Biomass upgrading with metal oxide catalyst systems

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomass Catalytic Upgrading Background and Objectives

Biomass conversion to value-added products represents a critical pathway toward sustainable energy and chemical production in the face of diminishing fossil fuel resources and increasing environmental concerns. The evolution of biomass upgrading technologies has progressed significantly over the past decades, transitioning from simple combustion methods to sophisticated catalytic conversion processes that enable selective transformation of complex biomolecules into targeted products.

Metal oxide catalyst systems have emerged as particularly promising platforms for biomass valorization due to their tunable properties, abundance, and versatility. Historically, biomass conversion relied heavily on homogeneous catalysts and harsh reaction conditions, resulting in poor selectivity and substantial waste generation. The paradigm shift toward heterogeneous metal oxide catalysts began in the early 2000s, with pioneering work demonstrating their efficacy in selective oxidation and hydrodeoxygenation reactions of biomass-derived compounds.

The technological trajectory has been characterized by continuous improvements in catalyst design, moving from simple metal oxides to complex mixed metal oxide systems with precisely engineered surface properties. Recent advances in nanotechnology and materials science have further accelerated this field, enabling the development of hierarchical catalyst structures with optimized mass transfer properties and enhanced active site accessibility.

Current research focuses on addressing the inherent challenges associated with biomass feedstocks, particularly their high oxygen content, complex structure, and variability. Metal oxide catalysts offer unique advantages in this context, as they can be tailored to perform multiple functions simultaneously, including C-O bond activation, selective oxidation, and hydrodeoxygenation.

The primary objectives of biomass catalytic upgrading with metal oxide systems encompass several dimensions. From a technical perspective, the goal is to develop robust catalyst formulations that maintain activity and selectivity under the challenging conditions imposed by biomass-derived substrates, including the presence of water and potential catalyst poisons. Process intensification represents another critical objective, aiming to reduce energy requirements and increase throughput while maintaining product quality.

From a broader perspective, the ultimate aim is to establish economically viable and environmentally sustainable processes for converting diverse biomass feedstocks into platform chemicals, fuels, and materials that can directly substitute petroleum-derived products. This includes developing integrated biorefinery concepts where metal oxide catalysts play central roles in multiple conversion steps, maximizing resource utilization and minimizing waste generation.

The technological evolution in this field continues to accelerate, driven by advances in computational modeling, in-situ characterization techniques, and high-throughput experimentation methodologies that enable more rational catalyst design and faster optimization cycles.

Metal oxide catalyst systems have emerged as particularly promising platforms for biomass valorization due to their tunable properties, abundance, and versatility. Historically, biomass conversion relied heavily on homogeneous catalysts and harsh reaction conditions, resulting in poor selectivity and substantial waste generation. The paradigm shift toward heterogeneous metal oxide catalysts began in the early 2000s, with pioneering work demonstrating their efficacy in selective oxidation and hydrodeoxygenation reactions of biomass-derived compounds.

The technological trajectory has been characterized by continuous improvements in catalyst design, moving from simple metal oxides to complex mixed metal oxide systems with precisely engineered surface properties. Recent advances in nanotechnology and materials science have further accelerated this field, enabling the development of hierarchical catalyst structures with optimized mass transfer properties and enhanced active site accessibility.

Current research focuses on addressing the inherent challenges associated with biomass feedstocks, particularly their high oxygen content, complex structure, and variability. Metal oxide catalysts offer unique advantages in this context, as they can be tailored to perform multiple functions simultaneously, including C-O bond activation, selective oxidation, and hydrodeoxygenation.

The primary objectives of biomass catalytic upgrading with metal oxide systems encompass several dimensions. From a technical perspective, the goal is to develop robust catalyst formulations that maintain activity and selectivity under the challenging conditions imposed by biomass-derived substrates, including the presence of water and potential catalyst poisons. Process intensification represents another critical objective, aiming to reduce energy requirements and increase throughput while maintaining product quality.

From a broader perspective, the ultimate aim is to establish economically viable and environmentally sustainable processes for converting diverse biomass feedstocks into platform chemicals, fuels, and materials that can directly substitute petroleum-derived products. This includes developing integrated biorefinery concepts where metal oxide catalysts play central roles in multiple conversion steps, maximizing resource utilization and minimizing waste generation.

