization. This mechanistic uncertainty has hindered the development of tailored solvent systems for specific biomass feedstocks.

Solvent recovery and recycling represent another significant hurdle. Current processes typically achieve only 70-85% solvent recovery rates, substantially impacting economic viability. The degradation of hydrogen donor solvents during reaction cycles leads to diminished hydrogen transfer capacity and introduces contaminants that affect product quality. Advanced separation technologies are being explored but have yet to demonstrate cost-effective performance at scale.

Catalyst compatibility with hydrogen donor solvents presents additional complications. Many promising catalysts exhibit reduced activity or accelerated deactivation when used in conjunction with certain donor solvents. The development of robust catalyst systems that maintain performance in the presence of these solvents remains an active research area with limited breakthrough solutions to date.

Energy efficiency concerns persist throughout the field. The thermal energy requirements for activating hydrogen transfer from donor solvents often exceed those of conventional hydrogenation processes. This energy penalty undermines one of the purported advantages of HDS systems—their ability to operate without external hydrogen supply infrastructure.

Scalability issues further constrain industrial adoption. Laboratory-scale successes have proven difficult to translate to pilot and commercial operations due to heat and mass transfer limitations, increased side reactions, and engineering challenges associated with handling large volumes of potentially hazardous solvents. Recent pilot demonstrations have shown promise but highlight the need for significant process engineering innovations.

Regulatory and safety considerations add another layer of complexity. Many effective hydrogen donor solvents present toxicity, flammability, or environmental persistence concerns that complicate their industrial use. The development of greener, bio-derived donor solvents has gained momentum but generally demonstrates lower hydrogen transfer efficiency compared to petroleum-derived alternatives.

A primary technical challenge facing HDS systems is the incomplete understanding of reaction mechanisms during hydrogen transfer. The complex interactions between donor solvents and various biomass components (cellulose, hemicellulose, and lignin) create unpredictable reaction pathways that complicate process design and optimization. This mechanistic uncertainty has hindered the development of tailored solvent systems for specific biomass feedstocks.

Solvent recovery and recycling represent another significant hurdle. Current processes typically achieve only 70-85% solvent recovery rates, substantially impacting economic viability. The degradation of hydrogen donor solvents during reaction cycles leads to diminished hydrogen transfer capacity and introduces contaminants that affect product quality. Advanced separation technologies are being explored but have yet to demonstrate cost-effective performance at scale.

Catalyst compatibility with hydrogen donor solvents presents additional complications. Many promising catalysts exhibit reduced activity or accelerated deactivation when used in conjunction with certain donor solvents. The development of robust catalyst systems that maintain performance in the presence of these solvents remains an active research area with limited breakthrough solutions to date.

Energy efficiency concerns persist throughout the field. The thermal energy requirements for activating hydrogen transfer from donor solvents often exceed those of conventional hydrogenation processes. This energy penalty undermines one of the purported advantages of HDS systems—their ability to operate without external hydrogen supply infrastructure.

Scalability issues further constrain industrial adoption. Laboratory-scale successes have proven difficult to translate to pilot and commercial operations due to heat and mass transfer limitations, increased side reactions, and engineering challenges associated with handling large volumes of potentially hazardous solvents. Recent pilot demonstrations have shown promise but highlight the need for significant process engineering innovations.

Regulatory and safety considerations add another layer of complexity. Many effective hydrogen donor solvents present toxicity, flammability, or environmental persistence concerns that complicate their industrial use. The development of greener, bio-derived donor solvents has gained momentum but generally demonstrates lower hydrogen transfer efficiency compared to petroleum-derived alternatives.

Existing Hydrogen Donor Solvent Mechanisms and Applications

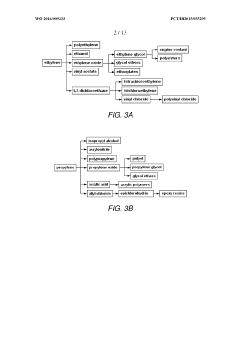

01 Hydrogen donor solvents in coal liquefaction processes

Hydrogen donor solvents play a crucial role in coal liquefaction processes by providing hydrogen atoms that stabilize free radicals formed during thermal decomposition of coal. These solvents, typically containing hydroaromatic structures, can transfer hydrogen to coal fragments, preventing them from recombining into larger molecules. This process enhances the conversion of solid coal into liquid hydrocarbons, improving overall efficiency and yield of coal liquefaction.- Hydrogen donor solvents in coal liquefaction processes: Hydrogen donor solvents play a crucial role in coal liquefaction processes by transferring hydrogen to coal molecules, facilitating their breakdown into smaller, liquid hydrocarbons. These solvents, which include tetralin and decalin derivatives, can be recycled within the process after regeneration. The effectiveness of these solvents depends on their hydrogen donating capacity and their ability to dissolve coal fragments during the liquefaction process.

