Biomass upgrading under supercritical fluid conditions

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercritical Fluid Biomass Upgrading Background and Objectives

Biomass upgrading using supercritical fluids represents a significant frontier in renewable energy and sustainable chemical production. This technology has evolved over several decades, beginning with early experiments in the 1970s that explored supercritical water for biomass conversion. The field gained momentum in the 1990s as environmental concerns and energy security issues prompted increased research into alternative energy sources and chemical feedstocks.

Supercritical fluids—substances at temperatures and pressures above their critical points—exhibit unique properties that combine aspects of both liquids and gases. These properties include high diffusivity, low viscosity, and excellent solvating capabilities, making them ideal media for biomass processing. The most commonly employed supercritical fluids in biomass upgrading include water, carbon dioxide, methanol, and ethanol, each offering distinct advantages for specific applications.

The evolution of this technology has been marked by significant improvements in reactor design, catalyst development, and process integration. Early systems suffered from corrosion issues, high energy requirements, and limited selectivity. Modern approaches have addressed these challenges through innovations in materials science, process intensification, and the development of specialized heterogeneous catalysts that enhance reaction specificity and yield.

Current technological trends in supercritical fluid biomass upgrading focus on process hybridization, combining supercritical treatment with other technologies such as enzymatic processes, microwave assistance, and ultrasonic enhancement. Additionally, there is growing interest in continuous flow systems that offer improved efficiency and scalability compared to batch processes that dominated earlier research.

The primary objectives of supercritical fluid biomass upgrading technology include maximizing the conversion efficiency of lignocellulosic materials, reducing energy inputs, minimizing waste generation, and producing high-value products from renewable resources. Specific goals encompass the development of economically viable processes for biofuel production, the creation of platform chemicals that can replace petroleum-derived compounds, and the valorization of agricultural and forestry residues.

Research aims to overcome persistent challenges such as reactor fouling, catalyst deactivation, and high capital costs. The field is increasingly focused on process intensification strategies that can reduce equipment size and energy consumption while maintaining or improving product yields and selectivity. Another critical objective is enhancing the technology's flexibility to accommodate diverse biomass feedstocks with varying compositions and characteristics.

The ultimate technological goal is to establish supercritical fluid biomass upgrading as a cornerstone of the biorefinery concept—creating integrated facilities that efficiently convert biomass into a spectrum of valuable products with minimal environmental impact, thereby contributing to circular economy principles and sustainable development goals.

Supercritical fluids—substances at temperatures and pressures above their critical points—exhibit unique properties that combine aspects of both liquids and gases. These properties include high diffusivity, low viscosity, and excellent solvating capabilities, making them ideal media for biomass processing. The most commonly employed supercritical fluids in biomass upgrading include water, carbon dioxide, methanol, and ethanol, each offering distinct advantages for specific applications.

The evolution of this technology has been marked by significant improvements in reactor design, catalyst development, and process integration. Early systems suffered from corrosion issues, high energy requirements, and limited selectivity. Modern approaches have addressed these challenges through innovations in materials science, process intensification, and the development of specialized heterogeneous catalysts that enhance reaction specificity and yield.

Current technological trends in supercritical fluid biomass upgrading focus on process hybridization, combining supercritical treatment with other technologies such as enzymatic processes, microwave assistance, and ultrasonic enhancement. Additionally, there is growing interest in continuous flow systems that offer improved efficiency and scalability compared to batch processes that dominated earlier research.

The primary objectives of supercritical fluid biomass upgrading technology include maximizing the conversion efficiency of lignocellulosic materials, reducing energy inputs, minimizing waste generation, and producing high-value products from renewable resources. Specific goals encompass the development of economically viable processes for biofuel production, the creation of platform chemicals that can replace petroleum-derived compounds, and the valorization of agricultural and forestry residues.

Research aims to overcome persistent challenges such as reactor fouling, catalyst deactivation, and high capital costs. The field is increasingly focused on process intensification strategies that can reduce equipment size and energy consumption while maintaining or improving product yields and selectivity. Another critical objective is enhancing the technology's flexibility to accommodate diverse biomass feedstocks with varying compositions and characteristics.

The ultimate technological goal is to establish supercritical fluid biomass upgrading as a cornerstone of the biorefinery concept—creating integrated facilities that efficiently convert biomass into a spectrum of valuable products with minimal environmental impact, thereby contributing to circular economy principles and sustainable development goals.