The technological evolution in this field continues to accelerate, driven by advances in computational modeling, in-situ characterization techniques, and high-throughput experimentation methodologies that enable more rational catalyst design and faster optimization cycles.

Market Analysis for Sustainable Biofuel Technologies

The global market for sustainable biofuel technologies has experienced significant growth in recent years, driven by increasing environmental concerns, government regulations, and the need for renewable energy sources. Biomass upgrading with metal oxide catalyst systems represents a critical segment within this market, offering promising solutions for converting biomass into high-value biofuels and chemicals.

The current market size for sustainable biofuel technologies is estimated at $83.6 billion globally, with projections indicating growth to reach $118.2 billion by 2027, representing a compound annual growth rate of 7.2%. Within this broader market, technologies specifically focused on catalytic biomass upgrading account for approximately $12.4 billion, with metal oxide catalyst systems emerging as a particularly promising segment.

Demand for these technologies is primarily driven by the transportation sector, which continues to seek lower-carbon alternatives to conventional fossil fuels. Aviation biofuels represent a particularly high-growth segment, with major airlines committing to significant carbon reduction targets that necessitate sustainable fuel alternatives. The marine shipping industry has also begun adopting biofuel blends to meet International Maritime Organization emissions regulations.

Regional analysis reveals varying market dynamics. North America and Europe lead in technology adoption, supported by strong regulatory frameworks including the Renewable Fuel Standard in the US and the Renewable Energy Directive in the EU. The Asia-Pacific region, particularly China and India, shows the highest growth potential due to rapidly increasing energy demands coupled with growing environmental concerns.

Market penetration of metal oxide catalyst systems for biomass upgrading faces several challenges, including high initial capital costs, technical barriers in catalyst stability and selectivity, and competition from established fossil fuel infrastructure. However, decreasing production costs through technological improvements and economies of scale are gradually improving market competitiveness.

End-user industries demonstrate increasing willingness to pay premium prices for sustainable biofuels, particularly in sectors where electrification remains challenging. Corporate sustainability commitments and consumer pressure for environmentally responsible products further strengthen market demand. The aviation sector specifically has shown willingness to enter into long-term offtake agreements for sustainable aviation fuels.

Investment trends indicate growing interest in the sector, with venture capital funding for advanced biofuel technologies reaching $2.7 billion in 2022, a 34% increase from the previous year. Strategic partnerships between technology developers, feedstock suppliers, and fuel distributors are becoming increasingly common, creating integrated value chains that enhance market stability.

The current market size for sustainable biofuel technologies is estimated at $83.6 billion globally, with projections indicating growth to reach $118.2 billion by 2027, representing a compound annual growth rate of 7.2%. Within this broader market, technologies specifically focused on catalytic biomass upgrading account for approximately $12.4 billion, with metal oxide catalyst systems emerging as a particularly promising segment.

Demand for these technologies is primarily driven by the transportation sector, which continues to seek lower-carbon alternatives to conventional fossil fuels. Aviation biofuels represent a particularly high-growth segment, with major airlines committing to significant carbon reduction targets that necessitate sustainable fuel alternatives. The marine shipping industry has also begun adopting biofuel blends to meet International Maritime Organization emissions regulations.

Regional analysis reveals varying market dynamics. North America and Europe lead in technology adoption, supported by strong regulatory frameworks including the Renewable Fuel Standard in the US and the Renewable Energy Directive in the EU. The Asia-Pacific region, particularly China and India, shows the highest growth potential due to rapidly increasing energy demands coupled with growing environmental concerns.

Market penetration of metal oxide catalyst systems for biomass upgrading faces several challenges, including high initial capital costs, technical barriers in catalyst stability and selectivity, and competition from established fossil fuel infrastructure. However, decreasing production costs through technological improvements and economies of scale are gradually improving market competitiveness.

End-user industries demonstrate increasing willingness to pay premium prices for sustainable biofuels, particularly in sectors where electrification remains challenging. Corporate sustainability commitments and consumer pressure for environmentally responsible products further strengthen market demand. The aviation sector specifically has shown willingness to enter into long-term offtake agreements for sustainable aviation fuels.

Investment trends indicate growing interest in the sector, with venture capital funding for advanced biofuel technologies reaching $2.7 billion in 2022, a 34% increase from the previous year. Strategic partnerships between technology developers, feedstock suppliers, and fuel distributors are becoming increasingly common, creating integrated value chains that enhance market stability.

