Biomass upgrading with heterogeneous catalysis approaches

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomass Catalytic Upgrading Background and Objectives

Biomass utilization represents a pivotal frontier in the global transition towards sustainable energy and chemical production systems. The evolution of biomass conversion technologies has progressed significantly over the past decades, transitioning from simple combustion methods to sophisticated catalytic approaches that enable selective transformation of complex biomolecules into high-value products. This technological progression has been driven by increasing environmental concerns, depleting fossil resources, and the urgent need to reduce carbon emissions across industrial sectors.

Heterogeneous catalysis has emerged as a cornerstone technology in biomass upgrading, offering distinct advantages in terms of catalyst recovery, process intensification, and continuous operation capabilities. The historical development of this field traces back to early wood chemistry research in the early 20th century, with significant acceleration occurring post-1970s oil crisis when alternative carbon sources gained strategic importance.

The primary objective of biomass catalytic upgrading research is to develop efficient, economically viable processes that can convert diverse biomass feedstocks into fuels, chemicals, and materials with properties comparable or superior to their fossil-derived counterparts. This encompasses several specific goals: enhancing catalyst selectivity to target desired products, improving catalyst stability under harsh biomass processing conditions, and developing integrated biorefinery concepts that maximize resource utilization.

Current technological trajectories indicate growing emphasis on designing multifunctional catalysts capable of orchestrating complex reaction cascades in single-pot processes. These advanced materials aim to overcome the inherent challenges posed by biomass's high oxygen content, complex structure, and variable composition. Parallel efforts focus on developing catalytic systems compatible with aqueous-phase processing to minimize energy-intensive drying steps.

The field is witnessing convergence with other cutting-edge technologies, including artificial intelligence for catalyst discovery, continuous flow processing, and hybrid biological-chemical conversion routes. These synergistic approaches promise to overcome traditional limitations in biomass valorization by enabling precise molecular transformations under milder conditions.

Looking forward, biomass catalytic upgrading technologies are expected to play an increasingly vital role in circular bioeconomy frameworks, where waste biomass streams are transformed into valuable products. The ultimate technological goal remains the development of versatile catalytic platforms that can efficiently process diverse biomass feedstocks while maintaining economic competitiveness with conventional petrochemical routes.

Heterogeneous catalysis has emerged as a cornerstone technology in biomass upgrading, offering distinct advantages in terms of catalyst recovery, process intensification, and continuous operation capabilities. The historical development of this field traces back to early wood chemistry research in the early 20th century, with significant acceleration occurring post-1970s oil crisis when alternative carbon sources gained strategic importance.

The primary objective of biomass catalytic upgrading research is to develop efficient, economically viable processes that can convert diverse biomass feedstocks into fuels, chemicals, and materials with properties comparable or superior to their fossil-derived counterparts. This encompasses several specific goals: enhancing catalyst selectivity to target desired products, improving catalyst stability under harsh biomass processing conditions, and developing integrated biorefinery concepts that maximize resource utilization.

Current technological trajectories indicate growing emphasis on designing multifunctional catalysts capable of orchestrating complex reaction cascades in single-pot processes. These advanced materials aim to overcome the inherent challenges posed by biomass's high oxygen content, complex structure, and variable composition. Parallel efforts focus on developing catalytic systems compatible with aqueous-phase processing to minimize energy-intensive drying steps.

The field is witnessing convergence with other cutting-edge technologies, including artificial intelligence for catalyst discovery, continuous flow processing, and hybrid biological-chemical conversion routes. These synergistic approaches promise to overcome traditional limitations in biomass valorization by enabling precise molecular transformations under milder conditions.

Looking forward, biomass catalytic upgrading technologies are expected to play an increasingly vital role in circular bioeconomy frameworks, where waste biomass streams are transformed into valuable products. The ultimate technological goal remains the development of versatile catalytic platforms that can efficiently process diverse biomass feedstocks while maintaining economic competitiveness with conventional petrochemical routes.

Market Analysis for Biomass-Derived Products

The global market for biomass-derived products has experienced significant growth in recent years, driven by increasing environmental concerns and the push for sustainable alternatives to fossil-based products. The market value for biomass-derived chemicals reached approximately $7.7 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 8.2% through 2030, potentially reaching $15.1 billion by the end of the decade.

Biofuels represent the largest segment within biomass-derived products, accounting for nearly 60% of the total market share. Bioethanol and biodiesel continue to dominate this segment, with global production volumes exceeding 110 billion liters annually. The biochemicals segment, though smaller, is showing the fastest growth rate at 9.7% annually, particularly for platform chemicals such as succinic acid, lactic acid, and levulinic acid.

Regionally, North America and Europe currently lead the market for biomass-derived products, collectively accounting for approximately 65% of global market value. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India making substantial investments in biomass conversion technologies and infrastructure. Latin America, particularly Brazil, remains a significant player in bioethanol production due to its established sugarcane industry.

End-use industries demonstrate varying adoption rates for biomass-derived products. The transportation sector remains the primary consumer of biofuels, while packaging, consumer goods, and pharmaceuticals are increasingly incorporating bio-based chemicals and materials. The construction industry has also begun adopting biomass-derived products, particularly for insulation materials and bio-based composites.