Market Analysis for Supercritical Biomass Conversion Technologies

The global market for supercritical biomass conversion technologies is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable energy solutions. Currently valued at approximately $2.3 billion, this market is projected to reach $4.7 billion by 2028, representing a compound annual growth rate (CAGR) of 15.3% during the forecast period.

North America dominates the market with a share of 38%, followed by Europe at 32% and Asia-Pacific at 24%. The remaining 6% is distributed across other regions. This regional distribution reflects varying levels of technological advancement, regulatory support, and investment in renewable energy infrastructure.

Key market segments include biofuels (accounting for 45% of the market), biochemicals (30%), and biomaterials (25%). Within the biofuels segment, biodiesel production using supercritical methanol has gained significant traction due to its higher efficiency and lower environmental impact compared to conventional processes.

The market is primarily driven by several factors: stringent environmental regulations promoting renewable energy sources, increasing demand for sustainable products, and technological advancements improving the efficiency and cost-effectiveness of supercritical fluid processes. Government incentives and subsidies for green technologies have further accelerated market growth in regions like the European Union and North America.

However, the market faces notable challenges including high initial capital investment requirements, technical complexities in scaling up processes, and competition from established fossil fuel industries. The average capital expenditure for a commercial-scale supercritical biomass conversion facility ranges from $50-150 million, creating significant barriers to entry for smaller players.

Consumer demand patterns show increasing preference for sustainably produced products, with 67% of global consumers willing to pay premium prices for environmentally friendly alternatives. This trend is particularly pronounced in developed economies where environmental awareness is higher.

The competitive landscape features both established energy companies diversifying into renewable technologies and specialized biotech firms. Major players include Neste (Finland), Total Energies (France), Chevron Renewable Energy Group (USA), and Eni (Italy), collectively holding approximately 45% market share.

Future market growth is expected to be fueled by technological innovations reducing operational costs, increasing process efficiency, and expanding the range of biomass feedstocks that can be effectively processed under supercritical conditions. Emerging economies in Asia and Latin America represent significant untapped potential, with projected growth rates exceeding 20% annually in these regions.

North America dominates the market with a share of 38%, followed by Europe at 32% and Asia-Pacific at 24%. The remaining 6% is distributed across other regions. This regional distribution reflects varying levels of technological advancement, regulatory support, and investment in renewable energy infrastructure.

Key market segments include biofuels (accounting for 45% of the market), biochemicals (30%), and biomaterials (25%). Within the biofuels segment, biodiesel production using supercritical methanol has gained significant traction due to its higher efficiency and lower environmental impact compared to conventional processes.

The market is primarily driven by several factors: stringent environmental regulations promoting renewable energy sources, increasing demand for sustainable products, and technological advancements improving the efficiency and cost-effectiveness of supercritical fluid processes. Government incentives and subsidies for green technologies have further accelerated market growth in regions like the European Union and North America.

However, the market faces notable challenges including high initial capital investment requirements, technical complexities in scaling up processes, and competition from established fossil fuel industries. The average capital expenditure for a commercial-scale supercritical biomass conversion facility ranges from $50-150 million, creating significant barriers to entry for smaller players.

Consumer demand patterns show increasing preference for sustainably produced products, with 67% of global consumers willing to pay premium prices for environmentally friendly alternatives. This trend is particularly pronounced in developed economies where environmental awareness is higher.

The competitive landscape features both established energy companies diversifying into renewable technologies and specialized biotech firms. Major players include Neste (Finland), Total Energies (France), Chevron Renewable Energy Group (USA), and Eni (Italy), collectively holding approximately 45% market share.

Future market growth is expected to be fueled by technological innovations reducing operational costs, increasing process efficiency, and expanding the range of biomass feedstocks that can be effectively processed under supercritical conditions. Emerging economies in Asia and Latin America represent significant untapped potential, with projected growth rates exceeding 20% annually in these regions.

Current Status and Technical Barriers in Supercritical Processing

Supercritical fluid processing for biomass upgrading has gained significant attention in recent years due to its unique properties that bridge the gap between liquid and gas phases. Currently, supercritical water (SCW) and supercritical carbon dioxide (scCO2) represent the most widely investigated mediums for biomass conversion. SCW operates at temperatures above 374°C and pressures exceeding 22.1 MPa, while scCO2 requires milder conditions (>31.1°C, >7.38 MPa).