Metal Oxide Catalyst Systems: Current Status and Barriers

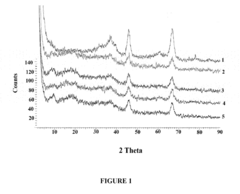

Metal oxide catalysts have emerged as critical components in biomass upgrading processes, offering promising pathways for converting renewable resources into valuable chemicals and fuels. Currently, these catalyst systems demonstrate significant potential across various biomass conversion routes, including hydrodeoxygenation, oxidation, and reforming processes. The most widely employed metal oxides include TiO2, ZrO2, CeO2, Al2O3, and mixed metal oxides, each exhibiting unique catalytic properties suitable for specific biomass transformation reactions.

Despite considerable advancements, several substantial barriers impede the widespread industrial implementation of metal oxide catalyst systems. Catalyst deactivation remains a primary challenge, with coking, sintering, and poisoning by biomass impurities significantly reducing catalyst longevity. The high oxygen content in biomass feedstocks (typically 40-60%) creates demanding reaction environments that accelerate catalyst degradation, particularly in hydrothermal conditions where water can induce structural changes in metal oxide supports.

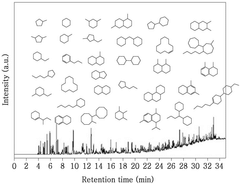

Selectivity limitations constitute another major obstacle. The complex, heterogeneous nature of biomass feedstocks leads to numerous parallel and consecutive reactions, making it difficult to achieve high selectivity toward desired products. Current metal oxide catalysts often lack the precision required to selectively cleave specific bonds while preserving others, resulting in product mixtures that necessitate costly separation processes.

Scale-up challenges further complicate industrial adoption. Laboratory-scale successes frequently encounter difficulties when transferred to industrial settings due to heat and mass transfer limitations, catalyst attrition, and reactor design constraints. The economic viability of these processes is compromised by the high costs associated with catalyst synthesis, particularly for complex mixed metal oxides or those requiring precise control of surface properties.

Fundamental understanding gaps persist regarding structure-activity relationships in metal oxide catalysts. The complex interplay between metal oxide surface properties, active site distribution, and biomass reaction mechanisms remains incompletely understood. This knowledge deficit hampers rational catalyst design approaches and necessitates empirical optimization strategies that are time-consuming and resource-intensive.

Sustainability concerns also present significant barriers. Many high-performance metal oxide catalysts incorporate rare earth elements or precious metals as dopants or active components, raising questions about resource availability and environmental impact. Additionally, the energy-intensive synthesis methods commonly employed for preparing metal oxide catalysts with controlled properties contradict the sustainability goals inherent to biomass utilization efforts.

Despite considerable advancements, several substantial barriers impede the widespread industrial implementation of metal oxide catalyst systems. Catalyst deactivation remains a primary challenge, with coking, sintering, and poisoning by biomass impurities significantly reducing catalyst longevity. The high oxygen content in biomass feedstocks (typically 40-60%) creates demanding reaction environments that accelerate catalyst degradation, particularly in hydrothermal conditions where water can induce structural changes in metal oxide supports.

Selectivity limitations constitute another major obstacle. The complex, heterogeneous nature of biomass feedstocks leads to numerous parallel and consecutive reactions, making it difficult to achieve high selectivity toward desired products. Current metal oxide catalysts often lack the precision required to selectively cleave specific bonds while preserving others, resulting in product mixtures that necessitate costly separation processes.

Scale-up challenges further complicate industrial adoption. Laboratory-scale successes frequently encounter difficulties when transferred to industrial settings due to heat and mass transfer limitations, catalyst attrition, and reactor design constraints. The economic viability of these processes is compromised by the high costs associated with catalyst synthesis, particularly for complex mixed metal oxides or those requiring precise control of surface properties.

Fundamental understanding gaps persist regarding structure-activity relationships in metal oxide catalysts. The complex interplay between metal oxide surface properties, active site distribution, and biomass reaction mechanisms remains incompletely understood. This knowledge deficit hampers rational catalyst design approaches and necessitates empirical optimization strategies that are time-consuming and resource-intensive.

Sustainability concerns also present significant barriers. Many high-performance metal oxide catalysts incorporate rare earth elements or precious metals as dopants or active components, raising questions about resource availability and environmental impact. Additionally, the energy-intensive synthesis methods commonly employed for preparing metal oxide catalysts with controlled properties contradict the sustainability goals inherent to biomass utilization efforts.