Market drivers include favorable government policies and incentives, growing consumer preference for sustainable products, and corporate sustainability commitments. The European Union's Renewable Energy Directive II and the United States' Renewable Fuel Standard continue to provide regulatory support for market growth. Additionally, over 200 major corporations have made commitments to increase their use of bio-based materials in the next decade.

Challenges affecting market growth include feedstock supply variability, competition with food production, and price competitiveness against petroleum-based alternatives. The cost of biomass-derived products typically ranges from 1.2 to 2.5 times higher than their fossil-based counterparts, though this gap is narrowing as technologies mature and economies of scale improve. Recent technological advancements in heterogeneous catalysis have shown promise in reducing production costs by 15-30%, potentially accelerating market penetration.

Biofuels represent the largest segment within biomass-derived products, accounting for nearly 60% of the total market share. Bioethanol and biodiesel continue to dominate this segment, with global production volumes exceeding 110 billion liters annually. The biochemicals segment, though smaller, is showing the fastest growth rate at 9.7% annually, particularly for platform chemicals such as succinic acid, lactic acid, and levulinic acid.

Regionally, North America and Europe currently lead the market for biomass-derived products, collectively accounting for approximately 65% of global market value. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India making substantial investments in biomass conversion technologies and infrastructure. Latin America, particularly Brazil, remains a significant player in bioethanol production due to its established sugarcane industry.

End-use industries demonstrate varying adoption rates for biomass-derived products. The transportation sector remains the primary consumer of biofuels, while packaging, consumer goods, and pharmaceuticals are increasingly incorporating bio-based chemicals and materials. The construction industry has also begun adopting biomass-derived products, particularly for insulation materials and bio-based composites.

Market drivers include favorable government policies and incentives, growing consumer preference for sustainable products, and corporate sustainability commitments. The European Union's Renewable Energy Directive II and the United States' Renewable Fuel Standard continue to provide regulatory support for market growth. Additionally, over 200 major corporations have made commitments to increase their use of bio-based materials in the next decade.

Challenges affecting market growth include feedstock supply variability, competition with food production, and price competitiveness against petroleum-based alternatives. The cost of biomass-derived products typically ranges from 1.2 to 2.5 times higher than their fossil-based counterparts, though this gap is narrowing as technologies mature and economies of scale improve. Recent technological advancements in heterogeneous catalysis have shown promise in reducing production costs by 15-30%, potentially accelerating market penetration.

Heterogeneous Catalysis State-of-Art and Challenges

Heterogeneous catalysis represents a cornerstone technology in biomass upgrading processes, offering significant advantages over homogeneous counterparts due to catalyst recoverability, product separation efficiency, and operational sustainability. Current state-of-the-art approaches primarily focus on metal-based catalysts, including noble metals (Pt, Pd, Ru), transition metals (Ni, Cu, Fe), and their combinations in various support structures.

Metal oxide catalysts have demonstrated remarkable performance in biomass conversion reactions, particularly in oxidation and hydrodeoxygenation processes. ZrO2, TiO2, and CeO2 have emerged as effective supports that enhance catalyst stability and selectivity. Recent advances in bifunctional catalysts combining metallic and acidic sites have shown promising results for cascade reactions in biomass transformation, enabling one-pot synthesis of valuable platform chemicals.

Zeolites and mesoporous materials represent another significant category of heterogeneous catalysts, offering tunable acidity and porosity that facilitate selective biomass conversion. HZSM-5, H-Beta, and H-Y zeolites have been extensively studied for their effectiveness in dehydration, isomerization, and cracking reactions of biomass-derived compounds. The integration of metals within zeolite frameworks has further expanded their application scope.

Despite these advancements, heterogeneous catalysis in biomass upgrading faces substantial challenges. Catalyst deactivation remains a persistent issue, primarily caused by coke formation, metal leaching, and structural collapse during reactions. The complex and variable nature of biomass feedstocks introduces impurities that can poison catalysts, significantly reducing their lifetime and efficiency.

Selectivity control presents another major challenge, as biomass conversion typically yields multiple products through competing reaction pathways. Achieving high selectivity toward desired products while minimizing side reactions requires sophisticated catalyst design and optimization of reaction conditions, which remains difficult to achieve consistently.

Water tolerance represents a critical challenge for many heterogeneous catalysts, as biomass processing often involves aqueous environments. Hydrothermal stability of catalysts under reaction conditions is essential but difficult to maintain, particularly for traditional acid catalysts and some metal-supported systems.

Scale-up and economic viability constitute significant barriers to industrial implementation. Many laboratory-developed catalysts utilize expensive noble metals or complex synthesis procedures that limit their commercial applicability. The development of cost-effective catalysts using earth-abundant elements while maintaining performance metrics remains an ongoing challenge.

Mechanistic understanding of catalytic reactions in biomass conversion is still limited, hampering rational catalyst design. The complex interaction between biomass molecules and catalyst surfaces, influenced by solvent effects and mass transfer limitations, requires advanced characterization techniques and computational modeling to fully elucidate.

Metal oxide catalysts have demonstrated remarkable performance in biomass conversion reactions, particularly in oxidation and hydrodeoxygenation processes. ZrO2, TiO2, and CeO2 have emerged as effective supports that enhance catalyst stability and selectivity. Recent advances in bifunctional catalysts combining metallic and acidic sites have shown promising results for cascade reactions in biomass transformation, enabling one-pot synthesis of valuable platform chemicals.