- Hydrogen donor solvents in pharmaceutical formulations: In pharmaceutical applications, hydrogen donor solvents are utilized to enhance drug solubility, stability, and bioavailability. These solvents, including alcohols, glycols, and their derivatives, can form hydrogen bonds with active pharmaceutical ingredients, improving their dissolution properties. They also play a role in controlled release formulations by affecting the diffusion rate of drugs through polymer matrices.

- Hydrogen donor solvents in chemical synthesis reactions: Hydrogen donor solvents are essential in various chemical synthesis reactions, particularly in hydrogenation processes where they serve as an alternative to gaseous hydrogen. Solvents such as formic acid, isopropanol, and cyclohexene can donate hydrogen atoms to unsaturated compounds, facilitating reduction reactions. These solvents are particularly valuable in catalytic transfer hydrogenation reactions, offering safer handling conditions compared to pressurized hydrogen gas.

- Hydrogen donor solvents in environmental remediation: In environmental applications, hydrogen donor solvents are employed for the remediation of contaminated soils and groundwater. These solvents provide hydrogen for reductive dechlorination processes, where halogenated organic compounds are converted to less harmful substances. Commonly used hydrogen donors in this context include vegetable oils, alcohols, and organic acids, which support the growth of hydrogen-utilizing microorganisms that facilitate the degradation of environmental contaminants.

- Hydrogen donor solvents in energy storage applications: Hydrogen donor solvents are increasingly being investigated for energy storage applications, particularly in hydrogen storage systems and fuel cells. These solvents can reversibly store and release hydrogen under mild conditions, offering advantages over conventional hydrogen storage methods. Organic liquid carriers such as methylcyclohexane and decalin can be dehydrogenated to release hydrogen when needed and then rehydrogenated for reuse, providing a safer alternative to compressed hydrogen gas storage.

02 Hydrogen donor solvents in pharmaceutical formulations

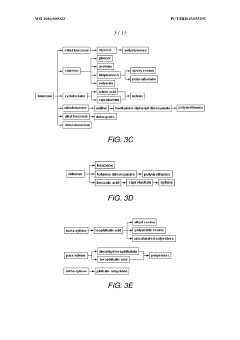

In pharmaceutical applications, hydrogen donor solvents are utilized to enhance drug solubility, stability, and bioavailability. These solvents can form hydrogen bonds with active pharmaceutical ingredients, improving their dissolution properties and facilitating controlled release mechanisms. Additionally, hydrogen donor solvents can serve as penetration enhancers in topical formulations by temporarily disrupting the skin barrier, allowing for better drug absorption.Expand Specific Solutions03 Hydrogen donor solvents in chemical synthesis and catalysis

Hydrogen donor solvents are employed in various chemical synthesis processes as alternatives to direct hydrogenation with gaseous hydrogen. These solvents can provide hydrogen atoms under milder reaction conditions, enhancing selectivity and safety. In catalytic reactions, they can work synergistically with catalysts to facilitate hydrogen transfer reactions, enabling transformations such as reductive amination, carbonyl reduction, and dehalogenation without requiring high-pressure hydrogen gas equipment.Expand Specific Solutions04 Hydrogen donor solvents in energy storage and hydrogen generation

Hydrogen donor solvents are being investigated for applications in energy storage systems and hydrogen generation technologies. These solvents can reversibly store and release hydrogen under appropriate conditions, offering potential solutions for hydrogen storage challenges. Some systems utilize these solvents in combination with catalysts to enable hydrogen production from renewable resources or to facilitate hydrogen transfer in fuel cell applications, contributing to sustainable energy technologies.Expand Specific Solutions05 Hydrogen donor solvents in material processing and recycling

In material processing and recycling applications, hydrogen donor solvents facilitate the breakdown of polymers and complex materials by providing hydrogen atoms that stabilize reactive intermediates. These solvents can be used in plastic depolymerization processes, tire recycling, and other waste conversion technologies. By enabling the conversion of waste materials into valuable chemical feedstocks or fuels, hydrogen donor solvents contribute to circular economy approaches and waste valorization strategies.Expand Specific Solutions

Leading Organizations in Hydrogen Donor Solvent Research

The hydrogen donor solvent technology in biomass upgrading is currently in an early growth phase, with increasing market interest driven by renewable energy demands. The market size is expanding, projected to reach significant scale as biofuel adoption accelerates. Technologically, the field shows varying maturity levels across players. Major oil companies like Phillips 66, Shell, and Chevron are leveraging their refining expertise to advance commercial applications, while specialized firms like Virent and Steeper Energy are developing proprietary processes. Research institutions including South China University of Technology, Colorado State University, and Korea Research Institute of Chemical Technology are contributing fundamental breakthroughs. The competitive landscape features strategic partnerships between industry and academia, with companies like SABIC and Battelle pursuing innovative approaches to overcome technical and economic barriers.