Contemporary Metal Oxide Catalyst Formulations and Applications

01 Transition metal oxide catalysts for chemical reactions

Transition metal oxides are widely used as catalysts for various chemical reactions due to their unique electronic properties and redox capabilities. These catalysts can facilitate oxidation, reduction, and other transformation processes with high selectivity and efficiency. The catalytic activity can be enhanced by controlling the metal oxide's crystal structure, surface area, and oxidation state. These systems are particularly valuable in industrial applications where high conversion rates and product selectivity are required.- Transition metal oxide catalysts for chemical reactions: Transition metal oxides are widely used as catalysts for various chemical reactions due to their unique electronic properties and surface chemistry. These catalysts can facilitate oxidation, reduction, and other transformation processes with high selectivity and efficiency. The catalytic activity can be enhanced by controlling the crystal structure, particle size, and surface area of the metal oxide. These catalysts are particularly effective for environmental applications such as emission control and waste treatment.

- Supported metal oxide catalyst systems: Metal oxide catalysts supported on various substrates show improved performance due to enhanced dispersion and stability. Common support materials include alumina, silica, and carbon-based materials, which can increase the active surface area and prevent sintering of the metal oxide particles. The interaction between the metal oxide and the support can create unique catalytic sites and modify the electronic properties of the catalyst. These supported systems often exhibit higher durability and can be tailored for specific reaction conditions.

- Mixed metal oxide catalyst compositions: Combining multiple metal oxides creates catalyst systems with synergistic effects and enhanced performance. These mixed oxide catalysts often exhibit properties that are not present in the individual components alone. The composition can be adjusted to optimize selectivity, activity, and stability for specific reactions. Common combinations include transition metals with rare earth elements or alkaline earth metals. These catalysts are particularly valuable in complex reactions where multiple catalytic functions are required simultaneously.

- Nanostructured metal oxide catalysts: Metal oxide catalysts with nanoscale dimensions offer significantly higher surface area and unique catalytic properties compared to bulk materials. These nanostructured catalysts can be synthesized in various morphologies including nanoparticles, nanorods, and nanosheets, each providing different catalytic performances. The controlled synthesis of these nanostructures allows for precise engineering of active sites and optimization of catalyst efficiency. Advanced characterization techniques are essential for understanding the structure-activity relationships in these nanoscale systems.

- Metal oxide catalysts for energy and environmental applications: Metal oxide catalyst systems play crucial roles in energy conversion and environmental remediation processes. These catalysts are employed in fuel cells, water splitting for hydrogen production, and conversion of greenhouse gases. They are also effective in pollution control technologies such as selective catalytic reduction of nitrogen oxides and oxidation of volatile organic compounds. Recent developments focus on improving the stability and activity of these catalysts under harsh operating conditions while reducing the use of precious metals.

02 Supported metal oxide catalyst systems

Metal oxide catalysts supported on various materials exhibit enhanced catalytic performance due to improved dispersion, stability, and surface area. Common support materials include alumina, silica, zeolites, and carbon-based materials. The interaction between the metal oxide and the support can create unique active sites and modify the electronic properties of the catalyst. These supported systems allow for better control of catalyst morphology and often show improved resistance to deactivation under reaction conditions.Expand Specific Solutions03 Mixed metal oxide catalyst compositions

Combining multiple metal oxides creates catalyst systems with synergistic effects and enhanced performance characteristics. These mixed oxide catalysts often display properties that are not achievable with single metal oxide components. The composition, preparation method, and calcination conditions significantly influence the catalyst's activity, selectivity, and stability. Mixed metal oxides are particularly effective for complex reactions requiring multiple catalytic functions or for reactions conducted under harsh conditions.Expand Specific Solutions04 Metal oxide catalysts for environmental applications

Metal oxide catalyst systems play a crucial role in environmental remediation and pollution control technologies. These catalysts are employed in processes such as exhaust gas treatment, volatile organic compound (VOC) removal, and wastewater purification. Their ability to catalyze oxidation reactions at relatively low temperatures makes them particularly suitable for removing harmful pollutants. Recent developments focus on improving the catalyst's activity at ambient conditions and enhancing their resistance to poisoning by contaminants.Expand Specific Solutions05 Novel preparation methods for metal oxide catalysts