Zeolites and mesoporous materials represent another significant category of heterogeneous catalysts, offering tunable acidity and porosity that facilitate selective biomass conversion. HZSM-5, H-Beta, and H-Y zeolites have been extensively studied for their effectiveness in dehydration, isomerization, and cracking reactions of biomass-derived compounds. The integration of metals within zeolite frameworks has further expanded their application scope.

Despite these advancements, heterogeneous catalysis in biomass upgrading faces substantial challenges. Catalyst deactivation remains a persistent issue, primarily caused by coke formation, metal leaching, and structural collapse during reactions. The complex and variable nature of biomass feedstocks introduces impurities that can poison catalysts, significantly reducing their lifetime and efficiency.

Selectivity control presents another major challenge, as biomass conversion typically yields multiple products through competing reaction pathways. Achieving high selectivity toward desired products while minimizing side reactions requires sophisticated catalyst design and optimization of reaction conditions, which remains difficult to achieve consistently.

Water tolerance represents a critical challenge for many heterogeneous catalysts, as biomass processing often involves aqueous environments. Hydrothermal stability of catalysts under reaction conditions is essential but difficult to maintain, particularly for traditional acid catalysts and some metal-supported systems.

Scale-up and economic viability constitute significant barriers to industrial implementation. Many laboratory-developed catalysts utilize expensive noble metals or complex synthesis procedures that limit their commercial applicability. The development of cost-effective catalysts using earth-abundant elements while maintaining performance metrics remains an ongoing challenge.

Mechanistic understanding of catalytic reactions in biomass conversion is still limited, hampering rational catalyst design. The complex interaction between biomass molecules and catalyst surfaces, influenced by solvent effects and mass transfer limitations, requires advanced characterization techniques and computational modeling to fully elucidate.

Current Heterogeneous Catalytic Approaches

01 Metal-based catalysts for hydrocarbon upgrading

Metal-based heterogeneous catalysts play a crucial role in upgrading hydrocarbon feedstocks. These catalysts typically contain transition metals such as nickel, cobalt, molybdenum, or noble metals like platinum and palladium supported on various substrates. The metal components facilitate hydrogenation, hydrocracking, and other conversion reactions that improve the quality and value of petroleum products. The efficiency of these catalysts can be enhanced through optimized metal dispersion, controlled particle size, and appropriate support materials.- Metal-based catalysts for improved efficiency: Metal-based heterogeneous catalysts play a crucial role in upgrading process efficiency. Various metals such as platinum, palladium, and nickel are used as active components on different supports to enhance catalytic activity and selectivity. These catalysts can be optimized through specific preparation methods to achieve higher conversion rates and better product yields in various chemical processes including hydrogenation, oxidation, and reforming reactions.

- Zeolite and molecular sieve catalysts: Zeolites and molecular sieves are widely used as heterogeneous catalysts due to their unique porous structure and acidity properties. These materials provide shape selectivity and can be tailored with different pore sizes and acid site distributions to enhance catalytic efficiency in various upgrading processes. The incorporation of metals into zeolite frameworks further improves their catalytic performance for reactions such as cracking, isomerization, and alkylation.

- Reactor design and process optimization: Innovative reactor designs and process optimization techniques significantly enhance heterogeneous catalysis efficiency. Fixed-bed, fluidized-bed, and structured reactors can be engineered to improve mass and heat transfer, reduce pressure drop, and extend catalyst lifetime. Advanced process control strategies, including temperature management and feed composition optimization, contribute to higher conversion rates and improved product selectivity.

- Catalyst regeneration and lifetime extension: Methods for catalyst regeneration and lifetime extension are essential for maintaining high efficiency in heterogeneous catalysis processes. Techniques such as controlled oxidation, solvent washing, and thermal treatments can effectively remove coke deposits and other contaminants from catalyst surfaces. Innovative approaches to prevent catalyst deactivation, including the use of promoters and protective coatings, help sustain catalytic activity over extended periods of operation.

- Novel support materials and composite catalysts: Advanced support materials and composite catalyst formulations offer enhanced performance in heterogeneous catalysis. Materials such as metal-organic frameworks (MOFs), carbon nanotubes, and mesoporous silica provide high surface area and controlled porosity for better dispersion of active sites. Composite catalysts combining multiple active components can achieve synergistic effects, leading to improved selectivity, activity, and stability in complex upgrading processes.