The global research landscape shows concentrated efforts in North America, Europe, and East Asia, with China, the United States, and Japan leading publication output. Industrial implementation remains limited primarily to demonstration plants, with few commercial-scale operations due to significant technical barriers.

A major technical challenge in supercritical processing is reactor design and material selection. The harsh operating conditions—high temperature, pressure, and often corrosive environments—severely limit material options and accelerate equipment degradation. Specialized alloys capable of withstanding these conditions substantially increase capital costs and maintenance requirements.

Process control presents another significant barrier. Maintaining precise temperature and pressure profiles throughout the reaction vessel is technically demanding, especially at scale. Small deviations can dramatically affect reaction pathways and product distributions, making consistent product quality difficult to achieve in continuous operation systems.

Energy efficiency remains problematic despite theoretical advantages. The high energy input required to reach and maintain supercritical conditions often undermines the net energy balance of the process. Heat recovery systems are essential but add complexity and cost to plant designs.

Catalyst deactivation occurs rapidly under supercritical conditions. The extreme environment accelerates sintering, leaching, and poisoning mechanisms, while the high solubility of supercritical fluids can dissolve and redistribute catalytic materials. Developing stable, regenerable catalysts remains an ongoing challenge.

Scaling issues present perhaps the most significant barrier to commercialization. Laboratory successes often fail to translate to industrial scales due to heat and mass transfer limitations, mixing inefficiencies, and flow distribution problems in larger reactors. The non-linear scaling relationships between laboratory and industrial equipment necessitate extensive pilot testing.

Feedstock variability compounds these challenges. Biomass heterogeneity introduces unpredictable reaction behaviors, requiring robust process designs capable of handling fluctuations in moisture content, ash composition, and structural components. This variability often necessitates extensive pre-treatment steps, adding cost and complexity.

Despite these barriers, recent advances in reactor design, catalyst development, and process intensification techniques have begun addressing these limitations, gradually improving the technical and economic feasibility of supercritical biomass processing technologies.

The global research landscape shows concentrated efforts in North America, Europe, and East Asia, with China, the United States, and Japan leading publication output. Industrial implementation remains limited primarily to demonstration plants, with few commercial-scale operations due to significant technical barriers.

A major technical challenge in supercritical processing is reactor design and material selection. The harsh operating conditions—high temperature, pressure, and often corrosive environments—severely limit material options and accelerate equipment degradation. Specialized alloys capable of withstanding these conditions substantially increase capital costs and maintenance requirements.

Process control presents another significant barrier. Maintaining precise temperature and pressure profiles throughout the reaction vessel is technically demanding, especially at scale. Small deviations can dramatically affect reaction pathways and product distributions, making consistent product quality difficult to achieve in continuous operation systems.

Energy efficiency remains problematic despite theoretical advantages. The high energy input required to reach and maintain supercritical conditions often undermines the net energy balance of the process. Heat recovery systems are essential but add complexity and cost to plant designs.

Catalyst deactivation occurs rapidly under supercritical conditions. The extreme environment accelerates sintering, leaching, and poisoning mechanisms, while the high solubility of supercritical fluids can dissolve and redistribute catalytic materials. Developing stable, regenerable catalysts remains an ongoing challenge.

Scaling issues present perhaps the most significant barrier to commercialization. Laboratory successes often fail to translate to industrial scales due to heat and mass transfer limitations, mixing inefficiencies, and flow distribution problems in larger reactors. The non-linear scaling relationships between laboratory and industrial equipment necessitate extensive pilot testing.

Feedstock variability compounds these challenges. Biomass heterogeneity introduces unpredictable reaction behaviors, requiring robust process designs capable of handling fluctuations in moisture content, ash composition, and structural components. This variability often necessitates extensive pre-treatment steps, adding cost and complexity.

Despite these barriers, recent advances in reactor design, catalyst development, and process intensification techniques have begun addressing these limitations, gradually improving the technical and economic feasibility of supercritical biomass processing technologies.