Innovative synthesis techniques for metal oxide catalysts can significantly enhance their performance characteristics. Methods such as sol-gel processing, hydrothermal synthesis, precipitation, and template-assisted growth allow precise control over particle size, morphology, and surface properties. Advanced preparation approaches can create hierarchical structures, core-shell architectures, or highly defective surfaces with unique catalytic properties. These novel preparation methods often result in catalysts with improved activity, selectivity, and stability compared to conventionally prepared counterparts.Expand Specific Solutions

Leading Organizations in Biomass Catalytic Upgrading

Biomass upgrading with metal oxide catalyst systems is currently in a growth phase, with increasing market adoption driven by sustainability demands. The global market size for this technology is expanding, estimated to reach several billion dollars by 2030 as industries seek renewable alternatives to petroleum-based products. Technologically, the field shows moderate maturity with significant ongoing innovation. Leading players include major petrochemical corporations (China Petroleum & Chemical Corp., ExxonMobil, BASF, Reliance Industries) investing in commercial applications, while specialized companies like Anellotech and Virent focus on proprietary catalyst technologies. Academic institutions (South China University of Technology, Huazhong University) contribute fundamental research, creating a competitive landscape balanced between established industry players and innovative startups developing next-generation catalyst systems for more efficient biomass conversion.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced metal oxide catalyst systems for biomass upgrading focusing on integrated bio-refinery concepts. Their technology employs hierarchical metal oxide catalysts, particularly CeO2-ZrO2 mixed oxides doped with transition metals (Ni, Co, Cu), for efficient conversion of lignocellulosic biomass to fuels and chemicals. Sinopec's approach features a two-stage catalytic process: initial catalytic fast pyrolysis using metal-modified zeolites followed by hydroprocessing over supported metal oxide catalysts. This combination enables selective deoxygenation while preserving valuable carbon structures. Their catalyst preparation involves innovative sol-gel and hydrothermal synthesis methods that create materials with controlled mesoporosity and high surface area, enhancing mass transfer during biomass conversion. Sinopec has successfully demonstrated this technology at pilot scale, processing agricultural residues and woody biomass with high conversion efficiency. Recent developments include catalyst systems specifically designed for rice straw and corn stover conversion, addressing China's abundant agricultural waste streams.

Strengths: Catalyst formulations optimized for regional biomass feedstocks; integration with existing petroleum refining infrastructure; scalable manufacturing processes; ability to process high-ash content biomass. Weaknesses: Higher hydrogen consumption compared to some competing technologies; catalyst deactivation issues with certain biomass contaminants; complex regeneration protocols required for sustained operation.

Research Triangle Institute

Technical Solution: Research Triangle Institute (RTI) has developed innovative metal oxide catalyst systems for biomass upgrading through their catalytic biomass pyrolysis (CBP) technology. Their approach utilizes specially formulated metal oxide catalysts, particularly ZSM-5 zeolites modified with transition metals (Fe, Cu, Ga) to enhance aromatic production from biomass. RTI's process integrates catalyst design with reactor engineering to achieve optimal mass and heat transfer during biomass conversion. Their technology employs a circulating fluidized bed system where catalyst and biomass interact efficiently, allowing for continuous catalyst regeneration. The metal oxide components provide oxygen transfer capabilities that facilitate selective deoxygenation pathways while minimizing carbon loss to coke and gases. RTI has demonstrated their technology at pilot scale, processing multiple tons of biomass per day with consistent product quality. Their catalysts show remarkable resistance to deactivation from alkali metals present in biomass feedstocks through proprietary pretreatment and catalyst protection strategies.

Strengths: Demonstrated scalability to pilot operations; effective integration of catalyst and reactor design; ability to process diverse biomass feedstocks; continuous catalyst regeneration capability. Weaknesses: Higher capital costs compared to conventional pyrolysis; catalyst attrition in fluidized systems; requires careful feedstock preparation to prevent impurity-related issues.

Critical Patents and Research in Biomass Catalytic Systems

Multi-metallic Catalyst System And Use Of The Same In Preparing Upgraded Fuel From Biomass

PatentInactiveUS20190083961A1

Innovation

- A multi-metallic catalyst system comprising a support, promoter component, and active component with at least two metals, prepared through calcination, impregnation, and reduction processes, is used to convert biomass into upgraded fuel by hydrogenating an intermediate product derived from a biomass slurry.