02 Zeolite and molecular sieve catalysts

Zeolites and molecular sieves are widely used as heterogeneous catalysts for upgrading processes due to their unique porous structure and acidity. These materials provide shape selectivity and active sites for cracking, isomerization, and alkylation reactions. The efficiency of zeolite catalysts can be improved by modifying their pore architecture, adjusting the silicon-to-aluminum ratio, and incorporating various metals. These modifications enhance catalyst stability, selectivity, and resistance to deactivation, leading to improved upgrading efficiency.Expand Specific Solutions03 Catalyst support materials and preparation methods

The choice of support material and preparation method significantly impacts heterogeneous catalyst performance in upgrading processes. Various supports such as alumina, silica, carbon, and mixed oxides provide different surface areas, pore structures, and interactions with active phases. Advanced preparation techniques including sol-gel methods, hydrothermal synthesis, and controlled impregnation help optimize catalyst properties. These approaches lead to better dispersion of active sites, enhanced stability, and improved mass transfer, ultimately increasing catalytic efficiency.Expand Specific Solutions04 Reactor design and process optimization

Innovative reactor designs and process optimization strategies are essential for maximizing heterogeneous catalysis efficiency in upgrading operations. Fixed-bed, fluidized-bed, and moving-bed reactors offer different advantages depending on the specific upgrading process. Advanced reactor configurations featuring improved heat and mass transfer, optimized flow patterns, and enhanced catalyst-reactant contact can significantly boost conversion rates and product selectivity. Process parameters such as temperature, pressure, space velocity, and feed composition must be carefully controlled to achieve optimal catalyst performance.Expand Specific Solutions05 Biomass conversion and renewable feedstock upgrading

Heterogeneous catalysts are increasingly being developed for upgrading biomass and renewable feedstocks into valuable fuels and chemicals. These catalysts facilitate various transformations including hydrodeoxygenation, decarboxylation, and reforming of bio-oils and other biomass-derived compounds. Bifunctional catalysts combining metal sites for hydrogenation with acidic sites for C-O bond cleavage show particular promise. Catalyst design considerations for biomass upgrading include tolerance to water, resistance to coking, and stability in the presence of contaminants commonly found in bio-feedstocks.Expand Specific Solutions

Leading Organizations in Biomass Catalytic Upgrading

Biomass upgrading with heterogeneous catalysis is currently in a transitional phase from early commercialization to growth, with the global market expected to reach $5-7 billion by 2025. The technology maturity varies across applications, with some processes reaching commercial scale while others remain in development. Leading players include Shell, which has established commercial-scale operations, and China Petroleum & Chemical Corp. (Sinopec), leveraging its extensive petrochemical infrastructure. Smaller specialized firms like Ensyn Renewables and Abundia Biomass To Liquids are driving innovation in niche applications. Academic institutions such as Hokkaido University and Zhejiang University are advancing fundamental catalytic research, while companies like JGC Corp. and Resonac Holdings are developing proprietary catalyst technologies for specific biomass conversion pathways.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed advanced catalytic fast pyrolysis (CFP) technology for biomass upgrading, focusing on zeolite-based catalysts that effectively convert lignocellulosic biomass into drop-in biofuels and chemicals. Their proprietary catalyst systems incorporate modified ZSM-5 zeolites with optimized acidity and pore structures to enhance aromatic hydrocarbon yields while minimizing coke formation. Shell's process integrates catalytic pyrolysis with hydroprocessing steps, allowing for the production of fungible transportation fuels with properties similar to petroleum-derived products. The company has demonstrated commercial-scale implementation through their IH² (Integrated Hydropyrolysis and Hydroconversion) technology, which converts biomass directly to transportation fuels in a two-stage process using proprietary catalysts. This approach achieves carbon conversion efficiencies exceeding 70% with significantly reduced oxygen content in the final products compared to conventional pyrolysis oils[1][3].

Strengths: Shell's extensive refining infrastructure enables seamless integration of biomass-derived intermediates into existing production streams. Their global R&D network provides substantial resources for catalyst optimization and process development. Weaknesses: The technology requires high-quality biomass feedstocks with consistent properties, potentially limiting deployment in regions with variable biomass resources. High capital costs for commercial implementation remain a barrier to widespread adoption.

Ensyn Renewables Inc

Technical Solution: Ensyn Renewables has developed the proprietary Rapid Thermal Processing (RTP™) technology, a catalytic approach to biomass upgrading that converts solid biomass into liquid biofuels and chemicals. Their process employs specialized heterogeneous catalysts in a circulating transported bed reactor system where biomass particles are rapidly heated (typically <2 seconds) in the absence of oxygen. The catalyst system consists of modified zeolites and metal oxides that facilitate selective cracking and deoxygenation reactions, producing a liquid product called Renewable Fuel Oil (RFO). Ensyn's catalysts are designed to minimize char formation while maximizing liquid yields, typically achieving bio-oil yields of 65-75% by weight from woody biomass. The company has refined their catalyst formulations to address traditional bio-oil challenges including acidity, instability, and high oxygen content. Their latest generation catalysts incorporate hierarchical pore structures and tailored surface functionalities that enhance mass transfer and reaction selectivity. Ensyn has successfully commercialized this technology with multiple operational facilities in North America, processing up to 400 tons of biomass daily in their largest installations[4][6].

Strengths: Ensyn's technology operates at atmospheric pressure and moderate temperatures, reducing capital and operating costs compared to high-pressure hydroprocessing approaches. Their process demonstrates exceptional feedstock flexibility, successfully processing various woody biomass types with minimal pretreatment. Weaknesses: The produced bio-oils still contain significant oxygen content requiring additional upgrading for transportation fuel applications. Catalyst deactivation due to coking remains a challenge, necessitating frequent regeneration cycles that impact overall process efficiency.