Current Supercritical Fluid Upgrading Methodologies

01 Thermochemical conversion processes for biomass upgrading

Thermochemical processes such as pyrolysis, gasification, and hydrothermal liquefaction are used to convert biomass into higher-value fuels and chemicals. These processes involve heating biomass at various temperatures and pressures, with or without catalysts, to break down complex organic structures into simpler, more energy-dense compounds. The resulting products can include bio-oils, syngas, and solid biochar, which can be further refined into transportation fuels or chemical feedstocks.- Thermochemical conversion processes for biomass upgrading: Thermochemical processes such as pyrolysis, gasification, and liquefaction are used to convert biomass into higher-value fuels and chemicals. These processes involve heating biomass at various temperatures and conditions to break down complex organic structures into simpler, more energy-dense compounds. The resulting products can include bio-oils, syngas, and solid biochar, which can be further refined into transportation fuels or chemical feedstocks.

- Catalytic upgrading of biomass-derived compounds: Catalysts play a crucial role in biomass upgrading by facilitating specific chemical transformations at lower temperatures and with greater selectivity. Various catalytic systems, including metal-based catalysts, zeolites, and acid catalysts, are employed to convert biomass-derived intermediates into valuable products. These catalytic processes can remove oxygen, increase hydrogen content, and promote carbon-carbon coupling reactions to produce higher-quality fuels and chemicals from biomass sources.

- Hydrothermal processing for biomass conversion: Hydrothermal processing utilizes water at elevated temperatures and pressures to convert biomass into valuable products. This approach is particularly suitable for wet biomass feedstocks, eliminating the need for energy-intensive drying steps. Under hydrothermal conditions, biomass undergoes hydrolysis, dehydration, and other reactions to form platform chemicals, biocrude oils, and gaseous products. The process can be tuned by adjusting temperature, pressure, and residence time to favor specific product distributions.

- Integrated biorefinery approaches for biomass valorization: Integrated biorefineries combine multiple conversion technologies to maximize the value extracted from biomass feedstocks. These facilities process biomass through a series of coordinated steps to produce a spectrum of products including fuels, chemicals, materials, and power. By utilizing various fractions of the biomass and integrating process streams, biorefineries can achieve greater economic viability and sustainability compared to single-product approaches. Advanced process integration and waste minimization are key features of modern biorefinery designs.

- Pretreatment methods for enhanced biomass processing: Pretreatment techniques are essential for breaking down the recalcitrant structure of lignocellulosic biomass prior to further upgrading. These methods include physical (milling, grinding), chemical (acid, alkali, solvent treatments), physicochemical (steam explosion, ammonia fiber explosion), and biological approaches. Effective pretreatment increases the accessibility of cellulose and hemicellulose components, improves conversion efficiency, and reduces the formation of inhibitory compounds in subsequent processing steps.

02 Catalytic upgrading of biomass-derived intermediates

Catalytic processes are employed to upgrade biomass-derived intermediates such as bio-oils and syngas into higher-quality fuels and chemicals. Various catalysts, including zeolites, noble metals, and transition metal compounds, facilitate reactions such as deoxygenation, hydrogenation, and cracking to improve the properties of biomass-derived products. These catalytic approaches help overcome challenges related to oxygen content, acidity, and thermal instability in biomass-derived intermediates.Expand Specific Solutions03 Biochemical conversion methods for biomass upgrading

Biochemical conversion methods utilize biological agents such as enzymes and microorganisms to transform biomass into valuable products. These processes include fermentation, enzymatic hydrolysis, and anaerobic digestion, which can convert biomass components like cellulose and hemicellulose into biofuels, biochemicals, and biogas. Biochemical approaches often operate under milder conditions compared to thermochemical methods and can be more selective for specific biomass components.Expand Specific Solutions04 Integrated biorefinery approaches for biomass valorization

Integrated biorefinery approaches combine multiple conversion technologies and processing steps to maximize the value extracted from biomass feedstocks. These systems may incorporate both thermochemical and biochemical conversion methods, along with separation and purification technologies, to produce a spectrum of fuels, chemicals, and materials from biomass. Integrated approaches aim to improve overall process economics and sustainability by utilizing all biomass fractions and minimizing waste streams.Expand Specific Solutions05 Pretreatment technologies for enhanced biomass conversion