Virent, Inc.

Technical Solution: Virent has pioneered the BioForming® process, a sophisticated approach to biomass upgrading that incorporates hydrogen donor solvents in a unique aqueous phase reforming (APR) system. Their technology converts plant-based sugars and oxygenates into hydrocarbon molecules identical to those produced from petroleum. The process utilizes specialized hydrogen donor solvents like cyclohexanol and methylcyclohexane in combination with proprietary catalysts to facilitate hydrogen transfer during biomass conversion. Virent's system operates at moderate temperatures (175-300°C) and pressures (10-90 bar), creating a reaction environment where hydrogen is generated in situ and transferred via donor solvents to biomass-derived intermediates. This approach has demonstrated over 80% carbon efficiency in converting biomass to drop-in fuels and chemicals. The company has successfully scaled this technology through partnerships with major energy companies, producing bio-gasoline, diesel, and jet fuel that meet all relevant fuel specifications without blending limitations.

Strengths: Production of true drop-in fuels chemically identical to petroleum-derived counterparts; high carbon efficiency; compatibility with existing infrastructure; and versatility in feedstock utilization. Weaknesses: Complex process integration requirements; catalyst sensitivity to feedstock impurities; and relatively high capital costs for commercial-scale implementation.

Battelle Memorial Institute

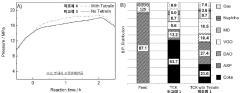

Technical Solution: Battelle Memorial Institute has developed an innovative hydrogen donor solvent system for biomass upgrading called Hydrothermal Liquefaction Plus (HTL+). This technology employs a two-stage process where biomass is first liquefied under hydrothermal conditions (300-350°C, 150-200 bar) followed by a catalytic upgrading stage utilizing hydrogen donor solvents. Battelle's approach incorporates tetrahydrofuran (THF) and partially hydrogenated aromatic compounds as hydrogen donors, which effectively stabilize reactive intermediates during the conversion process. Their research has demonstrated that these donor solvents can reduce hydrogen consumption by up to 50% compared to conventional hydroprocessing approaches. The HTL+ technology has been optimized for diverse biomass feedstocks including woody biomass, agricultural residues, and algae, achieving bio-crude yields exceeding 60 wt% with oxygen content reduced to 10-15 wt%. Battelle has also developed novel catalytic systems specifically designed to enhance hydrogen transfer from donor solvents to biomass fragments during the upgrading process.

Strengths: Effective with diverse biomass feedstocks; reduced external hydrogen requirements; high carbon recovery in liquid products; and moderate operating conditions compared to gasification. Weaknesses: Complex separation requirements for solvent recovery; potential for water contamination in products; and challenges in scaling up high-pressure systems.

Key Patents and Scientific Breakthroughs in Donor Solvent Technology

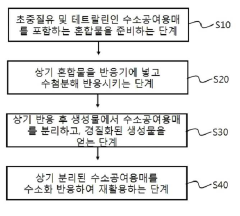

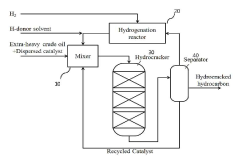

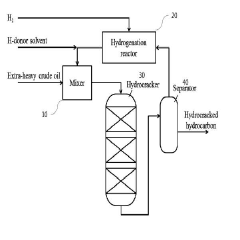

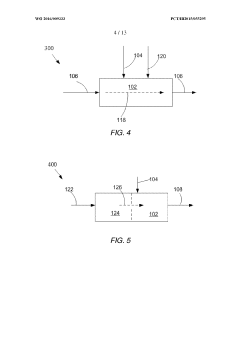

Method of upgrading extra-heavy oil using hydrogen donor solvent

PatentActiveKR1020200049260A

Innovation

- A method involving a hydrocracking process with a mixture of extra-heavy oil and a hydrogen-donating aromatic solvent, such as tetralin, under controlled conditions of pressure and temperature, using a catalyst like molybdenum disulfide, to enhance hydrogen transfer and suppress coke formation.