Key Patents and Breakthroughs in Biomass Catalysis

Converting biomass to lpg

PatentActiveGB2608923A

Innovation

- A process involving pyrolysis of low-moisture biomass at high temperatures (at least 950 °C) to produce a hydrocarbon feedstock, followed by separation and further processing to reduce sulphur content and improve fuel properties, using non-crop biomass feedstocks and indirect heating methods to enhance efficiency and safety.

Synergistic co-pyrolysis of biomass and methane for hydrocarbon fuels and chemicals production

PatentInactiveUS20180142159A1

Innovation

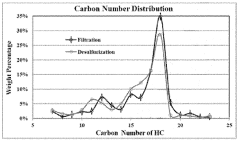

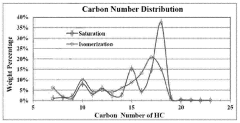

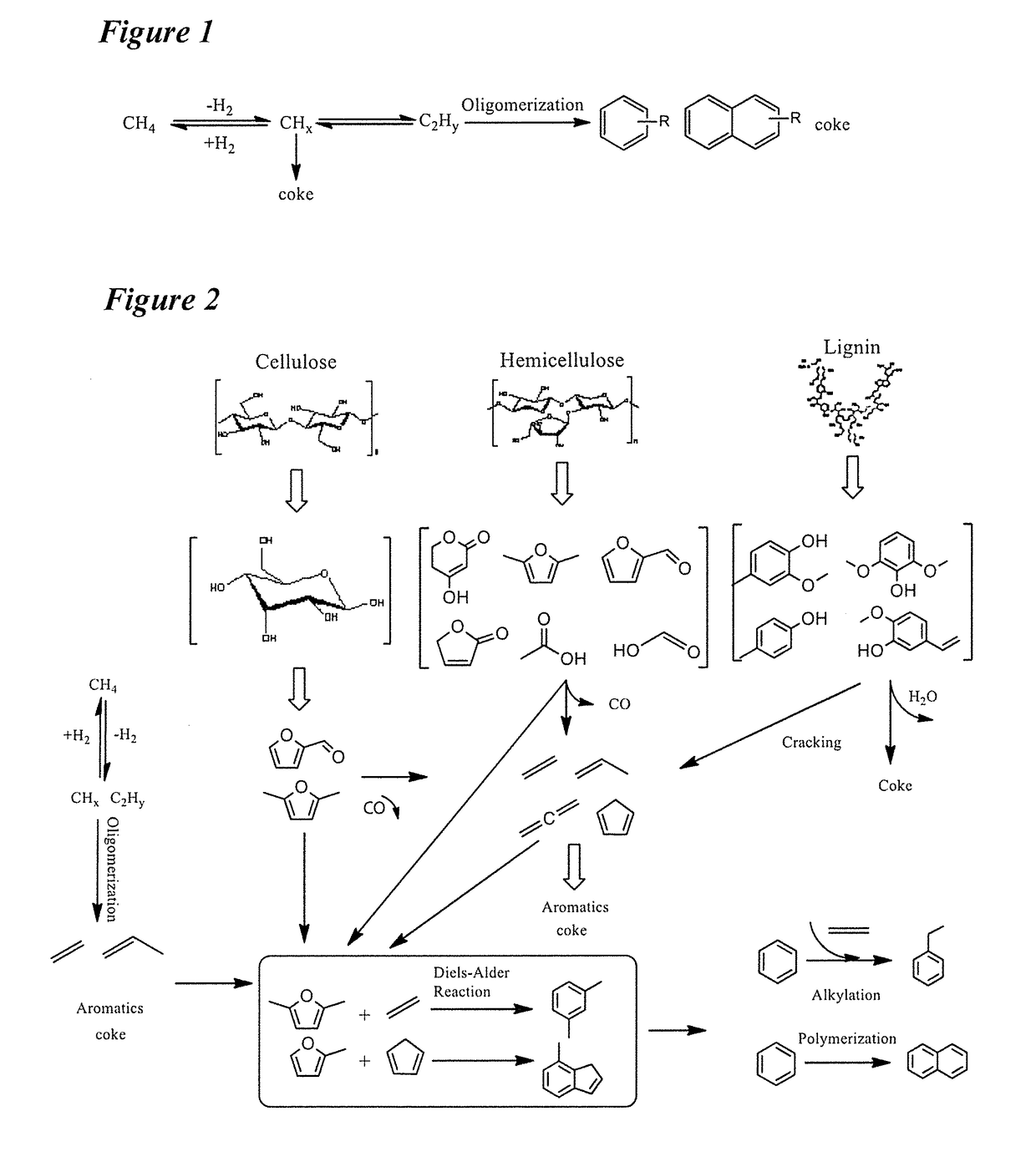

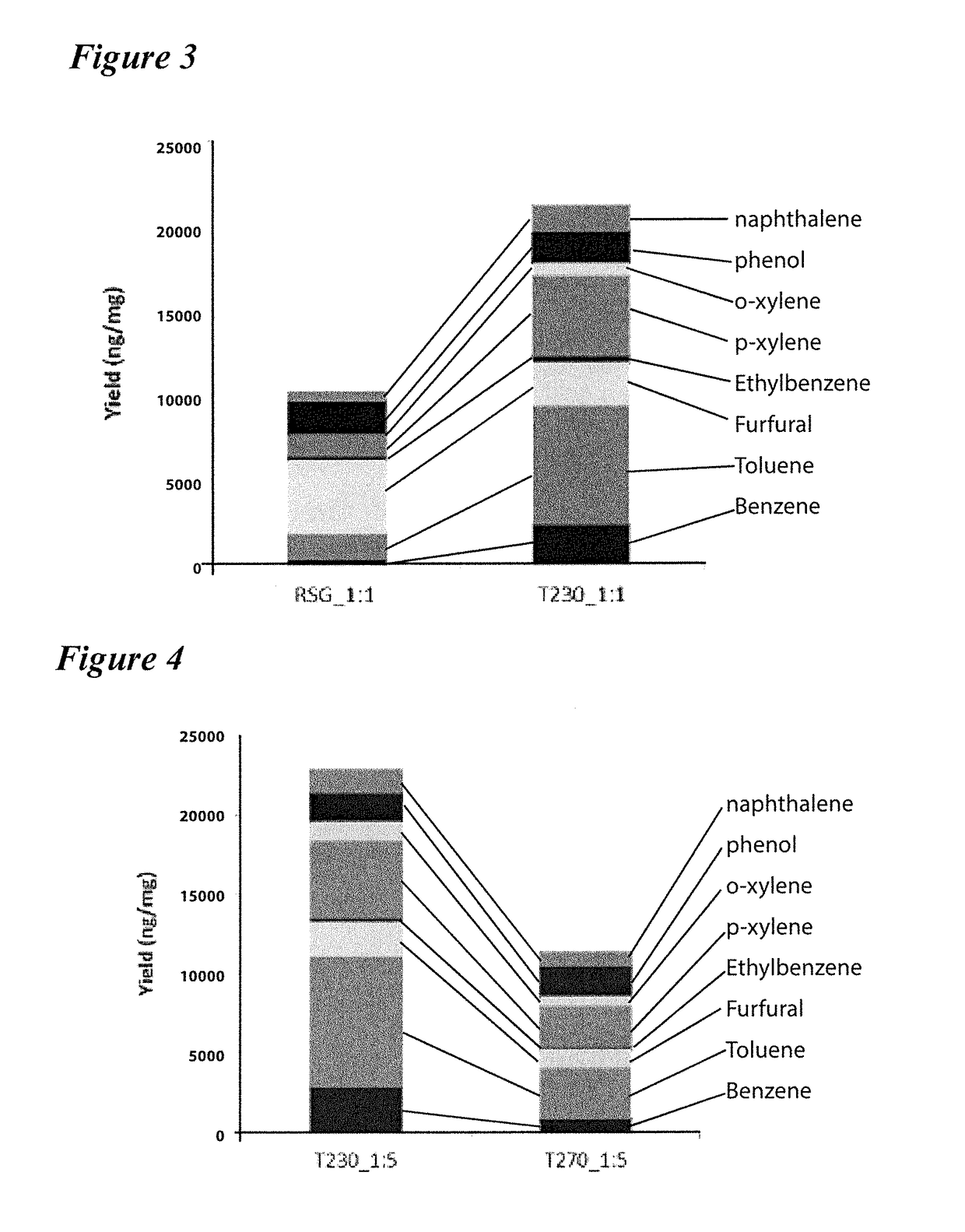

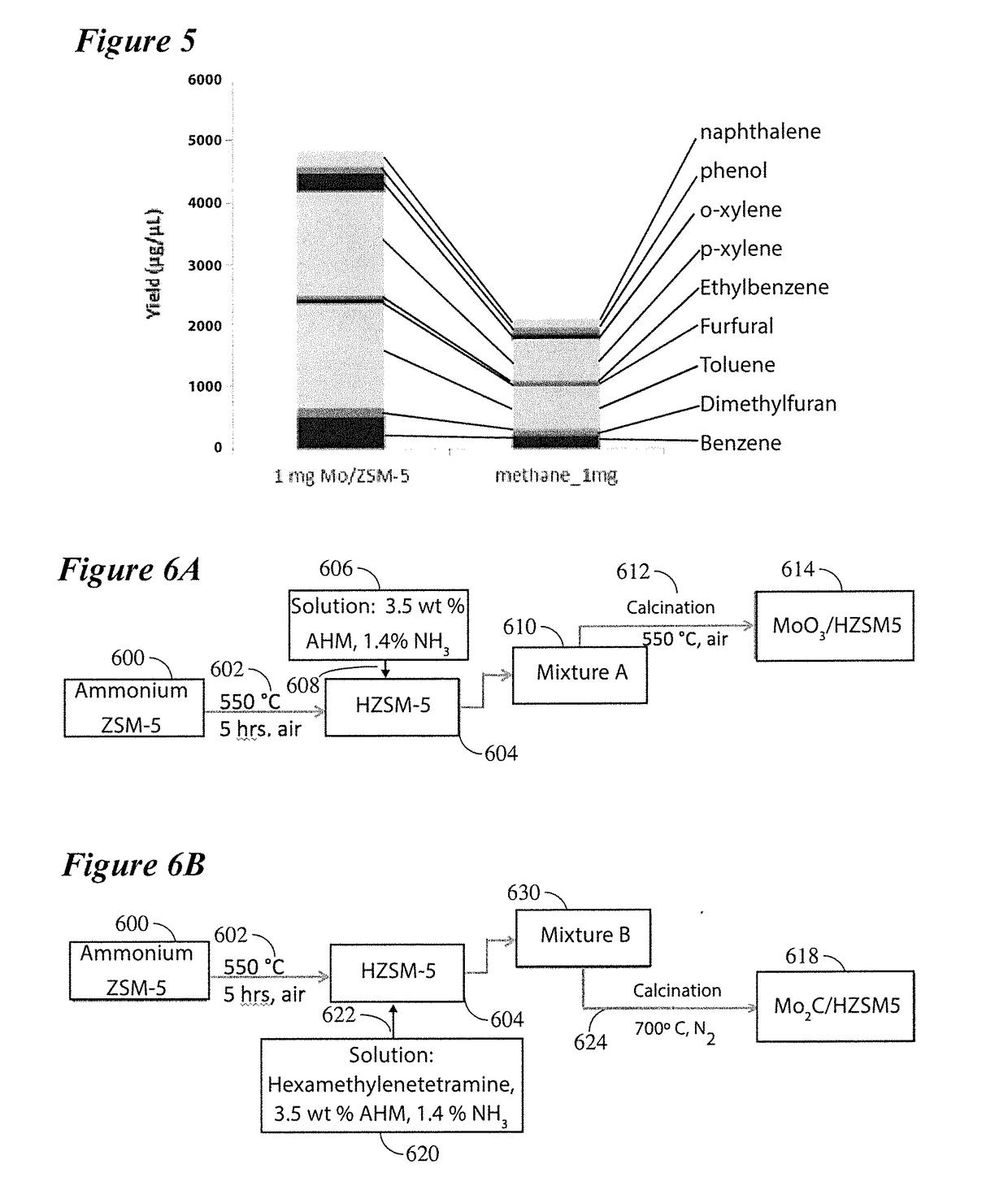

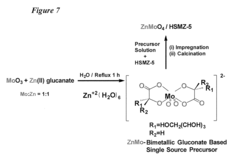

- A catalytic fast pyrolysis process using bimetallic catalysts, such as MoAg/HZSM-5 and MoZn/HZSM-5, impregnated into protonated zeolites, which activate methane to produce deoxygenated aromatic hydrocarbons like benzene, toluene, and naphthalene without requiring hydrogen, enhancing the bio-oil's properties and reducing production costs.

Sustainability and Life Cycle Assessment

Sustainability and Life Cycle Assessment of biomass upgrading with heterogeneous catalysis approaches requires comprehensive evaluation of environmental impacts across the entire process chain. The integration of these catalytic technologies must be assessed through rigorous methodologies that quantify resource consumption, emissions, and overall ecological footprint.