Pretreatment technologies are employed to modify the physical and chemical properties of biomass prior to conversion processes. These methods include mechanical size reduction, steam explosion, acid or alkaline treatments, and solvent fractionation, which help overcome biomass recalcitrance by disrupting the lignocellulosic structure. Effective pretreatment enhances the accessibility of biomass components to conversion agents, improving process efficiency and product yields in subsequent upgrading steps.Expand Specific Solutions

Leading Organizations in Supercritical Biomass Processing

Biomass upgrading under supercritical fluid conditions is currently in a growth phase, with the market expanding as renewable energy demands increase. The global market size is projected to reach significant scale as industries seek sustainable alternatives to fossil fuels. Technologically, the field shows varying maturity levels across applications. Leading players like Renmatix have pioneered supercritical hydrolysis for cellulosic sugar production, while major energy corporations including Saudi Aramco, Chevron, and ExxonMobil are investing in research capabilities. Academic institutions (Cornell, Zhejiang University) collaborate with industrial partners to advance fundamental science. Companies like Aphios, Steeper Energy, and KiOR represent specialized technology developers focusing on specific biomass conversion pathways, indicating a diversifying competitive landscape with both established energy giants and innovative startups.

Renmatix, Inc.

Technical Solution: Renmatix has developed the Plantrose® Process, a supercritical hydrolysis technology that uses water at high temperatures and pressures to fractionate biomass into valuable biochemicals. Their approach utilizes supercritical water (>374°C, >221 bar) as both solvent and catalyst to rapidly break down lignocellulosic biomass into cellulose, hemicellulose, and lignin fractions. The process occurs in two stages: first, hemicellulose is extracted using near-critical water conditions, then cellulose is separated using supercritical water, all within minutes rather than hours required by conventional methods. This technology eliminates the need for acids, bases, or enzymes typically used in biomass conversion, significantly reducing processing costs and environmental impact. Renmatix's supercritical fluid approach enables the production of industrial sugars and lignin that can serve as building blocks for biofuels, biochemicals, and biomaterials.

Strengths: Rapid processing time (minutes vs. hours/days for conventional methods); eliminates need for expensive enzymes or harsh chemicals; produces high-purity cellulosic sugars; lower operational costs. Weaknesses: High energy requirements for maintaining supercritical conditions; specialized high-pressure equipment needed; potential challenges in scaling up the technology for very large commercial operations.

Aphios Corp.

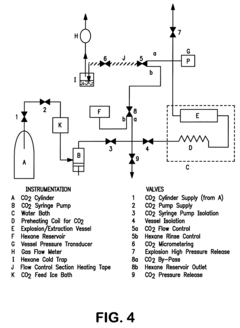

Technical Solution: Aphios Corporation has developed the SuperFluids™ CFB technology, which utilizes supercritical CO₂ and other fluids for biomass extraction and processing. Their approach employs a continuous flow system where biomass is subjected to rapidly cycling pressure conditions in supercritical fluids, creating a mechanical and chemical effect that enhances mass transfer and reaction rates. The technology is particularly effective for extracting high-value compounds from biomass prior to further conversion steps. Aphios has applied this technology to various biomass upgrading applications, including the extraction of nutraceuticals, pharmaceuticals, and specialty chemicals from plant materials. For biofuels applications, their process can be used to remove extractives that might interfere with subsequent conversion processes or to fractionate biomass components under milder conditions than conventional methods. The SuperFluids™ technology operates at lower temperatures than water-based supercritical systems (typically 40-80°C for CO₂), which helps preserve thermally sensitive compounds and reduces energy requirements, though it requires higher pressures (>73 bar for CO₂).

Strengths: Selective extraction capabilities; preservation of thermally sensitive compounds; lower temperature requirements than water-based systems; potential for high-value product streams. Weaknesses: Higher pressure requirements for CO₂-based systems; limited ability to process whole biomass for fuel production; better suited for high-value, low-volume products rather than commodity fuels.