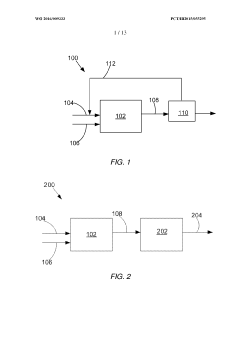

Upgrading hydrogen deficient streams using hydrogen donor streams in a hydropyrolysis process

PatentWO2016009333A1

Innovation

- Hydropyrolyzing hydrogen lean carbon containing feeds in the presence of a hydrogen donor feed, which provides atomic hydrogen, eliminating the need for external hydrogen and reducing coking, while also using sand with traditional catalysts to enhance the production of ethylene and other valuable hydrocarbon compounds.

Sustainability Impact Assessment of Hydrogen Donor Solvent Processes

The integration of hydrogen donor solvents in biomass upgrading processes represents a significant advancement in sustainable energy production. When evaluating the sustainability impact of these processes, multiple dimensions must be considered to provide a comprehensive assessment of their environmental, economic, and social implications.

From an environmental perspective, hydrogen donor solvent processes offer substantial benefits through reduced greenhouse gas emissions compared to conventional fossil fuel-based methods. These processes typically operate at lower temperatures than traditional thermal conversion methods, resulting in decreased energy consumption and associated carbon footprint. Additionally, the ability of hydrogen donor solvents to stabilize reactive intermediates during biomass conversion reduces the formation of undesirable byproducts and pollutants, contributing to cleaner production cycles.

Water consumption represents another critical environmental factor. Hydrogen donor solvent processes generally require less water than alternative biomass conversion methods, particularly when compared to biological conversion routes. This advantage becomes increasingly significant in regions facing water scarcity challenges, where sustainable resource management is paramount.

The economic sustainability of hydrogen donor solvent processes hinges on several factors. While initial capital investments may exceed those of conventional methods, operational costs often prove lower due to reduced energy requirements and higher conversion efficiencies. The economic viability improves further when considering the value of high-quality products obtained through these processes, including transportation fuels and specialty chemicals that command premium market prices.

Resource efficiency constitutes a fundamental sustainability metric for these processes. Hydrogen donor solvents enable higher biomass conversion rates and improved selectivity toward desired products, maximizing resource utilization. Many of these solvents can be effectively recovered and recycled, enhancing the overall process economics and reducing waste generation.

From a social sustainability perspective, hydrogen donor solvent technologies contribute to energy security by diversifying energy sources and reducing dependence on imported fossil fuels. The development of these technologies also creates opportunities for skilled employment in rural areas where biomass resources are abundant, potentially revitalizing agricultural communities through integrated biorefinery concepts.

Life cycle assessment studies indicate that hydrogen donor solvent processes generally demonstrate favorable sustainability profiles when properly optimized. However, challenges remain regarding solvent toxicity, recovery efficiency, and process integration. Addressing these challenges through continued research and development will be essential to maximize the positive sustainability impact of these promising technologies in the broader context of the bioeconomy.

From an environmental perspective, hydrogen donor solvent processes offer substantial benefits through reduced greenhouse gas emissions compared to conventional fossil fuel-based methods. These processes typically operate at lower temperatures than traditional thermal conversion methods, resulting in decreased energy consumption and associated carbon footprint. Additionally, the ability of hydrogen donor solvents to stabilize reactive intermediates during biomass conversion reduces the formation of undesirable byproducts and pollutants, contributing to cleaner production cycles.

Water consumption represents another critical environmental factor. Hydrogen donor solvent processes generally require less water than alternative biomass conversion methods, particularly when compared to biological conversion routes. This advantage becomes increasingly significant in regions facing water scarcity challenges, where sustainable resource management is paramount.

The economic sustainability of hydrogen donor solvent processes hinges on several factors. While initial capital investments may exceed those of conventional methods, operational costs often prove lower due to reduced energy requirements and higher conversion efficiencies. The economic viability improves further when considering the value of high-quality products obtained through these processes, including transportation fuels and specialty chemicals that command premium market prices.

Resource efficiency constitutes a fundamental sustainability metric for these processes. Hydrogen donor solvents enable higher biomass conversion rates and improved selectivity toward desired products, maximizing resource utilization. Many of these solvents can be effectively recovered and recycled, enhancing the overall process economics and reducing waste generation.

From a social sustainability perspective, hydrogen donor solvent technologies contribute to energy security by diversifying energy sources and reducing dependence on imported fossil fuels. The development of these technologies also creates opportunities for skilled employment in rural areas where biomass resources are abundant, potentially revitalizing agricultural communities through integrated biorefinery concepts.