Catalyst for aviation fuel production from bio-oil, method for preparation the same and method for bio-oil upgrading using the same

PatentActiveKR1020240075282A

Innovation

- A catalyst comprising a complex inorganic oxide of lanthanum (La), nickel (Ni), titanium (Ti), and cerium (Ce) is used in a two-stage process, where a metal catalyst supported on carbon is employed for the first stage and the complex inorganic oxide catalyst for the second stage, facilitating hydrocracking and hydrodeoxygenation reactions to break C-C and C-O bonds, thereby reducing carbon chain length and oxygen content.

Environmental Impact Assessment of Catalytic Biomass Processes

The environmental impact assessment of catalytic biomass processes reveals both significant benefits and potential concerns when utilizing metal oxide catalyst systems for biomass upgrading. These processes offer substantial environmental advantages compared to conventional fossil fuel-based production methods, primarily through reduced greenhouse gas emissions. Life cycle assessments indicate that catalytic biomass conversion can achieve carbon emission reductions of 60-80% compared to petroleum-based alternatives, depending on feedstock selection and process optimization.

Water usage represents a critical environmental consideration, as catalytic biomass processes typically require substantial water inputs for feedstock preparation, reaction media, and cooling systems. Advanced metal oxide catalyst systems have demonstrated improved water efficiency, with recent innovations reducing water consumption by approximately 30% compared to first-generation processes. However, water quality impacts from process effluents containing catalyst residues and organic byproducts remain a challenge requiring robust treatment protocols.

Air quality impacts from catalytic biomass upgrading are generally favorable when compared to fossil fuel processing. Emissions of sulfur oxides and nitrogen oxides are significantly lower, though volatile organic compound (VOC) emissions during certain process stages require mitigation through appropriate control technologies. Modern catalytic systems incorporating cerium and manganese oxides have demonstrated particular effectiveness in minimizing harmful air emissions during biomass conversion.

Land use considerations present complex tradeoffs. While biomass feedstock production can compete with food crops and potentially drive land-use changes, the high efficiency of advanced metal oxide catalysts allows for greater product yield per unit of biomass input, thereby reducing overall land requirements. Recent studies suggest that optimized catalyst systems can improve conversion efficiency by 25-40%, substantially decreasing the land footprint of biomass utilization.

Waste generation and management constitute another critical environmental dimension. Spent catalysts require proper handling and recycling to prevent heavy metal contamination. Encouragingly, recent advances in catalyst design have extended catalyst lifetimes by up to 300%, dramatically reducing waste generation rates. Additionally, innovative recovery techniques now enable the reclamation of over 90% of valuable metals from deactivated catalysts, creating a more circular approach to catalyst management.

Energy efficiency metrics reveal that metal oxide catalyst systems typically reduce process energy requirements by 40-60% compared to non-catalytic thermal conversion methods. This translates directly to lower environmental impacts across multiple categories, including reduced carbon footprint, decreased resource depletion, and minimized ecosystem disruption.

Water usage represents a critical environmental consideration, as catalytic biomass processes typically require substantial water inputs for feedstock preparation, reaction media, and cooling systems. Advanced metal oxide catalyst systems have demonstrated improved water efficiency, with recent innovations reducing water consumption by approximately 30% compared to first-generation processes. However, water quality impacts from process effluents containing catalyst residues and organic byproducts remain a challenge requiring robust treatment protocols.

Air quality impacts from catalytic biomass upgrading are generally favorable when compared to fossil fuel processing. Emissions of sulfur oxides and nitrogen oxides are significantly lower, though volatile organic compound (VOC) emissions during certain process stages require mitigation through appropriate control technologies. Modern catalytic systems incorporating cerium and manganese oxides have demonstrated particular effectiveness in minimizing harmful air emissions during biomass conversion.

Land use considerations present complex tradeoffs. While biomass feedstock production can compete with food crops and potentially drive land-use changes, the high efficiency of advanced metal oxide catalysts allows for greater product yield per unit of biomass input, thereby reducing overall land requirements. Recent studies suggest that optimized catalyst systems can improve conversion efficiency by 25-40%, substantially decreasing the land footprint of biomass utilization.

Waste generation and management constitute another critical environmental dimension. Spent catalysts require proper handling and recycling to prevent heavy metal contamination. Encouragingly, recent advances in catalyst design have extended catalyst lifetimes by up to 300%, dramatically reducing waste generation rates. Additionally, innovative recovery techniques now enable the reclamation of over 90% of valuable metals from deactivated catalysts, creating a more circular approach to catalyst management.