Life Cycle Assessment (LCA) studies on heterogeneous catalysis for biomass upgrading reveal significant advantages over conventional petroleum-based processes. Recent analyses indicate potential greenhouse gas emission reductions of 60-85% compared to fossil fuel pathways, particularly when utilizing agricultural and forestry residues as feedstock. However, these benefits can be diminished if energy-intensive catalyst preparation methods are employed or if catalyst lifetime is insufficient.

Critical sustainability parameters include catalyst recyclability, regeneration efficiency, and metal leaching prevention. Zeolite-based and metal oxide catalysts demonstrate superior sustainability profiles due to their stability across multiple reaction cycles, with some advanced formulations maintaining over 90% activity after ten consecutive uses. This extended lifetime substantially improves the environmental credentials of the overall process.

Water consumption represents another crucial sustainability metric, with hydrothermal processes requiring careful management. Innovative reactor designs incorporating water recycling systems have demonstrated potential reductions in freshwater requirements by up to 70%, significantly enhancing the sustainability profile of aqueous-phase biomass conversion routes.

Energy balance assessments indicate that heterogeneous catalytic processes typically achieve favorable energy return on investment (EROI) ratios between 3:1 and 8:1, depending on feedstock selection and process configuration. Integrated biorefinery approaches that utilize process heat recovery systems can further improve these ratios by 15-25%.

Land use impacts vary considerably based on feedstock source. Utilizing agricultural residues and waste biomass minimizes land use change effects, while dedicated energy crops require careful assessment of potential competition with food production. Sustainable certification schemes are increasingly being implemented to ensure responsible biomass sourcing practices.

Social sustainability dimensions must also be considered, including rural development opportunities, job creation potential, and impacts on local communities. Distributed processing facilities using heterogeneous catalysis can create decentralized value chains that benefit agricultural communities while reducing transportation-related emissions.

Future sustainability improvements will likely emerge from catalyst innovations that enable ambient temperature and pressure operations, reducing energy requirements while maintaining conversion efficiency. Additionally, bio-based catalyst supports and earth-abundant metal catalysts represent promising directions for enhancing the overall sustainability profile of biomass upgrading technologies.

Life Cycle Assessment (LCA) studies on heterogeneous catalysis for biomass upgrading reveal significant advantages over conventional petroleum-based processes. Recent analyses indicate potential greenhouse gas emission reductions of 60-85% compared to fossil fuel pathways, particularly when utilizing agricultural and forestry residues as feedstock. However, these benefits can be diminished if energy-intensive catalyst preparation methods are employed or if catalyst lifetime is insufficient.