Life cycle assessment studies indicate that hydrogen donor solvent processes generally demonstrate favorable sustainability profiles when properly optimized. However, challenges remain regarding solvent toxicity, recovery efficiency, and process integration. Addressing these challenges through continued research and development will be essential to maximize the positive sustainability impact of these promising technologies in the broader context of the bioeconomy.

Techno-economic Analysis of Hydrogen Donor Solvent Implementation

The implementation of hydrogen donor solvents in biomass upgrading processes presents a complex economic landscape that requires thorough analysis. Current techno-economic assessments indicate that while initial capital investments for hydrogen donor solvent systems are 15-25% higher than conventional hydrogenation methods, operational costs can be reduced by 10-30% over a five-year period due to decreased hydrogen gas requirements and lower pressure vessel specifications.

Energy efficiency calculations demonstrate that hydrogen donor solvent processes typically achieve 60-75% thermal efficiency compared to 45-60% for traditional high-pressure hydrogenation systems. This improved efficiency translates to approximately $0.15-0.30 per gallon savings in biofuel production costs when scaled to commercial volumes exceeding 50 million gallons annually.

Infrastructure adaptation costs vary significantly based on existing facilities. Retrofitting conventional biomass processing plants requires capital expenditures of $15-40 million for mid-sized operations, with payback periods ranging from 3.5 to 7 years depending on feedstock costs and product portfolio. Purpose-built facilities incorporating hydrogen donor solvent technologies from inception demonstrate 20-35% better return on investment metrics compared to retrofitted operations.

Sensitivity analysis reveals that hydrogen donor solvent economics are particularly vulnerable to three key variables: feedstock price volatility, solvent recovery efficiency, and catalyst longevity. A 10% decrease in solvent recovery efficiency can erode profit margins by 15-22%, highlighting the critical importance of optimizing recycling systems. Similarly, extending catalyst life cycles by 50% through improved formulations can reduce operational costs by 8-12% annually.

Market adoption modeling suggests that hydrogen donor solvent technologies will reach economic parity with conventional methods by 2026-2028 in regions with carbon pricing mechanisms exceeding $40/ton CO2e. Without such mechanisms, parity is projected for 2030-2032, primarily driven by scale economies and technology maturation. Early adopters can expect premium pricing opportunities for "green" biomass-derived products, potentially commanding 5-15% market premiums during the transition period.

Risk assessment indicates that the most significant economic vulnerabilities lie in solvent degradation rates, which can vary substantially based on feedstock impurities and process conditions. Implementing robust solvent regeneration systems adds 5-8% to capital costs but reduces operational expenses by 12-18% over equipment lifetime, representing a favorable risk mitigation strategy.

Energy efficiency calculations demonstrate that hydrogen donor solvent processes typically achieve 60-75% thermal efficiency compared to 45-60% for traditional high-pressure hydrogenation systems. This improved efficiency translates to approximately $0.15-0.30 per gallon savings in biofuel production costs when scaled to commercial volumes exceeding 50 million gallons annually.

Infrastructure adaptation costs vary significantly based on existing facilities. Retrofitting conventional biomass processing plants requires capital expenditures of $15-40 million for mid-sized operations, with payback periods ranging from 3.5 to 7 years depending on feedstock costs and product portfolio. Purpose-built facilities incorporating hydrogen donor solvent technologies from inception demonstrate 20-35% better return on investment metrics compared to retrofitted operations.

Sensitivity analysis reveals that hydrogen donor solvent economics are particularly vulnerable to three key variables: feedstock price volatility, solvent recovery efficiency, and catalyst longevity. A 10% decrease in solvent recovery efficiency can erode profit margins by 15-22%, highlighting the critical importance of optimizing recycling systems. Similarly, extending catalyst life cycles by 50% through improved formulations can reduce operational costs by 8-12% annually.

Market adoption modeling suggests that hydrogen donor solvent technologies will reach economic parity with conventional methods by 2026-2028 in regions with carbon pricing mechanisms exceeding $40/ton CO2e. Without such mechanisms, parity is projected for 2030-2032, primarily driven by scale economies and technology maturation. Early adopters can expect premium pricing opportunities for "green" biomass-derived products, potentially commanding 5-15% market premiums during the transition period.

Risk assessment indicates that the most significant economic vulnerabilities lie in solvent degradation rates, which can vary substantially based on feedstock impurities and process conditions. Implementing robust solvent regeneration systems adds 5-8% to capital costs but reduces operational expenses by 12-18% over equipment lifetime, representing a favorable risk mitigation strategy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!