Critical Patents and Research in Supercritical Biomass Conversion

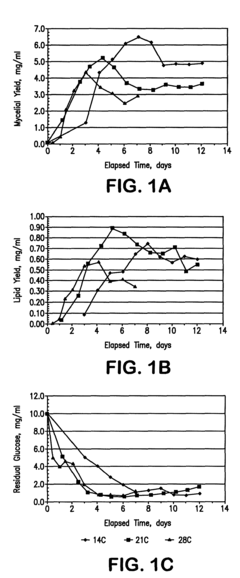

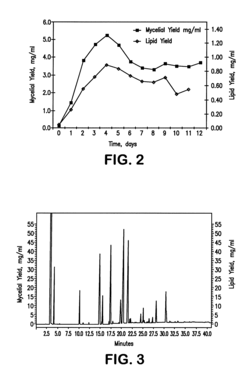

Supercritical fluid explosion process to aid fractionation of lipids from biomass

PatentInactiveUS8148559B1

Innovation

- A method involving the development of biomass on an oleaginous substrate, followed by bioconversion and extraction using supercritical fluid extraction with carbon dioxide, which disrupts cellular structures through a carbon dioxide explosion process, allowing for high-yield recovery of lipids with desired profiles, including high polyunsaturated fatty acids or medium and long-chain monounsaturated fatty acids.

Sustainability and Life Cycle Assessment

Sustainability and Life Cycle Assessment of biomass upgrading under supercritical fluid conditions reveals significant environmental advantages compared to conventional processing methods. The use of supercritical fluids, particularly water and CO2, demonstrates reduced environmental footprints through decreased energy consumption and minimized hazardous chemical usage. These processes operate at higher temperatures but often require less energy overall due to efficient heat transfer properties and shorter reaction times.

Life cycle assessments (LCAs) of supercritical biomass upgrading show 15-30% lower greenhouse gas emissions compared to traditional chemical conversion routes. This reduction stems primarily from the elimination of toxic solvents and catalysts that typically require energy-intensive production and disposal processes. Additionally, the water used in supercritical processes can be more easily recycled, reducing overall water consumption by up to 40% in closed-loop systems.

Carbon footprint analyses indicate that supercritical fluid technologies can achieve carbon neutrality when renewable energy sources power the process equipment. The carbon sequestration potential increases further when considering that many biomass upgrading pathways produce stable carbon materials as byproducts, which can serve as carbon sinks when appropriately utilized.

Resource efficiency metrics show that supercritical fluid processes typically achieve 85-95% atom economy, significantly higher than conventional methods averaging 60-75%. This efficiency translates to less waste generation and more complete utilization of feedstock materials. The circular economy potential is enhanced through the ability to process diverse and often low-value biomass streams, including agricultural residues and food processing wastes.

Economic sustainability assessments reveal that while initial capital investments for supercritical equipment remain high, operational costs over equipment lifetimes are increasingly competitive. The premium for "green" products derived from these processes continues to narrow as scale increases and technology matures, with current estimates suggesting price parity with fossil-derived alternatives could be achieved within 5-8 years in several product categories.

Social sustainability factors also favor supercritical processing, as these facilities typically pose lower health risks to workers and surrounding communities due to reduced hazardous chemical handling. Furthermore, distributed processing models enabled by smaller-scale supercritical units can support rural economic development through localized biomass valorization, creating sustainable employment opportunities in agricultural regions.

Life cycle assessments (LCAs) of supercritical biomass upgrading show 15-30% lower greenhouse gas emissions compared to traditional chemical conversion routes. This reduction stems primarily from the elimination of toxic solvents and catalysts that typically require energy-intensive production and disposal processes. Additionally, the water used in supercritical processes can be more easily recycled, reducing overall water consumption by up to 40% in closed-loop systems.

Carbon footprint analyses indicate that supercritical fluid technologies can achieve carbon neutrality when renewable energy sources power the process equipment. The carbon sequestration potential increases further when considering that many biomass upgrading pathways produce stable carbon materials as byproducts, which can serve as carbon sinks when appropriately utilized.

Resource efficiency metrics show that supercritical fluid processes typically achieve 85-95% atom economy, significantly higher than conventional methods averaging 60-75%. This efficiency translates to less waste generation and more complete utilization of feedstock materials. The circular economy potential is enhanced through the ability to process diverse and often low-value biomass streams, including agricultural residues and food processing wastes.

Economic sustainability assessments reveal that while initial capital investments for supercritical equipment remain high, operational costs over equipment lifetimes are increasingly competitive. The premium for "green" products derived from these processes continues to narrow as scale increases and technology matures, with current estimates suggesting price parity with fossil-derived alternatives could be achieved within 5-8 years in several product categories.