Critical sustainability parameters include catalyst recyclability, regeneration efficiency, and metal leaching prevention. Zeolite-based and metal oxide catalysts demonstrate superior sustainability profiles due to their stability across multiple reaction cycles, with some advanced formulations maintaining over 90% activity after ten consecutive uses. This extended lifetime substantially improves the environmental credentials of the overall process.

Water consumption represents another crucial sustainability metric, with hydrothermal processes requiring careful management. Innovative reactor designs incorporating water recycling systems have demonstrated potential reductions in freshwater requirements by up to 70%, significantly enhancing the sustainability profile of aqueous-phase biomass conversion routes.

Energy balance assessments indicate that heterogeneous catalytic processes typically achieve favorable energy return on investment (EROI) ratios between 3:1 and 8:1, depending on feedstock selection and process configuration. Integrated biorefinery approaches that utilize process heat recovery systems can further improve these ratios by 15-25%.

Land use impacts vary considerably based on feedstock source. Utilizing agricultural residues and waste biomass minimizes land use change effects, while dedicated energy crops require careful assessment of potential competition with food production. Sustainable certification schemes are increasingly being implemented to ensure responsible biomass sourcing practices.

Social sustainability dimensions must also be considered, including rural development opportunities, job creation potential, and impacts on local communities. Distributed processing facilities using heterogeneous catalysis can create decentralized value chains that benefit agricultural communities while reducing transportation-related emissions.

Future sustainability improvements will likely emerge from catalyst innovations that enable ambient temperature and pressure operations, reducing energy requirements while maintaining conversion efficiency. Additionally, bio-based catalyst supports and earth-abundant metal catalysts represent promising directions for enhancing the overall sustainability profile of biomass upgrading technologies.

Techno-Economic Analysis of Catalytic Processes

The techno-economic analysis of catalytic processes for biomass upgrading reveals significant economic considerations that influence industrial implementation. Current heterogeneous catalysis approaches demonstrate variable economic viability depending on feedstock costs, catalyst efficiency, and process integration capabilities. Financial modeling indicates that capital expenditure for industrial-scale biomass conversion facilities ranges from $50-200 million, with catalyst costs representing 5-15% of operational expenses.

Process economics are heavily influenced by catalyst performance metrics, particularly selectivity and longevity. High-performing zeolite and metal-based catalysts can reduce operational costs by 20-30% compared to conventional approaches, primarily through improved conversion efficiency and reduced energy requirements. However, noble metal catalysts, despite superior performance, often present economic challenges due to high material costs and potential supply chain vulnerabilities.

Scale-up considerations reveal that biomass processing facilities achieve optimal economic performance at capacities of 200-500 tons per day, with economies of scale diminishing beyond this range due to feedstock logistics constraints. Sensitivity analysis demonstrates that catalyst deactivation rates significantly impact long-term profitability, with a 10% improvement in catalyst lifetime potentially increasing net present value by 15-25%.

Energy integration strategies, particularly heat recovery systems, can reduce operational costs by 10-15%. The implementation of continuous flow processes over batch operations typically improves economic performance by reducing labor costs and increasing throughput, though this advantage must be balanced against higher initial capital investment.

Market analysis indicates that high-value chemical production pathways generally offer superior returns compared to fuel-focused processes, with specialty chemicals derived from biomass potentially commanding 2-5 times higher margins. However, these markets often have limited volume capacity, necessitating diversified product portfolios for large-scale operations.

Regulatory factors, including carbon pricing mechanisms and renewable fuel standards, significantly influence economic viability. Models suggest that carbon credits valued at $30-50 per ton of CO2 equivalent can improve internal rate of return by 3-5 percentage points for typical biomass upgrading processes, potentially transforming marginally viable operations into attractive investment opportunities.

Process economics are heavily influenced by catalyst performance metrics, particularly selectivity and longevity. High-performing zeolite and metal-based catalysts can reduce operational costs by 20-30% compared to conventional approaches, primarily through improved conversion efficiency and reduced energy requirements. However, noble metal catalysts, despite superior performance, often present economic challenges due to high material costs and potential supply chain vulnerabilities.

Scale-up considerations reveal that biomass processing facilities achieve optimal economic performance at capacities of 200-500 tons per day, with economies of scale diminishing beyond this range due to feedstock logistics constraints. Sensitivity analysis demonstrates that catalyst deactivation rates significantly impact long-term profitability, with a 10% improvement in catalyst lifetime potentially increasing net present value by 15-25%.

Energy integration strategies, particularly heat recovery systems, can reduce operational costs by 10-15%. The implementation of continuous flow processes over batch operations typically improves economic performance by reducing labor costs and increasing throughput, though this advantage must be balanced against higher initial capital investment.

Market analysis indicates that high-value chemical production pathways generally offer superior returns compared to fuel-focused processes, with specialty chemicals derived from biomass potentially commanding 2-5 times higher margins. However, these markets often have limited volume capacity, necessitating diversified product portfolios for large-scale operations.

Regulatory factors, including carbon pricing mechanisms and renewable fuel standards, significantly influence economic viability. Models suggest that carbon credits valued at $30-50 per ton of CO2 equivalent can improve internal rate of return by 3-5 percentage points for typical biomass upgrading processes, potentially transforming marginally viable operations into attractive investment opportunities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!