Energy efficiency metrics reveal that metal oxide catalyst systems typically reduce process energy requirements by 40-60% compared to non-catalytic thermal conversion methods. This translates directly to lower environmental impacts across multiple categories, including reduced carbon footprint, decreased resource depletion, and minimized ecosystem disruption.

Scalability and Industrial Implementation Challenges

The transition from laboratory-scale experiments to industrial implementation of biomass upgrading processes using metal oxide catalyst systems faces significant challenges. Current pilot plants typically operate at capacities of 1-10 tons per day, while commercial viability often requires processing hundreds or thousands of tons daily. This scale-up gap presents multifaceted engineering challenges that must be addressed systematically.

Heat and mass transfer limitations become increasingly problematic at industrial scales. Laboratory reactors benefit from ideal mixing and temperature control, whereas industrial-scale reactors encounter temperature gradients and diffusion limitations that can significantly reduce catalyst efficiency. These phenomena often lead to decreased conversion rates and selectivity when scaling up, requiring redesigned reactor configurations and enhanced heat management systems.

Catalyst deactivation represents another critical challenge for industrial implementation. Biomass feedstocks contain various impurities including sulfur, nitrogen compounds, and minerals that can poison metal oxide catalysts over time. Industrial operations require catalysts that maintain activity for months or years rather than hours or days typical in laboratory settings. Development of regeneration protocols and more robust catalyst formulations with improved resistance to deactivation is essential.

Economic viability remains a significant hurdle, with capital expenditure for biomass processing facilities typically ranging from $50-200 million. Current metal oxide catalyst systems often utilize precious metals or rare earth elements, making catalyst costs prohibitively high for large-scale operations. Innovations in catalyst design using earth-abundant metals and optimized support materials are necessary to reduce costs while maintaining performance.

Process integration challenges also emerge when implementing these technologies at industrial scale. Biomass upgrading facilities must efficiently integrate with existing infrastructure, including feedstock handling, product separation, and waste treatment systems. The heterogeneous nature of biomass feedstocks further complicates this integration, requiring flexible processing capabilities to accommodate seasonal and regional variations in biomass composition.

Regulatory compliance and sustainability metrics present additional implementation barriers. Industrial facilities must meet increasingly stringent environmental regulations regarding emissions, waste disposal, and resource utilization. Life cycle assessments indicate that some current metal oxide catalyst systems may have environmental footprints that partially offset their renewable energy benefits, necessitating holistic optimization of the entire process chain to ensure genuine sustainability advantages.

Heat and mass transfer limitations become increasingly problematic at industrial scales. Laboratory reactors benefit from ideal mixing and temperature control, whereas industrial-scale reactors encounter temperature gradients and diffusion limitations that can significantly reduce catalyst efficiency. These phenomena often lead to decreased conversion rates and selectivity when scaling up, requiring redesigned reactor configurations and enhanced heat management systems.

Catalyst deactivation represents another critical challenge for industrial implementation. Biomass feedstocks contain various impurities including sulfur, nitrogen compounds, and minerals that can poison metal oxide catalysts over time. Industrial operations require catalysts that maintain activity for months or years rather than hours or days typical in laboratory settings. Development of regeneration protocols and more robust catalyst formulations with improved resistance to deactivation is essential.

Economic viability remains a significant hurdle, with capital expenditure for biomass processing facilities typically ranging from $50-200 million. Current metal oxide catalyst systems often utilize precious metals or rare earth elements, making catalyst costs prohibitively high for large-scale operations. Innovations in catalyst design using earth-abundant metals and optimized support materials are necessary to reduce costs while maintaining performance.

Process integration challenges also emerge when implementing these technologies at industrial scale. Biomass upgrading facilities must efficiently integrate with existing infrastructure, including feedstock handling, product separation, and waste treatment systems. The heterogeneous nature of biomass feedstocks further complicates this integration, requiring flexible processing capabilities to accommodate seasonal and regional variations in biomass composition.

Regulatory compliance and sustainability metrics present additional implementation barriers. Industrial facilities must meet increasingly stringent environmental regulations regarding emissions, waste disposal, and resource utilization. Life cycle assessments indicate that some current metal oxide catalyst systems may have environmental footprints that partially offset their renewable energy benefits, necessitating holistic optimization of the entire process chain to ensure genuine sustainability advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!