Social sustainability factors also favor supercritical processing, as these facilities typically pose lower health risks to workers and surrounding communities due to reduced hazardous chemical handling. Furthermore, distributed processing models enabled by smaller-scale supercritical units can support rural economic development through localized biomass valorization, creating sustainable employment opportunities in agricultural regions.

Scalability and Industrial Implementation Challenges

The scaling of biomass upgrading processes from laboratory to industrial scale presents significant engineering challenges. Current pilot-scale operations typically process 1-10 kg/h of biomass, while commercial viability requires throughputs of several tons per hour. This substantial gap necessitates innovative reactor designs and process intensification strategies to maintain the unique advantages of supercritical fluid conditions at larger scales.

Pressure maintenance represents a primary challenge, as industrial-scale reactors must withstand operating pressures of 200-400 bar consistently and safely. The associated capital costs for high-pressure equipment increase non-linearly with scale, creating economic barriers to implementation. Additionally, the energy requirements for maintaining supercritical conditions across larger volumes significantly impact operational expenses and overall process efficiency.

Heat transfer limitations emerge prominently during scale-up. Laboratory reactors benefit from favorable surface-to-volume ratios, enabling rapid and uniform heating. In contrast, industrial-scale systems face challenges in achieving homogeneous temperature profiles throughout larger reaction volumes, potentially leading to product inconsistency and reduced conversion efficiencies.

Continuous flow systems offer promising solutions to these challenges, allowing for better heat and mass transfer compared to batch operations. However, they introduce complexities in handling solid biomass particles, which can cause clogging and erosion in high-pressure pumping systems. Innovative feeding mechanisms and reactor configurations are being developed to address these issues, including screw feeders coupled with pre-treatment steps to improve biomass pumpability.

Catalyst deactivation accelerates at industrial scales due to longer exposure times and higher throughput. Developing regeneration protocols or continuous catalyst replacement strategies becomes essential for maintaining process economics. Some companies have explored novel reactor configurations with catalyst beds that can be replaced without full system shutdown.

Corrosion management presents another significant hurdle, as supercritical water conditions are particularly aggressive toward conventional reactor materials. The development of cost-effective corrosion-resistant alloys or protective coatings remains crucial for extending equipment lifespan and reducing maintenance costs.

Regulatory frameworks and safety considerations further complicate industrial implementation. High-pressure operations require stringent safety protocols, specialized operator training, and compliance with pressure vessel regulations that vary globally, adding layers of complexity to facility design and operation.

Pressure maintenance represents a primary challenge, as industrial-scale reactors must withstand operating pressures of 200-400 bar consistently and safely. The associated capital costs for high-pressure equipment increase non-linearly with scale, creating economic barriers to implementation. Additionally, the energy requirements for maintaining supercritical conditions across larger volumes significantly impact operational expenses and overall process efficiency.

Heat transfer limitations emerge prominently during scale-up. Laboratory reactors benefit from favorable surface-to-volume ratios, enabling rapid and uniform heating. In contrast, industrial-scale systems face challenges in achieving homogeneous temperature profiles throughout larger reaction volumes, potentially leading to product inconsistency and reduced conversion efficiencies.

Continuous flow systems offer promising solutions to these challenges, allowing for better heat and mass transfer compared to batch operations. However, they introduce complexities in handling solid biomass particles, which can cause clogging and erosion in high-pressure pumping systems. Innovative feeding mechanisms and reactor configurations are being developed to address these issues, including screw feeders coupled with pre-treatment steps to improve biomass pumpability.

Catalyst deactivation accelerates at industrial scales due to longer exposure times and higher throughput. Developing regeneration protocols or continuous catalyst replacement strategies becomes essential for maintaining process economics. Some companies have explored novel reactor configurations with catalyst beds that can be replaced without full system shutdown.

Corrosion management presents another significant hurdle, as supercritical water conditions are particularly aggressive toward conventional reactor materials. The development of cost-effective corrosion-resistant alloys or protective coatings remains crucial for extending equipment lifespan and reducing maintenance costs.

Regulatory frameworks and safety considerations further complicate industrial implementation. High-pressure operations require stringent safety protocols, specialized operator training, and compliance with pressure vessel regulations that vary globally, adding layers of complexity to facility design and operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!